Beruflich Dokumente

Kultur Dokumente

Relining Pipes - HOBAS

Hochgeladen von

Anonymous 4MLEo9TVQOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Relining Pipes - HOBAS

Hochgeladen von

Anonymous 4MLEo9TVQCopyright:

Verfügbare Formate

h Relining Pipes

As Good as New: Relining with h Pipes

Rehabilitation Means New Not Repaired Pipes

When it is no longer feasible to carry out spot repairs on old pipelines, you have a choice either of successively replacing all the pipes or rehabilitating. The great disadvantage of replacing entire pipelines is that it is not only extremely expensive but also leads to tremendous disruptions, particularly in urban areas where the largest and most complex sewer systems are to be found. A convenient solution to this problem is pipe rehabilitation for example in the form of relining. Relining has an unbeatable advantage: the old pipeline is replaced quickly and easily and the client then has a pipe that is of the same quality as a new one in every way. The relining process involves pushing or pulling the new pipes into the existing pipeline and filling the remaining annular space between the host and liner pipes with pressureresistant grouting, usually a mixture of binding materials. This fixes the inserted pipe in position, making it responsible for the complete structural load capacity. HOBAS Relining Pipes are particularly suitable for pipe rehabilitation, as they are of low weight, corrosion resistant, quality assured, easy to install and resist the load from the grouting without any trouble. To put it in simple terms: relining is as good as new in every respect.

For the Sake of the Environment

HOBAS Relining Pipes seal old sewers and ensure that the soil and groundwater are reliably protected against wastewater. As environmental protection is not restricted to this area, our commitment to conservation can be seen throughout the entire product life cycle. During the production process, pipe transport, installation, operation, and in our employees' everyday lives, we ensure that we not only do the bare minimum required but also take every opportunity we can to protect the environment. The environmental management system in place at HOBAS Subsidiaries conforms to the requirements of the ISO 14001 standard. As part of our corporate social responsibility, we improve our life cycle assessment year on year. Cost- and energy-efficient management of raw materials and production processes is a matter of course for us, as is minimizing resource use and negative impact on the environment.

So You Can Rest Assured

Top Quality

Certified by independent institutes to various international standards, the HOBAS Plants ensure that the finished products meet the most stringent customer specifications. Compliance with ISO 9001 and uniformly high quality standards are key features of HOBAS Products and firmly rooted in our corporate philosophy. The quality management system covers all areas in the individual companies, from new product development through to quality control processes, shipping and service what you receive is consistently high quality without any ifs or buts. Our comprehensive quality control program not only meets international standards but also takes special customer specifications into consideration. HOBAS holds the octagon quality mark issued by Germany's TV technical service and many other approvals. Auditors from renowned certification companies and our specialists in the HOBAS R&D departments, application engineering and installation teams ensure that you can rely on consistently high, uniform quality no matter from what country the pipes are delivered to you. Our internal HOBAS Quality Control Program also includes the following quality assurance measures: Testing the raw materials Testing the semi-finished products Quality assured services Release testing for production Strength testing on finished products Visual inspection and dimension checks on finished products Hydrostatic and hydrodynamic testing Calibrating the instruments Ensuring the identification and traceability of the products Checking planning and design Checking the suppliers

Reliable Service

As a system supplier, HOBAS attaches great importance to service. Our experts will support you to ensure that your project runs smoothly from initial planning right through to completion. HOBAS is committed to providing customers worldwide with a broad product range and professional support. A matter of course for us: Technical advice for planning, installation and rehabilitation Feasibility studies Structural analyses to comply with various regulations Hydraulic calculations Design and drawings for manholes, structures and special units in 2D and 3D Consultancy, training and support for building contractors Installation services Technical documentation and information material Development of system-building-units and special pipes On-site support during construction work from HOBAS Pipe Consultants

h Relining Pipes: Your Benefits at a Glance

HOBAS Relining Pipes have the well-known HOBAS Pipe wall structure with the characteristic resin-rich inner layer. Thanks to the sophisticated design, you can rely on the following advantages:

1 2

Benefits During Installation

Easy installation given the various jointing systems Constant outside diameter and simple cutting, also on site Uniform outside diameters and couplings flush with the outside diameter make it easier to install the pipes, as there are no projecting parts in the way Little space required on site Installation possible irrespective of the weather Compatibility with other materials

4 5 6 7 8

Benefits When Operating the Rehabilitated Pipeline

The pipe walls are relatively thin but comparatively strong, which makes maximum use of the nominal width selected The smooth mirror-like inner surface prevents incrustations from forming and provides adequate hydraulic reserves, even if flow rates are low The same quality standards, tests and external quality control as for pipes for new installations Relining creates a completely stable pipe system that is as good as new in structural terms perfect rehabilitation Seamless quality throughout the complete rehabilitated system

Pipe Wall Structure*

1 External protective layer 2 Outer reinforced layer (glass fiber, polyester resin) 3 Transition layer (glass fiber, polyester resin, sand) 4 Reinforcing layer (sand, polyester resin, glass fiber) 5 Transition layer 6 Inner reinforced layer 7 Barrier layer 8 Inner pure resin layer

Benefits for the Environment

Little disruption to traffic Minimal noise disturbance Towns and landscapes do not suffer as a result of construction work Falls in the water table level, which affect vegetation, are prevented Soil is not excavated

*Schematic illustration of in reality seamlessly merged pipe wall construction. Layer design is adapted to suit requirements set by e.g. the conveyed medium, installation method, pressure, external forces, etc.

h Pipe Diameters

From Tiny to Titanic

HOBAS Relining Pipes can be supplied in the following sizes:

Available diameter DN | De in mm* 150 | 167 200 | 220 250 | 272 300 | 324 350 | 376 400 | 401 400 | 427 450 | 478 500 | 501 500 | 530 550 | 550 600 | 616 650 | 650 700 | 718 750 | 752 800 | 820 860 | 860 900 | 924 960 | 960 1000 | 1026 1100 | 1099 1200 | 1229 1280 | 1280 1350 | 1350 1400 | 1434 1500 | 1499 1535 | 1535 1600 | 1638 1720 | 1720 1800 | 1842 1937 | 1937 2000 | 2047 2160 | 2160 2200 | 2250 2400 | 2400 2400 | 2454 2555 | 2555 3000 | 2999 3600 | 3600

* Other sizes on request.

HOBAS Relining Pipes are produced in standard lengths of 1, 2, 3 and 6 meters (tolerances to company standards). Other pipe lengths can also be supplied on request.

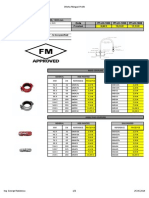

System Building h Products

HOBAS Relining Pipes can be joined using various different couplings to suit the environmental conditions and meet the contractor's or client's specifications.

FWC Coupling

Flush FWC Coupling

Flush GRP Coupling

Stainless Steel Coupling

Tangential Manholes

HOBAS Shaft Structures are supplied as complete, dimensionally accurate components. Installation is quick and easy no protective coatings or sealing work is required and they can also be connected to other materials without any problems. Our experts will be happy to provide you with advice on your manhole in proven HOBAS Quality.

Installing h Relining Pipes

Relining creates a new, leak-tight pipe within a pipe system, which is as good as new in both structural and hydraulic terms. The remaining annular space between the host and liner pipes is filled with grouting, fixing the new pipeline in place. HOBAS Relining Pipes can be inserted in the existing pipeline using the following methods: Pushing Pulling Floating Driving Bursting

1 | Pushing Relining Pipes

The pipes are joined in an entry pit or launch shaft and as shown in the diagram below pushed into the existing pipeline length by length using a jacking machine or excavator.

2 | Pulling Relining Pipes

The relining pipes are joined in a pit or shaft. Next, a steel cable is pulled through the old pipeline and the relining pipes from the exit shaft and attached to a cross bar at the end of the pipeline. The liner pipes are then pulled with a winch located in the exit shaft. Pipes with locked couplings can be installed in the same way, but the steel cable can also be attached to the start of the pipeline.

3 | Floating Relining Pipes

If the sewer joints are offset to any great extent, the floating method is better for installing the lining pipes. Unless the line to be rehabilitated has to be cleaned, the pipes can even be inserted live, i.e. with the wastewater still flowing. The medium then flows through the pipe and annulus, which causes it to float and makes insertion even easier.

4 | Driving Relining Pipes

The pipes are raised by a special vehicle until there is enough ground clearance for conveying them to their destination. There they are joined to the last relining pipe. This method is highly suitable for relining man-entry nominal widths and enables very high installation rates with optimal installation quality.

5 | Pipe Bursting

Pipe bursting technology involves pulling a cone-shaped head with a cable through the defective pipeline. As the head moves through, it breaks the old pipe and pushes the pieces into the surrounding soil. Attached behind the head is a new pipeline of the same or larger bore diameter.

Experts Float New Solution

h Pipes for Sewer Rehabilitation in Szczecin, PL

Year of Construction 2004 - 2008 Total Length of Pipeline 2,298 m Pipe Specifics De 960 - 1434, PN 1, SN 5000 - 20000, NC Profiles Application Sewer Special Features Easy installation from a floating platform, low weight, little space required during installation, corrosion resistance, pipe cutting possible on site

The HOBAS Experts had to pull out all the stops when renewing a sewer in Szczecin. Lack of space forced the engineers to tackle the problem from a different angle Szczecin in Poland not only has one of the largest ports on the Baltic Sea but also old brick sewers and concrete pipelines built in 1904/1905 and the 1930s. Some of the pipes were no longer capable of bearing loads, considerably damaged with cracks, corrosion and infiltration, and in danger of collapsing. The authorities were forced to rehabilitate as quickly as possible and the contractor recommended HOBAS GRP Pipes as the most suitable material for replacing the interceptors. Work began in December 2004. They installed the pipes from existing manholes or special access shafts, with the various different pipe lengths making the work much easier. In the straight runs, for example, they used 2.25-2.35 m long pipes and 0.5-1.5 m long ones in the curves. Unlike other materials, HOBAS Products can be cut anywhere along their length due to the constant outside diameter and also shortened on the construction site without affecting their excellent chemical and structural properties. A great challenge during installation was the narrow streets that called for a creative solution on the part of the contractor. What they came up with was a raft that they anchored in the harbor and used as an installation platform. A crane placed the pipes onto the 22 x 8 m floating steel platform and from there they were pulled into the old pipeline using a winch in a shaft located 100 m away from the harbor. To secure the new sections in the sewers and protect them against the groundwater pressure, the pipes were inserted in the old ones, thus preventing distortion and uplift. The annulus between the pipe and new lining was then filled. The client is convinced that they will not have any problems with the HOBAS Relining Pipes for the next 50 years or more.

Fmd: hobas.poland@hobas.com

Crystal Clear from the Faucet

h Relining Pipes Secure Potable Water Supply in Germany

A DN 1000 potable water pipeline made of cast iron caused the Dortmund Energy and Waterworks (DEW) considerable concern. It ran parallel to the B 234 main road and burst pipes were causing pressure loss increasingly frequently. The pipeline was severely damaged in places from corrosion and therefore in urgent need of rehabilitation. Having weighed up the various alternatives taking such factors into account as legal requirements, costs, disruptions to road traffic and for local residents, construction time and reliability of the new pipeline DEW opted for HOBAS Relining Pipes. The contractors dug three pits over a length of 530 m beside and partially along the road's route. In the middle was the entry shaft with the exit shafts at either end. They then inserted the individual pipes into the pit, aligned and joined them. Using a steel cable attached to a ring beam, the pipes were pulled from the entry shaft through the old pipeline to the two exit shafts. HOBAS also supplied fittings and a complete system made of GRP was thus created. In addition, tees with connections for cast iron and steel pipelines, bends and flanges were also used during installation. Finally, the annulus was filled with grout and the pipeline disinfected. A subsequent pressure test confirmed that the HOBAS Pipes were working perfectly. Given the well-designed HOBAS Pipe Systems, construction progressed very rapidly which pleased the client and meant that the nearby road traffic was hardly affected. As good as new, the potable water pipeline went into operation again after only three days and now reliably supplies the population of Dortmund with clean water.

Year of Construction 2002 Total Length of Pipeline 530 m Diameter DN 800 Pressure Class PN 10 Application Potable water pipeline Client Dortmund Energy and Waterworks Special Features Fast installation, excellent flow properties thanks to the smooth inner surface, low weight, long service life

Fmd: hobas.germany@hobas.com

10

Record Relining with h Pipes

Space-Saving and Fast Installation of Giant Pipes, USA

Evanston, Illinois, a town in the USA north of Chicago, was planning a comprehensive rehabilitation program for all its interceptors, including the replacement of a 2,100 m semi-elliptical concrete sewer pipe in DN 3000. A camera inspecting the pipeline brought the disastrous state of the sewer to light: the concrete had not only cracked in a number of places with lime deposits forming in the cracks, but had also corroded due to the action of the hydrogen sulfide and flowing water. In order to restore hydraulic and structural integrity, the sewer urgently needed to be rehabilitated. HOBAS Pipes have been in use in the USA for many years and the client also selected slip lining with GRP pipes as the most suitable rehabilitation method for this project. Both economic considerations because of the size of the pipeline and the time factor spoke for HOBAS Products. Relining is usually chosen as the installation method in densely built-up areas and here in particular HOBAS Pipes are ideal, as they do not require any heavy machinery and the construction site can be kept very small. There was so little space available on site for this project that the pipes had to be stored at a distance of 2.4 km. At the yard there was room for around 600 m of HOBAS Relining Pipes De 2900 mm, which were then taken by truck to the installation point as required. The old pipeline was so deteriorated that HOBAS Pipes with a De of 2740 mm had to be used for the remainder of the work. After pipe installation, grouting was also a great challenge, as the local conditions called for a special technology to be used to fill the annular space. To prevent pipe uplift, the grout had to be filled in stages. The contractors also successfully overcame this challenge to the satisfaction of everyone involved. HOBAS Pipes' unique characteristics such as smooth outer surface, high hydraulic capacity and high strength played a key role in the success of the longest HOBAS Relining project to date with this large diameter.

Year of Construction 2008 Total Length of Pipeline 2,100 m Pressure Class PN 1 Stiffness Class SN 5000 Diameter De 2740, De 2900 Application Sewer Special Features Smooth outer surface, high hydraulic capacity, high longitudinal stiffness, multiple diameters including many in-between sizes

Fmd: hobas.usa@hobas.com

11

Helping to Clean Up the Baltic Sea

h Sewer Pipes impress in Russia with long service life

Olgino in the St. Petersburg area is a residential district located near the easternmost arm of the Baltic Sea. The bay, also known as the Gulf of Finland, not only has St. Petersburg at its head, but also gives Helsinki and Tallinn direct access to the Baltic Sea. Whenever cities are situated on water, safe and eco-friendly wastewater disposal is top priority. In the case of the Olgino district, the wastewater is first conveyed to a treatment plant and then once treated pumped out to sea. At the beginning of the 1990s, a concrete pipeline was laid that did not, however, prove capable of withstanding the aggressive water for long. By 2006 the pipeline was so corroded and in danger of bursting that rapid rehabilitation was urgently needed. As HOBAS Pipes with their unique properties have proved their worth many times over in Russia, using HOBAS Relining Pipes for replacing the pipeline quickly and safely was an obvious choice. Over 5 km of DN 1800 liner pipes were slipped into the old sewer and soon the pipeline was as good as new. The excellent hydraulic properties of the pipes' extremely smooth inner surface not only prevent deposits from forming but also ensure that despite the pipeline diameter being reduced from 2,000 to 1,800 mm the hydraulic requirements are fully met. What impressed the client the most was that the pipes were easy to install: low weight, practical push-to-fit couplings and variable pipe lengths speeded up the installation process considerably. The old concrete pipes were not even capable of withstanding the harsh environmental conditions for two decades. Little wonder that St. Petersburg then looked for a pipe manufacturer with many years' experience and can now rest assured that HOBAS Pipes will do their job reliably for many years to come.

Year of Construction 2006 - 2007 Total Length of Pipeline 5,100 m Pressure Class PN 1 Stiffness Class SN 5000 Diameter DN 1800 Application Sea Outlet Special Features Easy installation, low weight, corrosion resistance

Fmd: hobas.russia@hobas.com

E Engineering GmbH Responsible for content: Wilfried Sieweke, Sabrina Sereinig, Sabine Friesser | Texts & Layout: Sabine Friesser, Sabrina Sereinig Publication: 03/2011 | Update: 03/2012 | Print: Carinthian Druck Beteiligungs GmbH 03/2012 All rights reserved. No part of this document may be reproduced or utilized in any form or by any means without our prior written permission. All information in the document is correct at the time of going to press. However, we reserve the right to make changes without notice, in particular to technical data. The data given is not binding and must therefore be checked in each individual case and revised as appropriate.

E Group Worldwide HOBAS manufactures and markets HOBAS GRP Pipe Systems. The HOBAS Network includes HOBAS Production Facilities and Sales Organizations throughout the world.

E Engineering Austria Pischeldorfer Strasse 128 9020 Klagenfurt | Austria T +43.463.48 24 24 | F +43.463.48 21 21 info@hobas.com | www.hobas.com

We develop and manufacture HOBAS Products conserving natures resources and with respect for our environment. Visit our website to find out more about the HOBAS Environmental Policy.

Das könnte Ihnen auch gefallen

- Abandonment of Sewer MainsDokument5 SeitenAbandonment of Sewer MainsbarouniamineNoch keine Bewertungen

- PVC Pipeline Reconstruction Bid SpecDokument5 SeitenPVC Pipeline Reconstruction Bid SpecChesterMercadoNoch keine Bewertungen

- Plastic Pipe Pressures in Siphonic Roof Drainage Systems: Building Research and Information February 2011Dokument2 SeitenPlastic Pipe Pressures in Siphonic Roof Drainage Systems: Building Research and Information February 2011imam muhsinNoch keine Bewertungen

- By: Norway C. Sucab & Carl Joe IgnacioDokument23 SeitenBy: Norway C. Sucab & Carl Joe Ignaciogame masterNoch keine Bewertungen

- Overview of Used Water Reticulation Network System in Singapore - Ms ChuaDokument38 SeitenOverview of Used Water Reticulation Network System in Singapore - Ms ChuaEra Reina Marie Cubangay100% (1)

- Stormwater Design CriteriaDokument15 SeitenStormwater Design CriteriaSyazwan AbhNoch keine Bewertungen

- Culvert DddesignDokument98 SeitenCulvert DddesignShashank YadavNoch keine Bewertungen

- ANSI-SDI A250.8 Overview PDFDokument8 SeitenANSI-SDI A250.8 Overview PDFYel DGNoch keine Bewertungen

- MOWE-UNDP 2014 - Assessment of Groundwater Resources of LebanonDokument47 SeitenMOWE-UNDP 2014 - Assessment of Groundwater Resources of LebanonNassif Abi AbdallahNoch keine Bewertungen

- Sewer DescriptionDokument27 SeitenSewer Descriptionroco_3213Noch keine Bewertungen

- Comparison GuideDokument20 SeitenComparison GuideMartin SabahNoch keine Bewertungen

- Water Tank Specifications (Final)Dokument3 SeitenWater Tank Specifications (Final)GowthamiNoch keine Bewertungen

- Sabas GRP Liner Spec v4Dokument17 SeitenSabas GRP Liner Spec v4ahmed_hlbyNoch keine Bewertungen

- PLUMBING SPECIALTIES TITLEDokument19 SeitenPLUMBING SPECIALTIES TITLEadel rihanaNoch keine Bewertungen

- Deluge Sprinkler SystemsDokument3 SeitenDeluge Sprinkler Systemsfalconcrest320% (1)

- Design and CFD Analysis of Different Pipe Joints Used in Water Supply IndutriesDokument7 SeitenDesign and CFD Analysis of Different Pipe Joints Used in Water Supply IndutriesPankaj AgarwalNoch keine Bewertungen

- Water hammer in pumped sewer mainsDokument45 SeitenWater hammer in pumped sewer mainsManikandanNoch keine Bewertungen

- C231-Subsoil and Foundation DrainsDokument11 SeitenC231-Subsoil and Foundation DrainsTsoekem SessouNoch keine Bewertungen

- Design of Firewater Network For A Typical Onshore Gas Processing PlantDokument9 SeitenDesign of Firewater Network For A Typical Onshore Gas Processing PlantAsis AriadiNoch keine Bewertungen

- German ATV DVWK A 168E Corrosion of Wastewater Systems Wastewater 1998 PDFDokument51 SeitenGerman ATV DVWK A 168E Corrosion of Wastewater Systems Wastewater 1998 PDFJosip Medved100% (1)

- The Water Supply Regulations 1995Dokument55 SeitenThe Water Supply Regulations 1995Intan Nurhafizah Fazriana100% (1)

- Optimal Design of A Sewer Line Using Linear ProgrammingDokument10 SeitenOptimal Design of A Sewer Line Using Linear ProgrammingYugs AryaNoch keine Bewertungen

- Bond Strand 5000 eDokument8 SeitenBond Strand 5000 eUmar KidaNoch keine Bewertungen

- Designing Property Drainage SystemsDokument287 SeitenDesigning Property Drainage SystemsUsama TahirNoch keine Bewertungen

- Specs for Underground Fire TanksDokument5 SeitenSpecs for Underground Fire TanksTeguh SetionoNoch keine Bewertungen

- Buried Exible Pipes: Design Considerations in Applying As2566 StandardDokument16 SeitenBuried Exible Pipes: Design Considerations in Applying As2566 StandardCarlos OrtizNoch keine Bewertungen

- Facility Fire HydrantsDokument2 SeitenFacility Fire HydrantsivanhoNoch keine Bewertungen

- OZKAN Butterfly ValvesDokument11 SeitenOZKAN Butterfly ValvesAhmed AbdelwaneesNoch keine Bewertungen

- Well Point Dewatering System ExplainedDokument15 SeitenWell Point Dewatering System ExplainedMostafa AbdellaNoch keine Bewertungen

- PLUMBIM GB-High Definition PDFDokument74 SeitenPLUMBIM GB-High Definition PDFMARIA DEL VALLE rodriguez leonNoch keine Bewertungen

- Saint Gobain PAM Cast Iron Drainage SystemsDokument120 SeitenSaint Gobain PAM Cast Iron Drainage SystemsParveez HusnooNoch keine Bewertungen

- John GumbelDokument18 SeitenJohn GumbelJMF_CORD100% (1)

- Sleeves and Sleeve Seals For Hvac PipingDokument4 SeitenSleeves and Sleeve Seals For Hvac PipingAhmed OmarNoch keine Bewertungen

- HOBAS Pressure Pipes SystemsDokument40 SeitenHOBAS Pressure Pipes Systemsu_florinNoch keine Bewertungen

- Atv M 143 e pt2Dokument27 SeitenAtv M 143 e pt2Laurentiu GheorghitaNoch keine Bewertungen

- Atv M 143 e pt3Dokument10 SeitenAtv M 143 e pt3Laurentiu GheorghitaNoch keine Bewertungen

- CT 5550 Pumping Stations and Transport PipelinesDokument45 SeitenCT 5550 Pumping Stations and Transport PipelineshamanoelgenNoch keine Bewertungen

- Everything about Eurotech PPR-C pipe system raw materials, manufacturing, standards, and applicationsDokument5 SeitenEverything about Eurotech PPR-C pipe system raw materials, manufacturing, standards, and applicationsAlex DulayNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument45 SeitenDisclosure To Promote The Right To Informationrajeshtak05Noch keine Bewertungen

- GFRG PracticeDokument6 SeitenGFRG PracticeGANGA RSNoch keine Bewertungen

- Bonna Sabla Concrete PipesDokument19 SeitenBonna Sabla Concrete Pipesst_calvoNoch keine Bewertungen

- Pipe Wall Buckling in Siphonic Systems - IAHR Conference 2011 by Terry Lucke and Simon BeechamDokument7 SeitenPipe Wall Buckling in Siphonic Systems - IAHR Conference 2011 by Terry Lucke and Simon BeechampradiptyaNoch keine Bewertungen

- Bar-Boljare Highway Tunnels SpecsDokument199 SeitenBar-Boljare Highway Tunnels SpecsjodjaNoch keine Bewertungen

- GeoMatt Datasheet TB11 Ed1 2017 ASTM ADDokument1 SeiteGeoMatt Datasheet TB11 Ed1 2017 ASTM ADganmosesNoch keine Bewertungen

- Ace Model Cv-101wh Di Gate Valves. Resilient Seated. Flange EndsDokument2 SeitenAce Model Cv-101wh Di Gate Valves. Resilient Seated. Flange EndsSatish Kumar MauryaNoch keine Bewertungen

- New Spirolite PipeDokument39 SeitenNew Spirolite PipeMario LunaNoch keine Bewertungen

- Awwa-C906-15 AWWA Has Published C906-15!Dokument1 SeiteAwwa-C906-15 AWWA Has Published C906-15!ToBertNoch keine Bewertungen

- Flexible Sprinkler Hose Installation GuideDokument7 SeitenFlexible Sprinkler Hose Installation GuideSopi LabuNoch keine Bewertungen

- BS en Iso 11299-1-2018 - (2019-01-06 - 09-13-21 Am)Dokument26 SeitenBS en Iso 11299-1-2018 - (2019-01-06 - 09-13-21 Am)wodonit136Noch keine Bewertungen

- Wavin QuickStream Specification Oct 14Dokument6 SeitenWavin QuickStream Specification Oct 14Syahrisal SaputraNoch keine Bewertungen

- RWS & Sanitation - 25.9.17Dokument93 SeitenRWS & Sanitation - 25.9.17Aditya TatecharlaNoch keine Bewertungen

- PAPER - Comparison of Pipeline Design Installation Requirements Rigid V Flexible FINALDokument17 SeitenPAPER - Comparison of Pipeline Design Installation Requirements Rigid V Flexible FINALC_unit08Noch keine Bewertungen

- M3c Hazen WilliamsDokument8 SeitenM3c Hazen WilliamsTariq AfridiNoch keine Bewertungen

- 1203 Jacking E WebDokument16 Seiten1203 Jacking E Webfbm9318Noch keine Bewertungen

- Tevi Necirculare - HOBASDokument12 SeitenTevi Necirculare - HOBASAnonymous 4MLEo9TVQNoch keine Bewertungen

- 1203 Sewer E Web GRPDokument12 Seiten1203 Sewer E Web GRPArun VaithyanathanNoch keine Bewertungen

- The Complete HOBAS GuideDokument76 SeitenThe Complete HOBAS GuideJoe RayNoch keine Bewertungen

- Structural Liner BrochureDokument5 SeitenStructural Liner BrochureNu FlowNoch keine Bewertungen

- Rigid PVC PipesDokument20 SeitenRigid PVC PipesNaeemSiddiquiNoch keine Bewertungen

- H CC-GRP Pipes Features, Tests and Benefits: Make Things HappenDokument78 SeitenH CC-GRP Pipes Features, Tests and Benefits: Make Things HappenChin Keong ChengNoch keine Bewertungen

- Tuyau Sme PDFDokument2 SeitenTuyau Sme PDFteiusanuNoch keine Bewertungen

- Dpu PDFDokument4 SeitenDpu PDFTEIUSANUNoch keine Bewertungen

- Belaria+SRM+ +technical+ INM-en+ 2017 PDFDokument30 SeitenBelaria+SRM+ +technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- Bio Lyt (50 - 160) - Carte Tehnica PDFDokument14 SeitenBio Lyt (50 - 160) - Carte Tehnica PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- Catalogue NST PDFDokument12 SeitenCatalogue NST PDFTEIUSANUNoch keine Bewertungen

- Correspondance Pouce MMDokument4 SeitenCorrespondance Pouce MMhichamNoch keine Bewertungen

- Guide Technique - FLUXO PDFDokument24 SeitenGuide Technique - FLUXO PDFteiusanuNoch keine Bewertungen

- Bio Lyt (50 - 160) - Carte Tehnica PDFDokument14 SeitenBio Lyt (50 - 160) - Carte Tehnica PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- PowerBloc EG20 - COGENERARE PDFDokument12 SeitenPowerBloc EG20 - COGENERARE PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- Belaria+twin+ Technical+ INM-en+ 2017 PDFDokument38 SeitenBelaria+twin+ Technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- Bio Lyt (50 - 160) - Carte Tehnica PDFDokument14 SeitenBio Lyt (50 - 160) - Carte Tehnica PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- Belaria+SRM+ +technical+ INM-en+ 2017 PDFDokument30 SeitenBelaria+SRM+ +technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- Katalog Fire Protection Systems G 105Dokument108 SeitenKatalog Fire Protection Systems G 105lucasNoch keine Bewertungen

- Belaria+twin+ Technical+ INM-en+ 2017 PDFDokument38 SeitenBelaria+twin+ Technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- Belaria+SRM+ +technical+ INM-en+ 2017 PDFDokument30 SeitenBelaria+SRM+ +technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- Sisteme Fixare - Sustinere - INKA PDFDokument36 SeitenSisteme Fixare - Sustinere - INKA PDFMatthew SuttonNoch keine Bewertungen

- Wellsee Wind Turbine CatalogueDokument10 SeitenWellsee Wind Turbine CatalogueAnonymous 4MLEo9TVQNoch keine Bewertungen

- Gear Box CouplingDokument30 SeitenGear Box Couplingdeepthik27100% (2)

- Catalogue Escospeed PDFDokument8 SeitenCatalogue Escospeed PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- Prospect DuctDokument1 SeiteProspect DuctAnonymous 4MLEo9TVQNoch keine Bewertungen

- PowerBloc EG20 - COGENERARE PDFDokument12 SeitenPowerBloc EG20 - COGENERARE PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- Katalog Fire Protection Systems G 105Dokument108 SeitenKatalog Fire Protection Systems G 105lucasNoch keine Bewertungen

- Catalogue CST PDFDokument29 SeitenCatalogue CST PDFTEIUSANUNoch keine Bewertungen

- Max-3 - Carte Tehnica PDFDokument17 SeitenMax-3 - Carte Tehnica PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- Ofeta Fitinguri Cu DiscountDokument6 SeitenOfeta Fitinguri Cu DiscountAnonymous 4MLEo9TVQNoch keine Bewertungen

- Therapetic Apparatus CatalogueDokument14 SeitenTherapetic Apparatus CatalogueAnonymous 4MLEo9TVQNoch keine Bewertungen

- DC Inverter aer conditionat caseta ideal pentru spatii comercialeDokument1 SeiteDC Inverter aer conditionat caseta ideal pentru spatii comercialeAnonymous 4MLEo9TVQNoch keine Bewertungen

- Catalogue Escorail PDFDokument4 SeitenCatalogue Escorail PDFTEIUSANUNoch keine Bewertungen

- Solar Controller and Inverter CatalogueDokument10 SeitenSolar Controller and Inverter CatalogueAnonymous 4MLEo9TVQNoch keine Bewertungen

- Aerospace SystemsDokument228 SeitenAerospace SystemskgrhoadsNoch keine Bewertungen

- Rotary Seal V-Ring GuideDokument25 SeitenRotary Seal V-Ring GuideAnonymous D5QForitcNoch keine Bewertungen

- Renson Sliding PanelsDokument20 SeitenRenson Sliding Panelsjoao85Noch keine Bewertungen

- Water for Pharma ValidationDokument14 SeitenWater for Pharma ValidationPépé TechopathamNoch keine Bewertungen

- JP Pdms 014 BoltinDokument10 SeitenJP Pdms 014 BoltinKodali Naveen KumarNoch keine Bewertungen

- Diffusion Experiment Group 4Dokument5 SeitenDiffusion Experiment Group 4Dianne VillanuevaNoch keine Bewertungen

- Reactor Modeling and Simulations in Synthesis Gas ProductionDokument39 SeitenReactor Modeling and Simulations in Synthesis Gas ProductionSteven Sandoval100% (1)

- Mine Rajhara DetailsDokument331 SeitenMine Rajhara DetailsAditya PrakashNoch keine Bewertungen

- Ilovepdf MergedDokument10 SeitenIlovepdf MergedSaidNoch keine Bewertungen

- SP Tools - MaytoJuly2013Dokument24 SeitenSP Tools - MaytoJuly2013Riverland Welding and Tool SuppliesNoch keine Bewertungen

- APCYDokument64 SeitenAPCYChachou MohamedNoch keine Bewertungen

- Lec 7 (Design of Pumping Station)Dokument17 SeitenLec 7 (Design of Pumping Station)hawkswimmer66100% (1)

- Jurnal Reaktor Metatesis Propilen PDFDokument8 SeitenJurnal Reaktor Metatesis Propilen PDFAnonymous 8UdbKWu2Noch keine Bewertungen

- Volume Ii: Specifications (Exterior Painting) : Issue: FINAL, 14th FEB 2013Dokument4 SeitenVolume Ii: Specifications (Exterior Painting) : Issue: FINAL, 14th FEB 2013Ahmad SaadeldinNoch keine Bewertungen

- 6-Tube Digit NIXIE Clock Setup GuideDokument14 Seiten6-Tube Digit NIXIE Clock Setup GuideEnéas BaroneNoch keine Bewertungen

- Nur Syafiqah Binti Jaafar - 2019405402 - 6B - Individual AssignmentDokument9 SeitenNur Syafiqah Binti Jaafar - 2019405402 - 6B - Individual AssignmentNUR SYAFIQAH JAAFARNoch keine Bewertungen

- Jar TestDokument7 SeitenJar TestWanShanuzieNoch keine Bewertungen

- Process for Producing Ammonium Nitrate from Ammonia OxidationDokument20 SeitenProcess for Producing Ammonium Nitrate from Ammonia OxidationGracia ManurungNoch keine Bewertungen

- Abcd. Proiect AdamDokument14 SeitenAbcd. Proiect AdamSfiriac LauraNoch keine Bewertungen

- Australian Wood Review December 2018Dokument100 SeitenAustralian Wood Review December 2018Maicon MorandiniNoch keine Bewertungen

- Kiln Mechanical ProblemsDokument40 SeitenKiln Mechanical ProblemsIrshad Hussain83% (6)

- UMP Faculty of Mechanical Engineering assignment on mechanics of composite materialsDokument2 SeitenUMP Faculty of Mechanical Engineering assignment on mechanics of composite materialsRima ChinnasamyNoch keine Bewertungen

- Machine Glass Thermometers Model 32, V-Form: ApplicationsDokument5 SeitenMachine Glass Thermometers Model 32, V-Form: ApplicationschauNoch keine Bewertungen

- Assignment AASDokument2 SeitenAssignment AASdean016026Noch keine Bewertungen

- Machine Tool Structure Design and AnalysisDokument40 SeitenMachine Tool Structure Design and AnalysisPrakash RajNoch keine Bewertungen

- Toshiba CodesDokument5 SeitenToshiba Codesbruxo70Noch keine Bewertungen

- 2013 Tuckwell Roberts toolemeraDokument282 Seiten2013 Tuckwell Roberts toolemeracrm102bNoch keine Bewertungen

- Lathe Machine CataloDokument72 SeitenLathe Machine CatalodharamvirpmpNoch keine Bewertungen

- Safety and Handling of Organic PeroxidesDokument26 SeitenSafety and Handling of Organic PeroxidesМаксим ХилоNoch keine Bewertungen

- Front Elevation Side Elevation: Stair Detail Stair DetailDokument1 SeiteFront Elevation Side Elevation: Stair Detail Stair DetailkangkongNoch keine Bewertungen