Beruflich Dokumente

Kultur Dokumente

Shell - TAMU Case Study Handouts3

Hochgeladen von

bon1ng0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

37 Ansichten6 SeitenTAMU Case Study

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTAMU Case Study

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

37 Ansichten6 SeitenShell - TAMU Case Study Handouts3

Hochgeladen von

bon1ngTAMU Case Study

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

Shell

Root Cause Analysis applied to a Cooling Water Tower Failure

20 October, 2003

1

Texas A&M Case Study

Typical Cooling Water Tower

As-built

Air Hot-water distribution pipe Hot-water distribution deck

30

Fan

42

Air

48

Cold-water Basin

Cooling Water Tower Introduction

Who needs a cooling water tower? The chemical and refining industry use many cooling water towers. You may also encounter cooling water towers in power industry as well as some public buildings. While each one is unique, they share many of the properties well discuss today. Why use a cooling water tower? The cooling water tower is used to turn warm water into cool water. That cool water is pumped throughout the refinery/chemical plant and used to cool hot streams. The water will become warm (sometimes hot). One could discharge the warm water into a lake or river (it is clean water that was not contaminated by process chemicals), but that would be expensive (it costs money to make the water clean in the first place). Instead, we take the warm water and cool it in a cooling water tower. Then, we re-use the water. How does it work? Warm water is delivered to the tower by distribution pipes. In the previous schematic, two pipes are shown in light green. The warm water is splashed down through the tower like a hard rain storm. Air flows through the tower and cools the water droplets. The cool water droplets collect at the bottom in the cold-water basin. From the cold-water basin, water is pumped back to the refinery/chemical plant to cool process streams. To get a good air flow through the tower, there are big fans on top that pull air through the sides of the tower. These fans can be stopped or started to allow just the right temperature in the water. A computer is often used to start or stop the fans and control the water temperature (the program can be sophisticated enough that each fan is run the same amount of time so that no one fan wears out prematurely).

Vent pipe Hot-water Deck

Fan Cylinder

Fan Hot-water Distribution Pipe

Drift Eliminator

Louvers on Outside walls

Column Diagonal Brace Plenum Cold-water basin

Wetted Area containing splash bars

Girt Splice block

Cooling Water Tower Features

The cooling water tower is typically made of wood (sometimes plastic or metal). From top to bottom, the tower may exceed 60 feet tall. The tower may be 60 feed wide and as much as 500 feet long. The structure is braced to withstand wind (typically designed to withstand hurricane-force winds). The water pipe, water, and wet wood weigh quite a lot (equivalent of two Suburbans stacked on some columns there may be 1000 columns each 50 feet tall!), so theres a lot of material in the tower to make it strong. The original water distribution pipes were made of wood! They actually looked like a very long wooden barrel with metal bands that held the wood together. Later, the wooden pipe was replaced with a plastic one. A vent pipe on the hot-water distribution pipe allows air bubbles to exit the pipe. Hot water from the process flows to the distribution pipe. Water from the hot-water distribution pipe flows on to the hotwater deck. Holes in the hot-water deck allow water to fall (like rain) through the wetted area. Splash bars in the wetted area slow the flow of water so it has time to cool before collecting in the cold-water basin. Air is pulled through the sides to cool the water. A drift eliminator separates the wetted area from the plenum. This drift eliminator coalesces water and reduces the amount of water lost by unwanted spray. The weight of the tower is held by columns. Since there are no boards long-enough to make 50 foot long columns, 18 boards are joined with splice blocks to make a column. Girts (horizontal boards) and diagonal braces keep the columns straight up and down which maximizes the load-carrying capacity. Louvers on the outside of the tower re-direct splashing water into the basin.

Whats technically possible .

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Improvised Plastic ExplosivesDokument49 SeitenImprovised Plastic ExplosivesJon Segars100% (14)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Lesson 8b Introduction To UBDDokument57 SeitenLesson 8b Introduction To UBDbon1ngNoch keine Bewertungen

- A Short Guide To Technical Writing PDFDokument20 SeitenA Short Guide To Technical Writing PDFbon1ngNoch keine Bewertungen

- World Legal Systems and Contracts For Oil and Gas November 2005 PDFDokument6 SeitenWorld Legal Systems and Contracts For Oil and Gas November 2005 PDFbon1ng50% (2)

- A Report of Training ONGCDokument33 SeitenA Report of Training ONGCmohan_17Noch keine Bewertungen

- Natural Gas ProcessingDokument35 SeitenNatural Gas ProcessingAleem AhmedNoch keine Bewertungen

- Operator's Manual: TK-56373-1-OPDokument83 SeitenOperator's Manual: TK-56373-1-OPمعمر حميد100% (1)

- 2003 1 Offshore TrenchingDokument3 Seiten2003 1 Offshore Trenchingbon1ngNoch keine Bewertungen

- JU-001-04-0222-0000-00-1C-0001 - WBS Mina JustaDokument15 SeitenJU-001-04-0222-0000-00-1C-0001 - WBS Mina JustaAzul BlueNoch keine Bewertungen

- Aashto T-85Dokument6 SeitenAashto T-85kampNoch keine Bewertungen

- Silt Control GuideDokument32 SeitenSilt Control GuidePcEngNoch keine Bewertungen

- Hydroponic Education LettuceDokument7 SeitenHydroponic Education LettuceHans Kristian Akar100% (1)

- QGL-CE-001Guidelines For Corridors and Corridor CrossingsRev2Dokument29 SeitenQGL-CE-001Guidelines For Corridors and Corridor CrossingsRev2tomNoch keine Bewertungen

- Ecological ModelingDokument421 SeitenEcological ModelingMiguel HLNoch keine Bewertungen

- Bimasena Menu-And-Price-ListDokument7 SeitenBimasena Menu-And-Price-Listbon1ngNoch keine Bewertungen

- Lesson 2: Rheology of Drilling and Completion FluidsDokument29 SeitenLesson 2: Rheology of Drilling and Completion Fluidsbon1ngNoch keine Bewertungen

- HessCorporation 10K 20130228Dokument131 SeitenHessCorporation 10K 20130228bon1ngNoch keine Bewertungen

- 12cgi Ps MiningDokument6 Seiten12cgi Ps Miningbon1ngNoch keine Bewertungen

- Lesson 14 Air, Gas, Mist ContDokument19 SeitenLesson 14 Air, Gas, Mist Contbon1ngNoch keine Bewertungen

- Lesson 3. Wellbore PressuresDokument64 SeitenLesson 3. Wellbore Pressuresbon1ngNoch keine Bewertungen

- 05 FishingPort2009Dokument113 Seiten05 FishingPort2009mahdani100% (1)

- Vessel Class Notations TableDokument153 SeitenVessel Class Notations Tablebon1ngNoch keine Bewertungen

- WhitePaper Mine PlanningDokument11 SeitenWhitePaper Mine PlanningAfif NugrohoNoch keine Bewertungen

- MartabeDokument51 SeitenMartabebon1ngNoch keine Bewertungen

- Ground WaterDokument20 SeitenGround WaterRahul BokanNoch keine Bewertungen

- Best Articles Ever - Want To Know - Complete Archive - News Articles-3,950Dokument3.950 SeitenBest Articles Ever - Want To Know - Complete Archive - News Articles-3,950Keith KnightNoch keine Bewertungen

- Abílio Et Al., 2005Dokument10 SeitenAbílio Et Al., 2005Wenner BritoNoch keine Bewertungen

- Heat Transfer Paper 2021Dokument1 SeiteHeat Transfer Paper 2021Hassan FaheemNoch keine Bewertungen

- Analysis Dr. Hans FerdinandDokument224 SeitenAnalysis Dr. Hans FerdinandCrysvenne Perez BisligNoch keine Bewertungen

- 6.4 Acid Deposition: IB Environmental Systems and SocietiesDokument6 Seiten6.4 Acid Deposition: IB Environmental Systems and SocietiesDevanshi MehtaNoch keine Bewertungen

- Delft3D Morphological Modelling of Sediment Management in Daily Peaking Run-Of-The-River Hydropower (PROR) Reservoirs in NepalDokument14 SeitenDelft3D Morphological Modelling of Sediment Management in Daily Peaking Run-Of-The-River Hydropower (PROR) Reservoirs in NepalPraa DeepNoch keine Bewertungen

- Course Outline Template Plumbing and Pipe FittingDokument4 SeitenCourse Outline Template Plumbing and Pipe Fittingombotopaul4Noch keine Bewertungen

- Bathtub: What Are They?Dokument5 SeitenBathtub: What Are They?John Paul DenajibaNoch keine Bewertungen

- Iron in Cereal: Separation of MixturesDokument2 SeitenIron in Cereal: Separation of MixturesliebofreakNoch keine Bewertungen

- Design of Sulemanki Barrage: University of Management & Technology, Lahore Department of Civil EngineeringDokument1 SeiteDesign of Sulemanki Barrage: University of Management & Technology, Lahore Department of Civil EngineeringWasif RiazNoch keine Bewertungen

- marketingmanagement báo cáo cuối kì môn quản trị marketing marketingmanagement báo cáo cuối kì môn quản trị marketingDokument33 Seitenmarketingmanagement báo cáo cuối kì môn quản trị marketing marketingmanagement báo cáo cuối kì môn quản trị marketingHien LuongNoch keine Bewertungen

- Metabolic Waste OrganismDokument7 SeitenMetabolic Waste OrganismAlrich VentusNoch keine Bewertungen

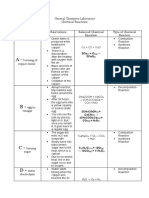

- General Chemistry Laboratory Chemical Reactions Results: Reaction Observations Balanced Chemical Equation Type of Chemical ReactionDokument2 SeitenGeneral Chemistry Laboratory Chemical Reactions Results: Reaction Observations Balanced Chemical Equation Type of Chemical ReactionArianeNoch keine Bewertungen

- Rainwater Harvesting 101 - Your How-To Collect Rainwater GuideDokument13 SeitenRainwater Harvesting 101 - Your How-To Collect Rainwater GuideNitheesh KumarNoch keine Bewertungen

- Climatology Book Part1 PDFDokument172 SeitenClimatology Book Part1 PDFamjad khan100% (1)

- Root Zone Method For Treatment of Waste Water-Ijaerdv04i0289634Dokument7 SeitenRoot Zone Method For Treatment of Waste Water-Ijaerdv04i0289634Editor IJAERDNoch keine Bewertungen

- HOPE 4 Q4 Module 7 8Dokument7 SeitenHOPE 4 Q4 Module 7 8Cyleeey PlangNoch keine Bewertungen

- Capitulo 661.2Dokument4 SeitenCapitulo 661.2Ivan Dario Oyola RNoch keine Bewertungen

- Diuretic Activity of Siddha Mineral Formulation Ashta Gunma Thiraavagam in RatsDokument4 SeitenDiuretic Activity of Siddha Mineral Formulation Ashta Gunma Thiraavagam in Ratsjmanuel108yahoo.co.ukNoch keine Bewertungen