Beruflich Dokumente

Kultur Dokumente

Safe circular duct dimensions and specifications

Hochgeladen von

cosmynnsOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Safe circular duct dimensions and specifications

Hochgeladen von

cosmynnsCopyright:

Verfügbare Formate

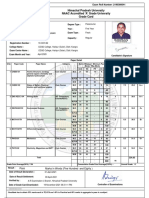

lin dab | safe

Circular duct

Dimensions

l

t

SR

1 2 3 4

d*

l

t

5

Description

Circular duct. Ducts are always produced locally and can therefore have different thicknesses and other specifications per country. Has normally not any Click function hasnt any notches. Can to order be delivered with Click function i.e. with notches. d std nom 63 80 100 112 125 140 150 160 180 200 224 250 280 300 315 355 400 450 500 560 600 630 710 800 900 1000 1120 1250 1400 1500 1600 O d m 0,198 0,251 0,314 0,352 0,393 0,440 0,471 0,503 0,565 0,628 0,704 0,785 0,880 0,942 0,990 1,115 1,257 1,414 1,571 1,759 1,885 1,979 2,231 2,513 2,827 3,142 3,519 3,927 4,398 4,712 5,027 A d/4 m2 0,003 0,005 0,008 0,010 0,012 0,015 0,018 0,020 0,025 0,031 0,039 0,049 0,062 0,071 0,078 0,099 0,126 0,159 0,196 0,246 0,283 0,312 0,396 0,503 0,636 0,785 0,985 1,227 1,539 1,767 2,011 t std mm 0,5 0,45 0,45 0,5 0,45 0,5 0,5 0,5 0,5 0,5 0,6 0,5 0,55 0,55 0,55 0,55 0,55 0,7 0,7 0,8 0,7 0,7 0,8 0,8 0,9 0,9 0,9 0,9 1,25 1,25 1,25 l std mm 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 2400 2400 2400 ml std kg/m 0,89 0,91 1,14 1,42 1,41 1,76 1,89 2,02 2,26 2,56 3,42 3,18 3,92 4,20 4,41 4,96 6,01 8,60 9,54 12,2 13,1 12,0 15,5 17,4 21,7 24,1 27,0 30,2 48,0 51,4 54,8

6 7 8 9 10 11 12 13 14 15 16 17 18

51

* * * * * * * * * * * * * * * * * * *

Ordering example

SR Product Dimension d Lenght l 200 3000

* With outturned stiffening corrugation

We reserve the right to make changes without prior notice

lindab | safe

Circular duct

Technical data

SR

1

[Pa/m]

2 3 4 5

pt

200

63

100 50

10

12

20 15

/s ]

80

20

25

31

10

16

d

0 0 5

[mm

0

]

0 63 0 80 0 00 10 12

50000 [l/s] 50000 100000 [m3/h]

v[ m

40

10

3 2

6 7 8 9 10 11 12 13 14 15 16 17 18

52

1

0.5

0.1 0.05 0.02 5 10 10 50 100 50 100 500 1000 500 1000 5000 10000

5000 10000

We reserve the right to make changes without prior notice

50

50

lin dab | safe

Circular duct

Technical data Special versions

We can supply ducts with the following special designs: In intermediate dimensions, see page 13. Extra tight, with nitrile rubber seal in the lock seam In other sheet metal thicknesses Extra tight, with seam seal When extremely good sealing is required in the spiral seam, the ducts can also be supplied with a special rubber seal in the seam. This seal is very effective at stopping leakage of vegetable oils and greases, and most petroleum products including white spirit. Other sheet metal thicknesses If extra stability is needed in ducts, because of high negative pressure etc., they can be supplied with thicker sheet metal than standard. Remember that the thickness increase always reduces the inner diameter. Fittings for such special ducts must be specified separately and sometimes have to be made specially. Reinforcement corrugations Ducts of 250 mm and above are normally given stiffening corrugations to increase radial stiffness.

SR

Strength

Positive pressure in case of high positive pressure, the seal moulding lips will first start to whistle. At considerably higher pressure, the joints between the ducts will be forced apart. If you manage to fix the connections very well, the ducts will burst at their seams at even higher pressure. The high pressures needed for this to happen are not relevant to ventilation installations. Negative pressure In installations with high negative pressure, there is a risk that the ducts could collapse. This phenomenon is referred to as buckling, and can suddenly happen at the weakest point in the system. Buckling wanders along the duct, which can be completely flattened. The weakest point is frequently a "transport dent" on a duct. For this reason, only use undamaged ducts in systems which are close to the critical pressure! Sealing The ability of the seal moulding to seal is different from these pressures, and is noted on page 39.

1 2 3 4 5 6 7 8 9 10 11

Collapsing pressure for duct SR Diameter Sheet metal

63 0,5 80 0,45 100 0,45 125 0,45 160 0,5 200 0,5 250 0,5 315 400 500 0,7 630 0,7 800 0,8 1000 1250 0,9 0,9

0,55 0,55

12 13 14 15

Without stiffening corrugations

0 -10 -7,2 -11,7 -20 -21,4 -30 -40 -40,4 * -50 -47,0 * -17,0 -4,3 -4,8

With stiffening corrugations

-3,2 -1,0 -0,8

-3,0

-4,0

-3,8

Negative pressure

16 17

* Collapse not achieved [kPa]

-60 63 80 100 125 160 200 250 315 400 500 630 800 1000 1250

18

We reserve the right to make changes without prior notice

53

Das könnte Ihnen auch gefallen

- 02 Circular Duct SystemsDokument42 Seiten02 Circular Duct SystemsDiki PrayogoNoch keine Bewertungen

- Barrajes Flexibes ISOLAMES EngDokument2 SeitenBarrajes Flexibes ISOLAMES EngalgotrNoch keine Bewertungen

- Cable TSJ y TSJ-N PDFDokument4 SeitenCable TSJ y TSJ-N PDFmakv12100% (1)

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDokument6 SeitenElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkNoch keine Bewertungen

- PC WireDokument7 SeitenPC Wirejupe01Noch keine Bewertungen

- Fischer CatalogDokument60 SeitenFischer CatalogAlex SihlanicNoch keine Bewertungen

- Oilfield Hoses Fittings AccembliesDokument29 SeitenOilfield Hoses Fittings Accembliesthapa786mNoch keine Bewertungen

- Cat Inglese ITALFILMDokument72 SeitenCat Inglese ITALFILMSérgio AmorimNoch keine Bewertungen

- Rotary Seals VringsDokument25 SeitenRotary Seals VringsPatrick BaridonNoch keine Bewertungen

- Mangas PDFDokument14 SeitenMangas PDFluisfer811Noch keine Bewertungen

- Upvc Pressure Pipes and FittingsDokument8 SeitenUpvc Pressure Pipes and FittingsjafarkhansfNoch keine Bewertungen

- Trellex Hose System Edit HQDokument6 SeitenTrellex Hose System Edit HQseanfsmythNoch keine Bewertungen

- Pulleys TechDokument8 SeitenPulleys TechashkansoheylNoch keine Bewertungen

- Conveyor BeltsDokument22 SeitenConveyor BeltsFavorSea Industrial Channel LimitedNoch keine Bewertungen

- StrapsDokument57 SeitenStrapsAngel Andres Oriundo OliveraNoch keine Bewertungen

- Walkway GratingDokument2 SeitenWalkway Gratingbijukoottala100% (1)

- Cast Steel and Stainless Steel Y StrainersDokument13 SeitenCast Steel and Stainless Steel Y StrainersNinad SherawalaNoch keine Bewertungen

- Rubber-Steel GasketsDokument12 SeitenRubber-Steel Gasketsgalici2002Noch keine Bewertungen

- Post Tension MultistrandDokument15 SeitenPost Tension MultistrandStephanie K ChanNoch keine Bewertungen

- KE Masterflex RubberDokument4 SeitenKE Masterflex RubberBenjamin StricklandNoch keine Bewertungen

- ETL Pressure Relief Valves Datasheet PDFDokument6 SeitenETL Pressure Relief Valves Datasheet PDFNanasaheb PatilNoch keine Bewertungen

- Series LF288A Specification SheetDokument2 SeitenSeries LF288A Specification SheetWattsNoch keine Bewertungen

- Drawing 80H30Dokument3 SeitenDrawing 80H30kpranjal15Noch keine Bewertungen

- Dextra Tie Rods Rev14 Y13M10D30Dokument10 SeitenDextra Tie Rods Rev14 Y13M10D30siva_ar100% (1)

- RT Duroid 6006 6010 Laminate Data SheetDokument2 SeitenRT Duroid 6006 6010 Laminate Data SheetSaravanakumar SermarajaNoch keine Bewertungen

- RTM AND RTM LIGHT ACCESSORY GUIDEDokument3 SeitenRTM AND RTM LIGHT ACCESSORY GUIDEThanh TruongNoch keine Bewertungen

- H1000e K FJDokument8 SeitenH1000e K FJSyarif HidayatullahNoch keine Bewertungen

- BARRAMENTO FLEXIVEL DA RITTAL Rittal White Paper The Flexible Busbar AdvantageDokument10 SeitenBARRAMENTO FLEXIVEL DA RITTAL Rittal White Paper The Flexible Busbar AdvantagedarkfacemooNoch keine Bewertungen

- Wire - Building Al FanarDokument63 SeitenWire - Building Al FanarKhaled BellegdyNoch keine Bewertungen

- Expension Joints Engineering AppliancesDokument30 SeitenExpension Joints Engineering AppliancesAcid BurnsNoch keine Bewertungen

- Style 808 Duo-Lock High Pressure Coupling: Product DescriptionDokument2 SeitenStyle 808 Duo-Lock High Pressure Coupling: Product Descriptionnrd9771Noch keine Bewertungen

- 100059s Zvlnena Tesneni (W1A, W11A, W2A ... )Dokument4 Seiten100059s Zvlnena Tesneni (W1A, W11A, W2A ... )brkmechNoch keine Bewertungen

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Dokument3 SeitenDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNoch keine Bewertungen

- D/CRCW E3: VishayDokument8 SeitenD/CRCW E3: VishayelecompinnNoch keine Bewertungen

- High performance steel anchors overviewDokument60 SeitenHigh performance steel anchors overviewAMIT GUPTANoch keine Bewertungen

- Shunt & Anti-Split Plates: For The Electrical Distribution IndustryDokument2 SeitenShunt & Anti-Split Plates: For The Electrical Distribution IndustryNhuVan NguyenNoch keine Bewertungen

- Copper Tube For HVACR ApplicationsDokument4 SeitenCopper Tube For HVACR ApplicationskabeerdossNoch keine Bewertungen

- Hot Strip Mill Product TolerancesDokument9 SeitenHot Strip Mill Product TolerancesAyman Al AnsaryNoch keine Bewertungen

- D/CRCW E3: VishayDokument8 SeitenD/CRCW E3: VishayFilipe BrendlerNoch keine Bewertungen

- FMC Weco Wing Union CatalogDokument16 SeitenFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- DSI-DYWIDAG Tie RoTie Rodsds 02 PDFDokument6 SeitenDSI-DYWIDAG Tie RoTie Rodsds 02 PDFAnonymous 4ghB3BQNoch keine Bewertungen

- Baum GMBH Assembly instructions-DIN April 2012 PDFDokument2 SeitenBaum GMBH Assembly instructions-DIN April 2012 PDFRensvanLoon1Noch keine Bewertungen

- Elastomeric Bearing PadDokument4 SeitenElastomeric Bearing PadMohammad Fikrie Bahrul Hayat100% (2)

- General Information Theory - LindabDokument27 SeitenGeneral Information Theory - LindabaudithanNoch keine Bewertungen

- Catalogues Au MyDokument28 SeitenCatalogues Au MyChu Hữu LạcNoch keine Bewertungen

- PSI Casing End Seals Installation GuideDokument10 SeitenPSI Casing End Seals Installation Guideanup_sahani100% (1)

- Construction Solutions for EngineersDokument16 SeitenConstruction Solutions for EngineersFida GNoch keine Bewertungen

- A1200 Red Thread II PipingDokument0 SeitenA1200 Red Thread II PipingjimmycabreraNoch keine Bewertungen

- Codeline, 150 PSI, Drawing - 80S15Dokument3 SeitenCodeline, 150 PSI, Drawing - 80S15RamanNegiNoch keine Bewertungen

- Elastomeric Ring Seals: Static and DynamicDokument13 SeitenElastomeric Ring Seals: Static and DynamicArnaldo BenitezNoch keine Bewertungen

- Series 774DCDA Specification SheetDokument2 SeitenSeries 774DCDA Specification SheetWattsNoch keine Bewertungen

- MeasurIT Tideflex Valves Full 0912Dokument9 SeitenMeasurIT Tideflex Valves Full 0912Lalo SepulvedaNoch keine Bewertungen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168Von EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168Noch keine Bewertungen

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosVon EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNoch keine Bewertungen

- Ielts 2013Dokument8 SeitenIelts 2013SuperSubbu2010Noch keine Bewertungen

- WKSHT Final EdDokument2 SeitenWKSHT Final EdveroguilveNoch keine Bewertungen

- VZA6E302 Sep2014LowresDokument44 SeitenVZA6E302 Sep2014LowrescosmynnsNoch keine Bewertungen

- FXSQ-P Technical Data (Tcm219-206045)Dokument30 SeitenFXSQ-P Technical Data (Tcm219-206045)Stephanie PavlidouNoch keine Bewertungen

- Aeroterma Electrica de Perete FRICO C9 9 KW 400V Fisa TehnicaDokument6 SeitenAeroterma Electrica de Perete FRICO C9 9 KW 400V Fisa TehnicacosmynnsNoch keine Bewertungen

- Calendar 2017Dokument1 SeiteCalendar 2017cosmynnsNoch keine Bewertungen

- Air Distrib CleaningDokument2 SeitenAir Distrib CleaningcosmynnsNoch keine Bewertungen

- Aquaciat HybridDokument6 SeitenAquaciat HybridcosmynnsNoch keine Bewertungen

- Schonbrunn Castle MapDokument1 SeiteSchonbrunn Castle MapcosmynnsNoch keine Bewertungen

- Tyco - Ultra Low Flow Aquamist AM30Dokument2 SeitenTyco - Ultra Low Flow Aquamist AM30cosmynnsNoch keine Bewertungen

- DKA Rsu-100 UkDokument16 SeitenDKA Rsu-100 UkcosmynnsNoch keine Bewertungen

- Cam 05 Calculation Tcm48-705084Dokument16 SeitenCam 05 Calculation Tcm48-705084Bao Kim100% (1)

- Schonbrunn Castle - Palace and Park MapDokument1 SeiteSchonbrunn Castle - Palace and Park MapcosmynnsNoch keine Bewertungen

- ODD ONE OUT - Vowel Practice: All of The VowelsDokument2 SeitenODD ONE OUT - Vowel Practice: All of The VowelscosmynnsNoch keine Bewertungen

- RT PRC022 E4 - 0912Dokument36 SeitenRT PRC022 E4 - 0912cosmynnsNoch keine Bewertungen

- A Few - Few and A Little - LittleDokument1 SeiteA Few - Few and A Little - LittlecosmynnsNoch keine Bewertungen

- 08 Roof Hoods Ads PDFDokument34 Seiten08 Roof Hoods Ads PDFkasztakatikaNoch keine Bewertungen

- Lindab - Psu - SaddleDokument3 SeitenLindab - Psu - SaddlecosmynnsNoch keine Bewertungen

- Willo General Overview 2009Dokument56 SeitenWillo General Overview 2009cosmynnsNoch keine Bewertungen

- Audio Guide 2 (Cg3511en) 07-2006Dokument54 SeitenAudio Guide 2 (Cg3511en) 07-2006Skidanje UputstavaNoch keine Bewertungen

- Multi 2,3,4 RoomsDokument1 SeiteMulti 2,3,4 RoomscosmynnsNoch keine Bewertungen

- York FW FL Fan CoilsDokument45 SeitenYork FW FL Fan CoilscosmynnsNoch keine Bewertungen

- TRANE - Parts Controls and Supplies - PRC002-E4Dokument1 SeiteTRANE - Parts Controls and Supplies - PRC002-E4cosmynnsNoch keine Bewertungen

- Seismic Joint FM 2.8Dokument1 SeiteSeismic Joint FM 2.8cosmynnsNoch keine Bewertungen

- ISO 14644 Cleanroom StandardsDokument84 SeitenISO 14644 Cleanroom StandardsDenny Simeon100% (8)

- Option Recupération ActiveDokument7 SeitenOption Recupération ActivecosmynnsNoch keine Bewertungen

- Chiller 25 KW (CH02) : Product Data SheetDokument1 SeiteChiller 25 KW (CH02) : Product Data SheetcosmynnsNoch keine Bewertungen

- Wba-S 1026Dokument2 SeitenWba-S 1026cosmynnsNoch keine Bewertungen

- KsuDokument3 SeitenKsucosmynnsNoch keine Bewertungen

- SIGMOID2K9Dokument709 SeitenSIGMOID2K9thanveermuzzuNoch keine Bewertungen

- O Repensar Da Fonoaudiologia Na Epistemologia CienDokument5 SeitenO Repensar Da Fonoaudiologia Na Epistemologia CienClaudilla L.Noch keine Bewertungen

- Diffusion Coefficient Full Report TiqaDokument19 SeitenDiffusion Coefficient Full Report TiqaprmzNoch keine Bewertungen

- Summative Test (Physics)Dokument3 SeitenSummative Test (Physics)Allen Paul GamazonNoch keine Bewertungen

- Moc3011 PDFDokument7 SeitenMoc3011 PDFAlvaro Mompi RuizNoch keine Bewertungen

- 1 Rack and PinionDokument6 Seiten1 Rack and PinionMectrosoft Creative technologyNoch keine Bewertungen

- Engineering Calculation Sheet Consulting EngineersDokument17 SeitenEngineering Calculation Sheet Consulting EngineersParthiban ArivazhaganNoch keine Bewertungen

- Venn Diagram Generator Academo - Org - Free, Interactive, EducationDokument1 SeiteVenn Diagram Generator Academo - Org - Free, Interactive, EducationChris DeBruyckereNoch keine Bewertungen

- Semiconductor: 1 PropertiesDokument9 SeitenSemiconductor: 1 PropertiesGilberto ManhattanNoch keine Bewertungen

- Topic 5 - Criticality of Homogeneous ReactorsDokument53 SeitenTopic 5 - Criticality of Homogeneous ReactorsSit LucasNoch keine Bewertungen

- Design Modification of A Mechanical Footstep Power Generator Olive KaburuDokument56 SeitenDesign Modification of A Mechanical Footstep Power Generator Olive KaburuDushyant HarneNoch keine Bewertungen

- Introduction to Solid Modeling Using SolidWorks 2012 SolidWorks Simulation TutorialDokument8 SeitenIntroduction to Solid Modeling Using SolidWorks 2012 SolidWorks Simulation TutorialAYAUWU LOVEDAYNoch keine Bewertungen

- Science Quiz BeeDokument5 SeitenScience Quiz BeeEr Win100% (1)

- Suntech STP225-20 WD 225Wp ENDokument2 SeitenSuntech STP225-20 WD 225Wp ENmax2503Noch keine Bewertungen

- KIN 335 - Biomechanics: Part 1. Reaction Board MethodDokument9 SeitenKIN 335 - Biomechanics: Part 1. Reaction Board MethodandyimoodeyNoch keine Bewertungen

- $binder 1Dokument156 Seiten$binder 1fchem11Noch keine Bewertungen

- Savi TancetDokument3 SeitenSavi TancetJasmine DavidNoch keine Bewertungen

- Programming ExercisesDokument2 SeitenProgramming ExercisesDaryl Ivan Empuerto HisolaNoch keine Bewertungen

- An Introduction To Fractional CalculusDokument29 SeitenAn Introduction To Fractional CalculusFredrik Joachim GjestlandNoch keine Bewertungen

- Rife Energy Medicine Cures DiseasesDokument5 SeitenRife Energy Medicine Cures DiseasesOna OnićNoch keine Bewertungen

- Lesson 6-4 Homework Examples 17, 21, 27Dokument2 SeitenLesson 6-4 Homework Examples 17, 21, 27Jay-anne CruzNoch keine Bewertungen

- Serial Number:1920110212668 Exam Roll Number Grade CardDokument2 SeitenSerial Number:1920110212668 Exam Roll Number Grade Cardsimran vaidNoch keine Bewertungen

- Design Charts for Bolts with Combined Shear and Tension ForcesDokument4 SeitenDesign Charts for Bolts with Combined Shear and Tension ForcescmkohNoch keine Bewertungen

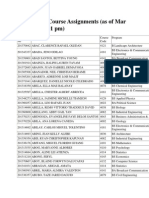

- UP Diliman Course AssignmentsDokument82 SeitenUP Diliman Course Assignmentsgamingonly_accountNoch keine Bewertungen

- X3 HydrostaticForceOnPlaneSurfaces BautistaDerwinDanielDokument18 SeitenX3 HydrostaticForceOnPlaneSurfaces BautistaDerwinDanielNadine Pascual100% (2)

- Weather ElementsDokument6 SeitenWeather ElementsFrenzie Mae Vasquez RiveraNoch keine Bewertungen

- Smart MaterialsDokument48 SeitenSmart Materialsmjrobust05Noch keine Bewertungen

- Biomechanics and Motor Control of Human Movement - Ch3Dokument37 SeitenBiomechanics and Motor Control of Human Movement - Ch3guillecabezaNoch keine Bewertungen

- Abutment Design CalculationsDokument13 SeitenAbutment Design CalculationsFitsum Abebe100% (1)

- Eurotherm 2116Dokument156 SeitenEurotherm 2116jessicrmNoch keine Bewertungen