Beruflich Dokumente

Kultur Dokumente

Lab Module: Consumption-Based Planning - ROP

Hochgeladen von

Rana Fathiya KusumaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lab Module: Consumption-Based Planning - ROP

Hochgeladen von

Rana Fathiya KusumaCopyright:

Verfügbare Formate

Labs Module: Consumption-based Planning: Reorder Point

SAP Username Name GBI-093 Rana Fathiya Kusuma

1.1 Create Raw Material

Menu Path Trans Code Logistics Production Master Data Material Master Material Create (Special) Raw Material MMR1

Enter RAW-### for material and select Retail for Industry Sector, then click on Select view(s): Basic Data 1, Purchasing, MRP 1, MRP 2, MRP 3, Accounting 1. Then click on enter.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

Enter DL00 for Plant, then click on enter icon (

).

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

Basic Data 1 View Description Unit of Measure Material Group

RAW-### EA BIKES

Purchasing Purchasing group

N00

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

MRP1 MRP Type manual reorder point planning Reorder point MRP Controller Lot size fixed Fixed lot size VB 80 000 FX 400

MRP2

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

Procurement type SchedMargin key Plnd delivery time Safety stock

external

F 001 2 30

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

MRP3 Availability check

indv req

02

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

Accounting 1 Valuation class Price control Standard Price

3000 (raw materials 1) S 8.5

Enter the data shown above, then click on the save icon (

) to save the new material master.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

1.2 Stock/Requirements List

Menu Path Trans Code Logistics Materials Management Inventory Management Environment Stock Stock/Requirements List MD04

Material RAW-### and plant DL00 should be entered automatically. If not, enter them, then click on the enter icon ( ).

Because this is a brand new material, the stock is 0. Because there should be a safety stock of 30 units, we are showing the available quantity as a negative 30, and there is an exception message.

Click on the exception message, then click on the search icon

To see what the exception message is, click on it and then click on the search icon.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

Exception message 96 notifies us that the stock level is below the safety stock level. Exception messages are particular useful when looking at a number of materials to see which need attention, and why. Close the list of exceptions by clicking on the close icon ( ).

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

Click on the Create new session icon

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

10

1.3 MRP Planning Run

We will want to keep the Stock/Requirements List open so we can quickly see the impact of planning procedures. Because the inventory for raw material is below the reorder point, the SAP system should create a purchase requisition that can be converted to a purchase order so that raw materials can be acquired. To create purchase requisitions for the raw materials, we need to execute an MRP planning run. We will do the MRP planning run for just this material, even though in practice it would probably be done for a group of materials (using an MRP Area) and would probably be scheduled regularly. To run the MRP planning process for a single material, follow the menu path: Logistics Production MRP Planning Single Level Single-Item Planning Menu Path Trans Code MD03 Enter material RAW-### and plant DL00. Use the default planning values, select Display results before they are saved, so we can see the planning results immediately, then click on the enter icon ( ).

The following message will appear at the bottom of the screen:

Depending on the situation, production planning can take a lot of computer resources, so SAP is just reminding you to make sure that you have everything set correctly. Click on the enter icon ( ) a second time and a screen very similar to the Stock/Requirements screen will be displayed.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

11

This screen shows us that a Purchase Requisition for 400 raw materials has been created as we are below our reorder point of 80 (and below the safety stock of 30 units as well). Click on the save icon ( ) to save these planning results.

Switch back to the session with the Stock/Requirements List. Click on the refresh icon ( ) to update the Stock/Requirements list. The Stock/Requirements List will now show the Purchase Requisition that was created by the planning run: 0010000320/00000

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

12

1.4 Create Purchase Order from Purchase Requisition

Next, we need to convert the Purchase Requisition into a Purchase Order, which can be done from the Stock/Requirements List. To convert the Purchase Requisition into a Purchase Order, click on the details icon ( ), which will call up the following pop-up window:

Click here

Click on the icon to convert the Purchase Requisition to a Purchase Order, and make sure that the Purchasing Org. (US00), Purch. Group (N00) and Company Code (US00) are entered. Make sure the organizational data shown above is entered and drag the divider over to display more of the Document overview.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

13

Click on the Open requisition line in the Document overview, then click on the Adopt icon ( will copy data from the Purchase Requisition to the Purchase Order screen.

). This

Next, we need to assign a vendor to this Purchase Order. Click on the Vendor field, then search vendor ### Portage Material. Click on the enter icon to retrieve data on the vendor.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

14

As the material is new and has never been purchased, there is no pricing data available, so the SAP system will request pricing data. Enter 8.5 for the Net price and USD for the Currency,

then click on the enter icon (

) and a warning message will be displayed:

Cick on the enter icon (

) a second time, then click on the save icon (

).

Switch back to the session with the Stock/Requirements List and click on the refresh icon ( ) to update the data. Not much will change, except that the Purchase Requisition will now be shown as a POitem.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

15

1.5 Goods Receipt for Purchase Order

Next, we will assume that ### Portage Material has delivered on purchase order for 400 raw materials. We need to let the SAP system know this by performing a goods receipt. To do this, switch back to the other session and follow the menu path: Menu Path Trans Code Logistics Materials Management Inventory Management Goods Movement Goods Receipt For Purchase Order GR for Purchase Order MIGO_GR

Use the search Purchase Documents per Vendor to find your PO with purchasing organization US00 and purchasing group N00 to find your purchase order.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

16

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

17

Then click, execute (

on Where tab, please select the Item OK checkbox, enter raw material (RM00) for Stor. Loc, then click on the Post icon ( ).

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

18

Switch to the Stock/Requirements list, then click on the refresh icon ( ) to see that the material is now available. Click on the refresh icon to see that the 400 raw materials are now in storage location 10.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

19

1.6 Goods Issue to Cost Center

When materials are taken out of inventory to be used, this information needs to be recorded and the cost of the materials removed needs to be attributed to a cost object, which can be a production order, a project, a customer order or a cost center. In general, costs should be assigned as closely to the activity that caused them, but for low cost items, the effort to attribute their cost to a particular cost driver may not be worth the effort. It can be debated whether raw materials fall into this category, but as it makes the exercise easier to issue the raw materials to a cost center, that is what well do. To issue raw materials to a cost center, follow the menu path: Logistics Materials Management Inventory Management Goods Movement Menu Path Goods Issue Trans Code MB1A Enter: Movement type 201 (consumption for cost center from warehouse) Plant DL00 Storage Location RM00 Then click enter.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

20

Enter the information shown above, which tells the SAP system that we are going to charge a cost center for the material, and will be taking the material out of storage location RM00, plant DL00. Click on the enter icon ( ). Enter NAPR1000 for the cost center, then 100 units of material RAW-### and click on the save icon ( ) and a message like the following will appear at the bottom of the screen:

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

21

Switch to the session with the Stock/Requirements list and click on the refresh icon ( the changes? Available Stock berkurang menjadi 300 buah

). What are

1.7 Planning File and MRP Planning Run

Because we have made a change to the stock level of the material, there should be an entry in the planning file. We can check the planning file for this material by following the menu path: Menu Path Trans Code Logistics Production MRP Planning Planning File Entry Display MD21 ).

Enter RAW-### for material and DL00 for plant, then click on the execute icon (

This will produce the planning file entry for your material:

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

22

Note that the goods issue created an entry in the planning file for both NETCH and NETPL planning options, respectively

The planning file entry means that the SAP system will check to see if a purchase requisition needs to be created the next time an MRP planning run is performed for the material. Perform an MRP planning run for the material by following the menu path: Logistics Production MRP Planning Single-Item, Single-Level Use the default settings, except select Display results before they are saved.

If you need more details on the MRP planning run, refer to Section 1.3. The results of the planning run should be like the following:

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

23

Note that the planning run did not create any purchase requisitions. Planning file entries are made whenever a transaction is executed that COULD cause the creation of a purchase requisition (or planned order, for materials produced in-house). A planning file entry does not mean that plans will necessarily change, just that they might, so an MRP planning run should plan the material.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

24

1.8 Second Goods Issue to Cost Center

We will issue a second batch of raw materials to a cost center. To do this, follow the menu path: Logistics Materials Management Inventory Management Goods Movement Goods Issue Enter: Movement type 201 (consumption for cost center from warehouse) Plant DL00 Storage Location RM00 Then click enter. Again, enter NAPR1000 for the cost center, then 200 units of material RAW-### and click on the save icon ( ).

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

25

Switch to the Stock/Requirements List and click on the refresh icon (

):

The inventory level, excluding safety stock, is 70 units. As the reorder point is 80 units, it would appear that an MRP planning run should create a purchase requisition. To see whether this is the case, perform a planning run again by following the menu path: Logistics Production MRP Planning Single-Item, Single-Level Use the default settings, except select Display results before they are saved. Again, if you need more details on the MRP planning run, refer to Section 1.3. The results of the planning run should be like the following:

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

26

Note: No purchase requisition was created

Even though the available quantity is 70, which is below the ROP of 80, no purchase requisition was created. Is SAP broken? Is there a configuration setting missing? This question can be answered with a little investigation. To start the process, switch to the Stock/Requirements list. By doubleclicking on the material number, the material master will be displayed. Select the view MRP 2.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

27

Click the safety stock entry of 30 and click on the F1 key to get information about this data field:

In manual reorder point planning, which is what has been specified for this material, the safety stock value is assumed to be included in the reorder point figure. In other words, the way SAP has programmed reorder point planning, the ROP (Reorder point) of 80 that we entered in view MRP 1 is assumed to include the safety stock of 30, so we expect to consume 50 raw materials before the order is received. Thus, the demand during lead time is 50 and the reorder point of 80 INCLUDES a safety stock of 30 units. In terms of the Stock/Requirements list, the ROP is compared to the stock available INCLUDING the safety stock: An order is triggered

when this quantity goes below 80

Not this one

This is an important point. SAP could have chosen to subtract the safety stock entry from the stock level and compare that value to the reorder point, but they chose to make the safety stock entry an

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

28

informational value. Both approaches are valid, and the important thing with any software is to be clear how things are calculated by testing it thoroughly.

1.9 Third and Final Goods Issue to Cost Center

To confirm that SAP compares the ROP to the stock level including safety stock, perform a final goods issue for 30 raw materials by following the menu path: Logistics Materials Management Inventory Management Goods Movement Goods Issue

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

29

See Section 1.6 for details. Switch back to the Stock/Requirements list and click on the refresh icon ( ) to see that the stock level is now below the ROP:

Stock is now below the reorder point of 80

Perform a final planning run by following the menu path: Logistics Production MRP Planning Single-Item, Single-Level Use the default settings, except select Display results before they are saved. The results of the planning run should be like the following:

A purchase requisition is created by the planning run

Click on the save icon ( ) to save the plans. Switch to the Stock/Requirements List and click on the refresh icon ( ) to see that the newly-created purchase requisition.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

30

Click on the print icon to print the Stock/Requirements list to hand in.

Print out a copy of the Stock/Requirements list to hand in. As you do this, ponder the questions: What issues might there be when implementing this policy in a production environment? Kemungkinan human error ketika melakukan input data sangat besar. Jika terdapat kesalahan ketika input data, dapat mempengaruhi proses yang lainnya seperti salah menentukan kapan harus melakukan reorder lagi karena purchase requisition tidak muncul. Dalam lingkungan produksi yang sibuk, lebih baik mengimplementasi prosedur automatic reorder point atau forecast-based planning untuk menghindari miskalkulasi atau kesalahan input dari user ketika ingin menentukan kapan harus melakukan reorder. How will the data be collected? Data demand didapatkan dari hasil Forecasting. Data berapa jumlah reorder point dan berapa jumlah safety stock ditentukan sendiri oleh perusahaan. What could go wrong? Ketika demand sedang tinggi dan terjadi miskalkulasi penentuan waktu reorder barang sehingga dapat terjadi stockout karena stock dan safety stock tidak dapat memenuhi demand tersebut. Manager salah memperhitungkan jumlah barang yang sebenarnya dimiliki.

Jot down your answers to these questions on the printout.

SCM Ganjil 2013/2014 Faculty of Computer Science University of Indonesia

31

Das könnte Ihnen auch gefallen

- Forecast-Based Rizki Amalia Putri 1106153990Dokument21 SeitenForecast-Based Rizki Amalia Putri 1106153990Mathias Kevin Phanama TobingNoch keine Bewertungen

- W06 PP Master DataDokument24 SeitenW06 PP Master Datah3mlockNoch keine Bewertungen

- Material MasterDokument31 SeitenMaterial Masterprashant kumarNoch keine Bewertungen

- Run MRP, Convert Planned Order To Production Order, Settle Costs of Production OrderDokument58 SeitenRun MRP, Convert Planned Order To Production Order, Settle Costs of Production OrderJayadeepauyaj UppalapatiNoch keine Bewertungen

- SAP Material Management Case StudyDokument51 SeitenSAP Material Management Case StudyObarArighi100% (1)

- How To Create Goods Receipt in SAPDokument8 SeitenHow To Create Goods Receipt in SAPvkeie0206Noch keine Bewertungen

- Integration Case Study PP: Sap Erp Ecc 5.0Dokument19 SeitenIntegration Case Study PP: Sap Erp Ecc 5.0Rajesh DhanNoch keine Bewertungen

- Sap Logistics 13Dokument242 SeitenSap Logistics 13José RoblesNoch keine Bewertungen

- SAP PP Intrw QTNDokument8 SeitenSAP PP Intrw QTN4ArunNoch keine Bewertungen

- 05 Intro ERP Using GBI Case Study MM (A4) en v2.01Dokument38 Seiten05 Intro ERP Using GBI Case Study MM (A4) en v2.01Debapriya Swain50% (2)

- Intro ERP Using GBI Case Study MM (A4) en v2.30Dokument38 SeitenIntro ERP Using GBI Case Study MM (A4) en v2.30Libin MathewNoch keine Bewertungen

- SAP PP 50 Interview Questions and Answers PDFDokument20 SeitenSAP PP 50 Interview Questions and Answers PDFHemamber ReddyNoch keine Bewertungen

- Sap PP Interview QuestionsDokument10 SeitenSap PP Interview QuestionsDhavalNoch keine Bewertungen

- MRP in SAP Business One: A Business ScenarioDokument11 SeitenMRP in SAP Business One: A Business ScenarioKrishna ManiNoch keine Bewertungen

- SAP Purchase Order ProcessDokument36 SeitenSAP Purchase Order ProcessRajiv Srivastava100% (1)

- Top 21 SAP MM Interview QuestionsDokument9 SeitenTop 21 SAP MM Interview QuestionsVishnu Kumar SNoch keine Bewertungen

- Sap FICODokument43 SeitenSap FICODeepak ChandraNoch keine Bewertungen

- ERP Initial Load 1708Dokument30 SeitenERP Initial Load 1708Mani KumarNoch keine Bewertungen

- What Is SAP MM Module? An OverviewDokument67 SeitenWhat Is SAP MM Module? An OverviewAswathyAkhoshNoch keine Bewertungen

- Activation of Material Ledger in S4 HANADokument7 SeitenActivation of Material Ledger in S4 HANAruntabNoch keine Bewertungen

- Discrete Manufacturing (Full Life CycleDokument10 SeitenDiscrete Manufacturing (Full Life CycleWasiYamanChoudhury50% (2)

- Scenariu de Productie in SAPDokument39 SeitenScenariu de Productie in SAPAdilé-Elena NemoianuNoch keine Bewertungen

- SAP MM Interview QnA 2Dokument9 SeitenSAP MM Interview QnA 2Shashwath NanjannavarNoch keine Bewertungen

- Sap Fico Latest Interview QuestionsDokument28 SeitenSap Fico Latest Interview Questionsgarudatrainings100% (1)

- Issue: 1. When One Product Is Purchased, System Should Propose 2 or 3 Products As Free GoodsDokument81 SeitenIssue: 1. When One Product Is Purchased, System Should Propose 2 or 3 Products As Free Goodsjyotimani1Noch keine Bewertungen

- MM Configuration TipsDokument10 SeitenMM Configuration TipsPrakash SomasundaramNoch keine Bewertungen

- B D PP1 1306396813Dokument19 SeitenB D PP1 1306396813Pyca GilyaNoch keine Bewertungen

- Product Costing SampleDokument17 SeitenProduct Costing SamplePetualang JagadNoch keine Bewertungen

- Sap Apo DP NutsellDokument53 SeitenSap Apo DP NutsellSundaran NairNoch keine Bewertungen

- Interview Questions of Production PlanningDokument7 SeitenInterview Questions of Production PlanningPriyank Patel0% (1)

- Decoding MRP and MRP ViewsDokument15 SeitenDecoding MRP and MRP ViewsBalanathan Virupasan100% (1)

- SAP R3 SD ManualDokument104 SeitenSAP R3 SD Manualvivid_sport100% (2)

- SAP Physical Inventory Tutorial: MI01, MI02, MI04, MI07Dokument10 SeitenSAP Physical Inventory Tutorial: MI01, MI02, MI04, MI07prasanthNoch keine Bewertungen

- SAP APO DP Interview Questions by NKDDokument7 SeitenSAP APO DP Interview Questions by NKDnileshNoch keine Bewertungen

- Long Term PlanningDokument20 SeitenLong Term PlanningSameer BagalkotNoch keine Bewertungen

- SAP PP - Demand ManagementDokument10 SeitenSAP PP - Demand ManagementKoustubha KhareNoch keine Bewertungen

- Value Added ServiceDokument22 SeitenValue Added ServicepatberteNoch keine Bewertungen

- SAP PP Module Interview Questions and Answers PDF SVR TechnologiesDokument27 SeitenSAP PP Module Interview Questions and Answers PDF SVR TechnologiesJemi AmiraNoch keine Bewertungen

- Evaluating Repetitive Structures in HR ABAP ProgrammingDokument4 SeitenEvaluating Repetitive Structures in HR ABAP Programmingrajeshb4usNoch keine Bewertungen

- PayrollDokument20 SeitenPayrollAmit Koushik100% (1)

- Intro ERP Using GBI Case Study PP (Letter) en v2.40Dokument39 SeitenIntro ERP Using GBI Case Study PP (Letter) en v2.40meddebyounesNoch keine Bewertungen

- Sap PP Interview QuestionsDokument10 SeitenSap PP Interview QuestionsMani RajNoch keine Bewertungen

- Master Data - Bill of MaterialDokument69 SeitenMaster Data - Bill of Materialbalu4indiansNoch keine Bewertungen

- Material Requirements Planning (MRP) Process in SAP Business OneDokument33 SeitenMaterial Requirements Planning (MRP) Process in SAP Business OneaunhavcNoch keine Bewertungen

- Sme Business Mantra Has Been Categorized Into Following Modules. Core ModulesDokument9 SeitenSme Business Mantra Has Been Categorized Into Following Modules. Core ModulesShiva KumarNoch keine Bewertungen

- 1.Ts Wbsedcl MM Material MasterDokument37 Seiten1.Ts Wbsedcl MM Material MasterAnshuman MitraNoch keine Bewertungen

- SAP MM WM Online - 9Dokument69 SeitenSAP MM WM Online - 9farazhussainkhan100% (3)

- SAP PP Materials Requirement Planning HTTP Sapdocs InfoDokument33 SeitenSAP PP Materials Requirement Planning HTTP Sapdocs InfokumarNoch keine Bewertungen

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyVon EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyBewertung: 4 von 5 Sternen4/5 (6)

- Sap Subject Project MaterialDokument233 SeitenSap Subject Project MaterialpavanNoch keine Bewertungen

- 06 Intro ERP Using GBI Case Study PP (Letter) en v2.11 PDFDokument41 Seiten06 Intro ERP Using GBI Case Study PP (Letter) en v2.11 PDFBhasker ECNoch keine Bewertungen

- SAP SD Questions & AnswersDokument220 SeitenSAP SD Questions & Answersshuku03Noch keine Bewertungen

- SAP Enterprise Structure Concept and Configuration Guide: A Case StudyVon EverandSAP Enterprise Structure Concept and Configuration Guide: A Case StudyBewertung: 5 von 5 Sternen5/5 (3)

- Flight Training Revenues World Summary: Market Values & Financials by CountryVon EverandFlight Training Revenues World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- SAP IS-Retail Interview Questions, Answers, and ExplanationsVon EverandSAP IS-Retail Interview Questions, Answers, and ExplanationsBewertung: 3 von 5 Sternen3/5 (11)

- Crushing, Pulverizing & Screening Machinery World Summary: Market Sector Values & Financials by CountryVon EverandCrushing, Pulverizing & Screening Machinery World Summary: Market Sector Values & Financials by CountryNoch keine Bewertungen

- Measuring & Controlling Devices World Summary: Market Values & Financials by CountryVon EverandMeasuring & Controlling Devices World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- GR Blocked Vs Block MaterialDokument4 SeitenGR Blocked Vs Block Materialashish sawantNoch keine Bewertungen

- HH 84-20Dokument16 SeitenHH 84-20Panganayi JamesNoch keine Bewertungen

- Procure To Pay' ProcessDokument16 SeitenProcure To Pay' ProcessDiwahar PuraviNoch keine Bewertungen

- S6 ENTREPRENUERSHIP Needed Notes To The EndDokument84 SeitenS6 ENTREPRENUERSHIP Needed Notes To The EndRAMZ RA WILZNoch keine Bewertungen

- Purchasing Notes Chap 2Dokument5 SeitenPurchasing Notes Chap 2Ravi NagarathanamNoch keine Bewertungen

- SAP Certified Application Associate - SAP S/4HANA Sourcing and Procurement - MiniDokument16 SeitenSAP Certified Application Associate - SAP S/4HANA Sourcing and Procurement - Minibharti savarkarNoch keine Bewertungen

- SAP MM - DocumentationDokument158 SeitenSAP MM - DocumentationrajaNoch keine Bewertungen

- CV For 18 Successful Years Experience in U.A.E. in Field of Procurement and Purchasing PDFDokument3 SeitenCV For 18 Successful Years Experience in U.A.E. in Field of Procurement and Purchasing PDFAnonymous SAYCBUXNoch keine Bewertungen

- Using Supply Chain OrchestrationDokument82 SeitenUsing Supply Chain OrchestrationJohnnyNoch keine Bewertungen

- SAP MM End User ResumeDokument2 SeitenSAP MM End User ResumeRupesh67% (3)

- Back To Back Sales OrderDokument10 SeitenBack To Back Sales OrderNidhi SaxenaNoch keine Bewertungen

- SAP MM SyllabusDokument3 SeitenSAP MM Syllabusbeema1977Noch keine Bewertungen

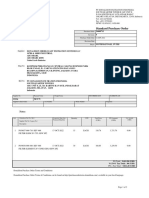

- Po 54008713Dokument2 SeitenPo 54008713Putri MuthmainnahNoch keine Bewertungen

- Tender058 190318Dokument79 SeitenTender058 190318jayasiinputNoch keine Bewertungen

- Replenishment Overview V14toV16Dokument76 SeitenReplenishment Overview V14toV16Apoorv SrivastavaNoch keine Bewertungen

- 80305A - Supply Chain Foundation Appendix For Microsoft Dynamics AX 2012 R2Dokument125 Seiten80305A - Supply Chain Foundation Appendix For Microsoft Dynamics AX 2012 R2imroz_alamNoch keine Bewertungen

- Sheik Shadul CVDokument4 SeitenSheik Shadul CVsheik shadulNoch keine Bewertungen

- InterCompany POSO SAPDokument9 SeitenInterCompany POSO SAPTejendra SoniNoch keine Bewertungen

- Movement TypesDokument9 SeitenMovement TypessuhradamNoch keine Bewertungen

- R12.1.3 and R12.2.10 New FeaturesDokument4 SeitenR12.1.3 and R12.2.10 New FeaturesMuzaffar UddinNoch keine Bewertungen

- Po# 4900050798plumbing KuysenDokument6 SeitenPo# 4900050798plumbing KuysenMaverick OmnesNoch keine Bewertungen

- Approval Workflows For Documents and ObjectsDokument1 SeiteApproval Workflows For Documents and Objectsraju221756_843567682Noch keine Bewertungen

- Sap Fms Lo SGT SegmentationDokument63 SeitenSap Fms Lo SGT SegmentationSushmita Ghosh Biswas60% (5)

- Brazilian Localization Basic SetupDokument17 SeitenBrazilian Localization Basic SetupHERNANIARINoch keine Bewertungen

- Dewpond Technology Private Limited: Perfection. DeliveredDokument3 SeitenDewpond Technology Private Limited: Perfection. DeliveredsunilNoch keine Bewertungen

- NOMI Monoclonal Antibody TreatmentDokument3 SeitenNOMI Monoclonal Antibody TreatmentThe Salt Lake TribuneNoch keine Bewertungen

- Resume@Monalisa SAP MMDokument3 SeitenResume@Monalisa SAP MMramanuj padhyNoch keine Bewertungen

- Complex - PO - Retainage InvoiceDokument16 SeitenComplex - PO - Retainage InvoiceRanjeet KumarNoch keine Bewertungen

- Oracle Procurement Cloud Release 9 Whats NewDokument84 SeitenOracle Procurement Cloud Release 9 Whats Newsieger74Noch keine Bewertungen

- Basics 1 Implementation User CreationDokument123 SeitenBasics 1 Implementation User CreationUpasan PNoch keine Bewertungen