Beruflich Dokumente

Kultur Dokumente

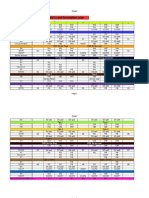

Yield Point Final

Hochgeladen von

Hamayoun MurtazaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Yield Point Final

Hochgeladen von

Hamayoun MurtazaCopyright:

Verfügbare Formate

TYPES OF STRENGTH

In engineering the term strength is always defined and is probably one of the following ompressi!e strength Tensile strength Shear strength depending on the type of loading" STRESS This is a meas#re of the internal resistan$e in a material to an e%ternally applied load" For dire$t $ompressi!e or tensile loading the stress is designated and is defined as&

stress s'load(area'w()

STR)IN *e m#st also define strain" In engineering this is not a meas#re of for$e b#t is a meas#re of the deformation prod#$ed by the infl#en$e of stress" For tensile and $ompressi!e loads&

strain e'in$rease in length(original length'%(l

Strain is dimensionless" +O),-,EFOR.)TION /R0E

This graph is $alled a load-deformation $#r!e" It shows #s how the member deforms1and #ltimately how it fails1as the load is in$reased" TENSI+E STRENGTH )s we follow the $#r!e #p and to the right2 we noti$e that the $#r!e is almost perfe$tly straight from 3ero all the way #p to abo#t 452666 po#nds" The straight line means that the deformation in$reases in dire$t proportion to the load" For e%ample2 the deformation at 762666 po#nds is e%a$tly twi$e as large as the deformation at 862666 po#nds" In this linear part of the load-deformation $#r!e2 the beha!ior of the steel bar is said to be elasti$" Elasti$ beha!ior means that2 if the load is remo!ed2 the deformation will also ret#rn to 3ero"

E+)STI

9EH)0IOR

Elasti$ beha!ior means that2 if the load is remo!ed2 the deformation will also ret#rn to 3ero" P+)STI 9EH)0IOR

Plasti$ beha!ior means that2 if the load is remo!ed2 the deformation will not ret#rn to 3ero i"e" the deformation will be permanent" )s we follow the $#r!e #p and to the right2 we noti$e that the $#r!e is almost perfe$tly straight from 3ero all the way #p to abo#t 452666 po#nds" The straight line means that the deformation in$reases in dire$t proportion to the load" For e%ample2 the deformation at 762666 po#nds is e%a$tly twi$e as large as the deformation at 862666 po#nds" In this linear part of the load-deformation $#r!e2 the beha!ior of the steel bar is said to be elasti$ " Elasti$ beha!ior means that2 if the load is remo!ed2 the deformation will also ret#rn to 3ero"

)s the load is in$reased beyond 452666 po#nds2 the beha!ior of the bar $hanges rather abr#ptly" There is s#ddenly a h#ge in$rease in deformation2 with !irt#ally no $hange in the load" The steel is beginning to fail" *hen a material #ndergoes large deformations with little $hange in load2 it is said to be yielding" The point on the load-deformation $#r!e where yielding begins is $alled the yield point2 and the for$e at whi$h yielding o$$#rs is $alled the yield strength"

YIE+,ING *hen a material #ndergoes large deformations with little $hange in applied load2 it is $alled as start of yielding" The yield point2 $alled the yield strength :Y;2 signifies the start of the plasti$ region"

)nd #nli<e the elasti$ beha!ior we obser!ed earlier2 any deformation that o$$#rs beyond the yield point will not disappear after the load is remo!ed" This permanent elongation of the member is $alled plasti$ deformation" Note that2 as the plasti$ deformation in$reases2 the bar e!ent#ally begins to $arry more load" The load pea<s at =>2666 po#nds2 whi$h is $alled the #ltimate strength of the member" )fter f#rther plasti$ deformation2 the spe$imen finally brea<s into two pie$es" This fail#re mode is $alled a r#pt#re " /+TI.)TE STRENGTH .a%im#m load $arried by by member in plasti$ region2 is $alled the #ltimate strength of the member"

R/PT/RE *hen load after #ltimate strength point is in$reased then with in$rease in load on member it a#tomati$ally start to loss applied load and finally brea<s it is $alled r#pt#ring of member" ,/ TI+ITY The $apa$ity of a member to #ndergo !ery large plasti$ deformation after yielding is $alled d#$tility" ,#$tility $an be defined as the amo#nt of deformation or strain that the material $an withstand before fail#re" For metal forming pro$esses2 in$reasing the d#$tility in$reases the material formability :Permanent formability;" ,#$tility is one of the most benefi$ial properties of steel2 and it is one of the most important reasons why steel is so widely #sed in str#$t#res"

9RITT+ENESS .aterials that do not #ndergo large plasti$ deformation prior to fail#re are $alled brittle materials " ) typi$al load-deformation $#r!e for a brittle material is shown at right" Note that the material r#pt#res witho#t yielding and th#s witho#t gi!ing any warning that a fail#re is abo#t to o$$#r" For this reason2 brittle materials are generally #ndesirable for str#$t#ral members"

Tensile Strength depends on& $ross-se$tional area of a member

type of material the member is made of

Tensile Strength does not depends on&

length of the member shape of the $ross se$tion

TR/E STRESS )N, STR)IN The tr#e stress #ses the instantaneo#s or a$t#al area of the spe$imen at any gi!en point2 as opposed to the original area #sed in the engineering !al#es" The tr#e strain is defined as the instantaneo#s elongation per #nit length of the spe$imen"

Note& For a gi!en !al#e of the load and elongation2 the tr#e stress is higher than the Eng" Stress2 while the tr#e strain is smaller than the Eng" Strain"

Stress Strain Elastic deformation

Stress

Permanent Deformation Plastic deformation

Strain

Lu Lf

.od#l#s of Elasti$ity If the strain is ?elasti$?" Hoo<e@s law may be #sed to define

Yo#ngs .od#l#s E ' Stress ( Strain

'

:* ( %;

A :+ ( );

Yo#ng@s mod#l#s is also $alled the mod#l#s of elasti$ity or stiffness and is a meas#re of how m#$h strain o$$#rs d#e to a gi!en stress" 9e$a#se strain is dimensionless Yo#ng@s mod#l#s has the #nits of stress or press#re

It is !ery diffi$#lt to find the a$t#al e%perimentally" Instead2 we #se a 6"7B offset yield

yield strength strength"

6"7B offset yield strength is the point on the $#r!e whi$h is offset by a strain of 6"7B :6"667; Cthe interse$tion of the $#r!e with a line parallel to the linear elasti$ line and is offset by a strain of 6"667D The stress at ma%im#m :Fma% ()o ; is referred to as the Tensile Strength :TS; and signifies& the end of #niform elongation" the start of lo$ali3ed ne$<ing i"e" plasti$ instability" /ltimate

If a sample is loaded #p to the 6"7B proof stress and then #nloaded to a stress s the strain % ' 6"7B E s(E where E is the Yo#ngFs mod#l#s

Yield

Plastic

0.2% proof stress

Failure

Stress

0.2%

Strain

Das könnte Ihnen auch gefallen

- DAT Practice TestDokument75 SeitenDAT Practice TestJustinTsui88% (8)

- CAPE Chemistry Unit 2 Paper 2 2017 AnswersDokument12 SeitenCAPE Chemistry Unit 2 Paper 2 2017 Answersemanuel coates100% (9)

- The Load Extensions Curve For Metallic Wire and Hence Determine The Modulus of Elasticity of Material of WireDokument5 SeitenThe Load Extensions Curve For Metallic Wire and Hence Determine The Modulus of Elasticity of Material of Wirewindgust82100% (1)

- 01hookes LawDokument2 Seiten01hookes LawEdgar PascasioNoch keine Bewertungen

- MDB Lecture Simple StrainDokument9 SeitenMDB Lecture Simple StrainAura Paige Montecastro-RevillaNoch keine Bewertungen

- 0 Chapter 04 Part ADokument14 Seiten0 Chapter 04 Part Aamandguraya91293Noch keine Bewertungen

- Poisson EffectDokument5 SeitenPoisson EffectKin HamzahNoch keine Bewertungen

- Relationship Between Shear Stress and Shear StrainDokument4 SeitenRelationship Between Shear Stress and Shear Strainwindgust820% (1)

- Topic 3Dokument8 SeitenTopic 3Fakhrul Izzuddin RozaliNoch keine Bewertungen

- L in Which It Was Measured, Thereby Obtaining: Chapter 2 - Simple Strain 2-A. IntroductionDokument8 SeitenL in Which It Was Measured, Thereby Obtaining: Chapter 2 - Simple Strain 2-A. IntroductionJasleneDimarananNoch keine Bewertungen

- 2001 - Notch Effect in Fatigue & FractureDokument22 Seiten2001 - Notch Effect in Fatigue & FractureSainath JadhavNoch keine Bewertungen

- Andrés Nichrome Investigation CorrectedDokument14 SeitenAndrés Nichrome Investigation CorrectedAndres BereznevNoch keine Bewertungen

- Geometric Derivation of The Infinitesimal Strain TensorDokument14 SeitenGeometric Derivation of The Infinitesimal Strain Tensoralokesh1982Noch keine Bewertungen

- Infinitesimal Strain TensorDokument16 SeitenInfinitesimal Strain Tensoralokesh1982Noch keine Bewertungen

- Introduction and Review: PreambleDokument6 SeitenIntroduction and Review: PreamblebhaskarrajusaNoch keine Bewertungen

- Chapter 4 - Columns and Other Compression MembersDokument8 SeitenChapter 4 - Columns and Other Compression MembersShaira CalderonNoch keine Bewertungen

- Som ProjectDokument37 SeitenSom ProjectVarun SinghNoch keine Bewertungen

- Elastic Behavior of Materials: Continuum Aspects: 1. Deformation and StrainDokument7 SeitenElastic Behavior of Materials: Continuum Aspects: 1. Deformation and StrainNawar TahaNoch keine Bewertungen

- CH 02Dokument17 SeitenCH 02Jason ChenNoch keine Bewertungen

- PowerPoint PresentationDokument65 SeitenPowerPoint PresentationMRIDUL SINGLANoch keine Bewertungen

- Chap02 ADokument64 SeitenChap02 ALUIS ISAAC LEON PARONoch keine Bewertungen

- Mathematical FormulaDokument6 SeitenMathematical Formulasayhigaurav07Noch keine Bewertungen

- Orthopaedic BiomechanicsDokument17 SeitenOrthopaedic BiomechanicsIacobescu EmiliaNoch keine Bewertungen

- 3 Thick VesselsDokument29 Seiten3 Thick VesselsKumail Al KhuraidahNoch keine Bewertungen

- Chapter 2: Pressure Distribution in A Fluid: Pressure and Pressure GradientDokument46 SeitenChapter 2: Pressure Distribution in A Fluid: Pressure and Pressure Gradientkothapalli21Noch keine Bewertungen

- Infinitesimal Strain TheoryDokument16 SeitenInfinitesimal Strain Theoryalokesh1982Noch keine Bewertungen

- Behaviour of MaterialsDokument9 SeitenBehaviour of MaterialsAkash Kumar DevNoch keine Bewertungen

- Chapter 3: Basic Concepts and Definitions 3.1basic DefinitionsDokument25 SeitenChapter 3: Basic Concepts and Definitions 3.1basic Definitionsram_shyam2621Noch keine Bewertungen

- Fillet Weld Research Paper - For UndercuttingDokument7 SeitenFillet Weld Research Paper - For UndercuttingHemantNoch keine Bewertungen

- ESFINALNADokument13 SeitenESFINALNAAngelyn Kate ClaroNoch keine Bewertungen

- HOME ASSIGNMENT 2 (AutoRecovered)Dokument15 SeitenHOME ASSIGNMENT 2 (AutoRecovered)ATIF KHANNoch keine Bewertungen

- Ch-2 - Simple StrainDokument17 SeitenCh-2 - Simple StrainSirajul IslamNoch keine Bewertungen

- Pages From StrainGage - Measurement-2Dokument1 SeitePages From StrainGage - Measurement-2palanaruvaNoch keine Bewertungen

- Static Assigment222222Dokument4 SeitenStatic Assigment222222mousa77dNoch keine Bewertungen

- Chapter TwoDokument13 SeitenChapter Twoعبدالله خيريNoch keine Bewertungen

- 06 Deformation in A System of Axially Loaded Members StudentsDokument5 Seiten06 Deformation in A System of Axially Loaded Members StudentsEJ GonzalesNoch keine Bewertungen

- Lab 2 3-26-2015Dokument10 SeitenLab 2 3-26-2015Niteesh KumarNoch keine Bewertungen

- CSICOL Manual Update - Stress Viewer New FucntionalityDokument6 SeitenCSICOL Manual Update - Stress Viewer New FucntionalityAndre Villegas RomeroNoch keine Bewertungen

- Som Unit - IDokument24 SeitenSom Unit - Inithesh kumar jNoch keine Bewertungen

- 16.properties Related To StrengthDokument30 Seiten16.properties Related To StrengthHarrison WoodwardNoch keine Bewertungen

- Course Objectives 5. Properties of Naval MaterialsDokument31 SeitenCourse Objectives 5. Properties of Naval MaterialsLenin ValerioNoch keine Bewertungen

- Street Strain CurveDokument2 SeitenStreet Strain CurveAnamika YadavNoch keine Bewertungen

- Stress and StrainDokument9 SeitenStress and StrainapplepiNoch keine Bewertungen

- Stress and StrainDokument6 SeitenStress and StrainTugas00Noch keine Bewertungen

- Stress and StrainDokument6 SeitenStress and StrainTugas00Noch keine Bewertungen

- Shell Stress &forceDokument13 SeitenShell Stress &forceKutty MansoorNoch keine Bewertungen

- Dislocation Theory: Dislocations and Strengthening MechanismsDokument4 SeitenDislocation Theory: Dislocations and Strengthening MechanismsgunapalshettyNoch keine Bewertungen

- Strength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeDokument6 SeitenStrength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeansarNoch keine Bewertungen

- Advanced Structural BehaviorDokument6 SeitenAdvanced Structural Behaviornedumaran.sNoch keine Bewertungen

- CE 323/ BES 222 Mechanics of Deformable Bodies: Chapter 2 - StrainDokument6 SeitenCE 323/ BES 222 Mechanics of Deformable Bodies: Chapter 2 - StrainNadlor Gasco OzausNoch keine Bewertungen

- A Model For Plate Clash in Disk Refiners: Frédéric Alfonsi and D.J. JeffreyDokument4 SeitenA Model For Plate Clash in Disk Refiners: Frédéric Alfonsi and D.J. JeffreyDiogo StrapassonNoch keine Bewertungen

- Fracture Toughness and FatigueDokument10 SeitenFracture Toughness and FatigueiamjemahNoch keine Bewertungen

- Fatigue and Fracture Mechanics: S.G.Ghalme, S.G.Thorat, R.N.ZawareDokument7 SeitenFatigue and Fracture Mechanics: S.G.Ghalme, S.G.Thorat, R.N.ZawareGeorge CamachoNoch keine Bewertungen

- Simple: StrainDokument41 SeitenSimple: Strainstephaniejeancortez522Noch keine Bewertungen

- Pressure Vessels: Lab BackgroundDokument3 SeitenPressure Vessels: Lab BackgroundnacachimbandiNoch keine Bewertungen

- CH 2Dokument45 SeitenCH 2Said EliasNoch keine Bewertungen

- Final CompilitionDokument116 SeitenFinal CompilitionNilesh GohelNoch keine Bewertungen

- Complex StiffenersDokument13 SeitenComplex StiffenersDaniel BoniniNoch keine Bewertungen

- FERDIN 1 (1) - Removed - Removed (1) - RemovedDokument3 SeitenFERDIN 1 (1) - Removed - Removed (1) - RemovedGildardo VillalpbosNoch keine Bewertungen

- Deformations Normal and Shear Strains Material For NotesDokument21 SeitenDeformations Normal and Shear Strains Material For NotesKen SelorioNoch keine Bewertungen

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingVon EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNoch keine Bewertungen

- Quality of Vacuum: Quality Torr Pa Milli BarDokument1 SeiteQuality of Vacuum: Quality Torr Pa Milli BarHamayoun MurtazaNoch keine Bewertungen

- Altitude or HeightDokument1 SeiteAltitude or HeightHamayoun MurtazaNoch keine Bewertungen

- Imperial Units Length: Edmund GunterDokument2 SeitenImperial Units Length: Edmund GunterHamayoun MurtazaNoch keine Bewertungen

- Bushing DesignDokument1 SeiteBushing DesignHamayoun MurtazaNoch keine Bewertungen

- Campus MapDokument1 SeiteCampus MapHamayoun MurtazaNoch keine Bewertungen

- Instrument Transformers 11010Dokument48 SeitenInstrument Transformers 11010Hamayoun MurtazaNoch keine Bewertungen

- Symmetrical ComponentsDokument2 SeitenSymmetrical ComponentsHamayoun Murtaza100% (1)

- Tan DeltaDokument1 SeiteTan DeltaHamayoun MurtazaNoch keine Bewertungen

- 500KV Switch Yard DrawingDokument2 Seiten500KV Switch Yard DrawingHamayoun MurtazaNoch keine Bewertungen

- Power Transformers: Your Partner in Energy SolutionsDokument24 SeitenPower Transformers: Your Partner in Energy SolutionsHamayoun MurtazaNoch keine Bewertungen

- Project Management Procedures4266Dokument27 SeitenProject Management Procedures4266Hamayoun MurtazaNoch keine Bewertungen

- What Is Trip Circuit Supervision Relay How Does It Work in SwitchgearDokument7 SeitenWhat Is Trip Circuit Supervision Relay How Does It Work in SwitchgearHamayoun MurtazaNoch keine Bewertungen

- Preventive Maintenance and Reliability of LV Overcurrent Protective DevicesDokument7 SeitenPreventive Maintenance and Reliability of LV Overcurrent Protective DevicesHamayoun MurtazaNoch keine Bewertungen

- Creepage DistanceDokument2 SeitenCreepage DistanceHamayoun MurtazaNoch keine Bewertungen

- High Frequency VCO Design and SchematicsDokument18 SeitenHigh Frequency VCO Design and SchematicsHamayoun MurtazaNoch keine Bewertungen

- Causes of Over Fluxing in TransformerDokument3 SeitenCauses of Over Fluxing in TransformerHamayoun Murtaza0% (1)

- Sab 'S 1.618 System: Test Physics (Full Book) Total Marks 50 Q1:Give Brief Answers of The Following QuestionsDokument2 SeitenSab 'S 1.618 System: Test Physics (Full Book) Total Marks 50 Q1:Give Brief Answers of The Following QuestionsHamayoun MurtazaNoch keine Bewertungen

- Tertiary Winding of TransformerDokument2 SeitenTertiary Winding of TransformerHamayoun MurtazaNoch keine Bewertungen

- Capacitance Power FactorDokument1 SeiteCapacitance Power FactorHamayoun MurtazaNoch keine Bewertungen

- Excitation Current in TransformersDokument2 SeitenExcitation Current in TransformersHamayoun Murtaza100% (1)

- Line BayDokument17 SeitenLine Bayabhinav_baishwarNoch keine Bewertungen

- What Is Magnetizing Current in A TransformerDokument1 SeiteWhat Is Magnetizing Current in A TransformerHamayoun MurtazaNoch keine Bewertungen

- 3 Properties of Sea WaterDokument73 Seiten3 Properties of Sea WaterMarissa RamonNoch keine Bewertungen

- Jotun Thinner No. 2 - EnglishDokument13 SeitenJotun Thinner No. 2 - EnglishBams ArifinNoch keine Bewertungen

- Astm D 1353 - NVM PDFDokument2 SeitenAstm D 1353 - NVM PDFVijith Jayakrishnan100% (2)

- Cold Crack Criterion For ADC12 Aluminum Alloy Die CastingDokument6 SeitenCold Crack Criterion For ADC12 Aluminum Alloy Die CastingVinodNoch keine Bewertungen

- Hot Forging: ProcessDokument3 SeitenHot Forging: ProcessRicardo KharisNoch keine Bewertungen

- Kuliah-7&8 Pengelolaan Lapangan Migas - Reservoir EvaluationDokument15 SeitenKuliah-7&8 Pengelolaan Lapangan Migas - Reservoir EvaluationAly RasyidNoch keine Bewertungen

- Ak 174 Photoetch Burnishing PDFDokument1 SeiteAk 174 Photoetch Burnishing PDFLea LeaNoch keine Bewertungen

- Chelatin-Sa: Sarex ChemicalsDokument2 SeitenChelatin-Sa: Sarex Chemicalssivanesan seeranganNoch keine Bewertungen

- Sri Chaitanya IIT Academy., India.: Key SheetDokument38 SeitenSri Chaitanya IIT Academy., India.: Key SheetAjay BhatnagarNoch keine Bewertungen

- Fine Bubble aeration-EPADokument7 SeitenFine Bubble aeration-EPARizkydwiArizkaNoch keine Bewertungen

- CHEM 1067 Lec 3 - 2019 - NJ - 4 PDFDokument21 SeitenCHEM 1067 Lec 3 - 2019 - NJ - 4 PDFIbrahim AliNoch keine Bewertungen

- Experience With Lined and Clad PipelinesDokument17 SeitenExperience With Lined and Clad Pipelinesjoni Mart Sitio100% (1)

- Supplement 10 TS Calibration ECSPP ECBSDokument16 SeitenSupplement 10 TS Calibration ECSPP ECBSKingston Rivington100% (1)

- Drug MetabolismDokument46 SeitenDrug Metabolismأحمد عاطفNoch keine Bewertungen

- Unit 2Dokument104 SeitenUnit 2Sagar DhageNoch keine Bewertungen

- Chemical Digestion and Absorption - A Closer Look - Anatomy and PhysiologyDokument20 SeitenChemical Digestion and Absorption - A Closer Look - Anatomy and PhysiologyMa Mayla Imelda LapaNoch keine Bewertungen

- 5lab - Serial DilutionDokument3 Seiten5lab - Serial DilutionBianca ANoch keine Bewertungen

- ME8792 - Notes by EasyEngineering - Net 1Dokument127 SeitenME8792 - Notes by EasyEngineering - Net 1Akash smartNoch keine Bewertungen

- Plant Pathology Fst3Dokument19 SeitenPlant Pathology Fst3Alishba SherazNoch keine Bewertungen

- L-20 General Characterstics of The P-Block ElementsDokument10 SeitenL-20 General Characterstics of The P-Block ElementsAkhilesh KumarNoch keine Bewertungen

- HSE Fire Watcher TrainingDokument32 SeitenHSE Fire Watcher TrainingMuneeb RehmanNoch keine Bewertungen

- Laboratory Study On Nano Clay Modified Asphalt PavementDokument17 SeitenLaboratory Study On Nano Clay Modified Asphalt PavementAli YousefNoch keine Bewertungen

- System Practices For Ammonia and Carbon Dioxide RefrigerantsDokument27 SeitenSystem Practices For Ammonia and Carbon Dioxide Refrigerants1940LaSalleNoch keine Bewertungen

- Local Anesthetics 2006Dokument22 SeitenLocal Anesthetics 2006Shashikant DrShashikant BagadeNoch keine Bewertungen

- The Chemistry of Cooking and Cleaning - Ellen RichardsDokument106 SeitenThe Chemistry of Cooking and Cleaning - Ellen RichardsSandra Mian100% (2)

- Practice Exam Questions: Unit 4Dokument2 SeitenPractice Exam Questions: Unit 4alamphyNoch keine Bewertungen

- Iso 2063 2 2017 en PDFDokument11 SeitenIso 2063 2 2017 en PDFMichael Hii0% (1)

- Penetration of Microwaves Into AluminumDokument5 SeitenPenetration of Microwaves Into AluminumJohn Michael WilliamsNoch keine Bewertungen