Beruflich Dokumente

Kultur Dokumente

Inductive and Capacitive Sensors

Hochgeladen von

metalshockOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Inductive and Capacitive Sensors

Hochgeladen von

metalshockCopyright:

Verfügbare Formate

Model Number Index

Table of Contents

Main Menu

Back One Page

Fundamentals of Inductive and Capacitive Proximity Sensors

Principles of Operation 10 Construction 11 Electrical Output 12-18 Styles of Sensors 19 Sensing Range 20 Actuating Sensors 21 Mounting 22-23 Special Considerations 24-25 Key To Model Numbers 26

PEPPERL+FUCHS

Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087-2245 www.am.pepperl-fuchs.com Telephone (330) 486-0001 FAX (330) 405-4710 E-Mail: sales@us.pepperl-fuchs.com

Fundamentals of Inductive and Capacitive Proximity Sensors

Principles of Operation Inductive

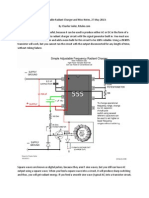

P+F inductive proximity sensors are the Eddy Current Killed Oscillator (ECKO) type. This type of sensor contains four basic elements as shown at the right.

Output Switching Device

Model Number Index

Table of Contents

Main Menu

Back One Page

Coil

Oscillator

Trigger Circuit

Sensing Field

The oscillator creates a radio frequency that is emitted from the coil away from the face of the sensor. If a metal plate enters this radiated field, eddy currents circulate within the metal.

Proximity Sensor

Sensing Field

Target

The oscillator requires energy to maintain the eddy currents in the metal plate. As the plate approaches the sensor, the eddy currents increase and cause a greater load on the oscillator. The oscillator stops when the load becomes too great. The trigger circuit senses when the oscillator stops, then changes the state of the switching device (a transistor in DC sensors, a thyristor in AC sensors) to control the load.

Target Absent

Target Approaching Sensor

Oscillator Stalled Amplitude ON OUTPUT STAGE Shown as Normally Open OFF

Capacitive

Oscillator

Trigger Circuit

Output Switching Device

Target

Plate

P+F capacitive sensors act similar to a simple capacitor. A metal plate, in the end of the sensor, is electrically connected to the oscillator. The object to be sensed acts as a second plate. When power is applied to the sensor, the oscillator senses the external capacitance between the target and the internal sensor plate. This forms a part of the feedback capacitance in the oscillator circuit.

Target Absent

Target Approaching Sensor

Amplitude of Oscillations ON Output Stage Shown as Normally Open OFF

Capacitive sensors detect targets in the opposite manner as inductive sensors. As a target approaches a capacitive sensor, the oscillations increase until they reach a threshold level and activate a switching device.

10

PEPPERL+FUCHS

Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087-2245 www.am.pepperl-fuchs.com Telephone (330) 486-0001 FAX (330) 405-4710 E-Mail: sales@us.pepperl-fuchs.com

Fundamentals of Inductive and Capacitive Proximity Sensors

Model Number Index

Table of Contents

Main Menu

Back One Page

Construction

The majority of P+F proximity sensor housings are manufactured from either 303 stainless steel, nickel-plated brass or crastin. Crastin housings are made with a semicrystalline polyenterephthalate material reinforced with short glass fibers. This combination of material is ideal for producing superior precision molded parts with exceptionally low conductance. Crastin will retain dimensional stability and its electrical and dielectric properties are virtually unaffected by temperature changes or by wet environments. This rugged material is resistant to abrasion and has excellent antifriction properties. In tests conducted by an independent testing laboratory, a Crastin housing was found to have exceptional resistance to chemicals, oils, fats and most aqueous media. These tests were made over a 60 day period and conducted at a temperature of +70F. Crastin proved resistant to the following:

Crastin Housings

Cover paste Epoxy resin O-ring Crastin cylindrical proximity sensors are ideal when the application requires Coil resistance to water Ultrasonic and corrosion. Weld The solid-state Crastin housing Ferrite Integrated Printed core circuit circuit components are embedded in an epoxy resin under vacuum and the end cap is ultrasonically welded to the body. This combination is impervious to water and prevents condensation. Crastin sensors may be immersed in water up to +158F without damage to the sensor. Inductive styles withstand 75psi, while capacitive styles withstand 15psi.

I I I I I I I I I I I I I I I I I I I I I I I

Acetaldehyde Acetic Acid Acetone 10% Ammonia Benzene Benzol Chloride Butyl Acetate 10% Calcium Chloride Carbon Tetrachloride Diputyl Phtalate Drilling Emulsion Engine & Diesel Oil Ethanol Ethyl Ethylic Ether 30% Formaldehyde 10% Formic Acid Freon Gasoline Glycerine Glycol Heptane Hexane

I I I I I I I I I I I I I I I I I I I I I

10% Hydrochloric Acid 35% Hydrogen Peroxide Kerosene Methanol Mineral Oils 10% Nitric Acid Perchlorethylene Petrol Petroleum Phosphoric Acid 5% Potassium Bichromate 10% Potassium Permanganate Sea Water 10% Sodium Carbonate 10% Sodium Chloride 28% Sulphuric Acid Toluene Transformer Oil Trichlorethylene 158F Water Xylene

303 Stainless Steel and Nickel-Plated Brass Housings

O-ring Metal cylindrical proximity sensors are manufactured with an Coil injection molded plastic sleeve fitted inside the metal case Ferrite Metal 303 Integrated Printed at the sensing end. core Stainless Steel housing circuit circuit This plastic sleeve provides exceptional protection against moisture entering the sensing unit. Like the Crastin unit, solid-state components are embedded in an epoxy resin under vacuum to provide protection against moisture. Plastic sleeve Cover paste LED Epoxy resin

Pepperl+Fuchs SN sensor housings are made of Ryton, a crystalline polypheylene sulfide that provides structural and dielectric stability in temperatures up to 392F. Ryton is resistant to most industrial agents.

LED (Light Emitting Diode)

P+F provides LEDs in most of the metal sensors. They are not available in many Crastin sensors. The reasoning is that the Crastin sensors are designed to operate underwater throughout the temperature range (+158F maximum) without damage to the sensor because the housings are ultrasonically welded. If an LED were included, it is possible under temperature changes that water could leak around the LED. Most sensors have one amber (target present) LED, although most limit switch style sensors have an amber and a green LED (power on) . For W4 outputs, the amber LED indicates the N.O. output is energized and the green LED indicates the N.C. output is energized.

Note: Chemicals may affect sensor cable. Contact P+F for suggestions.

PEPPERL+FUCHS

Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087-2245 www.am.pepperl-fuchs.com Telephone (330) 486-0001 FAX (330) 405-4710 E-Mail: sales@us.pepperl-fuchs.com

11

Fundamentals of Inductive and Capacitive Proximity Sensors

Electrical Output

Model Number Index

Table of Contents

Main Menu

Back One Page

Pepperl+Fuchs offers sensors for both AC and DC outputs that connect to loads commonly used in industry such as programmable logic controls (PLCs), solenoids, relays and microprocessors. The following are summaries of electrical outputs:

2-Wire NAMUR

NAMUR is a standard issued by the Standards Committee of Measurement and Control of the Chemical Industry in Europe. P+F NAMUR sensors meet NFPA standards and are UL Listed. Additionally, P+F NAMUR sensors are CSA and FM approved for use in potentially explosive atmospheres when used in conjunction with a P+F WE or K series intrinsic safety barrier.

Capacitive NAMUR Sensors and N1 NAMUR Outputs

Capacitive and N1 inductive output sensors with NAMUR outputs are very similar in operation to inductive sensors except the current vs. target distance characteristics are exactly opposite.

3.5 3.0

Inductive NAMUR Sensors, N and N0 Outputs

The inductive NAMUR sensors contain only the coil and oscillator from the standard sensor shown in Principle of Operation Inductive (page 26). The trigger circuit and output switching device are contained in a separate amplifier. NAMUR sensors act similar to a variable resistor with a change of resistance of approximately 1K-8K (target absent target present respectively) for distance from the sensor (at 8VDC power supply with an internal resistance of 1K). When metal is absent (sensor 1K) the circuit oscillates and has a current draw greater than 3mA. When metal is present (sensor 8K) the oscillator stalls and lowers the current to less than 1mA. The graph below illustrates the relationship between the current draw and the sensing distance for inductive NAMUR sensors and for N and N0 outputs:

2.5

Current (mA) 1.5

1.0 .5 0 20 40 60 80 100 120

2.0

% Sensing Distance

P+F switching amplifiers have a switchpoint that triggers output switching devices at approximately 1.65mA. P+F provides many amplifiers compatible with NAMUR sensors. The following circuits are recommended for use with NAMUR sensors to provide on/off outputs:

+7 to +9VDC

3.5 3.0 2.5

Interface circuit using discrete components

1K

NAMUR Sensor

Load

8VDC

Current (mA) 1.5

1.0 .5 0

4.7K

2.0

360

1f

470K

20

40

60

80

100

120

100

2.2K

% Sensing Distance

NAMUR Sensor

Op-Amp

Output

910 100

Interface using operational amplifier

12

PEPPERL+FUCHS

Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087-2245 www.am.pepperl-fuchs.com Telephone (330) 486-0001 FAX (330) 405-4710 E-Mail: sales@us.pepperl-fuchs.com

Fundamentals of Inductive and Capacitive Proximity Sensors

Model Number Index

Table of Contents

Main Menu

Back One Page

Styles of Sensors

Physical constraints may determine the style of sensor that can be used. P+F offers the following styles:

Surface Mount

Depending on the surface mount sensor that is used, some sense from the top and some from the side.

Cylindrical

The sensing field is in the front of the sensing device. The sensor is activated when a target enters the sensing field in an axial or lateral direction.

Slot

The sensing field is concentrated between two coils on a common axis. The sensor is activated when a metallic object (target) enters the area between the coils.

Limit Switch Style

This sensor contains a sensing face that is field changeable to any one of five positions, from front to top to both sides to bottom. This sensor has the same mounting dimensions as a standard style limit switch, therefore, this sensor is a replacement for electro-mechanical limit switches.

Ring

The sensing field is concentrated inside the ring. The sensor is activated when a metallic object (target) enters the ring.

PEPPERL+FUCHS

Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087-2245 www.am.pepperl-fuchs.com Telephone (330) 486-0001 FAX (330) 405-4710 E-Mail: sales@us.pepperl-fuchs.com

19

Fundamentals of Inductive and Capacitive Proximity Sensors

Sensing Range

Model Number Index

Table of Contents

Main Menu

Back One Page

The sensing range of a proximity sensor is determined by the size of the coil. Thus, the longer the sensing range, the larger the sensor. Factors that affect the sensing range include target size and composition, as well as ambient temperature.

Example for calculating Reduction Factor:

Actual (Nominal sensing range) x (Reduction factor) = sensing range Reduction factor for Stainless Steel: 20mm x 0.85 = 17mm

Target Construction

The ideal target should have sides equal to the diameter of the sensor or three times the nominal sensing range, whichever is greater. The target should be approximately 1mm thick.

If a target constructed from the materials listed above is used, multiply the nominal sensing range by the reduction factor listed in order to determine the new nominal sensing distance for that target.

Ambient Temperature

Once the actual sensing range has been established, the sensing distance and repetition accuracy will vary depending on the ambient temperature. P+F proximity sensors are guaranteed for 10% of the actual sensing range within the given temperature specifications.

Examples:

1. Sensor diameter: 18mm Sensing range: 5mm 3x sensing range = 15mm <diameter Target should be 18x18x1mm Sensor diameter: 18mm Sensing range: 8mm 3x sensing range = 24mm >diameter Target should be 24x24x1mm

2.

The composition of the target is of great importance in determining actual sensing distance. Nominal sensing ranges are based on the use of a target constructed of mild steel. The following reduction factors apply when using a target other than mild steel.

Approximate reduction factor (may vary by switch) 1.0 1.0 .85 .40 .40 .30

Material MILD STEEL ALUMINUM FOIL STAINLESS STEEL ALUMINUM BRASS COPPER

NOTE: These reduction factors are only approximate. Individual metal alloys and/or unique mounting configurations may have varying effect on the working sensing range. For more information, contact P+F.

20

PEPPERL+FUCHS

Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087-2245 www.am.pepperl-fuchs.com Telephone (330) 486-0001 FAX (330) 405-4710 E-Mail: sales@us.pepperl-fuchs.com

Fundamentals of Inductive and Capacitive Proximity Sensors

Model Number Index

Table of Contents

Main Menu

Back One Page

Actuating Sensors

There are two methods of sensor actuation, lateral and axial (head-on). The sensor activates when the leading edge of the target reaches the solid line, and de-activates when the target reaches the dotted line.

Working Sensing Range (Sw)

This is the sensing range within which the proximity sensor operates under all specified operating conditions. The working range is (0 Sw .81Sn).

Test Plate

switched off with certainty

Standard response curve for capacitive proximity switch

axial

Standard target

S U max

S U max + Hysteresis S r max + Hysteresis S n + Hysteresis S r min + Hysteresis S U min + Hysteresis

switching point hysteresis effective operating distance

Standard target

S r max Sn S r min S U min switched on with certainty S w

radial

Active Face

Proximity Switch

diameter of the active face

x [%]

To allow for manufacturing tolerances and external variations such as temperature, power supply, etc., we recommend adjusting the sensing distance to 80% of the nominal sensing range.

Standard response curve for inductive proximity switch

axial

Standard target

switching point hysteresis

Standard target

effective operating distance

Hysteresis is the distance between the operating point as the target approaches the sensor and the release point as the target moves away. The hysteresis is usually figured as a percentage of the nominal sensing distance. See specifications for individual model values. Repeatability measures the accuracy of the sensor to turn on and off under prolonged successive operations.

radial

diameter of the active face

x [%]

Tightening Torque For Lock Nuts

Nominal Sensing Range (Sn)

Sn is a theoretical value. Sn does not take into account production tolerances or variations due to temperature and voltage.

1 Nm = 0.74 ft-lb

Actual Sensing Range (Sr)

This figure is determined at the nominal voltage and at a fixed ambient temperature of 68F (20C). Sr must not deviate from Sn by more than 10% (0.9Sn Sr 1.1Sn).

Sensor Diameter 5mm 8mm 10mm 12mm 18mm 30mm

Stainless Nickel-Plated Crastin Steel Brass 3.0Nm 10.0Nm 10.0Nm 15.0Nm 30.0Nm 60.0Nm 3.0Nm 7.0Nm 10.0Nm 20.0Nm 40.0Nm 0.75Nm 1.5Nm 3.0Nm

Effective Sensing Range (Su)

This value accounts for all specified voltage and temperature ranges for each sensor. Su must not deviate more than 10% from Sr (0.9Sr Su 1.1Sr). Therefore, (0.81Sn Su 1.21Sn).

Excessive torque could damage the sensor.

PEPPERL+FUCHS

Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087-2245 www.am.pepperl-fuchs.com Telephone (330) 486-0001 FAX (330) 405-4710 E-Mail: sales@us.pepperl-fuchs.com

21

Fundamentals of Inductive and Capacitive Proximity Sensors

Mounting

Model Number Index

Table of Contents

Main Menu

Back One Page

P+F can have several Sensing range (mm) sensing ranges for Diameter NonNBB NBN each cylindrical sensor. Extended X Series X Series (mm) Shielded Shielded Shielded Unshielded These ranges are defined as: 6.5 1.5 2 2 3 8 1.5 2 2 3 Shielded (flush-mounted) 12 2 4 4 8 Unshielded 18 5 8 8 12 (nonflush-mounted) 30 10 15 15 25 X Series Extended Range The chart shows some typical sensing ranges.

Limit Switch and Surface Mount Sensors

Distance Model

NJ1.5-F-__ NJ2-F1-__ NBB-V3-__ NJ4-F1-__ NJ6-F-__ NJ15-M__-__ NBB15-L__ NJ20+U4+__(AC) A 8 0 0 0 0 20 0 20 0 0 30 40 40 40 0 40 40 B 40 0 0 0 0 90 0 200 0 0 250 300 300 120 0 300 150 C 4.5 6 6 12 18 45 45 60 45 45 90 120 120 120 120 120 150 D 12 0 0 0 0 25 0 0 0 0 20 20 20 0 0 20 0 E 0 0 0 0 0 0 0 15 0 0 30 40 40 0 0 40 0 F 16 0 0 24 22 40 40 80 40 40 120 150 150 150 100 150 240 Installation not flush flush flush not flush flush not flush flush not flush flush flush not flush not flush not flush not flush flush not flush not flush

Shielding

As was previously mentioned, proximity sensors contain coils which are wound in ferrite cores to point the radiated fields in the direction of use. The field, however, also radiates laterally. This lateral radiation of the field could be sufficient to prevent the sensor from being flush mounted in metal, because this could actuate the sensor.

NBB20-L__ NJ20+U4+E__,A__ NBN30-L__ NBN40-L__ NCN40+U__ NJ40-FP-__ NJ40-FP__-B1-__ NJ40+U__ NJ50-FP-__

Unshielded Sensor

If flush mounting in metal is desired, a metal ring is placed around the ferrite core to restrict the lateral radiation of the field, however, this will cause the sensing range to be reduced.

Shielded Sensor

Limit switch style sensors Metal with 15mm nominal sensing distance may be flush mounted.

The example shows a shielded sensor flush mounted in a metal plate and an unshielded sensor mounted in a metal plate with dimensions for safe installation.

3 Times Diameter D

Metal

2 Times Sensing Range

Unshielded sensor mounted in a metal plate with dimensions for safe installation

Shielded sensor flush mounted

Limit switch style sensors with nominal sensing distances of 20mm, 30mm and 40mm cannot be flush mounted. Dimensions are shown in the chart above for installing sensors.

A C B

The possibility of frequency interference exists when sensors are mounted adjacent to each other. The figure below shows the minimum spacing between sensors.

Once again the possibility of frequency interference exists under certain circumstances when mounting sensors next to each other. Use the dimensions shown in the chart above to determine distances between sensors. In applications where these distances cannot be observed, contact P+F for assistance.

3xD

D 1xD D

Unshielded sensor distance D must be 3 times the diameter

F

Distance between shielded sensors should be equal to the diameter of the sensor

E D

22

PEPPERL+FUCHS

Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087-2245 www.am.pepperl-fuchs.com Telephone (330) 486-0001 FAX (330) 405-4710 E-Mail: sales@us.pepperl-fuchs.com

Fundamentals of Inductive and Capacitive Proximity Sensors

Model Number Index

Table of Contents

Main Menu

Back One Page

Mounting

Basic Series Surface Mount Sensors

Use the dimensions shown in the chart below to determine distances between sensors. In applications where these distances are not practical, contact P+F for assistance.

Effects of Surrounding Metals

Target Plate

C B

Mounting NEB Series Extended Range Sensors

When installing NEB series extended range sensors the following guidelines should be observed.

Material

A C B

A = 0.2 x diameter in ferrous metals A = 0.1 x diameter in non-ferrous metals B = 2 x diameter C = 3 x diameter

Frequency interference can occur when sensors are mounted adjacent to each other. A distance equal to the diameter of the sensor should be maintained.

E

E

E = Sensor diameter

E E

Mutual Interference

Target Plate F

Switching Frequency

Target Plate

Switching frequency is the rate at which a sensor can turn on and off each second and is measured in Hertz (Hz).

2xD

Basic Series Surface Mount Sensors

Distance (mm) Model

NBN4-F29-__ NBB5-F9-__ NBN5-F7-__ NBB7-F10-__ NBN10-F10-__ NCB10-F17-__ NBN15-F11-__ A 4 0 0 0 0 7.5 0 B 4 0 0 0 0 0 0 C 12 15 15 20 30 30 45 D 4 0 0 0 0 0 0 E 4 0 0 0 5 0 10 F 12 16 17 25 25 40 30 G 16 20 20 30 40 40 60

The spacing between targets should be twice the width of the target. The width of the target should be equal to or greater than the diameter of the sensor face. The maximum switching frequency for each sensor is shown in the individual charts.

Target Spacing

Note: Unshielded sensors cannot be surrounded by metal on all four sides.

PEPPERL+FUCHS

Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087-2245 www.am.pepperl-fuchs.com Telephone (330) 486-0001 FAX (330) 405-4710 E-Mail: sales@us.pepperl-fuchs.com

23

Fundamentals of Inductive and Capacitive Proximity Sensors

Special Considerations

Model Number Index

Table of Contents

Main Menu

Back One Page

Leakage Current and Voltage Drop Across Sensors

When using 2-wire self-contained sensors, consideration must be given to leakage current and voltage drop when choosing the load. The drawings below show ladder diagrams to better explain the effects of 2-wire self-contained sensors. The voltage and current values shown are worst case.

24VDC

Hazardous Locations

P+F NAMUR sensors may be used in potentially explosive atmospheres when used in conjunction with P+F FM and CSA approved switch isolators. These may be used in place of explosion-proof sensors, resulting in substantial cost savings. NAMUR sensors may be utilized in locations of all classes, divisions and groups without explosion-proof enclosures or conduit.

Mechanical Limit Switch 2-wire DC Self-Contained Proximity Sensor

Current (mA)

0

FM

Load

APPROVED

Current (mA)

1

Certified

Hazardous Area

Load

Safe Area

Mechanical Limit Switch Load 2-wire DC Self-Contained Proximity Sensor

Voltage (V)

24

P+F Switch Isolator P+F NAMUR Proximity Sensor

Load

Voltage (V)

20

120VAC

Mechanical Limit Switch

2-wire AC Self-Contained Proximity Sensor

Current (mA)

0

Load

Current (mA)

1.7

Load

Mechanical Limit Switch Load

2-wire AC Self-Contained Proximity Sensor

Voltage (V)

120

Load

Voltage (V)

115

24

PEPPERL+FUCHS

Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087-2245 www.am.pepperl-fuchs.com Telephone (330) 486-0001 FAX (330) 405-4710 E-Mail: sales@us.pepperl-fuchs.com

Fundamentals of Inductive and Capacitive Proximity Sensors

Model Number Index

Table of Contents

Main Menu

Back One Page

Special Considerations

Mechanical

Series and Parallel Wiring

Self-contained proximity sensors may be connected either in series or in parallel in order to create AND, OR, NAND or NOR circuits. The following must be considered when connecting sensors in this manner: 1. Parallel connection For multiple 2-wire sensors connected in parallel, the leakage currents will add, and the total leakage current from all sensors will flow through the load. The drawings below show formulas that indicate how many sensors can be connected in parallel. 3-wire sensors may be connected in parallel although decoupling diodes are recommended. The maximum number of sensors is restricted by the current capacity of the supply. The maximum off state draw by P+F sensors is approximately 10mA, and the maximum on state current draw is dependent upon the sensors used. 2. Series connection Proximity sensors have a voltage drop in the on state. The maximum number of sensors that may be wired in series is restricted by the voltage drop across each sensor, supply voltage and minimum operating voltage of the load. There will be a delay in operation experienced with series sensors.

Contact When a proximity sensor Load is wired in parallel with a mechanical contact (see Proximity Sensor example at right), the sensor will not receive power when the contact is closed. Therefore, when Voltage (V) the mechanical contact opens and allows power 0 to reach the sensor, it takes the sensor 10s to overcome its readiness delay. During this time it is possible for the load to de-energize. As a result, caution must be taken when using proximity sensors as latching contacts. The same is true for proximity sensors wired in series with mechanical contacts. In this case, however, the proximity sensor will not operate until the contact is closed.

Mechanical Contact

Proximity Sensor

Current

0

Load

Metric Threads

All P+F sensors have metric threads as shown in the dimensional diagrams.

Series

2-wire sensors

Load Consult Factory

Example: M18x1 (18mm diameter and 1mm/thread)

Conduit adapters (page 579) are available from P+F which have metric threads on one end and 1/2" NPT threads on the other.

Parallel

2-wire sensors

Load Sensors =

Holding current load leakage current

-1

Sensor Specifications

Temperature range:

-14F to +158F Extended temperature range of -40F to +212F available on some models.

Series

3-wire sensors

PNP output shown, reverse polarity for NPN output

Repeatability:

( )

Load

( )

( )

( )

.01mm when tested at 75F 10% with a nominal supply voltage of VS 5%.

Consult Factory

Hysteresis:

0.03mm to 3mm for inductive sensors 0.03mm to 10mm for capacitive sensors

Parallel

3-wire sensors

PNP output shown, reverse polarity for NPN output

( )

( )

Shock: (IEC 68-2-6)

Load

Sinewave, acceleration 30 times gravitational constant, less than 11 milliseconds, 3 shocks in both directions (forward and back), in all three planes, X, Y and Z.

The maximum number of sensors is restricted by the current capacity of supply voltage source. If five or fewer 3-wire DC sensors are wired in parallel, decoupling diodes are typically not required.

Vibration: (IEC 68-2-27)

Frequency range 10-55Hz, amplitude 1mm, cycle time 5 minutes, 30 minutes in each plane X, Y and Z.

PEPPERL+FUCHS

Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087-2245 www.am.pepperl-fuchs.com Telephone (330) 486-0001 FAX (330) 405-4710 E-Mail: sales@us.pepperl-fuchs.com

25

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 505 Enhanced Instruction Manual V1Dokument212 Seiten505 Enhanced Instruction Manual V1metalshock67% (3)

- NEW 505 Configuration TransferDokument4 SeitenNEW 505 Configuration TransfermetalshockNoch keine Bewertungen

- B Protech Gii ImDokument201 SeitenB Protech Gii ImmetalshockNoch keine Bewertungen

- 505 Enhanced Service Manual V2Dokument144 Seiten505 Enhanced Service Manual V2metalshock75% (4)

- Order Number:: Order: Time: Purchase l3.SEMS Airport RsposibleDokument1 SeiteOrder Number:: Order: Time: Purchase l3.SEMS Airport RsposiblemetalshockNoch keine Bewertungen

- Physics: DPP - Daily Practice ProblemsDokument4 SeitenPhysics: DPP - Daily Practice ProblemsTuba NrNoch keine Bewertungen

- NTS TESCO Junior Engineer - SDO Test - 2019Dokument11 SeitenNTS TESCO Junior Engineer - SDO Test - 2019asimNoch keine Bewertungen

- RRE Reed Switch NotesDokument19 SeitenRRE Reed Switch NotesMario MasettiNoch keine Bewertungen

- Chapter - 2 Transformers: 2.1 What Is A Transformer?Dokument23 SeitenChapter - 2 Transformers: 2.1 What Is A Transformer?muralibeee2874Noch keine Bewertungen

- SynchrosDokument43 SeitenSynchrosjashjaNoch keine Bewertungen

- Elex 2Dokument4 SeitenElex 2Joshua DoctorNoch keine Bewertungen

- 4PH1 2P Que 20190615 PDFDokument20 Seiten4PH1 2P Que 20190615 PDFMd. Kutub UddinNoch keine Bewertungen

- Insulation of Turbogenerators by VPI Process PDFDokument65 SeitenInsulation of Turbogenerators by VPI Process PDFprinceshankerNoch keine Bewertungen

- Generation of Alternating Voltages and Currents: AC FundamentalsDokument56 SeitenGeneration of Alternating Voltages and Currents: AC FundamentalsLovelly ViniNoch keine Bewertungen

- Koher AvrDokument133 SeitenKoher AvrMuneer Haq100% (3)

- New Adjustable Frequency Radiant Charger PDFDokument5 SeitenNew Adjustable Frequency Radiant Charger PDFlancerdoom1100% (6)

- Drive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Dokument90 SeitenDrive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Anonymous ntE0hG2TPNoch keine Bewertungen

- Expe YesDokument107 SeitenExpe YesviolatorNoch keine Bewertungen

- Circuit Symbols of Electronic Components PDFDokument17 SeitenCircuit Symbols of Electronic Components PDFKarlos NikoNoch keine Bewertungen

- Tsividis - Putting The Lab TogetherDokument24 SeitenTsividis - Putting The Lab TogetheryeiaNoch keine Bewertungen

- Deh-2000r Deh-2020 2030Dokument85 SeitenDeh-2000r Deh-2020 2030jop351Noch keine Bewertungen

- End Fed Halfwave Antenna and Matching Unit For 40M by ZS1JHGDokument4 SeitenEnd Fed Halfwave Antenna and Matching Unit For 40M by ZS1JHGJohn Howard Green100% (1)

- WIRELESS - ELECTRICITY - A - SEMINAR - REPORT Mukund Nikam .....Dokument41 SeitenWIRELESS - ELECTRICITY - A - SEMINAR - REPORT Mukund Nikam .....mukund nikamNoch keine Bewertungen

- Product Model Number Guide 120417Dokument12 SeitenProduct Model Number Guide 120417Ernesto Emmanuel Garza SalazarNoch keine Bewertungen

- Data Acquisition TechniquesDokument25 SeitenData Acquisition TechniquesZarWinNoch keine Bewertungen

- Agilent LNA Design NoteDokument62 SeitenAgilent LNA Design NotejrmciNoch keine Bewertungen

- TransformersDokument36 SeitenTransformersdurgaraoNoch keine Bewertungen

- InternshipDokument17 SeitenInternshipBruno Joe KenNoch keine Bewertungen

- Coilgun BlueprintsDokument9 SeitenCoilgun Blueprintsjumpupdnbdj100% (1)

- Industrial Electrical Symbols: Contact UsDokument5 SeitenIndustrial Electrical Symbols: Contact Ustroy guillNoch keine Bewertungen

- Summative Test in Science 10 Week 7 & 8Dokument4 SeitenSummative Test in Science 10 Week 7 & 8Esther Mae Ann Trugillo0% (1)

- Edminister Stari PDFDokument297 SeitenEdminister Stari PDFIvan PurgarNoch keine Bewertungen

- ApspDokument163 SeitenApspMahesh SreeNoch keine Bewertungen

- Defectometer M: Mobile Crack DetectionDokument4 SeitenDefectometer M: Mobile Crack DetectionRicardo HeinzelmannNoch keine Bewertungen

- Electrical ParametersDokument16 SeitenElectrical Parametersapi-295377694Noch keine Bewertungen