Beruflich Dokumente

Kultur Dokumente

Fuzzy

Hochgeladen von

sowsthikaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fuzzy

Hochgeladen von

sowsthikaCopyright:

Verfügbare Formate

Broad Analysis Of Pollutants Using Fuzzy Logic Could Guide Water Quality Improvement

Apr. 18, 2008 A fuzzy logic approach to analyzing water quality could help reduce the number of people in the developing world forced to drink polluted and diseased water for survival. Writing in a forthcoming issue of the International Journal of Environmental Technology and Management, an Inderscience publication, researchers from the University of Malaya, explain how a new approach to water quality assessment uses fuzzy logic to combine disparate problems and provide a more accurate indicator of overall quality.

Share This:

5

Rivers are often the main source of freshwater resources for citizens of developing nations. Their social well-being, economics and political development float on the availability and distribution of these freshwater resources. However, in many parts of the world dam construction, irrigation development, and flood mitigation have led to an increased incidence of diseases, such as malaria, Japanese encephalitis, schistosomiasis, lymphatic filariasis and others. Water quality assessment is an essential part for maintaining good water quality, explained by Ramani Bai Gopinath and Mohamad Rom Tamjis. They explain that a river ecosystem and the quality of the water depend mainly on pH (acidity), levels of dissolved oxygen (DO), biochemical oxygen demand, suspended solids, and the presence of chemicals including chlorides, phosphates, nitrates and sodium. The researchers have developed a data mining approach to water quality assessment that uses a Fuzzy Inference System (FIS) to extract patterns of river water quality from water sampling data. They have demonstrated the efficacy of this approach using data collected from the river Kerayong of the Klang river basin in West Malaysia. The principle of "fuzzy" analysis is based on using approximations in the calculations rather than precise values to give a broad and potentially more useful response. Moreover it allows disparate parameters to be combined in a meaningful way even though their values may not be related. Just as apples and oranges are different but all represent the quality of fruitiness, so biochemical oxygen demand and chemical concentrations, for instance, may represent a particular aspect of water quality and so can be combined through fuzzy analysis. In the present study, the fuzzy analysis of the river Kerayong reveals that it is highly polluted river with a very low water quality index, despite superficial analysis of individual parameters are necessary. This suggests that the quality of life of those relying on the river as a freshwater source could be improved considerably by addressing the individual pollution problems. "We recommend further studies on data mining capabilities of the Fuzzy Inference System using more than six indicators of water quality," the researchers conclude.

Behavior analysis of synthesis unit in fertilizer plant

Document Information: Title: Author(s): Behavior analysis of synthesis unit in fertilizer plant Harish Garg, (Department of Mathematics, Indian Institute of Technology Roorkee, Roorkee, India), S.P. Sharma, (Department of

Mathematics, Indian Institute of Technology Roorkee, Roorkee, India) Citation: Harish Garg, S.P. Sharma, (2012) "Behavior analysis of synthesis unit in fertilizer plant", International Journal of Quality & Reliability Management, Vol. 29 Iss: 2, pp.217 - 232 Availability, India, Maintainability, Maintenance reliability, Petri net,Reliability, Reliability management, Urea industry Research paper 10.1108/02656711211199928 (Permanent URL) Emerald Group Publishing Limited

Keywords:

Article type: DOI: Publisher:

Acknowledgements: The authors would like to thank the referees for providing very helpful comments and suggestions. Also, the corresponding author (Harish Garg) acknowledges the Ministry of Human Resources and Development (MHRD), India for all financial support to carry out the research work. Abstract:

Purpose The purpose of this paper is to present a technique for analyzing the behavior of an industrial system utilizing vague, imprecise, and uncertain data. The synthesis unit of a urea plant situated in northern part of India has been considered to demonstrate the proposed approach. Sensitivity analysis of system's behaviour has also been done in it. Design/methodology/approach In the proposed approach, traditional Lambda-Tau technique is used to analyze the behavior of a complex repairable synthesis unit of a fertilizer industry up to a desired degree of accuracy. This technique has been demonstrated by computing eight well-known reliability indices which are used for behaviour analysis of the considered system in a more promising way. Findings The study of analysis of reliability, availability, maintainability etc can help in increasing the production and quality of synthesis. To ensure the system performance throughout its service life, it is necessary to set up proper maintenance, planning and control which can be done after studying the variation of reliability, availability with respect to

time. Thus, it may be a more useful analysis tool to access the current system condition and involved uncertainties. The present paper suggested an approach to improve the system's performance. Originality/value The paper suggests a technique for analyzing the stochastic behavior of an industrial subsystem by computing eight well-known reliability indices in the form of fuzzy membership function. The benefits for the methodology include the ability to model and deal with highly complex system as fuzzy sets can deal easily with approximations and it helps in improving and handling the uncertainties and possibilities.

Analysis of sequential failures for assessment of reliability and safety of manufacturing systems

Angela Adamyan, David He

,

Intelligent System Modeling and Analysis Laboratory, Department of Mechanical and Industrial Engineering, The University of Illinois at Chicago, 842 West Taylor Street, 3049 ERF, Chicago, IL 60607, USA http://dx.doi.org/10.1016/S0951-8320(02)00013-3, How to Cite or Link Using DOI Permissions & Reprints

View full text

Purchase $41.95

Abstract

Assessment of reliability and safety of a manufacturing system with sequential failures is an important issue in industry, since the reliability and safety of the system depend not only on all failed states of

system components, but also on the sequence of occurrences of those failures. Methods that are currently available in sequential failure analysis always start with given sequences of the failures in the system, which is not the case in real life situations; therefore, the sequences of the failures should be identified and the probability of their occurrence should be determined. In this paper, we represent a methodology that can be used for identifying the failure sequences and assessing the probability of their occurrence in a manufacturing system. The method employs Petri net modeling and reachability trees constructed based on the Petri nets. The methodology is demonstrated on an example of an automated machining and assembly system.

Keywords

Reliability; Manufacturing systems safety; Sequential failures; Petri nets

Das könnte Ihnen auch gefallen

- Etop and Mckinsey AnalysisDokument34 SeitenEtop and Mckinsey Analysisraj0419740% (1)

- Bba 113 Notes On Production and Operations ManagementDokument29 SeitenBba 113 Notes On Production and Operations Managementsowsthika100% (1)

- Research Proposal-1Dokument28 SeitenResearch Proposal-1sowsthikaNoch keine Bewertungen

- A To Z Glossary: Shop For Cookbooks On Indian CuisineDokument18 SeitenA To Z Glossary: Shop For Cookbooks On Indian CuisinesowsthikaNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Auditing Technique: Kinds of Audit TechniquesDokument7 SeitenAuditing Technique: Kinds of Audit TechniquesQasim DodhyNoch keine Bewertungen

- Chapter Sixteen: Analysis of Variance and CovarianceDokument51 SeitenChapter Sixteen: Analysis of Variance and CovarianceSAIKRISHNA VAIDYANoch keine Bewertungen

- MTTM 2nd Year 2023-1Dokument13 SeitenMTTM 2nd Year 2023-1adiNoch keine Bewertungen

- Kemp Model Lesson Plan Template-ExampleDokument1 SeiteKemp Model Lesson Plan Template-Exampleapi-489428298100% (2)

- San Francisco St. Butuan City 8600, Region XIII Caraga, PhilippinesDokument4 SeitenSan Francisco St. Butuan City 8600, Region XIII Caraga, Philippineskuro hanabusaNoch keine Bewertungen

- CTED Lecture On Statistical ToolsDokument34 SeitenCTED Lecture On Statistical ToolsVia Bianca R. BeguiaNoch keine Bewertungen

- Lesson 4 Review of Related Lit Part 1 PDFDokument24 SeitenLesson 4 Review of Related Lit Part 1 PDFjhonel ballerasNoch keine Bewertungen

- DNB Vol34 No4 706 PDFDokument9 SeitenDNB Vol34 No4 706 PDFEmir BegagićNoch keine Bewertungen

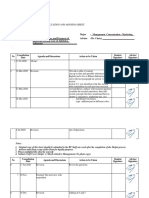

- Form Skripsi Consultation Sheet 01042021Dokument4 SeitenForm Skripsi Consultation Sheet 01042021Psikologi Cahaya NuraniNoch keine Bewertungen

- Running Head: Parental Involvement On Academic Performance 1Dokument14 SeitenRunning Head: Parental Involvement On Academic Performance 1jade tagabNoch keine Bewertungen

- Potential Soureces of Error FinalDokument3 SeitenPotential Soureces of Error FinalNishant DuttaNoch keine Bewertungen

- International Course: Epidemiology, Biostatistics & Qualitative Research MethodsDokument2 SeitenInternational Course: Epidemiology, Biostatistics & Qualitative Research MethodsAna MarianaNoch keine Bewertungen

- AS1 Digital Marketing ReportDokument5 SeitenAS1 Digital Marketing ReportNimra TahirNoch keine Bewertungen

- Anthropometric Assessment of Nutritional Status of Adolescent Girls of Indore CityDokument4 SeitenAnthropometric Assessment of Nutritional Status of Adolescent Girls of Indore CitynjmdrNoch keine Bewertungen

- Sociology PPT, 6th SemDokument9 SeitenSociology PPT, 6th SemUtkarsh ShubhamNoch keine Bewertungen

- W10 Anova Dua HalaDokument50 SeitenW10 Anova Dua HalaAnonymous hHT0iOyQAzNoch keine Bewertungen

- Statistics - How To Draw Probability Density Function in MatLabDokument3 SeitenStatistics - How To Draw Probability Density Function in MatLabyousnailNoch keine Bewertungen

- Mgsu MaDokument11 SeitenMgsu Majagjeet singhNoch keine Bewertungen

- BCA Notes FinalDokument150 SeitenBCA Notes Finalsahil vermaNoch keine Bewertungen

- Essential of Pharmacy LawDokument136 SeitenEssential of Pharmacy Lawcesp100% (3)

- Using PICO & PEO:: Developing Your Research Question and Search StrategyDokument2 SeitenUsing PICO & PEO:: Developing Your Research Question and Search StrategyDiego Marcelo Aragon Caqueo50% (2)

- The Effects of Corporate Brand Attributes On Attitudinal and Behavioural Consumer LoyaltyDokument12 SeitenThe Effects of Corporate Brand Attributes On Attitudinal and Behavioural Consumer LoyaltyjoannakamNoch keine Bewertungen

- 2004 Prenticehall S Thomas Foster Jr1595Dokument53 Seiten2004 Prenticehall S Thomas Foster Jr1595roxanna_mohammedNoch keine Bewertungen

- Autonomous Vehicles Need Experimental EthicsDokument15 SeitenAutonomous Vehicles Need Experimental EthicsbambamaNoch keine Bewertungen

- Detailed Lesson Plan (DLP) Format: Practical Research 1Dokument1 SeiteDetailed Lesson Plan (DLP) Format: Practical Research 1lenieNoch keine Bewertungen

- Review: David Huron, Voice Leading: The Science Behind A VIII + 263 Pp. ISBN: 9780262034852Dokument8 SeitenReview: David Huron, Voice Leading: The Science Behind A VIII + 263 Pp. ISBN: 9780262034852Esteban Carrasco ZehenderNoch keine Bewertungen

- How Much Does The Dallas Pain Questionnaire Score Have To Improve To Indicate That Patients With Chronic Low Back Pain Feel Better or Well?Dokument6 SeitenHow Much Does The Dallas Pain Questionnaire Score Have To Improve To Indicate That Patients With Chronic Low Back Pain Feel Better or Well?mitchNoch keine Bewertungen

- SSRC Policy FinalDokument38 SeitenSSRC Policy FinaldmahiuNoch keine Bewertungen

- 2016CFA一级强化班 数量Dokument313 Seiten2016CFA一级强化班 数量Mario XieNoch keine Bewertungen

- Camila E Mulero Morales - GRED 603 - d2 Test of Attention in Professional Counseling Presentation (Recording)Dokument19 SeitenCamila E Mulero Morales - GRED 603 - d2 Test of Attention in Professional Counseling Presentation (Recording)Kae Mulero MoralesNoch keine Bewertungen