Beruflich Dokumente

Kultur Dokumente

Commissioning Procedure For Governing System

Hochgeladen von

murugesanramasamyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Commissioning Procedure For Governing System

Hochgeladen von

murugesanramasamyCopyright:

Verfügbare Formate

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 1 of 25 DATE OF ISSUE:

NUCLEAR POWER CORPORATION OF INDIA LIMITED (A Govt o! I"#$% E"t&'('$)&* TARAPUR ATOMIC POWER PRO+ECT-3&4

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

Concurred BY

N%,& & #&)$-" NPC D&)$-" G'o.(

PREPARED /Y

C0EC1ED /Y

REVIEWED /Y

APPROVED /Y

ISSUED /Y

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 2 of 25 DATE OF ISSUE:

-T2$) (%-& $) $"t&"t$o"%334 3&!t 53%"6-

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 3 of 25 DATE OF ISSUE:

REVISION LOG Revision Details Issue No. Rev.No. Details Date Page No. Preparation Details Prepared by Concurred by Checked by Approved by Reviewed by

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 4 of 25 DATE OF ISSUE:

-T2$) (%-& $) $"t&"t$o"%334 3&!t 53%"6-

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 5 of 25 DATE OF ISSUE:

CONTENTS ! #I#!$ C!A% $ N". Cover sheet Revision log Contents '. Purpose Pre,re-uisites +.' tatus o. other syste/s +.+ yste/ Re-uire/ents +.( 0anpower re-uire/ents +.1 Re-uire/ent o. special $-uip/ents +.) Re-uire/ent o. outside agencies +.* 2a3ards 4 precautions &eneral /ethod Design intents $7pected process para/eters 9ork plan #est report .or/at Re.erence ;eri.ication process COMMISSIONING PROCEDURE ACCEPTANCE NOTE ' ( ) * PA&$ N".

+.

(. 1. ). *. :. 5. 6. '8.

5 '6 +8 +8 +' +( +1 +)

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 6 of 25 DATE OF ISSUE:

10

P.'(o)&: #he purpose o. this procedure is to provide guidelines .or co//issioning o. the governing syste/.

70 7.1

P'&-'&8.$)$t&): St%t.) o! ot2&' )4)t&,): a b c d e . g h i All erection activities should be co/pleted. "il .lushing o. the syste/ should be co/pleted. yste/ should be available with .resh oil. Pipes should be nor/ali3ed in all respects. #e/porary supports should be re/oved. A"Ps are available .or running. "il Puri.ication yste/ should be in operation. ervice air should be available near .ilters .or cleaning. Cooling water at oil cooler should be available.

7 7 S4)t&, R&8.$'&,&"t) #he .ollowing e-uip/ents and Instru/ents shall be /ade available. a< Portable vacuu/ pu/p one No. b< 2ydraulic pressure pu/p one No. c< tandard pressure gauges with an accuracy o. 8.'kg=c/+ '8 kg=c/+ 1 Nos. > 8 ?+8 kg=c/+ ' Nos. > 8 ? 18 kg=c/+ ' Nos d< tandard vacuu/ gauge range 8 ? :*8 // 2g. e< Dial gauge with 0agnetic Base 8,'8 // one No. .< Depth gauge one No. range 8,)8 // g< lip gauges Bo7 one No. h< @iler gauge 8.8) to ' // ' et. i< Di..ent si3es o. spanner set Adouble end< B< Ring spanner ( // to +: // one set. k< Allen Cey one set ( // to '8 //. l< crewdriver s/all to big one set. /<;oltage inBection test kit one No. n< 0ulti/eter, one No.

range 8,

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 7 of 25 DATE OF ISSUE:

o< Digital speed indicator, one No. 8,1888 rp/ range. 7 3 M%"(o9&' '&8.$'&,&"t): Co//issioning tea/ o. /echanicalD electrical 4 C4I engineers 4 supporting /anpower. 7 4 R&8.$'&,&"t o! )(&:$%3 E8.$(,&"t): A. b. &. *. 1000V MEGGER D g !a" M#"! $e!e% C"a$'(o) $e!e% M "" (a$'e%e +o#%&e

7 ; R&8.$'&,&"t o! o.t)$#& %-&":$&) Nil 7 < 0%=%'#) & ('&:%.t$o") #he hydraulic syste/s o. governing syste/ are e-uipped with oil storing accu/ulators. !oosening or tightening o. any /echanical ite/ should be done a.ter depressuri3ation 4 draining o. the syste/. A telephone should be available near by and the telephone nu/bers o. hospitalD a/bulance and .ire brigade is displayed. 9hile testing and adBusting the !P Bypass 4 governing syste/s no insulation work shall be allowed. @ire .ighting e-uip/ents shall be /ade available. #he operating personnel shall be aware o. the procedure. Debris in and around oil syste/s and 0"# .loor to be re/oved. Approach= tair Case=Plat.or/ wherever re-uired are /ade available. ign boards to be displayed at strategic location to indicate that "il yste/ is charged and oil pu/ps are E"NF.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page , of 25 DATE OF ISSUE:

30

G&"&'%3 ,&t2o#

Check the co/pletion o. erection as per the design .low sheets and drawings. Check the co/pletion o. e-uip/ents and supports in all oil pipe syste/s. Check the N+ pressure in the accu/ulators. 0ake up N+ i. re-uired. AN+ pressureG(.8 bar.,2yd rack .or C D; controller.2P syste/GbarD !P syste/ prG1.) bar< Check whether the test valves o. 2P stop valves 0AH 1: AA +'' ? +'+ are kept opened .ully. Check whether the isolating valve in $2C circuit in 2P secondary oil is closed 0AH 1) AA )8+ 4 0AH 1) AA)8' is open while setting the hydraulic controller. Close the trip oil line,isolating valve 0AH )' AA )+'D )++D )+1D )+)D )+:D )+5D )(8D )('D)(*D)(5 o. e7traction NR; test valves 0AH )' AA 81'D and 81+D811D81)D81:D815D8)8D8)'D8)*D8)5. @i7 a dial gauge 8,'8 // underneath bellow CA 86 in the hydraulic speed &overnor 0AH 1* By 88'. @i7 three standard gauges in Au7iliary secondary oil 4 2P secondary oil lines. A8,5 kg=c/+ to read upto 8.' kg=c/+ accuracy<. "pen the top cover o. 2ydraulic a/pli.ier 0AH 1) By 8'' to /easure the power piston CA 85 li.t. $nsure that the Boiler stop valve is .ully closed and the /ain stea/ line is not charged with stea/. $nsure starting device is in closed condition 4 li/it switch 1:C&88'C is operated. Ceep the speeder gear in /a7i/u/ set positionsDAnot /andatory<. Check whether oil pu/p is running.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page - of 25 DATE OF ISSUE:

0aintain oil te/perature in oil tank around )88 C = ))8 C. $nsure that the /ain trip valve is in reset conditions. witch o.. A#R panel supplyD so that hydraulic governor can be checked when boiler is not in service. Record the .ollowing pressure in the rack. Control oil pressure tart up oil pressure Au7. tart up oil pressure

#rip oil pressure Au7. #rip oil pressure $nsure that the respective governor characteristics are used while setting the governor. ADrg No.',''188,86+88 4 ','+58886(88< Procedure .or checking and setting o. 2ydraulic &overnor. Note down the initial reading o. starting device when the starting device is in .ull closed condition. "perate starting device 0AH 1* BY 88' gradually .ro/ 0ini/u/ to 0a7i/u/ position and carry out the .ollowing checks. Check whether the start up and Au7iliary start up oil pressure drops. "perate the starting device gradually and increase the Au7iliary secondary oil pressure to +.( kg=c/+ and note down 2P secondary oil pressure. 9hen starting device is .ully openedD note down the starting device li.t. #he li.t should be +1.)// and au7iliary secondary oil pressure should be 1.+ kg=c/+ or above.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 10 of 25 DATE OF ISSUE:

I. the au7. econdary oil pressure is not obtainedD adBust Au7iliary .ollow up piston CA 85 which is in service o. 0AH 1* By 88' to obtain au7. econdary oil pressure o. 1.+ kg=c/+ and aboveD when starting device is .ully opened condition. Note down the 2P secondary oil pressure corresponding to 1.+ kg=c/ + o. Au7iliary secondary oil pressure. Bring back the starting device gradually towards the closing position and check the trip point o. au7. econdary oil pressure. #he trip point should be around +.' kg=c/+ appro7i/ately. At least under +.( kg=c/+. NoteI #rip point o. Au7iliary .ollow up piston is the pressure at which au7iliary secondary oil pressure suddenly .alls. Bring back the starting device to .ully closed position. $nsure the starting device is in closed condition. @i7 the dial gauge below the bellow and adBust it to read 3ero //. Note down the initial reading o. power piston CA 85 o. 0AH 1) By 8'' by a depth gauge. Note down the starting device initial readings. "perate the starting device gradually to open position till the au7iliary secondary oil pressure increases to +.( kg=c/+. At +.( kg=c/+ o. Au7iliary secondary oil pressure check whether the 2P secondary oil pressure is (.8 kg=c/+. I. the value is not achievedD adBust the .ollow up pistons CA 8' o. 0AH 1) By 8'' o. 2P secondary oil pressure e-ually. Check the li.t o. power piston CA 85 o. 0AH 1) By 8'' is around * to : // Aappro7.<D when the 2P secondary oil pressure is around (.8 kg=c/ +. I. the value is not achievedD adBust the start up opening o. pilot valve CA 8: o. 0AH 1) By 8''. Note down the values o. .ollowingsI ,

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 11 of 25 DATE OF ISSUE:

tarting device travel. !i.t o. the bellow. Power piston li.t o. 2ydraulic controller. Au7. econdary oil pressureD 2P secondary oil pressure Increase the Au7iliary secondary oil pressure to 1.+ kg=c/ + and check whether 2P secondary oil pressure reaches ).8 kg=c/+. I. the value is not achievedD adBust the proportionality adBuster CA 86 o. 0AH 1) By 8'' to get 2P secondary oil pressure o. ).8 kg=c/ + when au7iliary secondary oil pressure is around 1.+ kg=c/ +. Check by closing the isolating valve 0AH 1' AA )8'D)8+ 4)') o. speed control rack and note at what pressure o. trip oilD #ripping device 0AH )' AA 88*D 0AH )' AA 88) and e/ergency trip valve 0AH )+ AA 88) trips suddenly. #rip device and e/ergency trip valve should trip at ( A+.6 J 8.'< bar o. trip oil pressure. A.ter checking and ensuring that trip devices and e/ergency trip valve trips at ( barsD bring down starting device .ro/ open position to closed position. "perate the starting device .ro/ closed position and once again check at +.( kg=c/+ o. Au7iliary secondary oil pressureD the 2P secondary oil pressure is (.8 kg=c/+. Increase the au7iliary secondary oil pressure in steps o. and note down the .ollowing. 2P secondary oil pressure. Power Piston li.t o. 2ydraulic converter. tarting device travel. Check that a closing and opening reserve o. (.) //D is available .or power piston CA 85 2ydraulic A/pli.ier 0AH 1) By 8''. 8.+ kg=c/ +

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 12 of 25 DATE OF ISSUE:

Check the bellow travel CA 86 o. 0AH 1* By 88' between au7iliary secondary oil pressure o. +.( to 1.+ kg=c/+D should be appro7. ) //. Check the total travel o. A/pli.ier power piston. It should be )8 // appro7i/atelyD .ro/ .ully closed position to .ully open condition o. starting device 0AH 1: By 88'. Plot the .ollowing curve. Power piston li.t versus Au7iliary secondary oil pressure. Bellow li.t versus au7iliary secondary oil pressure. Bellow li.t versus 2P secondary oil pressure. Bring the starting device to /ini/u/ positionD to calibrate 2P control valves. AdBust the local position trans/itter to indicate 3ero // .or 2P control valves. Bring the starting device to a position where 2P secondary oil pressure is (.8 kg=c/+. AdBust the start o. opening o. 2P control valvesD Bust to open at (.8 kg=c/+ o. 2P secondary oil pressure. Increase the Au7iliary oil pressures in steps o. 8.+ kg=c/ + and note down the .ollowing upto the /a7i/u/ position o. starting device. 2P secondary oil pressure. 2P control valve li.t. Plot the curve .or the .ollowing. 2P secondary oil pressure versus 2P control valve li.t. I. the li.ts o. control valves are not co/ing e-ual adBust the .ulcru/ point o. lever .eed back linkage as shown in "40 /anual.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 13 of 25 DATE OF ISSUE:

"pen the test valve o. 2P stop valve .ully and check whether stop valve opens .ully. @ully close the test valves o. 2P stop valve and check whether the stop valve closes .ully. $nsure .ull li.t o. 2P stop valves 4 co/pare with the design values. Now open 2P stop valve by opening the test valve .ully and ensure that the stop valve has opened .ully. Note down at what trip oil pressure 2P stop valve suddenly closes. Bring back the starting device to .ull close condition. Bring back the starting device to closed position. Check the dial gauge below the bellow is set at 3ero. Note down the intial reading o. starting device. "pen gradually the starting device .ro/ .ully closed position to .ully open position and note down the .ollowing. Bellow li.t. Au7iliary secondary oil pressure. 2P secondary oil pressure. tarting device travel. Plot the .ollowing curve Bellow travel versus Au7iliary secondary oil pressure. Bellow travel versus 2P secondary oil pressure. During the actuation o. load shed relays 0AH 1* AA8'' 4 8'+ check whether Au7. econdary oil pressure drops down to 3ero and co/es backD to the value at which the load shedding relay was actuated.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 14 of 25 DATE OF ISSUE:

witch on the A#R

supply.

Check the 0ain trip valve trips i//ediately and all the stop valves and control valves closes i//ediately. Check the Au7iliary secondary oil pressureD 2P secondary oil pressureD trip oil pressure and Au7iliary trips oil pressure reads 3ero. witch o.. A#R panel supply.

I"$t$%3 :2&:6) to 5& :%''$&# o.t 5&!o'& )&tt$"- o! E3&:t'o-04#'%.3$: Co"v&'t&' "pen the isolating valves 0AH 1) AA )8+ in 2P secondary oil line .ro/ $2CD which was keptD closed while checking the hydraulic controller. Ceep the starting device 0AH 1: By 88' in /a7i/u/ position 4 close 0AH 1)AA)8'. $nsure that the control oil line isolating valves 0AH 1+ AA *'+ is kept opened. $nsure that au7 secondary oil line,isolating valve 0AH 1* AA )8+ is kept opened. $nsure a pressure gauge 8 to 5 kg=c/ + in the pressure gauge point provided be.ore $2C 0AH 1) By 88' in au7 sec oil line. P'o:&#.'& !o' :2&:6$"- %"# )&tt$"- o! E0C @eed through set point voltageD a .i7ed voltage in co,ordination with C 4 I $ngineer. Check whether the voltage in /oving coil 0AH 1) C& 88' # is around /inus ' volts. #he $-uilibriu/ voltage should be between /inus 5 volts to /inus '.+ volts.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 15 of 25 DATE OF ISSUE:

I. it is notD adBust the /oving coil by loosening the three locking screws to such a position where the e-uilibriu/ voltage is around /inus ' volt. A.ter adBustingD .eed 3ero volt through set point and note down the power piston li.t. A0ini/u/ reading< @eed '8 volts through set point voltage and note down the power piston li.t. A0a7. reading< #he di..erence in li.t between /a7i/u/ and /ini/u/ li.t should be appro7i/ately )8//. ;ary the controller .ro/ /ini/u/ to /a7i/u/ position and note down the output o. Collins II and I in the /ini/u/ and /a7i/u/ position. #he Collins I and II out put should be ?:.); to J:.);. AdBust the Collins 0AH 1) C& 88'AD 0AH 1) C& 88'C to get this voltageD i. it is not achieved. Increase the set point voltage and hold the power piston li.t CA 85 o. $2C 0AH 1) By 88' about * to :// as obtained in 2ydraulic &overnor setting. Check the 2P secondary oil pressureD and adBust the .our .ollow up pistons CA 8' o. $2C 0AH 1) By 88' e-ually to get 2P secondary oil pressure o. (.8 kg=c/+ when power piston li.t is * to :// as obtained in 2ydraulic &overning setting. Increase set point voltage and hold the 2P secondary oil pressure at (.+1 kg=c/+. Increase the set point voltage in steps on one volt and note down Collins out put I and II and power piston li.t. Check whether the 2P secondary oil pressure obtained is e-ual to the hydraulic governor characteristics set earlier. $nsure by plotting the curveD that a closing and opening reserve o. ( to ) // is available .or power piston CA 85 o. $2C 0AH 1) By 88'.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 16 of 25 DATE OF ISSUE:

$nsure the start o. opening o. 2P control valves re/ains at (.8 kg=c/ + o. 2P secondary oil pressuresD as set earlier during hydraulic controller adBust/ent. Check and ensure that the 2P control valves open with respect to 2P secondary oil pressure as per the governor characteristicsD .ro/ .ull close to .ull open position. ADrg No. ',''188,86+88< Plot the .ollowing curves. et point voltage versus Collins I and II voltage E3&:t'$:%3 :%3$5'%t$o" >o5 )2%33 5& t%6&" .( $nsure the .ollowing settings in coordination with C4I = electrical $ngineers. $nsure the starting device percentage position at control roo/ indication .ro/ 8 to '88K /atches with .ull close to .ull open position. AdBust the .our nu/ber o. li/it switches provided on the starting device .or 'KD 1+KD )5K and '88K 0AH 1: C&88'CD'DD'@ 4 'B respectively o. starting device opening. $nsure the speeder gear percentage position at control .ro/ indicationD .ro/ 8 to '88K /atches with .ull close to .ull open position. AdBust the li/it switches in .ull open direction and .ull close direction .or o. 2P stop valves and IP stop valves. $nsure the open and close indication is appearing .or all the stop valve at control roo/. AdBust the percentages position o. the control valves o. 2P in their respective position indicators. $nsure the local scale indicator /ounted on the body o. valves in the .ully open and .ully closed directions. Correct the scale i. re-uired o. 2P control

$nsure that the potentio/eter .or e7traction valves are indicating the valve opening position is calibrated.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 17 of 25 DATE OF ISSUE:

$nsure the e7traction NR; solenoid 0AH )' AA 8+'D 8++D 8+1D 8+)D 8+:D 8+5D 8(8D8('D8(* 4 8(5 indication at control roo/ .or energi3ed and de, energised condition. CONDUCT T0E FOLLOWING C0E1S AT 3000 RPM Check whether the turbine speed is e7actly (888 rp/. Carry out oil inBection tests #he actuation o. over speed bolt is indicated on the test rack by la/ps and can be observed by the actuation o. li/it switches 0AH '8 C& 88' J 88+D provided on the !2 o. .ront bearing pedestal. Note down the test oil pressure at which over speedD bolt nu/ber one co/es out and over speed bolt nu/ber two co/es out. Repeat the test two to three ti/es and check whether test oil pressure co/es to a steady valve. #esting o. :K regulation o. 2ydraulic &overnor. Check the /achine is running on electro hydraulic or 2ydraulic. I. it is running on $lectro 2ydraulic change over to 2ydraulic by closing the isolating valve Ain the secondary line to $2C,0AH 1) AA )8+<. $nsure the starting device in /a7i/u/ position 4 control on speeder gear. Increase the speeder gear to .ull open condition and check the speed increases to (+'8 rp/ at .ully open condition. I. the speed is not achievedD loosen the lock nut and increase the co/pression o. spring o. hydraulic speed governorD to get the re-uired speed. A.ter getting :K o. rated speedD at speeder gear and starting device in /a7i/u/ positionD lockD the lock nutD o. 2ydraulic speed governor. Actual over speed #est '') J8.) K o. rated speed.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 1, of 25 DATE OF ISSUE:

$nsure be.ore carrying out actual over speed testD the both over speed governors are operative by conducting oil inBection test as e7plained above $nsure that all speed indicators and recorders are indicating the sa/e speed when the /achine is at (888 rp/ and at (+'8 rp/. $nsure that turbine is running at a speed o. (+'8 rp/ with starting device and speeder gear in /a7i/u/ position. Press continuously the over speed testing lever provided in the start and load li/iting device 0AH 1* by 88'D by watching the speed indication. $nsure the speed raise is steady and the /achine trips at Aappro7. '') J8.) K o. rated speed< by the actuation o. over speed governors. NoteI Release the lever i. the over speed governor is not acting at '') J8.) K o. rated speed. AdBust the over speed governor bolt to act '') J8.) K o. rated speed. Record the speed at which over speed governors ' or + acts. A.ter trip out when /achine reaches (888 rp/D note down the coasting down ti/e .ro/ (888 rp/D to turning gear speed at '88,rp/ interval. Bring back the /achine to the rated speed .or .urther checks.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 1- of 25 DATE OF ISSUE:

40

D&)$-" $"t&"t):

D&)$-" o'$!$:&): 0AH 0AH 0AH 0AH 0AH 0AH 0AH 0AH 0AH 0AH 0AH 1) 1) 1) 1) 1* 1* 1* 1* 15 15 1+ BP BP BP BP BP BP BP BP BP BP BP 88' 88+ 88( 881 881 88) 88' 88+ 88' 8++ 88' Dia Dia Dia Dia Dia Dia Dia Dia Dia Dia Dia 1.) 1.) 1.) 1.) (.) (.) 1.8 1.8 ).) ).) +.) %PP!Y @"!!"9 %P PI #"N B!"CC %PP!Y @"!!"9 %P PI #"N B!"CC %PP!Y @"!!"9 %P PI #"N B!"CC %PP!Y @"!!"9 %P PI #"N B!"CC %PP!Y $!$C#.2YDR C"N;$R#$R %PP!Y $!$C#.2YDR C"N;$R#$R %PP!Y A%H $C"NDARY "I! %PP!Y A%H $C"NDARY "I! DRAIN #RIP D$;IC$ DRAIN #RIP D$;IC$ %PP!Y B$@"R$ "!$N"ID ;A!;$ #AR# %P "I! ;$N# PRI0ARY "I!

A%H

0AH 11 BP 88'

Dia '.)

Proportional rangeG)J8.+ K 2PC; 0 li.tG'6) // $ ; trip pressureG( J 8.( bar #rip pressure .or #rip devicesG+.6J 8.' bar " bolts optdG'')KJ8.)K Accu/ulators,2P syste/ charging pressureG+1 bar at +8 deg Accu/ulators,!P syste/ charging pressureG1.) bar at +8 deg AdBust/ents o. !#. witchesI 0AH 1: C& 88'B G '88KG+1.) // 0AH 1: C& 88'C G 8KG8 // 0AH 1: C& 88'D G 1+KG'8.61 // 0AH 1: C& 88'@ G )5KG'1.+' // P$$D$R &$AR "%#G:K

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 20 of 25 DATE OF ISSUE:

;0

E?(&:t&# ('o:&)) (%'%,&t&')

D&)$-" '&8.$'&,&"t) !o' )&tt$"- 04# -ov&'"o' N '. +. (. 1. ). *. :. 5. 6. '8. ''. <0 Bellow !i.t 8 8.)'5 ' '.)( +.8 +.) (.8 (.+5 (.) (.: 1.' Wo'6 (3%": a b c Co//issioning o. hydraulic governor Co//issioning o. electro,hydraulic governor Co//issioning o. syste/ in dyna/ic conditions. Au7 ec. "il Pressure +.( +.)1 +.:* (.8' (.++ (.1* (.*6 (.5+ (.6+ 1.8+ 1.+ econdary oil pressure (.8 (.+) (.) (.:1 (.65 1.++ 1.1* 1.*8 1.: 1.5 ).8 Control valve li.t 8 ''.) +( () 1) )6 :* 6' ''+ '18 '6)

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 21 of 25 DATE OF ISSUE:

@0

T&)t '&(o't !o',%t

(A* Fo' 04# Gov&'"o': 2ydraulic conveyor Below li.t # Device 2P "P

0easured Calculated 0easured Calculated 0easured Calculated

(/* Fo' E3&:t'o 04# Gov&'"o':

;olt

CollinFs I

CollinFs II

"P 2P

$2C K

8 ' + ( 1 ) * :

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 22 of 25 DATE OF ISSUE:

5 6 '8 (.11* *.'): :.(:8

(C* Fo' v%3v&): N Bellow !i.t Au7 ec. "il Pressure econdary oil pressure Control valve li.t

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 23 of 25 DATE OF ISSUE:

A0

R&!&'&":& a. #urbine "40 /anual b. Drawing no. ',''188,86+88

B 0 V&'$!$:%t$o" ('o:&)) ;eri.ication points are included in 1.8 general /ethods ;eri.ication re-uire/ents, all .unctional re-uire/ents have been listed in general /ethod. Also please re.er Drawing no. ',''188, 86+88. 10 0 L$)t o! %""&?.'& Drawing no. 1-11400-09200(Please refer supplied drg)

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 24 of 25 DATE OF ISSUE:

APPENDIX VERIFICATION TABLE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

COMMISSIONING PROCEDURE NO..................................

S/. NO

ACTIVIT0 VERI1IED

ACCEPTANCE CRITERIA

VERI10ING AGENC0

CERTI1ICATION 20 VERI10ING AGENC0 PROCEDURE VERI1ICATION INSPECTION 3ITNESS 1UNCTION (A/ TEST RESU/T VERI1ICA (TION GENERA/ REMAR4S

P" %efe% 4.0

P" %efe% 4.0

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

PROCEDURE NO: 3&4ISSUE REV NO:0 NO:01 Page 25 of 25 DATE OF ISSUE:

ANNEXURE NUCLEAR POWER CORPORATION OF INDIA LIMITED (A Govt. of India Ente ! i"e# TARAPUR ATOMIC POWER PRO$ECT%&'( COMMI))IONING PROCEDURE ACCEPTANCE NOTE Co)!%a&!o% &o$$ ++ o) )g '%o&e*#%e )#$be% ........................... fo% !5e &o$$ ++ o) )g of GOVERNING SYSTEM +#b$ !!e* b6 27E/ #)*e% !5e &o)!%a&! )#$be% .............. + %e&e 8e* a)* fo#)* &o)fo%$ )g !o !5e %e9# %e$e)! of NPCI/ +'e& f &a! o)+ : No%$+ : 5e)&e a&&e'!e*.

Co$$ ++ o) )g '%o&e*#%e )#$be%; Co$$ ++ o) )g '%o&e*#%e ! !"e;

.....................................

COMMISSIONING PROCEDURE FOR GOVERNING SYSTEM

NAME ' DE)IGNATION Re8 e<e* b6; Co)&e%)e* Co$$g. E)g+.= S%.Co$$g. E)g+= SME+ Co)&e%)e* ENC+=S#'!*+. Co)&#%%e* b6; NPC De+ g) G%o#'

)IGNATURE

A''%o8e* b6;

Das könnte Ihnen auch gefallen

- Barring GearDokument30 SeitenBarring GearJeffrey MuellerNoch keine Bewertungen

- Procedure For Governing Oil SystemDokument29 SeitenProcedure For Governing Oil SystemLakshmi NarayanNoch keine Bewertungen

- 105 Transformer Installation Instructions enDokument3 Seiten105 Transformer Installation Instructions enSujit AdhyaNoch keine Bewertungen

- Kwu Governing SystemDokument25 SeitenKwu Governing SystemLakshmi Narayan100% (2)

- Gas Turbine StartupDokument9 SeitenGas Turbine Startuppawangwl100% (2)

- Cold Startup 1Dokument51 SeitenCold Startup 1Vel MuruganNoch keine Bewertungen

- Gas Turbine Lecture (LOGICS)Dokument8 SeitenGas Turbine Lecture (LOGICS)Vikas OzaNoch keine Bewertungen

- D6M Test Hydraulic SystemDokument21 SeitenD6M Test Hydraulic SystemTeresa Marina Peralta100% (4)

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDokument16 SeitenGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNoch keine Bewertungen

- TC Operation ManualDokument49 SeitenTC Operation ManualGleb Vospitanyuk100% (5)

- TACH DWELL Tester Instructions PDFDokument7 SeitenTACH DWELL Tester Instructions PDFVinay Mathad100% (1)

- Cat D-3600sek PDFDokument2 SeitenCat D-3600sek PDFMargaret DaughertyNoch keine Bewertungen

- BFP TDDokument22 SeitenBFP TDJackSparrow8650% (2)

- Authority Prepared by Reviewed L1 Reviewed L2 Approved byDokument33 SeitenAuthority Prepared by Reviewed L1 Reviewed L2 Approved byASHXQ39WNoch keine Bewertungen

- APHDokument3 SeitenAPHMallinatha PNNoch keine Bewertungen

- R32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettDokument580 SeitenR32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettNick Viccajee100% (1)

- Air Compressor House: Guide Book For Utility Operation, Section 9: Air Compressor Page 1 of 12Dokument12 SeitenAir Compressor House: Guide Book For Utility Operation, Section 9: Air Compressor Page 1 of 12joymotiNoch keine Bewertungen

- Boiler ProtectionDokument36 SeitenBoiler ProtectionAshish Lanjewar100% (1)

- Remote Control Unit Manual BookDokument21 SeitenRemote Control Unit Manual BookIgor Ungur100% (1)

- CPT-0013 Commissioning Procedure of Boiler Ignition SystemDokument7 SeitenCPT-0013 Commissioning Procedure of Boiler Ignition SystemJ Bagien100% (1)

- G T Start Up ProcedureDokument11 SeitenG T Start Up ProcedureJJ100% (1)

- Cessna 172 Skyhawk, Owners Manual, (English) Manual Del RioDokument48 SeitenCessna 172 Skyhawk, Owners Manual, (English) Manual Del Riofedor andres100% (1)

- Boiler Emergency Control ProcedureDokument34 SeitenBoiler Emergency Control ProcedureAshish LanjewarNoch keine Bewertungen

- Group 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDokument7 SeitenGroup 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNoch keine Bewertungen

- 2f EngineDokument138 Seiten2f Engineryaneatsstringcheese50% (2)

- Air in Fuel - TestDokument4 SeitenAir in Fuel - TestKopyuk Kopyuk Kopyuk KopyukNoch keine Bewertungen

- SOP - ID FanDokument2 SeitenSOP - ID Fanarvidkumar87060Noch keine Bewertungen

- D3705Dokument6 SeitenD3705rimi7alNoch keine Bewertungen

- Commissioning Checklist PDFDokument74 SeitenCommissioning Checklist PDFaanouar77Noch keine Bewertungen

- Experiment Internal Combustion Engine Laboratory MAE 650:431 Mechanical Engineering LaboratoryDokument8 SeitenExperiment Internal Combustion Engine Laboratory MAE 650:431 Mechanical Engineering Laboratoryjack jackNoch keine Bewertungen

- 777DDokument3 Seiten777DsuperbludnikNoch keine Bewertungen

- LC HDP 1100 D2数显喷油器13版说明书Dokument22 SeitenLC HDP 1100 D2数显喷油器13版说明书DariusNoch keine Bewertungen

- Air Pre HeaterDokument7 SeitenAir Pre HeaterLakshminarayanNoch keine Bewertungen

- Standard ChecklistscorrectedDokument51 SeitenStandard Checklistscorrectedmohan_krishna372Noch keine Bewertungen

- Energy Conversion Lab Manual NewDokument50 SeitenEnergy Conversion Lab Manual NewRavi TejNoch keine Bewertungen

- SEBU6965-06 Before StartDokument6 SeitenSEBU6965-06 Before StartLUIZ GUSTAVONoch keine Bewertungen

- Group 3 Tests and AdjustmentsDokument7 SeitenGroup 3 Tests and Adjustmentsmãi bên emNoch keine Bewertungen

- PD-808 Flight ManualDokument49 SeitenPD-808 Flight Manualscribd4uallNoch keine Bewertungen

- 9-GTG Hydraulic & Lift Oil Systems Normalization & Start UpDokument2 Seiten9-GTG Hydraulic & Lift Oil Systems Normalization & Start UpSarah CohenNoch keine Bewertungen

- Turbine SopDokument8 SeitenTurbine SopDominic Daniel100% (1)

- Governing SystemDokument24 SeitenGoverning Systemlrpatra100% (1)

- SuzDokument54 SeitenSuzBranko Ferenčak100% (1)

- Purifier Optimization Lab 2 - Version 1Dokument8 SeitenPurifier Optimization Lab 2 - Version 1papaki2Noch keine Bewertungen

- Brake Accumulator Test and ChargeDokument8 SeitenBrake Accumulator Test and ChargeBarzola Soto Omar100% (1)

- Halliburton: MO# OK F Fail (Create RPM Order) N/A Not ApplicableDokument4 SeitenHalliburton: MO# OK F Fail (Create RPM Order) N/A Not ApplicableKhalfan Al HabsiNoch keine Bewertungen

- Motor C6.6 Caterpillar Prueba de AireDokument4 SeitenMotor C6.6 Caterpillar Prueba de AiremanuelNoch keine Bewertungen

- Seal Oil FlushingDokument21 SeitenSeal Oil FlushingSam50% (2)

- 3306 Industrial Engine 64Z05381-UP (SEBP1989 - 33) - Sistemas y ComponentesDokument15 Seiten3306 Industrial Engine 64Z05381-UP (SEBP1989 - 33) - Sistemas y ComponentesLynda Carroll100% (2)

- Unit Start UpDokument8 SeitenUnit Start UpDebabrata TantubaiNoch keine Bewertungen

- Caterpillar 236B-246B-252B Y 262BDokument22 SeitenCaterpillar 236B-246B-252B Y 262BVictor Montesdeoca100% (1)

- Operation Procedures For MDBFPDokument7 SeitenOperation Procedures For MDBFPJackSparrow86100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesVon EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNoch keine Bewertungen

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SVon EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNoch keine Bewertungen

- Major Process Equipment Maintenance and RepairVon EverandMajor Process Equipment Maintenance and RepairBewertung: 4 von 5 Sternen4/5 (4)

- Advanced Temperature Measurement and Control, Second EditionVon EverandAdvanced Temperature Measurement and Control, Second EditionNoch keine Bewertungen

- GT Gen Trip Logic PDFDokument1 SeiteGT Gen Trip Logic PDFmurugesanramasamyNoch keine Bewertungen

- Wedding Card WordsDokument4 SeitenWedding Card WordsmurugesanramasamyNoch keine Bewertungen

- STG Gen Trip Logic PDFDokument1 SeiteSTG Gen Trip Logic PDFmurugesanramasamyNoch keine Bewertungen

- Principle of Combustion PDFDokument6 SeitenPrinciple of Combustion PDFmurugesanramasamyNoch keine Bewertungen

- Maths Question Paper For Class 4Dokument5 SeitenMaths Question Paper For Class 4murugesanramasamyNoch keine Bewertungen

- Treating Migraines: More Ways To Fight The PainDokument2 SeitenTreating Migraines: More Ways To Fight The PainmurugesanramasamyNoch keine Bewertungen

- 1 ADokument11 Seiten1 AmurugesanramasamyNoch keine Bewertungen

- Engineering Economics and Cost Analysis FormulaeDokument2 SeitenEngineering Economics and Cost Analysis FormulaemurugesanramasamyNoch keine Bewertungen

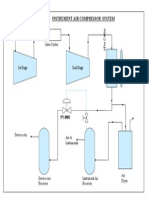

- Instrument Air Compressor System: Air From Atmosphere Inter CoolerDokument1 SeiteInstrument Air Compressor System: Air From Atmosphere Inter CoolermurugesanramasamyNoch keine Bewertungen

- OHSAS 18001 Awareness FAQDokument4 SeitenOHSAS 18001 Awareness FAQmurugesanramasamyNoch keine Bewertungen

- The Indian Mining Sector: Effects On The Environment & FDI InflowsDokument10 SeitenThe Indian Mining Sector: Effects On The Environment & FDI InflowsMehul MandanakaNoch keine Bewertungen

- Market AnalysisDokument4 SeitenMarket AnalysisSaniya CharaniyaNoch keine Bewertungen

- Hopeless PlacesDokument1.304 SeitenHopeless Placesmoreblessingmarvellous659Noch keine Bewertungen

- G.S 5Dokument2 SeitenG.S 5Jamsher BalochNoch keine Bewertungen

- Considerations For Impeller Trimming - Empowering Pumps and EquipmentDokument8 SeitenConsiderations For Impeller Trimming - Empowering Pumps and Equipment김기준Noch keine Bewertungen

- CBSE DetailsDokument6 SeitenCBSE DetailsNARESH KUMARNoch keine Bewertungen

- Module-4 (PDFDrive)Dokument67 SeitenModule-4 (PDFDrive)Divya priya KNoch keine Bewertungen

- BC-6000 Installation Guide V7.0 enDokument111 SeitenBC-6000 Installation Guide V7.0 enmentule88Noch keine Bewertungen

- 123 09-Printable Menu VORDokument2 Seiten123 09-Printable Menu VORArmstrong TowerNoch keine Bewertungen

- 1970 - Transformer FMEA PDFDokument7 Seiten1970 - Transformer FMEA PDFSing Yew Lam0% (1)

- Indor Lighting DesignDokument33 SeitenIndor Lighting DesignRajesh MalikNoch keine Bewertungen

- Naming Hydrocarbons Worksheet1 Key 12 26 08 PDFDokument2 SeitenNaming Hydrocarbons Worksheet1 Key 12 26 08 PDFMarilyn Castro Laquindanum100% (1)

- Sat Vocabulary Lesson and Practice Lesson 5Dokument3 SeitenSat Vocabulary Lesson and Practice Lesson 5api-430952728Noch keine Bewertungen

- Dusta ManaDokument16 SeitenDusta ManamahaphalaNoch keine Bewertungen

- Biophoton RevolutionDokument3 SeitenBiophoton RevolutionVyavasayaha Anita BusicNoch keine Bewertungen

- Shree New Price List 2016-17Dokument13 SeitenShree New Price List 2016-17ontimeNoch keine Bewertungen

- Physical and Morphological Characterisation of Typha Australis FibresDokument12 SeitenPhysical and Morphological Characterisation of Typha Australis FibresIJAR JOURNALNoch keine Bewertungen

- Amnaya Sutra (English)Dokument458 SeitenAmnaya Sutra (English)Assam Bhakti SagarNoch keine Bewertungen

- Mean Variance Portfolio TheoryDokument85 SeitenMean Variance Portfolio TheoryEbenezerNoch keine Bewertungen

- Fyp-Hydraulic Brakes CompleteDokument32 SeitenFyp-Hydraulic Brakes CompleteRishabh JainNoch keine Bewertungen

- Middle Range Theory Ellen D. Schulzt: Modeling and Role Modeling Katharine Kolcaba: Comfort TheoryDokument22 SeitenMiddle Range Theory Ellen D. Schulzt: Modeling and Role Modeling Katharine Kolcaba: Comfort TheoryMerlinNoch keine Bewertungen

- DOC-20161226-WA0009 DiagramaDokument61 SeitenDOC-20161226-WA0009 DiagramaPedroNoch keine Bewertungen

- Emw 2007 FP 02093Dokument390 SeitenEmw 2007 FP 02093boj87Noch keine Bewertungen

- June 2021 QP - Paper 1 (H) Edexcel Chemistry GCSEDokument28 SeitenJune 2021 QP - Paper 1 (H) Edexcel Chemistry GCSEmiapoppycollinsNoch keine Bewertungen

- AKI in ChildrenDokument43 SeitenAKI in ChildrenYonas AwgichewNoch keine Bewertungen

- Training Report On Self Contained Breathing ApparatusDokument4 SeitenTraining Report On Self Contained Breathing ApparatusHiren MahetaNoch keine Bewertungen

- 02-Building Cooling LoadsDokument3 Seiten02-Building Cooling LoadspratheeshNoch keine Bewertungen

- Purpose in LifeDokument1 SeitePurpose in Lifeaashish95100% (1)

- Combined Shear and TensionDokument16 SeitenCombined Shear and TensionDAN MARK OPONDANoch keine Bewertungen

- Recipes From The Perfect Scoop by David LebovitzDokument10 SeitenRecipes From The Perfect Scoop by David LebovitzThe Recipe Club100% (7)