Beruflich Dokumente

Kultur Dokumente

Quality Manual

Hochgeladen von

gs_humboldt0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

386 Ansichten29 SeitenThis document is the Quality Management Manual for Terna S.A. outlining the company's quality management system. It describes the system's general requirements including the quality manual, document control, and records control. It also covers management commitment, customer focus, quality planning, responsibilities and reviews. The system applies to all of Terna's business activities and aims to fulfill the requirements of the ISO 9001:2008 standard.

Originalbeschreibung:

MANUAL ON QUALITY MANAGEMENT

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document is the Quality Management Manual for Terna S.A. outlining the company's quality management system. It describes the system's general requirements including the quality manual, document control, and records control. It also covers management commitment, customer focus, quality planning, responsibilities and reviews. The system applies to all of Terna's business activities and aims to fulfill the requirements of the ISO 9001:2008 standard.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

386 Ansichten29 SeitenQuality Manual

Hochgeladen von

gs_humboldtThis document is the Quality Management Manual for Terna S.A. outlining the company's quality management system. It describes the system's general requirements including the quality manual, document control, and records control. It also covers management commitment, customer focus, quality planning, responsibilities and reviews. The system applies to all of Terna's business activities and aims to fulfill the requirements of the ISO 9001:2008 standard.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 29

DOCUMENT TYPE : QUALITY MANUAL

DOCUMENT CODE : QAM - 001

DOCUMENT TTLE : QUALITY MANAGEMENT MANUAL

DATE OF SSUE: 13/06/2012 STATUS : ACTVE REVSON : 2 Page 1 of 29

CONTROLLED DOCUMENT

CONTROLLED

COPY

NUMBER

UNCONTROLLED

APPROVED BY :

MANAGING DIRECTOR

ISSUED BY :

QUALITY MANAGER

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -001

Page 2 of 29

Date of Issue: 13/06/2012 Rev. 2

REVISION PAGE

PARAGRAPH

NUMBER

DESCRIPTION OF ALTERATION

0 0 N N T T A AL L S SS SU UE E

1 1

R RE EV V S S O ON N D DU UE E T TO O R RE EV V S SE ED D S ST TA AN ND DA AR RD D

S SO O 9 90 00 01 1: :2 20 00 08 8

2 2

A AP PP PR RO OV VA AL L A AU UT TH HO OR R T TY Y O OF F T TH HE E Q QU UA AL L T TY Y

M MA AN NU UA AL L A AN ND D T TH HE E Q QU UA AL L T TY Y P PO OL L C CY Y

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -001

Page 3 of 29

Date of Issue: 13/06/2012 Rev. 2

1. TABLE OF CONTENTS

1. TABLE OF CONTENTS ....................................................................................................................... 3

2. SCOPE OF APPLICATION.................................................................................................................. 5

3. BACKGROUND AND ACTIVITIES OF TERNA S.A. - GEK-TERNA GROUP .......................... 5

4. QUALITY MANAGEMENT SYSTEM ............................................................................................... 6

4.1. GENERAL REQUIREMENTS.................................................................................................. ..6

4.1.1. IN GENERAL.............................................................................................................................. 7

4.1.2. QUALITY MANUAL................................................................................................................... 7

4.1.3. DOCUMENT CONTROL ........................................................................................................... 8

4.1.4. RECORDS CONTROL ............................................................................................................... 9

4.2. MANAGEMENT`S COMMITMENT............................................................................................ 9

4.3. FOCUSINGONTHE CUSTOMER ............................................................................................. 10

4.4. QUALITYPOLICY...................................................................................................................... 11

4.5. QUALITYPLANNING(DESIGN) .............................................................................................. 12

4.5.1. QUALITY OBJECTIJES .......................................................................................................... 12

4.5.2. PLANNING OF THE QUALITY MANAGEMENT SYSTEM.................................................... 12

4.6. RESPONSIBILITIES, AUTHORITIES ANDCOMMUNICATION........................................... 13

4.6.1. RESPONSIBILITIES AND AUTHORITIES.............................................................................. 13

4.6.2. MANAGEMENT REPRESENTATIJE...................................................................................... 13

4.6.3. INTERNAL COMMUNICATION.............................................................................................. 13

4.7. REVIEWOF THE QUALITYMANAGEMENT SYSTEMBYTHE MANAGEMENT ............ 14

4.7.1. GENERAL................................................................................................................................. 14

4.7.2. REJIEW DATA (REJIEW INPUT) .......................................................................................... 14

4.7.3. REJIEW RESULTS (REJIEW OUTPUT) ................................................................................ 15

5. RESOURCE MANAGEMENT........................................................................................................... 16

5.1. PROVISIONOF RESOURCES.................................................................................................... 16

5.1.1. MEANS (RESOURCES) ........................................................................................................... 16

5.2. HUMANRESOURCES................................................................................................................ 16

5.2.1. GENERAL................................................................................................................................. 16

5.2.2. SKILLS, INFORMATION, TRAINING ..................................................................................... 16

5.3. INFRASTRUCTURE.................................................................................................................... 17

5.4. WORKENVIRONMENT............................................................................................................. 17

6. PRODUCTIVE PROCESS IMPLEMENTATION (PRODUCT REALIZATION) ....................... 18

6.1. PRODUCT REALIZATIONPLANNING.................................................................................... 18

6.2. CUSTOMER RELATEDPROCESSES........................................................................................ 19

6.2.1. DETERMINATION OF PRODUCT RELATED REQUIREMENTS ......................................... 19

6.2.2. REJIEW OF PRODUCT RELATED REQUIREMENTS.......................................................... 20

6.2.3. COMMUNICATION WITH THE CUSTOMER........................................................................ 20

6.3. DESIGNANDDEVELOPMENT................................................................................................. 20

6.3.1. DESIGN PLANNING................................................................................................................ 20

6.3.2. DESIGN INPUTS ..................................................................................................................... 21

6.3.3. DESIGN OUTPUTS, REJIEW, JERIFICATION, JALIDATION............................................ 21

6.3.4. CONTROL OF DESIGN CHANGES........................................................................................ 22

6.4. PURCHASES................................................................................................................................ 22

6.4.1. PURCHASE PROCESS ............................................................................................................ 22

6.4.2. PURCHASE INFORMATION .................................................................................................. 22

6.4.3. JERIFICATION OF PURCHASED PRODUCTS .................................................................... 23

6.5. PRODUCTIONANDPROVISIONOF SERVICES .................................................................... 23

6.5.1. CONTROL OF PRODUCTION AND PROJISION OF SERJICES......................................... 23

6.5.2. JALIDATION OF PRODUCTION AND SERJICE PROJISION PROCESSES...................... 23

6.5.3. IDENTIFICATION AND TRACEABILITY ............................................................................... 24

6.5.4. CUSTOMER PROPERTY......................................................................................................... 24

6.5.5. PRODUCT PRESERJATION................................................................................................... 24

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -001

Page 4 of 29

Date of Issue: 13/06/2012 Rev. 2

6.6. CONTROL OF INSPECTION, MEASURING ANDTESTINGEQUIPMENT .......................... 25

7. MEASUREMENT, ANALYSIS AND IMPROVEMENT................................................................. 25

7.1. GENERAL REQUIREMENTS..................................................................................................... 25

7.2. MEASUREMENT ANDMONITORING..................................................................................... 26

7.2.1. CUSTOMER SATISFACTION.................................................................................................. 26

7.2.2. INTERNAL AUDITS................................................................................................................. 26

7.2.3. MONITORING AND MEASURING PROCESSES ................................................................... 27

7.2.4. PRODUCT MONITORING AND MEASUREMENT................................................................ 27

7.3. CONTROL OF NON- CONFORMINGPRODUCTS.................................................................. 27

7.4. DATAANALYSIS ....................................................................................................................... 28

7.5. SYSTEMIMPROVEMENT......................................................................................................... 28

7.5.1. CONTINUAL IMPROJEMENT ............................................................................................... 28

7.5.2. CORRECTIJE ACTIONS ......................................................................................................... 29

7.5.3. PREJENTIJE ACTIONS.......................................................................................................... 29

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 5 of 29

Date of Issue: 13/06/2012 Rev. 2

2. SCOPE OF APPLICATION

The Quality Management Manual presents the Quality Policy of TERNA S.A. and

describes the Quality Management System applied by the company, as established in

order to fulfill the SO 9001:2008 standard and the company's Quality Policy. The Quality

Management System covers all market sectors in which the company has commenced

business activities:

preparation for participation in Construction Project Tendering Procedures

organization and construction of construction projects up to the stage of the

project's final acceptance by the customer and the completion of the

respective contractual requirements.

The Company is committed to implement the Quality Management System it has

developed.

3. BACKGROUND AND ACTIVITIES OF TERNA S.A. - GEK-TERNA GROUP

n 1999 GEK and TERNA, in the context of the development of the construction branch,

and in order to better utilize their capabilities, decides to unite their powers and to create

a strong and flexible Group.

GEK was established in 1969 and has been mainly active in the construction of

ndustrial Buildings. n short time, its activities expanded to building projects of all kinds

and to special constructions.

TERNA was established in 1972 and has since then been active in undertaking and

performing a wide spectrum of composite construction and investment projects.

Today, TERNA S.A. is one of the most important Contractor Companies in Greece with

a strong presence in the regions of Southeastern Europe and the Middle East. TERNA

covers the entire spectrum of Construction, ndustrial and Energy projects both of the

Public and of the Private Sector. Today, it successfully implements a substantial number

of major and complex infrastructure, Building and Energy projects.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 6 of 29

Date of Issue: 13/06/2012 Rev. 2

TEPNA is a subsidiary company controlled 100% by the GEK-TERNA S.A. Group, which

covers the sectors of construction activity (private and public projects, building and

infrastructure projects), concessions, i.e. major self-financed projects (e.g. Motorways),

Public-Private Partnerships (PPP), energy production and real estate development.

TERNA possesses high level infrastructure as regards owned equipment and T

systems, a modern organizational structure and particularly experienced human

recourses.

TERNA's development is incorporated into the overall strategy of the GEK-TERNA

Group and is based on:

ts capability to build major projects achieving a level of quality, effectiveness and

reliability which secures long-term stable relationships with its customers and a large

share in the construction market.

The extensive investment program it implements and the improvement of the skills of

its human resources through continuous education and training.

4. QUALITY MANAGEMENT SYSTEM

4.1. GENERAL REQUIREMENTS

The written Quality Management System of the company fulfills the requirements of the

SO 9001:2008 standard and supports the company's Quality Policy. Special emphasis

is given in this written Quality Management System to the identification and satisfaction

of the customer's requirements.

The procedures developed are organized under an "activities group" rationale (process

oriented), in order to ensure the functionality of the company's Quality Management

System.

n particular it:

identifies and documents the processes comprising the system

specifies the interactions between processes

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 7 of 29

Date of Issue: 13/06/2012 Rev. 2

specifies criteria and methods in order to ensure efficient operation and control of

processes

secures the availability of required information in order to support and monitor the

processes

t also carries out measurements and analyses of processes and specifies measures in

order to achieve planned objectives and continual improvement.

DOCUMENTATION REQUIREMENTS

4.1.1. IN GENERAL

The Quality Management System comprises the following levels of documentation:

Quality Manual

Quality Procedures

Work nstructions

Quality Forms

4.1.2. QUALITY MANUAL

The method of mplementation of the requirements of the SO 9001:2008 standard

through the written quality management system (with the above structure) is depicted in

the table showing the correspondence between the SO 9001:2008 standard and the

Written Quality Management System of the company, such table being attached hereto

as Annex (B)

The Quality Management Manual describes the quality policy of TERNA, the general

structure of the company and the method of fulfillment of the requirements of the SO

9001:2008 standard in each of its paragraphs in order to confirm that each action has

been performed according to the requirements.

Job

Descriptions

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 8 of 29

Date of Issue: 13/06/2012 Rev. 2

Quality Procedures specify "who does what and when, as well as the method of

documenting that each action has been implemented according to the prescribed

requirements as well as which data will be filled with a view to properly manage acquired

knowhow.

Work nstructions describe how a job is done and are developed wherever their lack

could influence quality.

Forms and Lists: The forms are used in order to provide "evidence that the system is

properly managed and that the quality requirements are met. Completed forms are

hereinafter referred to as Documents and Files. The Lists are usually ancillary files

supporting specific procedures.

Job Descriptions specify/summarize authorities -responsibilities of every employee of the

company.

4.1.3. DOCUMENT CONTROL

A written procedure for the management of documents and data has been established

by the company.

All quality forms are drafted in a specific manner, prescribed under the respective

procedures, in order to avoid errors and omissions.

All quality documents are inspected before being issued, both as regards their

sufficiency and conformity with the company Quality Policy by the person responsible for

their approval and as regards their compliance with the SO 9001:2008 standard by the

person responsible for their issuance.

TERNA maintains a Master Controlled Documents List showing the current status of

quality documents.

At TERNA the original of the controlled quality documents is maintained under the

responsibility of the Quality Manager who distributes the documents of the Quality

Management System in a controlled manner to all company employees, wherever

necessary.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 9 of 29

Date of Issue: 13/06/2012 Rev. 2

Cases of mass reproduction of system forms are handled with care in order to avoid the

use of previous/invalid issues.

Previous, revised and invalid issues are destroyed, except of some Original Documents

of previous issues kept for legal and/or historical reasons and which must be identified in

order to ensure that they will not be used.

Changes are reviewed and approved by the same person who has carried out the initial

inspection and approval. n case this is not possible, a new person with sufficient

experience in this matter is appointed.

Where required, the nature of the change is noted in the documents.

4.1.4. RECORDS CONTROL

Completed forms constituting proof of successful achievement of quality and fulfillment

of the customer's requirements, as well as forms which are useful for the continual

improvement of the Quality Management System are kept as records at the company

and are specified in the respective procedures.

The manner of identification, collection, filling, storage and maintenance of the records

as well as the period of their maintenance is set out under the respective procedures.

MANAGEMENT RESPONSIBILITY

4.2. MANAGEMENT'S COMMITMENT

The company Management is committed to fully satisfy the requirements of its

customers.

The company fully observes legislative and other requirements during the construction of

all projects (building, infrastructure, energy etc. projects).

A customer-centered policy is implemented in order to satisfy the needs and

expectations of its customers and to gain their trust, while, at the same time, the

company's interest is always focused on issues of quality, technological development,

support etc.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 10 of 29

Date of Issue: 13/06/2012 Rev. 2

TERNA fulfills the above requirements through its organization pursuant to the Quality

Management System according to the SO 9001:2008 standard based on:

the qualified and specialized personnel operating within the framework of a perfectly

organized internal structure;

the constant training of its employees and the evaluation of its results;

the continual evaluation of its suppliers and associates;

the continual improvement and modernization of the work environment and

equipment;

the constant updating on issues pertinent to its activities.

The Management's Commitment relates to the everyday level of operation of the

company and is documented by the decisions carried at the Quality Management

System Review meetings of the Management.

4.3. FOCUSING ON THE CUSTOMER

The company identifies the needs and expectations of the customers in combination with

the technological developments in the sector and introduces the experience acquired

from each customer to the existing service provision framework.

Furthermore, TERNA identifies the needs of all persons or organizations directly or

indirectly influenced by it and it handles their requests as if they were customers of the

company. Hereinafter we will designate the above category of the population as ndirect

Customers.

Moreover, the company is able to assess the percentage of achievement of the quality

objectives specified by itself as regards customer satisfaction, thus being able to

constantly improve the quality of its services.

For the above reasons it has established and implements a series of procedures

securing that the provision of services to its customers meets the quality requirements.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 11 of 29

Date of Issue: 13/06/2012 Rev. 2

4.4. QUALITY POLICY

Our Companv is committed to achieve the Maximum Possible Degree of Satisfaction of

the customer, and the full observance of all contractual requirements and modern state-

of art best practices.

Our obfectives are.

Building of construction profects.

Within the period specified under the contractual obligations or within the time

schedules specified bv the companv.

Incorporating the excessive knowhow of the companv and fostering its growth at

the same time

Research and utili:ation of new activities related to the Companvs subfect-manner

Constant efficiencv improvement.

The obfectives are achieved through the existence and completion of the following

conditions.

Detailed planning of companv activities

Maintenance of experienced and active personnel

Confirmation of the fact that companv emplovees understand the requirements of the

customer

Renewal and constant maintenance of the Mechanical equipment

Monitoring market requirements and scientific developments

Knowhow transfer from and to each profect through an organi:ed communication

svstem

Continual improvement of the Qualitv Management Svstem of the Companv based on

market requirements and experiences gained from the profects

Careful evaluation of suppliers and subcontractors

Training of the Companvs personnel

The Managing Director

George Peristeris

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 12 of 29

Date of Issue: 13/06/2012 Rev. 2

4.5. QUALITY PLANNING (DESIGN)

4.5.1. QUALITY OBJECTIVES

The company establishes quality objectives as regards the construction and operation of

the projects, which are both qualitative and quantitative, and are measured, analyzed

and revised during Quality Management System Review meetings of the Management.

The recording and measurement of the objectives is carried out based of documented

indices.

4.5.2. PLANNING OF THE QUALITY MANAGEMENT SYSTEM

At TERNA S.A. planning in quality issues is carried out through the implementation of

the written Quality Management System and the establishment of system control and

improvement procedures.

The Quality Management System planning for each project undertaken by TERNA is

based on the determination of the following:

Activities influencing the quality of the project

Required inspections and tests

Equipment and resources in general required for the project

Personnel qualifications

Required control and progress records

Observed specifications and regulations

A Project Quality Manager is appointed for each project, who, in cooperation with the

Company's Quality Manager and the entire staff, undertakes the planning of the project's

Quality Management System according to the requirements of the SO 9001 standard,

the specifications, the state-of-the-art, as described in the respective procedures of the

quality management system.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 13 of 29

Date of Issue: 13/06/2012 Rev. 2

4.6. RESPONSIBILITIES, AUTHORITIES AND COMMUNICATION

4.6.1. RESPONSIBILITIES AND AUTHORITIES

The organizational structure of TERNA S.A. is described in the attached Organization

Chart of Annex (A), where the levels of responsibilities and authorities of the staff

directing, performing and verifying works influencing the quality of company's activities

are laid down.

The distribution of responsibilities and authorities at TERNA S.A. is described at an initial

level in the Company's Job Descriptions or in the Job Descriptions of each project and

more detailed at a second level in the System Procedures

. .

4.6.2. MANAGEMENT REPRESENTATIVE

The Management Representative is responsible for ensuring that the Quality

Management System is effectively implemented, fulfilling the principles of the SO

9001:2008 standard and of the Quality Policy, by all company employees as regards the

role played by each employee and procures its continual improvement and upgrading.

The Management Representative directly cooperates with the Project Quality Managers

in order to monitor the effective implementation of the System, informs the Company's

Management on all quality issues either directly or by convening the Quality

Management System Review Board and secures the implementation of the measures

specified by the Review Board.

4.6.3. INTERNAL COMMUNICATION

nternal communication within the company is secured at all levels and for all activities

required for the maintenance of the Quality Management System. n particular:

mportant information is communicated through the notice boards located at obvious

spots.

The findings of nternal Audits are communicated to the interested parties

n particular, the company's Quality Policy is notified to all company employees using

one of the following manners:

This Manual

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 14 of 29

Date of Issue: 13/06/2012 Rev. 2

Direct publication (posting).

Training of employees in quality matters

Quality procedures

The Management closely monitors through the Management Representative the

establishment and implementation of the Quality Policy.

4.7. REVIEW OF THE QUALITY MANAGEMENT SYSTEM BY THE

MANAGEMENT

4.7.1. GENERAL

A written Procedure for the planning and conduct of the Quality Management System

Review Meeting is established in the Company. The review is carried out at least once in

each year.

During the Review it is examined:

whether the Quality Managements System is sufficient and effective

whether Quality Policy has been achieved

whether the level of training of the staff covers the needs pertinent to the works

suggestions for the improvement of the Quality Management System in general

Members of the Quality Review Board are the Chairperson of the BoD, the Managing

Director of the Company, the Technical Directors, the Management Representative, the

Quality Manager(s) and any other person deemed necessary by the Management

Representative. The findings of the Review are notified to the higher levels of the

company's management.

4.7.2. REVIEW DATA (REVIEW INPUT)

The Management Representative in cooperation with the Quality Manager(s), before the

commencement of the Quality Management System review meeting, organize a file with

all data to be used during the meeting, such file been forwarded to the participants.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 15 of 29

Date of Issue: 13/06/2012 Rev. 2

The file contains:

1. Findings of Audits

2. nformation Customer Complaints Data regarding degree of customer

satisfaction

3. Data on the implementability and functionality of the procedures

4. Records of non-conforming products.

5. Suggestions on points requiring the development and implementation of

Corrective Preventive Actions

6. Progress- evaluation of the implementability of corrective actions decided at the

previous Quality Management Review Meeting

7. Monitoring measures decided by the previous Quality Management Review

Meeting.

8. Changes that might influence the quality of the Management System.

9. New technologies and trends

4.7.3. REVIEW RESULTS (REVIEW OUTPUT)

nclude decisions and measures related to:

The improvement of the effectiveness of the Quality Management System and its

procedures.

mprovements on projects under construction by the company in relation to

customer requirements.

Resources required for improvement.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 16 of 29

Date of Issue: 13/06/2012 Rev. 2

5. RESOURCE MANAGEMENT

5.1. PROVISION OF RESOURCES

5.1.1. MEANS (RESOURCES)

At TERNA the means (resources) required for the operation of the company at all levels

are identified as specified in the respective Procedures.

The resources required may be divided into the following categories:

Smooth operation of the company

dentification, evaluation and participation in tendering procedures for the

construction of projects and conclusion of contracts with the customer.

Construction of projects.

The identification of the resources is performed for each of the aforementioned sectors

due to the particularities of each sector. Through the organization of the company and

the communication structures the resources required for the qualitative operation of each

sector are identified and evaluated and the method of their provision is organized.

5.2. HUMAN RESOURCES

5.2.1. GENERAL

TERNA has established a written procedure based on which the human resources

required for the establishment and improvement of the Quality Management System are

defined and provided. t is ensured that the members of the staff whose work affects the

quality of services have the proper training and experience.

5.2.2. SKILLS, INFORMATION, TRAINING

The company has established a written procedure in order to secure that:

Works affecting the quality of projects are performed by employees having suitable

skills, information and training.

Training needs are identified

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 17 of 29

Date of Issue: 13/06/2012 Rev. 2

Proper training procedures are planned and implemented

the distribution and transfer of knowhow from experienced company employees to

younger employees will be achieved

Records are kept regarding training/experience of personnel.

5.3. INFRASTRUCTURE

The needs for the improvement of material-technical infrastructure are analyzed and

identified at the company and the necessary measures are implemented in order to

ensure its continual improvement. The Equipment of the company is fully recorded and

codified and the operating status of each device is indicated. Maintenance cards are

provided for each device, insofar as its operation is crucial, and a file for the device is

also provided where all documents related to the operation of the respective device are

included.

The needs for the improvement of the infrastructure result from the Quality Management

Review Meeting, the nternal Audits, the corrective and preventive actions and the

collected problem reports.

5.4. WORK ENVIRONMENT

TERNA ensures a satisfactory work environment:

During the construction and the operation of the projects the work-areas are

functional, manageable and safe.

All health and safety regulations are observed.

A written risk assessment is regularly prepared.

An emergency plan has been established.

Fire safety design.

The proper safety singing has been installed in the company's premises.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 18 of 29

Date of Issue: 13/06/2012 Rev. 2

Employees are obliged to use the appropriate personal protective equipment and

access to construction sites is controlled

Suitable accident prevention equipment is provided

Finally, the equipment necessary for diminishing the effects of an accident has

been installed

6. PRODUCTIVE PROCESS IMPLEMENTATION (PRODUCT REALIZATION)

6.1. PRODUCT REALIZATION PLANNING

Written Procedures have been established at TERNA in order to secure that

construction and operation is planned and performed under controlled conditions.

"Controlled conditions include the following:

All personnel performing crucial work for the quality of the project is selected, trained

and evaluated in order to ensure its capability to successfully complete its work.

Personnel which has not yet completed its training or deemed as having received

insufficient training for the performance of any specific activity is employed in

activities not affecting the quality of the project or is closely supervised by a

supervisor as regards every part of its work..

During all phases of the construction of the project all kinds of tests are conducted in

order to ensure that the product will be of the required quality. Checks are conducted

by experienced and trained personnel using the equipment necessary.

The company's equipment is sufficiently maintained and calibrated on a

prescheduled basis in order to ensure continuity of the works. Equipment not

calibrated is only used for ancillary measurements conducted by the company. An

Equipment List exists (including crucial equipment for the quality of the final product),

based on which all equipment is monitored.

Personnel training records and maintenance control and equipment calibration records

are kept.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 19 of 29

Date of Issue: 13/06/2012 Rev. 2

6.2. CUSTOMER RELATED PROCESSES

6.2.1. DETERMINATION OF PRODUCT RELATED REQUIREMENTS

TERNA possesses a written description of the methodology based on which the

identification of the requirements related to the final product is ensured.

n particular, the method of identification of the requirements related to the product is

detailed therein for each sector where TERNA is active.

TERNA has established written Procedures in order to secure that contracts (tenders,

project contracts, customer orders) are reviewed.

During the preparation phase of the tender for a project, the contractual requirements

are analyzed by experienced personnel and the ability of the company to meet the

requirements is ensured. Justification may be provided for the tender upon a respective

request of the customer.

n case the project is awarded to TERNA, experienced personnel confirms, following an

examination of the contract, that the requirements of the customer are clear and

documented and ensures that any differences between the contract and the tender are

solved.

During the project organization phase the contract is examined and its requirements

regarding time, quality and work control are determined.

During the implementation of the project, oral orders of the customer are documented

and reviewed and any amendments to the contract are examined, in order to evaluate

their effect on the works already completed, on the time schedule and on costs.

Communication with the customer on contractual issues is in writing and the respective

correspondence is kept based on a written procedure.

Required information is available at the Company's Management.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 20 of 29

Date of Issue: 13/06/2012 Rev. 2

6.2.2. REVIEW OF PRODUCT RELATED REQUIREMENTS

The company reviews the requirements related to the product during each phase of its

construction or production. The detailed methodology used for the review of the

requirements is described in the procedures.

6.2.3. COMMUNICATION WITH THE CUSTOMER

Communication with the customer is ensured by means of the written Quality

Management System where the methodology used in such communication is detailed.

Communication prevents the production or construction of products not compliant with

the customer's requirements, solves any discrepancies, enables the identification and

review of all requirements laid down by the customer in relation to the construction of the

product, enables the identification of the degree of customer satisfaction and, finally,

enables the recording of any complains.

6.3. DESIGN AND DEVELOPMENT

TERNA S.A. possesses a written Procedure ensuring control and review at the required

stages of the designing in order to meet the specified requirements.

6.3.1. DESIGN PLANNING

n case that the development of a Design is a requirement under the tender and/or the

Contract documents; the Company analyzes the documents (tender or contract) for

defining:

subject-matter and categories of the design (type of design, degree level etc.)

design stages/phases

design specifications and applicable Legislation

milestones and time schedule data for the development of the design.

Based on the aforementioned the categories/specializations of the designers who will

have to be engaged in the preparation of the design are specified and a design

development plan is laid down, specifying the basic deadlines and the persons

responsible for monitoring its development.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 21 of 29

Date of Issue: 13/06/2012 Rev. 2

6.3.2. DESIGN INPUTS

The design inputs, which include the following, are determined:

Minimum contractual requirements of the customer which define the design

boundaries and provide project objectives and operation and performance

requirements

Applicable legal and regulatory requirements

nformation from previous similar designs, where possible

All the essential design requirements

The sufficiency and completeness of design inputs is examined, while, where

deficiencies, ambiguous or conflicting requirements are ascertained, all required actions

are undertaken for the provision of supplementary clarifications by the Company or the

customer, if necessary.

6.3.3. DESIGN OUTPUTS, REVIEW, VERIFICATION, VALIDATION

ntermediate and final design outputs are recorded, verified and reviewed as regards

their correctness. t is also examined whether they meet the requirements of the design

inputs and the prescribed requirements.

The review of the design by the competent personnel is then conducted, which

comprises:

Examination whether all design specifications have been met

Examination whether the performance of the works, as designed, is feasible

Examination whether it is possible to procure the materials, as specified in the

design

Examination whether the construction of the project is feasible based on the

prescribed acceptance criteria

Determination of construction characteristics and parameters that are crucial for

safety and proper operation

Examination whether the construction of the project is financially feasible

The designs approved by the company are submitted for approval to the customer

according to the call for tenders or the contract of the Project.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 22 of 29

Date of Issue: 13/06/2012 Rev. 2

6.3.4. CONTROL OF DESIGN CHANGES

All changes and amendments to be made on any design are documented, identified,

reviewed, verified and approved by competent persons before their implementation. The

review of the amendments includes an evaluation of the effects of the design

amendments.

6.4. PURCHASES

6.4.1. PURCHASE PROCESS

The Company has established written procedures in order to ensure that the products

and services to be procured meet specified requirements.

The procurements procedure includes equipment procurements, equipment

maintenance services, equipment calibrations, personnel training and special services.

6.4.2. PURCHASE INFORMATION

All the suppliers of goods and services cooperating with the Company are evaluated in

order to ensure that their features correspond to the requirements. Thus, in order to

select a supplier the following are examined, if applicable:

References to the supplier company's history.

References to the production system or the quality system by independent

auditors.

nspection / Audit of the supplier's premises by TERNA.

The Company maintains a list of approved suppliers for goods and services that are

crucial for the quality of the final product.

The Company issues official documents for all procured goods, equipment and services.

Procurement documents, as applicable, include information such as:

Description of procured material.

Purpose of the procurement

Packaging requirements

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 23 of 29

Date of Issue: 13/06/2012 Rev. 2

Specifications

Certification requirements

Manual requirements

Storage/transportation requirements

Handling requirements

Material labeling (serial or lot number)

Delivery time.

6.4.3. VERIFICATION OF PURCHASED PRODUCTS

Materials procured by TERNA are checked upon delivery to ensure that they meet

agreed requirements. Conducted checks are scheduled for each case and recorded in a

special form.

6.5. PRODUCTION AND PROVISION OF SERVICES

6.5.1. CONTROL OF PRODUCTION AND PROVISION OF SERVICES

TERNA has established written Procedures and work instructions in order to ensure that

the completion of the projects as well as their operation is designed and conducted

under controlled conditions.

6.5.2. VALIDATION OF PRODUCTION AND SERVICE PROVISION PROCESSES

All production and service provision processes implemented by TERNA S.A. are

controlled and validated in an organized manner.

As regards the project construction sector, the validation of the processes is conducted

by means of the organization and implementation procedure for the new project and, in

particular, through the development of the Project Quality Management System and the

Project Quality Plan.

n general, for each company activity:

Process review and approval criteria are specified

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 24 of 29

Date of Issue: 13/06/2012 Rev. 2

Human and material resources used are evaluated in order to meet the requirements

of each process

Methods used comply to the existing specifications and the state-of-the art

Required records are kept

Finally, the causes making a review and re-validation of the processes necessary are

identified.

6.5.3. IDENTIFICATION AND TRACEABILITY

dentification and traceability at the projects implemented by the company is enabled,

to the extent necessary (contractual requirements, project significance) and feasible

(nature of works), by means of:

the labeling of the materials incorporated in the project

the filing of drawings and specifications

the completion and filing of control and progress forms

the filing of information, such as material certificates, order forms,

agreements with subcontractors/suppliers etc..

the Project Log

6.5.4. CUSTOMER PROPERTY

For the materials supplied by the customer a special procedure is developed for the

project, describing the entire flow of the material (from its procurement to its

incorporation in the project) and how to contact the customer in case of non-

conforming material.

6.5.5. PRODUCT PRESERVATION

TERNA S.A. identifies for each product the necessary conditions which must exist for its

preservation until it is incorporated in the project but also during its delivery to the

customer. Therefore, all storage requirements are observed both for the materials to be

incorporated in the project and for the materials to be used at any stage of the operation

of the company. Also, all measures necessary are taken in order to preserve the

products to be incorporated in the projects during transportation.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 25 of 29

Date of Issue: 13/06/2012 Rev. 2

6.6. CONTROL OF INSPECTION, MEASURING AND TESTING EQUIPMENT

TERNA has established a written procedure for the management of measurement

equipment in order to ensure that:

the method of calibration of the measuring equipment is specified

the suitable devices (i.e. those capable of providing the required accuracy and

reliability) are selected

the manner of handling, maintenance and storage of such devices ensures their

accuracy and suitability for use

no measuring devices are used that have not been calibrated except in cases where

their use aims to a simple indication.

The Company maintains a list including all devices and their calibration plan.

The handling, maintenance and storage of measuring devices are carried out according

to the specifications of their manufacturers, in order to ensure their accuracy and

suitability for use.

Calibration of the measurement equipment is conducted at prescribed intervals, based

on the instructions of the manufacturer. Calibration is carried out by an accredited

organization and the respective certificates are kept.

n case a device is no longer accurate, the consequences of its use are examined and

required measures are decided.

7. MEASUREMENT, ANALYSIS AND IMPROVEMENT

7.1. GENERAL REQUIREMENTS

The company has, on the one hand, specified the operation standards and the objective

to successfully perform its activities and, on the other hand, has planned and maintains

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 26 of 29

Date of Issue: 13/06/2012 Rev. 2

an effective and decentralized measurement, analysis and continual improvement

system for the Quality Objectives, and the operation and the efficiency of the Quality

Management System.

7.2. MEASUREMENT AND MONITORING

7.2.1. CUSTOMER SATISFACTION

A written procedure exists at TERNA S.A. based on which the degree of customer

satisfaction in relation to provided services is examined and necessary measures are

undertaken in order to improve such satisfaction.

The identification of the customer satisfaction degree (customers may be direct or

indirect, as described under the respective procedure) is carried out by means of the

dispatch to the customer of the evaluation form for the offered services. Completed

forms are received by the Quality Manager who analyses and evaluates the data. The

processing of the aforementioned forms enables the determination of the customer

satisfaction indices. The company's objective is the improvement of the above indices. n

order to achieve the objectives the respective corrective and preventive actions are

planned.

7.2.2. INTERNAL AUDITS

nternal Quality Audits at the company are always conducted according to the written

Procedure, in order to maintain an effective System.

Audits are scheduled by the Quality Manager based on the importance and complexity

of the works, the experience of involved personnel and of the findings of previous audits.

Auditors may belong to the company's personnel (but they must be independent from

the audited activity) and must be trained in the conduct of audits or may be external

specialized consultants.

The findings of Audits are recorded and notified to the personnel responsible for the

audited unit. Deviations or failure trends observed during Audits are investigated in order

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 27 of 29

Date of Issue: 13/06/2012 Rev. 2

to undertake suitable Corrective Actions. Finally, competent persons monitor the actions

undertaken in order to abolish any deviations.

The findings of the Audits are examined at the Quality Management Review Meeting.

nternal Quality Audits reports are kept as records.

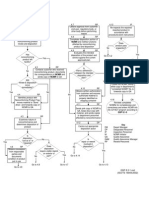

7.2.3. MONITORING AND MEASURING PROCESSES

TERNA S.A. has established a written procedure based on which critical processes are

monitored. A flow chart exists depicting the processes flow and the conducted controls.

Each activity is monitored and both its significance for the production of the final product

and measurable performance indicators are established. The evaluation regards both

compliance of the manner of performance of the specific activity in relation to the

provisions of the respective written procedure and the procedure itself.

The purpose of all aforementioned actions is the identification of the points for which

corrective or preventive actions must be undertaken in order to achieve the objectives

prescribed by the agency.

7.2.4. PRODUCT MONITORING AND MEASUREMENT

Controls and measurements of products have been specified in order to ensure the

quality of the product as well as it compliance with the specifications/requirements laid

down by the Management or prescribed by the legislation.

7.3. CONTROL OF NON - CONFORMING PRODUCTS

TERNA S.A. has established a written Procedure for the management of materials and

works not compliant with the specified requirements. t includes the methods of

identification, recording, assessing and immediate handling of the non-conformity as well

as the method for the notification of the non-conformity where needed.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 28 of 29

Date of Issue: 13/06/2012 Rev. 2

The authorities and responsibilities for the acceptance and disposal/handling or non-

acceptance of the non- conforming products are defined, as described in the respective

Procedure, depending on the case in question

Non-conforming materials are clearly distinguished in order to avoid their use until their

disposal.

Non-Conformities are monitored in order to confirm their settlement.

Non-Conformities and the method of their settlement are examined during the Quality

Management Review Meeting.

The company keeps records of Non-Conformities, including the actions taken and the

decisions made.

7.4. DATA ANALYSIS

Achievement or failure to achieve the preferable Quality of the works provided by the

Company is monitored through the Quality Records.

Observance and updating of Quality records serves the following objectives:

Documentation of provided works.

Documentation of the operation of the Quality Management System.

Support for traceability requirements.

Provision of information and measurable results regarding performance and

effectiveness of the company's works.

7.5. SYSTEM IMPROVEMENT

7.5.1. CONTINUAL IMPROVEMENT

Written Procedures exist at the company for the continual improvement of the Quality

Management System.

TERNA S.A.

DOCUMENT TYPE : QUALITY MANAGEMENT MANUAL

DOCUMENT CODE : QAM -01

Pages : 29 of 29

Date of Issue: 13/06/2012 Rev. 2

Customer complaints, non-conformity reports, findings of internal and external quality

audits and expected trends of problem occurrence are recorded and investigated in

order to determine the required measures for the avoidance of their repetition.

Each action taken for the improvement of the Quality Management System is defined as

a Corrective or Preventive Action. Competent for the approval of corrective and

preventive actions is the Management Representative of TERNA S.A., who, when he

deems it expedient based on the particularities of each case and the significance/ extent

of the corrective/preventive action, requests approval by the competent Director of the

Company through the Quality Management Review Meeting.

Upon completion of the implementation of the corrective/preventive actions their effect

on other elements of the Quality Management System is examined.

7.5.2. CORRECTIVE ACTIONS

At TERNA S.A., non conformities, customer complaints and supplier problems are

examined by the Management Representative in order to indentify the causes and to

plan the most effective method for the solution of the problems and the prevention of a

repetition of the problems.

Respective records are kept.

7.5.3. PREVENTIVE ACTIONS

The prevention of repetition of errors and omissions in a project, the incorporation of new

information, technology and developments into the system and the identification, by

means of the monitoring of the system, of its failure trends, lead to the preparation of the

Preventive Actions Plan. Respective records are kept.

Das könnte Ihnen auch gefallen

- Health & Safety ManualDokument37 SeitenHealth & Safety Manualgs_humboldt50% (2)

- Iso 9001:2015 Quality Management System Manaual: Doc. Ref. No: Rev/Issue-Date: Page 1 of 31Dokument31 SeitenIso 9001:2015 Quality Management System Manaual: Doc. Ref. No: Rev/Issue-Date: Page 1 of 31Martin50% (2)

- Temecula Quality Plating AS9100 REV C MANUALDokument13 SeitenTemecula Quality Plating AS9100 REV C MANUALHoang TanNoch keine Bewertungen

- Criminal Law Book 1 Key Principles and CasesDokument32 SeitenCriminal Law Book 1 Key Principles and CasesNoel Sinco100% (2)

- Job Description: Department/Project Title Reports ToDokument3 SeitenJob Description: Department/Project Title Reports ToAhmed Said Ghonimy100% (1)

- Ethics Code ConductDokument9 SeitenEthics Code ConductSurabhi SrivastavaNoch keine Bewertungen

- Procedure For Control of Non-ConformanceDokument8 SeitenProcedure For Control of Non-ConformanceraviNoch keine Bewertungen

- ISO 9001 Quality Management SystemDokument5 SeitenISO 9001 Quality Management SystemRodel B. AradaNoch keine Bewertungen

- Drug and Alcohol PolicyDokument5 SeitenDrug and Alcohol PolicyBonteanu CameliaNoch keine Bewertungen

- Master List of Quality Records MR-LS-09, RevDokument5 SeitenMaster List of Quality Records MR-LS-09, RevSuraj RawatNoch keine Bewertungen

- (ISO 9001) Procedure For TrainingDokument3 Seiten(ISO 9001) Procedure For TrainingTuan AnhNoch keine Bewertungen

- QMS of The Company As Per IsoDokument62 SeitenQMS of The Company As Per IsogalavaNoch keine Bewertungen

- OHS Management ReviewDokument7 SeitenOHS Management ReviewJoachimNoch keine Bewertungen

- Induction ProcedureDokument12 SeitenInduction Procedurepaulmagbojos100% (1)

- ISO PlanDokument12 SeitenISO PlanTamara Johnson-PariagNoch keine Bewertungen

- KCT Quality ManualDokument30 SeitenKCT Quality ManualBALAJINoch keine Bewertungen

- ESCL SOP 013, Outsourcing ProcedureDokument7 SeitenESCL SOP 013, Outsourcing ProcedureadiqualityconsultNoch keine Bewertungen

- Environmental ManualDokument34 SeitenEnvironmental Manualgs_humboldt100% (3)

- Strategic Quality PlanningDokument13 SeitenStrategic Quality PlanningDeekshita DuttaNoch keine Bewertungen

- Nonconformance Control ProcedureDokument5 SeitenNonconformance Control ProcedureAlex Dcosta50% (2)

- PRO-CAL-01 Measuring Equipment Calibration ProgramDokument2 SeitenPRO-CAL-01 Measuring Equipment Calibration ProgramChiekoi PasaoaNoch keine Bewertungen

- Document Control ChecklistDokument3 SeitenDocument Control ChecklistKool Adam100% (3)

- Quality Manual: ISO/TS 16949:2009 Quality Management SystemDokument47 SeitenQuality Manual: ISO/TS 16949:2009 Quality Management Systemluismi081300Noch keine Bewertungen

- Procedure for Training EmployeesDokument3 SeitenProcedure for Training EmployeesSharif Khan100% (1)

- Control Records ProcedureDokument1 SeiteControl Records ProcedureaezacsNoch keine Bewertungen

- QC-GF-002 - Material Inspection ReportDokument2 SeitenQC-GF-002 - Material Inspection ReportDarrel Espino Aranas100% (1)

- 01 - Design & Development PlanDokument1 Seite01 - Design & Development Planasderbva100% (1)

- Management Review Wasit-1Dokument7 SeitenManagement Review Wasit-1SANUNoch keine Bewertungen

- Mgt Review MinutesDokument6 SeitenMgt Review Minutesmgamal1080100% (1)

- Method Statement Procedure For Control of Non Conforming ProductDokument6 SeitenMethod Statement Procedure For Control of Non Conforming Productmangeshshinde124Noch keine Bewertungen

- IATF Quality Management System Manual (Telamon)Dokument51 SeitenIATF Quality Management System Manual (Telamon)Avyan KelanNoch keine Bewertungen

- Material Control Procedure SAMPLEDokument24 SeitenMaterial Control Procedure SAMPLEJanardhan Surya82% (17)

- QMS 080 GMP Audit Procedure SampleDokument9 SeitenQMS 080 GMP Audit Procedure SampleCarolina TarifNoch keine Bewertungen

- Procedures Manual 8-31-07Dokument36 SeitenProcedures Manual 8-31-07vabimhahNoch keine Bewertungen

- SOP - 01 - Structure Organization ChartDokument10 SeitenSOP - 01 - Structure Organization ChartSuci YatiningtiyasNoch keine Bewertungen

- Master List of Quality Procedures IndexDokument71 SeitenMaster List of Quality Procedures IndexLILIANAMAR100% (2)

- 1.0 Purpose / Scope: 2.1 HSE ObjectiveDokument1 Seite1.0 Purpose / Scope: 2.1 HSE ObjectiveKhaldoon AlnashiNoch keine Bewertungen

- Happy Forgings EMS PerformanceDokument3 SeitenHappy Forgings EMS Performancemool raj100% (1)

- Senior QA Engineer ResumeDokument6 SeitenSenior QA Engineer ResumeantonyNoch keine Bewertungen

- Quality ManualDokument26 SeitenQuality ManualGerardo Gómez SalasNoch keine Bewertungen

- SOP Corrective Action: SOP As Approved by The Program Signing AuthorityDokument1 SeiteSOP Corrective Action: SOP As Approved by The Program Signing Authoritysudar1477Noch keine Bewertungen

- Non-Conforming Product ProcedureDokument3 SeitenNon-Conforming Product ProcedureHamzah Abbass SibaiNoch keine Bewertungen

- Competency Awareness & Training ProcedureDokument3 SeitenCompetency Awareness & Training ProcedureYousaf Richu100% (3)

- Project Plan For Implementation of The Quality Management System in LaboratoryDokument6 SeitenProject Plan For Implementation of The Quality Management System in LaboratoryMansi Thaker100% (1)

- Quality Manual RS QMS 002Dokument11 SeitenQuality Manual RS QMS 002WayneNoch keine Bewertungen

- QMS Work PlanDokument4 SeitenQMS Work PlanWael BouabdellahNoch keine Bewertungen

- Work Instruction - Plate CuttingDokument11 SeitenWork Instruction - Plate Cuttingbalakumar rajaram0% (1)

- Reflection Paper On LeadershipDokument3 SeitenReflection Paper On LeadershipTrishia Collene RosarealNoch keine Bewertungen

- Equipment Operation and MaintenanceDokument2 SeitenEquipment Operation and MaintenanceSarat KumarNoch keine Bewertungen

- Quality Management SpecificationDokument15 SeitenQuality Management SpecificationSyed Shoaib RazaNoch keine Bewertungen

- Quality Record Procedure Rev-JDokument4 SeitenQuality Record Procedure Rev-JherminNoch keine Bewertungen

- Construction Job Responsibility - DS-90!00!400!2!080529Dokument40 SeitenConstruction Job Responsibility - DS-90!00!400!2!080529李君Noch keine Bewertungen

- Record Retention Checklist Rev.0Dokument2 SeitenRecord Retention Checklist Rev.0Sameer ParambathNoch keine Bewertungen

- Quality Policy - RevisedDokument1 SeiteQuality Policy - RevisedMoinuddin AnsariNoch keine Bewertungen

- Exhibit B 1 Subcontractor Evaluation Sheet4Dokument44 SeitenExhibit B 1 Subcontractor Evaluation Sheet4Isabelle LemieuxNoch keine Bewertungen

- SITE-SPECIFIC QC PLANDokument3 SeitenSITE-SPECIFIC QC PLANloveanbu24100% (1)

- Eaton Global Supplier Excellence ManualDokument30 SeitenEaton Global Supplier Excellence Manualfdsa01100% (1)

- PALS Civil Law (Persons, Property & Oblicon)Dokument123 SeitenPALS Civil Law (Persons, Property & Oblicon)Raq Kho100% (1)

- Quality Assurance Manager Job DescriptionDokument2 SeitenQuality Assurance Manager Job DescriptionDaniel Ratna RajuNoch keine Bewertungen

- Document Control ProcedureDokument3 SeitenDocument Control ProcedureHeny Kusumawati100% (1)

- QM-004-0 Document Distribution, Retrieval and Disposal Form From Control of Documents ProcedureDokument2 SeitenQM-004-0 Document Distribution, Retrieval and Disposal Form From Control of Documents Procedurezafeer100% (1)

- Historical Lies and Historical Rights in The West Philippine SeaDokument78 SeitenHistorical Lies and Historical Rights in The West Philippine Seags_humboldtNoch keine Bewertungen

- Concept of ISO 9000, Six Sigma & Lean Production For Apparel Industry PDFDokument13 SeitenConcept of ISO 9000, Six Sigma & Lean Production For Apparel Industry PDFtaqi1122Noch keine Bewertungen

- The Pharmaceutical Guide To The Perfect Quality Assurance PlanDokument17 SeitenThe Pharmaceutical Guide To The Perfect Quality Assurance PlansamontoyaNoch keine Bewertungen

- Controlled Quality ManualDokument51 SeitenControlled Quality ManualMoment BatureNoch keine Bewertungen

- Job Safety Environmental Analysis Pre-Task BriefingDokument5 SeitenJob Safety Environmental Analysis Pre-Task BriefingFerman TokgözoğluNoch keine Bewertungen

- Communication, Participation & ConsulatationDokument7 SeitenCommunication, Participation & ConsulatationSuresh MuruganNoch keine Bewertungen

- QMS Document Management and Record ControlDokument3 SeitenQMS Document Management and Record ControlNurul AfizaNoch keine Bewertungen

- ISO 9001 Certified Precision MachiningDokument21 SeitenISO 9001 Certified Precision Machiningqmicertification100% (2)

- Training ProcedureDokument14 SeitenTraining ProcedureThee BouyyNoch keine Bewertungen

- Schedule your competency assessmentDokument3 SeitenSchedule your competency assessmentPrince MoniNoch keine Bewertungen

- NCR Flow ChartDokument1 SeiteNCR Flow ChartPramod AthiyarathuNoch keine Bewertungen

- Memorandum Data PrintDokument51 SeitenMemorandum Data PrintGabyyOstosPicon0% (1)

- Rules of Procedure For IP Rights CasesDokument20 SeitenRules of Procedure For IP Rights CasesJay GarciaNoch keine Bewertungen

- Republic of The Philippines BC-CSC Form No. 1 (Position Description Form)Dokument2 SeitenRepublic of The Philippines BC-CSC Form No. 1 (Position Description Form)gs_humboldtNoch keine Bewertungen

- JJMega HoldingsDokument2 SeitenJJMega Holdingsgs_humboldtNoch keine Bewertungen

- PB Guangzhou 2012Dokument6 SeitenPB Guangzhou 2012ejikieru03Noch keine Bewertungen

- BS Ohsas 18001Dokument1 SeiteBS Ohsas 18001gs_humboldtNoch keine Bewertungen

- En Iso 14001Dokument1 SeiteEn Iso 14001gs_humboldtNoch keine Bewertungen

- Jimenez Calida Political Law Review Doctrines (Arts.2, 6-12,17)Dokument23 SeitenJimenez Calida Political Law Review Doctrines (Arts.2, 6-12,17)gs_humboldtNoch keine Bewertungen

- Chapter 2 Quality TheoryDokument30 SeitenChapter 2 Quality TheoryMoon2803100% (1)

- Manual Testing SyllabusDokument4 SeitenManual Testing SyllabusBaranishankarNoch keine Bewertungen

- Managing quality and logisticsDokument75 SeitenManaging quality and logisticsJoost VerheyenNoch keine Bewertungen

- Screenshot 2021-01-06 at 12.00.46Dokument1 SeiteScreenshot 2021-01-06 at 12.00.46Bruher BruhbruhNoch keine Bewertungen

- Navi Pizza Hut AssDokument12 SeitenNavi Pizza Hut AssManinder Kahlon0% (1)

- LRQA Management System Audit 2010Dokument10 SeitenLRQA Management System Audit 2010ServosteelNoch keine Bewertungen

- Quality Management System of IVRCL LIMITEDDokument70 SeitenQuality Management System of IVRCL LIMITEDSagar Paul'g100% (1)

- Risk Assessment For Construction of Urban Rail Transit ProjectsDokument8 SeitenRisk Assessment For Construction of Urban Rail Transit ProjectsSilvana Jerez MartinezNoch keine Bewertungen

- Weekly Summary 3 - Group ADokument11 SeitenWeekly Summary 3 - Group AOlivio CampanerNoch keine Bewertungen

- Training Calendar 2024Dokument28 SeitenTraining Calendar 2024Arne OsabelNoch keine Bewertungen

- Comparision BRC IFS QMS 22K From BV PDFDokument44 SeitenComparision BRC IFS QMS 22K From BV PDFAhmedElSayedNoch keine Bewertungen

- Marie Skłodowska-Curie Actions (MSCA) : - Horizon 2020Dokument53 SeitenMarie Skłodowska-Curie Actions (MSCA) : - Horizon 2020vitis12Noch keine Bewertungen

- Guidelines Fmea - Dyadem Press - 2003Dokument143 SeitenGuidelines Fmea - Dyadem Press - 2003Cali MelendezNoch keine Bewertungen

- Week 14 - EnGG 406 - Managing ProductionDokument54 SeitenWeek 14 - EnGG 406 - Managing ProductionKATE SARAH MARANANNoch keine Bewertungen

- Quality Function DeploymentDokument13 SeitenQuality Function DeploymentAyon SenguptaNoch keine Bewertungen

- IQA Iso9001-Iso14001Dokument44 SeitenIQA Iso9001-Iso14001Jitendra BhosaleNoch keine Bewertungen

- Productivity of Cement Industry of PakistanDokument37 SeitenProductivity of Cement Industry of Pakistansyed usman wazir100% (9)

- Procedure For Management ReviewDokument6 SeitenProcedure For Management ReviewAman JasujaNoch keine Bewertungen

- Total Quality Management Literature Review and An Agenda For Future ResearchDokument12 SeitenTotal Quality Management Literature Review and An Agenda For Future ResearchafdtzfutnNoch keine Bewertungen

- Skyworks SystemmanualDokument31 SeitenSkyworks SystemmanualColinNoch keine Bewertungen

- BSBPMG411-418-CUE405 Mungunbaatar Losolsuren Task 3Dokument15 SeitenBSBPMG411-418-CUE405 Mungunbaatar Losolsuren Task 3Oyunsuvd AmgalanNoch keine Bewertungen

- KEY JURNAL - Evolution of Operations Management PDFDokument29 SeitenKEY JURNAL - Evolution of Operations Management PDFDani Muhammad RamdhaniNoch keine Bewertungen