Beruflich Dokumente

Kultur Dokumente

10.1134 S0036029509070118

Hochgeladen von

Amir JoonOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

10.1134 S0036029509070118

Hochgeladen von

Amir JoonCopyright:

Verfügbare Formate

ISSN 0036-0295, Russian Metallurgy (Metally), Vol. 2009, No. 7, pp. 608609. Pleiades Publishing, Ltd., 2009.

. Original Russian Text V.G. Zinchenko, N.V. Malkov, M.O. Peshkov, V.E. Roshin, 2008, published in Elektrometallurgiya, 2008, No. 12, pp. 1416.

MANUFACTURE OF FERROUS AND NONFERROUS METALS

Refining of the Forging Ingot Metal from Nonferrous Metals Using High-Activity Elements

V. G. Zinchenko, N. V. Malkov, M. O. Peshkov, and V. E. Roshin

OAO ORMETO-YuUMZ Southern Ural State University, Chelyabinsk, Russia DOI: 10.1134/S0036029509070118

It was found earlier [1] that the contamination of metal with oxide and sulde nonmetallic inclusions decreases and their distribution over the section of large ingots becomes more inform compared to that in a standard metal as result of the modication of a liquid steel used for 6- to 50-t forging ingots by a complex modier (CaMgBaAlSirare-earth metal (REM)) in an automated combined steel processing unit (ACSPU). The contamination of the surface zone of ingots for rolls with nonmetallic inclusions decreases substantially. In estimating the contamination of a metal with nonmetallic inclusions, the number of pure elds of view increases. As was shown in [2], the decrease in the contents of elements induced by the modication of a metal in the ACSPU was

, abs % P S As Sn Zn 0.0040.006 0.003 0.00370.0041 0.00100.0013 0.00600.0172 , rel % 1926 1523 3036 12.517.5 7383

In this work, we studied the effect of the calculated amounts of REMs introduced into a metal by a modier in the ACSPU on the content of nonferrous metals in steel 60KhN and the mechanical properties of large forgings made of steel 17G1S. The modier contained (wt %) 1012% Ca, 11.5% Mg, to 4% Ba, to 2% Al, 4560% Si, 1012% REM, and Fe for balance [3]. Steels 60 KhN and 17G1S were melted in a DSP-50 arc steel-making furnace. The seminished product was deoxidized in a ladle and the ladle with a metal was moved to ACSPU, where the newly formed slag was treated with breeze coke and aluminum. Aluminum was introduced in the form of a wire by a tribe apparatus for nal deoxidation and control of the grain size. The metal in the ACSPU was modied after the introduction of aluminum. The consumption of the modier was 6001200 g/t. 36-t forging ingots were cast from the experimental metal. The content of nonferrous metals in large ingots made of the 60KhN steel and the amounts of the introduced complex REM-containing modier are given in Table 1. The mechanical properties of the 17G1S steel in forgings are presented in Table 2.

Table 1. Content of nonferrous metal impurities in forgings Element As Parameter Maximum content in the metal in the ACSPU, ppm Average content in the forging metal, ppm Absolute decrease, ppm Relative decrease, % Maximum content in the metal in the ACSPU, ppm Average content in the forging metal, ppm Absolute decrease, ppm Relative decrease, % Maximum content in the metal in the ACSPU, ppm Average content in the forging metal, ppm Absolute decrease, ppm Relative decrease, % 608 [REM]calc, % 0.0052 133 97 36 27 82 56 26 31.7 43 42 1 2.3 0.0056 72 72 0 0 55 48 7 12.7 67 48 19 28.3 0.0068 140 72 68 48.6 94 51 43 45.7 37 13 24 64.9 0.0097 105 68 37 35.2 74 67 7 9.5 207 24 183 88.4 0.0100 133 110 23 17.3 81 80 1 0 79 20 59 74.7

Sn

Zn

REFINING OF THE FORGING INGOT METAL FROM NONFERROUS METALS Table 2. Mechanical properties of the 17G1S steel in forgings Parameter Relative elongation, % Relative reduction of area, % Impact toughness at 20C, J/cm2 [REM]calc, % 0 29.4 59.4 57.7 0.0064 30.8 65.0 69.0 0.0070 31.2 67.5 114.0 0.0081

609

32.033.0 68.071.0 129.0

According to the experimental results, the content of nonferrous metals in the forging ingots decreases as the amount of REMs introduced into the liquid steel by the complex modier in the ACSPU increases. This is due to the fact that REMs present in the modier have a high chemical afnity for these elements and xed them with the formation of compounds to be removed from the metal. In studying samples of ingots made of the modied and unmodied 60KhN steel in a JEOL JSM-6460LV scanning electron microscope, we revealed nonferrous-metal impurities in the form of complex inclusions containing REMs [4], which are present in the metallic matrix of only the unmodied ingot. It was found that the conditions most favourable for the removal of nonferrous metals are created in the case of introduction of the modier during processing of the melt in the ACSPU. When the metal is processed by the modier in a mold, the reaction products have no time

to be removed even during simultaneous argon blowing of the metal. REFERENCES

1. V. G. Zinchenko and I. V. Sudorgin, Ladle Processing Rolling Steel by a Complex Modier, in Proceedings of XII International Conference on Modern Problems of Steel Electrometallurgy (Izd. YuUGU, 2004) [in Russian]. 2. V. G. Zinchenko, I. V. Sudorgin, and V. E. Roshchin, Processing 60KhN Steel for Large Ingots by a Complex Modier, Electrometallurgiya, No. 1, 2428 (2006). 3. Ya. E. Goldshtein and V. G. Mizin, Modication and Microallowing of Iron and Steel (Metallurgiya, Moscow, 1986) [in Russian]. 4. V. G. Zinchenko, V. E. Roshchin, and N. V. Malkov, Effect of Modication Technology on the Content and Distribution of Detrimental Impurities in Forging Ingots, Electrometallurgiya, No. 2, 1115 (2007) [Rus. Metall., No. 7, 621625 (2007)].

RUSSIAN METALLURGY (METALLY)

Vol. 2009

No. 7

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Signal Processing: Darian M. Onchis, Pavel RajmicDokument6 SeitenSignal Processing: Darian M. Onchis, Pavel RajmicAmir JoonNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- 4 (Hydrostatics 2)Dokument34 Seiten4 (Hydrostatics 2)Amir JoonNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Cycling HRSGS: Jeffrey PhillipsDokument19 SeitenCycling HRSGS: Jeffrey PhillipsAmir JoonNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- 6 (System & Control Volume-1)Dokument34 Seiten6 (System & Control Volume-1)Amir JoonNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- 8 (Dimensional Analysis)Dokument21 Seiten8 (Dimensional Analysis)Amir JoonNoch keine Bewertungen

- 7 (System & Control Volume-2)Dokument16 Seiten7 (System & Control Volume-2)Amir JoonNoch keine Bewertungen

- 5 (Fluid Flow)Dokument23 Seiten5 (Fluid Flow)Amir JoonNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Aspen Plus DEPG ModelDokument23 SeitenAspen Plus DEPG ModelAmir JoonNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- AmmoniaDokument24 SeitenAmmoniaCamilo GarzonNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- An Inverse Problem in Estimating Simultaneously The Effective Thermal Conductivity and Volumetric Heat Capacity of Biological TissueDokument13 SeitenAn Inverse Problem in Estimating Simultaneously The Effective Thermal Conductivity and Volumetric Heat Capacity of Biological TissueAmir JoonNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Aspen Plus NMP ModelDokument24 SeitenAspen Plus NMP ModelAmir JoonNoch keine Bewertungen

- Aspen OLI V7.1 ReadmeDokument2 SeitenAspen OLI V7.1 ReadmeAmir JoonNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- s2.0 S1875389210000635 MainDokument7 Seitens2.0 S1875389210000635 MainAmir JoonNoch keine Bewertungen

- An Integrated Design and CAPP System For Cold or Hot Forging ProductsDokument8 SeitenAn Integrated Design and CAPP System For Cold or Hot Forging ProductsAmir JoonNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Aspen Dynamics DIERS BenchmarksDokument9 SeitenAspen Dynamics DIERS BenchmarksAmir JoonNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Influence of Semisolid Forging Ratio On The Microstructure and Mechani-Cal Properties of Ti14 AlloyDokument7 SeitenInfluence of Semisolid Forging Ratio On The Microstructure and Mechani-Cal Properties of Ti14 AlloyAmir JoonNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Development of A Remote Collaborative Forging Engineering SystemDokument9 SeitenDevelopment of A Remote Collaborative Forging Engineering SystemAmir JoonNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Solving Single Nonlinear Equations (Part 2) : Using Excel GOAL SEEK FunctionDokument4 SeitenSolving Single Nonlinear Equations (Part 2) : Using Excel GOAL SEEK FunctionAmir JoonNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Choice of A Rational Scheme For Casting of A Forging Ingot For Producing Hollow ForgingsDokument4 SeitenChoice of A Rational Scheme For Casting of A Forging Ingot For Producing Hollow ForgingsAmir JoonNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Piezoelectric Materials PDFDokument19 SeitenPiezoelectric Materials PDFAmir JoonNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- International Journal of Solids and Structures: Anil K. Vashishth, Vishakha GuptaDokument13 SeitenInternational Journal of Solids and Structures: Anil K. Vashishth, Vishakha GuptaAmir JoonNoch keine Bewertungen

- EOT CRANE - Rev 2Dokument6 SeitenEOT CRANE - Rev 2Koushik BhaumikNoch keine Bewertungen

- Bhushan Power & Steel Ltd.Dokument17 SeitenBhushan Power & Steel Ltd.navdeeplakheraNoch keine Bewertungen

- SS316LNDokument4 SeitenSS316LNsamruddhiNoch keine Bewertungen

- A Semi-Detailed Lesson PlanDokument5 SeitenA Semi-Detailed Lesson PlanCharisse Magallon Dagondon100% (1)

- Steel MakingDokument8 SeitenSteel MakingCheeragNoch keine Bewertungen

- Xomox-HPBF Double Offset PDFDokument24 SeitenXomox-HPBF Double Offset PDFPinak VadherNoch keine Bewertungen

- EPMA Introduction To PM HIP Technology English PDFDokument32 SeitenEPMA Introduction To PM HIP Technology English PDFFlávia CostaNoch keine Bewertungen

- Is 6862 2005Dokument11 SeitenIs 6862 2005sarath6725Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Specification For Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelDokument4 SeitenSpecification For Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelmalsttarNoch keine Bewertungen

- Asme b18!8!4m Pin Materials and HardnessDokument2 SeitenAsme b18!8!4m Pin Materials and Hardnessjaskaran singhNoch keine Bewertungen

- API 571-Damage Mechanism (October 4-7-2010)Dokument4 SeitenAPI 571-Damage Mechanism (October 4-7-2010)ananda_27Noch keine Bewertungen

- Mechanical Workshop PracticeDokument19 SeitenMechanical Workshop PracticeAnonymous SLKWYHBo50% (2)

- Characteristic Data Standard MaterialsDokument6 SeitenCharacteristic Data Standard MaterialsSuresh Kumar MittapalliNoch keine Bewertungen

- KLM Panel SpecificationsDokument2 SeitenKLM Panel Specificationsvikas_ojha54706Noch keine Bewertungen

- 7.8 Cutting Tool Materials CompleteDokument15 Seiten7.8 Cutting Tool Materials CompleteNikhil Batham67% (6)

- Standard Steel PlatesDokument39 SeitenStandard Steel PlatesCuong TranHung100% (1)

- Halogen at EdDokument4 SeitenHalogen at EdgganageNoch keine Bewertungen

- Mil DTL 38999 Series IIIDokument10 SeitenMil DTL 38999 Series IIIthulasi_krishnaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

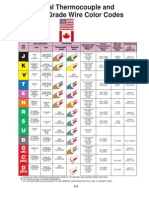

- International Thermocouple and Extension Grade Wire Color CodesDokument6 SeitenInternational Thermocouple and Extension Grade Wire Color CodesEdguitar TheLonelyNoch keine Bewertungen

- Rake AngleDokument2 SeitenRake AnglezidaaanNoch keine Bewertungen

- 01.4TB.076 Bus Duct Enclosure MaterialDokument1 Seite01.4TB.076 Bus Duct Enclosure MaterialJonathan FerueloNoch keine Bewertungen

- MIL-DTL-64159 - Chemical Agent Resistant CoatingDokument27 SeitenMIL-DTL-64159 - Chemical Agent Resistant Coatingformick71Noch keine Bewertungen

- KTZDokument4 SeitenKTZmanbkkNoch keine Bewertungen

- FCAW For COR TEN Structure: Technical and Economical ConsiderationsDokument9 SeitenFCAW For COR TEN Structure: Technical and Economical ConsiderationsDan PopaNoch keine Bewertungen

- Language of Chemistry' PDFDokument13 SeitenLanguage of Chemistry' PDFsanat kr pratiharNoch keine Bewertungen

- Stainless Steel Products PDFDokument72 SeitenStainless Steel Products PDFlemuel bacsaNoch keine Bewertungen

- C & SSC SeriesDokument6 SeitenC & SSC SeriesErick PachasNoch keine Bewertungen

- Carbon and Alloy Steel Bars Subject To End-Quench Hardenability RequirementsDokument48 SeitenCarbon and Alloy Steel Bars Subject To End-Quench Hardenability Requirementsalucard375Noch keine Bewertungen

- GREASe Process ReportDokument110 SeitenGREASe Process Reportrazamalik01Noch keine Bewertungen

- Chem QueastionsDokument137 SeitenChem QueastionsdjftNoch keine Bewertungen

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- ICH Quality Guidelines: An Implementation GuideVon EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNoch keine Bewertungen

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincVon EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincBewertung: 3.5 von 5 Sternen3.5/5 (137)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeVon EverandChemistry for Breakfast: The Amazing Science of Everyday LifeBewertung: 4.5 von 5 Sternen4.5/5 (14)