Beruflich Dokumente

Kultur Dokumente

PDF Uj Dimensions

Hochgeladen von

Wijayanto BekasiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PDF Uj Dimensions

Hochgeladen von

Wijayanto BekasiCopyright:

Verfügbare Formate

18 Technical appendix

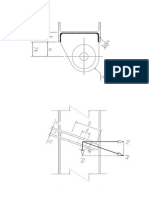

Calculating the dimensions of the universal joints G

The selection of a universal joint ist not determined exclusively by the max. torque to be transmitted. There are also other operative conditions which must be taken into account, such as impact load, angular ratios, angular velocities, etc. The diagrams presented below give approximate preliminary values for calculating the dimensions of the universal joints and contain the corresponding standard values. Figure 1 shows the power and torque values transmitted by single precision universal joints during permanent operation with a deection angle of = 10.

Note: The loads to which double universal joints are exposed may only be about 90 % of the corresponding values for single universal joints. This also applies to shaft joints.

Figure 2 shows the adjustment value to be taken into consideration for greater deflection angles. For deflection angles less than 10, e.g. between 0 to 5 you may increase the standard power value shown in figure 1 by 25%.

There are no general standard values for precision universal joints with friction bearings, for which it is possible to specify the service life, as the stress and strain to which the friction surfaces are exposed is determined by the regularity of the lubrication intervals.

Fig. 2: Adjustment value in relation to the deflection angle

Example

Given values: the power to be transmitted P = 1,5 kW speed n = 250 r.p.m. deflection angle = 22 30 adjustment value from fig. 2 n = 0,45

Calculation:

P 1,5 standard power P = = = 3,3 kW n 0,45 Figure 1 yields for n = 250 r.p.m. and 3,3 kW: shaft joint E 32 x 63 (or E 40 x 63) with the admissible torque value of M = 125 Nm.

Fig. 1: Power diagram for precision universal joints with friction bearings in accordance with DIN 808-G The universal joints are delivered without pinholes and clamping studs. The length of the clamping studs is determined by the outer diameter of the univseral joint; it must be flush when set.

19 Technical appendix

Calculating the dimensions of the universal joints W

Figure 5 shows the service life of BCOs maintenanceFigure 6 shows the adjustment value for calculating the free precision universal joints with needle bearings service life of BCOs maintenance-free precision depending on the impact factor (e.g. standard universal joints with needle bearings. value 1.5 for an electromotor drive without flexible coupling), the adjustment value for the deflection Note: The loads to which double universal joints are exposed angle and the torque value to be transmitted. may only be about 90% of the corresponding values for single universal joints. This also applies to shaft joints.

Fig. 6: Adjustment values with relation to the deflection angle fZ = impact factor (see technical questionnaire) n = adjustment value (from figure 6) M = torque value to be transmitted Mred = M x fZ x n

Example

Given values: the power to be transmitted M = 70 Nm speed n = 1400 r.p.m. service life L = 500 h deflection angle = 20 impact factor fZ = 1,5 adjustment value from fig. 6 n = 1,1 reduced torque Mred = M x fZ x n = 70 x 1,5 x 1,1 = 116 L x n = 500 x 1400 = 700 000 = 70 x 104 Figure 5 yields: universal joint E 32 x 63.

Fig. 5: Service life diagram for precision universal joints with needle bearings DIN 808-W

The universal joints are delivered without pinholes and clamping studs. The length of the clamping studs is determined by the outer diameter of the univseral joint; it must be flush when set.

20 Technical appendix

Calculating the dimensions of the universal joints bracket version

Figure 3 shows the power and torque values transmitted by single precision universal joints (bracket version) during permanent operation and with a deflection angle of = 10. Figure 4 shows the adjustment value to be taken into consideration for greater deflection angles. For deflection angles between 0 to 5 you may increase the standard power value by 25%.

Fig. 4: Adjustment values with relation to the deflection angle

Example

Given values: the power to be transmitted P = 0,540 kW speed n = 300 r.p.m. deflection angle = 30 Calculation: adjustment value from fig. 4 n = 0,45 P = 0,540 standard power P = = 1,2 kW n 0,45 Figure 3 yields for n = 300 r.p.m. and 1,2 kW a universal joint E 16 x 32 with the admissible torque value of M = 40 Nm. Fig. 3: Power diagram for precision bracket joints with friction bearings

The universal joints are delivered without pinholes and clamping studs. The length of the clamping studs is determined by the outer diameter of the univseral joint; it must be flush when set.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Tail Lifting Lug Calculation MS WordDokument11 SeitenTail Lifting Lug Calculation MS WordWijayanto BekasiNoch keine Bewertungen

- Surface Preparation & Painting Procedure r1Dokument4 SeitenSurface Preparation & Painting Procedure r1Wijayanto BekasiNoch keine Bewertungen

- Stresses in BeamDokument34 SeitenStresses in BeamWijayanto BekasiNoch keine Bewertungen

- Lifting Lug ArrangementDokument1 SeiteLifting Lug ArrangementWijayanto BekasiNoch keine Bewertungen

- Cog CalculationDokument4 SeitenCog CalculationWijayanto BekasiNoch keine Bewertungen

- Steel Beams AnalysisDokument15 SeitenSteel Beams AnalysisWijayanto BekasiNoch keine Bewertungen

- Modco Closures: Operation, Maintenance & Welding InstructionsDokument7 SeitenModco Closures: Operation, Maintenance & Welding InstructionsWijayanto BekasiNoch keine Bewertungen

- Designed by Checked by Approved by Date DateDokument1 SeiteDesigned by Checked by Approved by Date DateWijayanto BekasiNoch keine Bewertungen

- Sample Itp For VesselDokument10 SeitenSample Itp For VesselWijayanto BekasiNoch keine Bewertungen

- Nbi Vertical Agitator: Installation, Service and Maintenance InstructionsDokument20 SeitenNbi Vertical Agitator: Installation, Service and Maintenance InstructionsWijayanto BekasiNoch keine Bewertungen

- R100 Data SheetDokument1 SeiteR100 Data SheetWijayanto BekasiNoch keine Bewertungen

- Commissioning Results On Dtvv44079 S/D Dtvv44091Dokument2 SeitenCommissioning Results On Dtvv44079 S/D Dtvv44091Wijayanto BekasiNoch keine Bewertungen

- Forensic 1 MidtermDokument22 SeitenForensic 1 MidtermNezel Jade GanzanNoch keine Bewertungen

- A Non-Silver Manual (Sarah Van Keuren)Dokument119 SeitenA Non-Silver Manual (Sarah Van Keuren)Anestis AlexandridisNoch keine Bewertungen

- 7th - Term 3 - ScienceDokument106 Seiten7th - Term 3 - ScienceRiya Richard100% (1)

- Forensic PhotographyDokument143 SeitenForensic PhotographyNelo Arjay Farochelin Molo100% (1)

- Computer Vision Projective Geometry and Calibration: Professor HagerDokument67 SeitenComputer Vision Projective Geometry and Calibration: Professor Hagersab108Noch keine Bewertungen

- Astm E1165Dokument7 SeitenAstm E1165Sai FujiwaraNoch keine Bewertungen

- Pinhole Camera InformationDokument4 SeitenPinhole Camera InformationD'ferti AnggraeniNoch keine Bewertungen

- Polaroid PinholeDokument8 SeitenPolaroid Pinholehallo35mmfilmNoch keine Bewertungen

- Triple Principle Integrated: 3D Laser Scanning MicroscopeDokument36 SeitenTriple Principle Integrated: 3D Laser Scanning Microscopeaa999666aaaNoch keine Bewertungen

- 1e.beam Exapnder: Equipment & Procedure EquipmentDokument2 Seiten1e.beam Exapnder: Equipment & Procedure EquipmentaMtrinityNoch keine Bewertungen

- Science 10Dokument153 SeitenScience 10YASHVI MODINoch keine Bewertungen

- Principles of Robot Autonomy I: Robotic Sensors and Introduction To Computer VisionDokument38 SeitenPrinciples of Robot Autonomy I: Robotic Sensors and Introduction To Computer VisionratjerryNoch keine Bewertungen

- L 11 - Light, Shadows and ReflectionsDokument15 SeitenL 11 - Light, Shadows and ReflectionsChaitra KamuriNoch keine Bewertungen

- Elements of Photographic SystemsDokument61 SeitenElements of Photographic SystemsMehmet YILMAZNoch keine Bewertungen

- MODULE NA YELLOW PROFEd 104Dokument14 SeitenMODULE NA YELLOW PROFEd 104Shiella mhay FaviNoch keine Bewertungen

- Mirrors Prisms and LensesDokument624 SeitenMirrors Prisms and Lensesjamespar1992100% (1)

- LightDokument11 SeitenLightamp1279Noch keine Bewertungen

- From Pinhole To PrintDokument16 SeitenFrom Pinhole To PrintHugo Leandro Pendragons100% (5)

- Police Photography Handouts: Iii. Concept of PhotographyDokument30 SeitenPolice Photography Handouts: Iii. Concept of PhotographyDhave Hero Ubaldo Bayaw100% (2)

- 7.4, 7.5 Experiment Optical InstrutmentDokument26 Seiten7.4, 7.5 Experiment Optical InstrutmentMiNH HayatNoch keine Bewertungen

- Leonardo Da Vinci's Solution To The Problem of The Pinhole CameraDokument29 SeitenLeonardo Da Vinci's Solution To The Problem of The Pinhole CameraGorka EtxagueNoch keine Bewertungen

- Journal of Physical Security 14Dokument59 SeitenJournal of Physical Security 14Roger JohnstonNoch keine Bewertungen

- Pinhole Camera ThesisDokument7 SeitenPinhole Camera Thesisnijnoqiig100% (2)

- Cbse Questions On LightDokument5 SeitenCbse Questions On Lightjoydeep_d3232100% (1)

- Barrier of Alu FoilDokument5 SeitenBarrier of Alu FoilHOANGVUNL1988Noch keine Bewertungen

- A Brief History of Light & Photography: by Rick DobleDokument23 SeitenA Brief History of Light & Photography: by Rick Doblesilverfish67Noch keine Bewertungen

- Standard Test Method For Measurement of Focal Spots of Industrial X-Ray Tubes by Pinhole ImagingDokument7 SeitenStandard Test Method For Measurement of Focal Spots of Industrial X-Ray Tubes by Pinhole ImagingWagner Renato AraújoNoch keine Bewertungen

- Alternative Processes For The Contemporary PhotographerDokument317 SeitenAlternative Processes For The Contemporary PhotographerrenfellowNoch keine Bewertungen

- Latihan Light f1Dokument19 SeitenLatihan Light f1igori76Noch keine Bewertungen

- NCERT Summary - Light, Shadow & Reflection Notes - Study Science Class 6 - Class 6Dokument3 SeitenNCERT Summary - Light, Shadow & Reflection Notes - Study Science Class 6 - Class 6manishNoch keine Bewertungen