Beruflich Dokumente

Kultur Dokumente

Gem Stone GB

Hochgeladen von

Jutt AwaraCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gem Stone GB

Hochgeladen von

Jutt AwaraCopyright:

Verfügbare Formate

DISCLAIMER

The purpose and scope of this Pre Feasibility Study is to introduce the Project and

provide a general idea and information on the said Project including its marketing,

technical, locational and financial aspects. All the information included in this Pre-

Feasibility is based on data/information gathered from various secondary and primary

sources and is based on certain assumptions. Although, due care and diligence have been

taken in compiling this document, the contained information may vary due to any change

in the environment.

The Planning & Development Division, Government of Pakistan, Ali Consultants who

have prepared this Pre-Feasibility or National Management Consultants (Pvt.) Ltd. who

have quality assured this document do not assume any liability for any financial or other

loss resulting from this Study.

The prospective user of this document is encouraged to carry out his/her own due

diligence and gather any information he/she considers necessary for making an informed

decision.

i

TABLE OF CONTENTS

ACRONYMS ................................................................................................................. iii

EXECUTIVE SUMMARY ...........................................................................................iv

CHAPTER 1 - INTRODUCTION................................................................................... 1

1.1 OVERVIEW................................................................................................................................1

1.2 OBJ ECTIVE ..............................................................................................................................2

1.3 SCOPE OF STUDY ...................................................................................................................2

1.4 METHODOLOGY AND APPROACH.....................................................................................3

1.5 STUDY TEAM...........................................................................................................................3

CHAPTER 2 MARKET / NEED ASSESSMENT....................................................... 4

2.1 THE WORLD TRADE IN GEMSTONES.................................................................................4

2.2 MAJ OR WORLD PRODUCERS................................................................................................4

2.3 MAJ OR GLOBAL MARKETS................................................................................................... 6

2.4 GEMSTONE POTENTIAL OF PAKISTAN ............................................................................. 8

2.5 LOCAL GEMS & J EWELLERY MARKET............................................................................ 12

2.6 PROPOSED MARKETING STRATEGY ............................................................................... 13

2.7 PROPOSED PRODUCT MIX ................................................................................................. 14

CHAPTER 3 TECHNICAL EVALUATION........................................................... 15

3.1 LOCATIONAL ANALYSIS....................................................................................................15

3.2 GEMSTONE CUTTING & POLISHING................................................................................16

3.3 GEMSTONE FORMS..............................................................................................................19

3.4 PROCESS FLOW CHART .....................................................................................................22

3.5 PHYSICAL FACILITIES..........................................................................................................23

3.6 MACHINERY & EQUIPMENT..............................................................................................24

3.7 ACQUISITON OF TECHNOLOGY.......................................................................................24

CHAPTER 4 GOVERNANCE & MANAGEMENT STRUCTURE ...................... 25

4.1 GOVERNANCE .......................................................................................................................25

4.2 MANAGEMENT STRUCTURE .............................................................................................26

4.3 MANPOWER............................................................................................................................28

CHAPTER 5 FINANCIAL EVALUATION............................................................. 29

5.1 CAPITAL COST ......................................................................................................................29

5.2 OPERATING RESULTS..........................................................................................................30

5.3 PROJ ECTED CASH FLOWS...................................................................................................31

5.4 PROJ ECTED BALANCE SHEET..........................................................................................32

5.5 PAYBACK PERIOD................................................................................................................32

CHAPTER 6 CONCLUSION .................................................................................... 33

LIST OF TABLES

TABLE 1 SUMMARY OF MACHINERY AND EQUIPMENT ........................................................24

TABLE 2 HUMAN RESOURCE REQUIREMENT .............................................................................28

TABLE 3 TOTAL PROJ ECT COST......................................................................................................29

TABLE 4 PROJ ECTED PROFIT & LOSS ACCOUNT FOR 5 YEARS............................................30

TABLE 5 YEARLY SALES PROJ ECTIONS IN CARATS...............................................................30

TABLE 6 YEARLY SALES PROJ ECTION IN RUPEES...................................................................31

ii

TABLE 7 PROJ ECTED CASH FLOW..................................................................................................31

TABLE 8 PROJ ECTED BALANCE SHEET ........................................................................................32

TABLE 9 PAYBACK PERIOD..............................................................................................................32

ANNEXURE - 1 PAKISTAN - A PROFILE

ANNEXURE 2 MAJOR WORLD GEMSTONE PRODUCERS

iii

ACRONYMS

AJ K Azad J ammu and Kashmir

ASEAN Association of South East Asian Nations

BOO Build Operate Own

BOT Build Operate Transfer

CAA Civil Aviation Authority

CEO Chief Executive Officer

CSO Central Selling Organisation

ECO Economic Cooperation Organisation

EIZ Eastern Industrial Zone

EPB Export Promotion Bureau

EU European Union

FBS Federal Bureau of Statistics

GCC Gulf Cooperation Council

GJ EPC Gems and J ewellery Export Promotion Council of India

GoP Government of Pakistan

IRR Internal Rate of Return

KPT Karachi Port Trust

NMC National Management Consultants (Pvt.) Ltd.

NWFP North West Frontier Province

P&DD Planning and Development Division

P&L Profit and Loss

PNSC Pakistan National Shipping Corporation

PTA Pakistan Telecommunication Authority

PTCL Pakistan Telecommunication Ltd.

RoE Return on Equity

RoI Return on Investment

SAARC South Asian Association for Regional Cooperation

SPC Special Purpose Company

WTO World Trade Organization

iv

iv

EXECUTIVE SUMMARY

The international trade in gemstones excluding diamonds is estimated at more than

US$18.0 billion per annum. Pakistans share in this trade is less than US$ 50.0 million

per year even though it has got the 5

th

or perhaps the 6

th

largest reserves of precious and

semi precious gems in the world.

Pakistan has reserves of emeralds, ruby, topaz, tourmaline, aquamarine, sapphire etc. It

is, however, not able to benefit from this resource as it lacks skills in lapidary (the art of

cutting, shaping and polishing stones), because of which, most of the exports are in the

form of uncut or raw gemstones.

The value addition due to lapidary can be as much as 1:100 over the uncut form. In order

to avail the opportunity that Pakistans gemstones reserves offer, it is proposed to set up a

Gemstone Lapidary Centre in Gemstone Market in Saddar, Karachi, Pakistan.

The 50,000 carat per annum capacity unit will have state of the art Lapidary Machinery

and will cut and polish locally procured raw material. In the initial stage, it is proposed to

work at 60% capacity and cut and polish emeralds, rubies and tourmaline and this

product mix can be changed depending on international demand.

The total cost of the project is estimated at Rs.187.0 million and has a payback period of

less than 1 year. In order to make the Project successful, it is proposed that technology for

setting up and operations of the unit be obtained and an international joint venture

agreement be signed to obtain technology for marketing of the product in the world

markets. International experts need to be hired to train the local workers. Provision has

been made for international marketing and training of the workers.

1

CHAPTER 1

INTRODUCTION

1.1 OVERVIEW

Gemstones are minerals, which when cut and polished become precious and can

be used for jewellery. Diamonds, emeralds, rubies, sapphires, topaz, zircon,

aquamarine, amethyst, peridots etc. are some of the most rare and valuable

gemstones. The four Cs that determine the value of a gem are color, clarity, carat

(weight) and cut.

Other than diamonds, the world trade in gemstone in 2006 is estimated to be in

excess of US$18.0 billion per annum. Gems are a unique type of resource because

a very small amount can have extremely high value.

Currently most of the gemstone mines found in Pakistan are located in a) the

northern mountainous regions, b) the northern areas of the NWFP and c) in Azad

Kashmir. The major exports of gemstones from Pakistan are in uncut, unpolished

forms The price difference between uncut and cut and polished gemstones which

used to be 1:30 about 5 years back has increased up to 1:100 in some cases. This

is because of improvement in cutting and polishing techniques as well as because

of artificial enhancement of colors. Pakistan has not been able to benefit from this

value addition as lapidary (the art of cutting, shaping and polishing stones)

techniques used in Pakistan are outdated and need to be modernized.

With the liquidation of the Gemstone Corporation of Pakistan (GEMCP), except

for two significant deposits in Azad Kashmir, all identified precious and semi

precious stone deposits of the country have been leased out to the private sector

for commercial exploration. The Government of NWFP has auctioned almost all

its identified precious and semi precious stone deposits. After scientific evaluation

of Kashmir Ruby and Green Tourmaline deposits by the public sector, efforts are

2

underway by the Government of AJ K to secure private investment for commercial

exploitation.

As most of the mines are now in the private sector and it is difficult to access and

exploit these mines, it is proposed that in the first stage a project for Gemstone

Lapidary be set up. In the second stage mines which produce the highest qualities

of gemstones be identified for joint ventures or outright purchase.

The main market for gemstones in Pakistan is in Saddar, Karachi. Most of the

owners of the mines and individual miners travel with the raw uncut gems to

Karachi to sell them to dealers. In addition, the main export market for gemstones

is also located in Karachi from where buyers from Europe, the Middle East and

Far East pick and choose the best gems.

It is proposed that the Gemstone Lapidary Project be set up in the gemstone

market in Saddar, Karachi, where unlike the other local dealers who purchase on

credit, gemstones are purchased with cash; this will result in both better quality

and lower prices.

It is also proposed that the Lapidary Unit may have a joint marketing venture with

some international dealer of gemstones while for Lapidary techniques another

joint venture or technical collaboration be done with some company in the Far

East which maybe willing to transfer technology.

1.2 OBJECTIVE

The objective of the study is to determine the feasibility of setting up a gemstone

Production, Processing and Marketing project in Pakistan.

1.3 SCOPE OF STUDY

The scope of the study is to undertake, inter alia, need assessment, technical

evaluation, assessment of governance and management structure and financial

3

evaluation of the project, on the basis of which recommendations are to be

developed for setting up the said project.

1.4 METHODOLOGY AND APPROACH

The methodology used in conducting this study is given as under:

Secondary data was collected from government publications, FBS, journals

and magazines, internet and other sources.

The primary data was collected from visit to gem markets, discussions with the

experts on gems and gemology, officials of EPB and concerned trade

associations.

Prices of machinery and technical know-how cost were obtained from

international suppliers of machinery for Lapidary work and reputed technology

suppliers.

1.5 STUDY TEAM

The study team consisted of market analyst, HRD & technical experts and

financial analyst who contributed their inputs in coordination with the Team

Leader. The Support Staff consisted of field Surveyors, data tabulators and word

processors.

4

CHAPTER 2

MARKET / NEED ASSESSMENT

2.1 THE WORLD TRADE IN GEMSTONES

The world trade in gemstones excluding diamonds is estimated at US$18.0 billion

per annum as stated earlier. The total exports of gemstones from Pakistan is

estimated at US$50.0 million per annum. The gems industry has undergone a

major qualitative change during the last two decades. These changes relate mainly

to new techniques in cutting and polishing including using laser beams; artificial

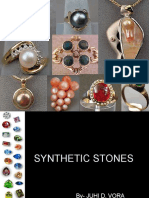

enhancement of color and production of synthetic gems and stimulants.

In more than 30 percent of cases, particularly in Europe, North America and

J apan the color of gemstones is enhanced artificially. This is accomplished by one

of the three methods; a) heating under controlled conditions; b) exposure to X-ray

or radium; or c) the application of pigment as colored foil to pavilion (base) facet.

Gemstones like other mineral deposits are the product of complex, geological

processes that have operated on and inside the earth for millions of years in an

uneven style. Resultantly, the present occurrence and distribution of gemstones

shows a remarkable diversity. In Pakistan the occurrence of gemstones is also

confined to a few discernible geographical zones in the northern mountainous

belts of the country.

2.2 MAJOR WORLD PRODUCERS

Coloured precious and semi-precious gemstones are found in many countries of

the world. Most of the producing countries have their own mining and production

methods which makes it very difficult to determine the quality and value of their

production.

5

Thailand is the worlds largest producer of gemstones having an annual export of

around US 2.5 billion. On one hand it produces/ mines a large variety of gem

stones on the other hand it imports raw and uncut stones for processing and

conversion into jewellery.

USA is the second largest producer of gemstones and the largest market/

consumer in the world. The US market exceeded US $ 9 billion in 1999 and it is

well over US $ 12 billion presently.

Sri Lanka is the worlds third largest producer. It produces a large variety of

coloured gemstones some of which are unique in the world. Besides production of

raw/un-cut stones, Sri Lanka has a thriving industry for cutting, polishing and

exporting finished stones and jewellery.

Brazil is perhaps the fourth largest producer of coloured gem stones Because of

vast unexplored areas in Brazil, the industry experts believe that in case of Brazil

only the surface has been scratched. New mines are constantly being developed

and old ones upgraded.

Australia is regarded as the fifth largest producer. It is most famous for its opal. In

addition, sapiens, pearls, and diamonds from Australia are also well known.

Tanzania and Zambia in Africa also have large deposits of a variety of coloured

gemstones and their mines have now become productive.

India is another major success story in development. India produces both raw/un-

cut stones as well as it cuts, polishes and converts them into high quality

J ewellery. Its exports are around US $ 250 million.

6

Pakistan has a small share of this sector at around US$ 50 million / year.

However, aggressive measures are being taken to develop this sector from export

of raw/un-cut stones to export of cut, polished stones and jewellery.

Annexure 2 contains a brief write-up on the major world producers of coloured,

precious and semi precious gem stones.

2.3 MAJOR GLOBAL MARKETS

The three largest markets for loose colored gemstones are undoubtedly the United

States, J apan and Europe. The United States is the world leader bringing in more

than US$609 million in1998. Europe trailed a close second that year with US$573

million in imports, while J apan standing third at more than US$ 159 million.

Based on world gemstone import data from the United Nations' International

Trade Centre (ITC), all other countries accounted for approximately $487 million

in loose gems. That makes the global total for 1998 $1.83 billion. In 1999, there

was more buying in all three of the major markets: the United States imported

more than $661 million, Europe brought in approximately $587 million, and

J apan improved but was still trailing at $209 million. However, countries outside

the United States, J apan and Europe accounted for 27% of the world total in 1998.

Assuming the same ratio in 1999, they would have imported approximately

US$538 million, for a global total of US$2 billion.

Although Thailand has lost ground in the gem trade since its golden years in the

mid-1990s, it is still the world's biggest colored stone trading center by a

comfortable margin. Overall gemstone exports in 1999 were an estimated US$367

million, with US$286 million of that going to the United States, the European

Union, and J apan.

At present, the total Indian gems and jewellery market including exports is

estimated at US$18 billion. The increase in the value of India's colored stone

7

exports may be due to the diversification of the country's cutting industry.

Traditionally, India has been known for cutting diamond and emerald, but after

controversy over emerald treatments erupted in late 1997, Indian cutters began

working with other gems, particularly tanzanite.

Hong Kong is the world's second largest exporter of jewellery and, as surging

export figures show, is growing in strength. Last year, Hong Kong exported

US$2.4 billion worth of jewellery products, 17% more than the same period year

on year. It is a major player, especially given its links to China's inexpensive and

increasingly skilled labor pool.

Another major trading center is Switzerland, which exported more than US$150

million in colored gemstones in 1999. Switzerland has an active trading

community and one very large player, the Golay Group, which contributes a

sizable percentage to the total. Switzerland is also the site of several high-end gem

and jewelry auctions, which affect the total figures. Together, these four countries

supply 46 percent of the world gem market. Other leading trading centers are

Germany, with a gem cutting tradition that stretches back 500 years, and Israel, a

major cutting center with close trading ties to gem-rich Africa.

In contrast, Africa, which many industry observers consider to be the most

prolific source of gemstones in the world right now, exported just under US$27

million to the United States, the European Union, and J apan in 1999. The nature

of doing business in Africa makes it less likely for dealers to go there: It is

difficult and expensive to get to the mines, and the prices there can be the same as

a dealer would pay elsewhere. Also, dealers from trading centers like Thailand

and India have carefully built up and maintained a presence in gem-rich African

countries and they purchase much of the rough gems.

Although some countries have better import and export records than others,

overall the world gem trade remains difficult to track. While that can be

8

frustrating for financiers looking for hard numbers, for many in the industry that

is part of the charm: The freewheeling nature of colored stone trading adds to the

overall romance.

The numbers that are available indicate that more and more consumers around the

world are getting into colored gemstones, especially gems other than ruby,

emerald, and sapphire. As awareness of color increases, there is a huge potential

for growth, especially in developing markets. The coming decades promise to be

an interesting time for the colored stone industry.

2.4 GEMSTONE POTENTIAL OF PAKISTAN

As stated earlier, Pakistan is considered to have the 5

th

or 6

th

largest deposits of

gemstones in the World. These deposits are located in three district area; a)

NWFP; b) Northern Areas; and c) Azad Kashmir.

The following paragraphs contain a brief description of major deposits in these

three areas.

2.4.1 GEMSTONE DEPOSITS OF NWFP

EMERALD

The emerald deposits occur in a 70- kilometre long belt in District Swat. The

main mines are located at Shamozai, Mingora and Gujjar Killi. Two other small

deposits at Kakhad and Charbagh are also located in the same belt. The

emeralds found in this belt are famous for their brilliant medium to deep green

color and unique transparency comparable to the finest Colombian emeralds. The

potential of Mingora, Shamozai and Gujjar Killi is roughly estimated at 70.0

million carats per annum which can fetch US$210 million in uncut form per year

in the international markets. In addition, significant deposits of emeralds are also

found in Mohmand and Bajaur Agencies but the potential of these deposits has

not yet been fully evaluated.

9

TOPAZ

Topaz Pink and pale beige color topaz deposits occur near Katlang and

Shamozai villages about 70 kilometres from Mardan The colors of these

deposits range from colorless to pale beige to light brown and from pale to deep

pink or deep red. The pink topaz of Katlang is a unique stone which is found

only in Pakistan, if properly promoted its price can be greatly enhanced in

the world market. The geological resource potential is likely to be around 9

million carats or US$180 million per annum in uncut form.

AQUAMARINE

Deeper color aquamarine is reported from District Chitral. The area merits

exploration from the viewpoint that good quality aquamarine, tourmaline and

kunzite bearing pegmatites are found in Afghanistan just across the border.

GARNET

Gem quality almandine (red) garnet is found in Chitral District, beautiful honey

yellow, euthedral crystals of hessonite garnet are found in Bajaur Agency. Green

garnet or tsavolite is found in Jambil area of Swat, Malakand District and in

Bajaur Agency, the potential has however not been fully exploited.

TOURMALINE, QUARTZ & PERIDOT

Blue tourmaline is found near Garam Chasma in District Chitral which needs

further evaluation. Clear and well formed crystals of quartz occur near Garam

Chashma in District Chitral. Peridot in transparent to translucent and pale to dark

yellowish green or rarely greenish yellow in color has been found in Hazara

Kohistan, deposit potential has not been fully estimated.

10

2.4.2 GEMSTONE DEPOSITS OF NORTHERN AREAS

RUBY

The ruby deposits occur in the 100-kilometer dolomitized marble belt

extending between Hunza valley and Ishkoman valley. Currently mining is

being done in the Hunza valley. The rubies are transparent to translucent and

brownish pink to pinkish red or deep red. After Burma, Vietnam and Cambodia,

Pakistan is the only region in the world that is producing blood red rubies. Violet

or indigo color sapphire also occur with rubies in this area.

Experimental mining operations have established a reserve potential of 1.8

million carats of ruby, spinal and sapphire in Hunza ruby belt alone. The value of

these reserves is estimated at US$3.6 million per annum. The ruby belt is fairly

large and is being worked sporadically at present. The blood red rubies are in

great demand and fetch a very high price in the international markets.

AQUAMARINE

Light blue, transparent and clear euhedral crystals of aquamarine occur in

abundance in the gem bearing pegmatites of Gilgit, Skardu and Hunza areas.

Morganite, the pinkish red variety of beryl, is also associated with aquamarine in

the gem bearing pegamatites of Shigar (Hunza) area. The important deposits of

aquamarine are located in Shengus, Dusso, Heramosh, Iskere, Tistung and

Shigar areas. Exploratory mining operations by the defunct Gemstone

Corporation of Pakistan in the seventies in Shengus and Dusso areas established

swarms of pegamatites yielding an average annual production of about 32,000

carats. It is estimated that a production target of 200,000 carats of aquamarine can

be conveniently achieved.

TOURMALINE

Gem quality tourmaline of pink, blue and green colors is found in the Harmosh

Range, District Gilgit. The best known deposit is in Stak Nallah producing bi

11

and tri color tourmaline crystals and mineral specimens. The crystals are dark

green or black at the base with grass green, blue or pink terminations. Green, red

and black tourmaline is found in Shengus and Bulche areas of District Gilgit.

An average production of about 100,000 carats annually is considered feasible.

SPINAL, PARGASITE, TOPAZ, MOON STONE, GARNET Etc.

Spinals with a variety of colors ranging from brown, red, plum red, violet to blue

are closely associated with Hunza ruby deposits. These occur as euhedral

crystals and are far more attractive than the spinals associated with the ruby

deposits elsewhere in the world.

Pargasite locally also known as Hunza emerald is found in the Hunza valley

and crystals are translucent to opaque with exquisite deep pistachio green color

and produce fascinating cabochon grade material.

Topaz is largely found in Bulche and Shengus areas of District Gilgit and in

Dusso in Skardu District. The topaz crystals are colorless to yellowish brown to

deep cherry color.

Moonstone is mostly found in Shengus and Bulche areas, color ranges from soft

gray to silvery white. The deposits are of good quality, fairly large and can ensure

steady production.

Garnet is found in Gilgit and Skardu and has a deep red color. Clear and well

formed crystals of quartz are found in Hunza, Gilgit and Skardu Districts. Smokey

quartz is also found in Hunza and Gilgit while rose quartz is in abundance near

Dusso in Skardu.

12

2.4.3 GEMSTONE DEPOSITS OF AZAD KASHMIR

RUBY

Rubies have been discovered in Nangimali, Chitta Katha, Khundigali and Naril

in Shontar Valley and Kalejandar areas in Neelum Valley. The Nangimali

deposits have been explored in detail and have been found to have a recovery

ratio of 55 carats per cubic meter of limestone. A reserve potential of 125 million

carats of ruby have been estimated for the deposit.

The color of ruby crystals varies from pinkish red to deep red and improves in

depth to almost pigeon blood red. The color and grade of Kashmir rubies is much

better than the Hunza rubies.

TOURMALINE

Tourmaline has been found in Dunga Nar area of Upper Neelum Valley. Green,

red and bi-color tourmaline has been discovered. The depth of the material is

about 40 meters. The deposit has produced good quality carving materials and

some excellent quality mineral specimens.

PINK BERYL, TOPAZ & QUARTZ

Some Pink Beryl crystals have been found associated with tourmaline in the

pegmatites of Dunga Nar area. Topaz has been found in Dunga Nar area, while

smoky and clear quartz are found associated with other gem minerals in the

Dunga Nar area.

2.5 LOCAL GEMS & JEWELLERY MARKET

Gems and jewellery are an essential component of the formal as well as informal

attire of Pakistani women and men throughout the year of all income classes.

Gems and diamond studded jewellery is given as dowry to girls at the time of

marriage by their parents, relatives and friends. Men often wear rings with

different varieties of gemstones. There are thriving gold and jewellery centers in

13

all the major cities of the country including Karachi, Lahore, Rawalpindi,

Faisalabad, Hyderabad, Multan, Gujrat, Peshawar, Quetta, etc.. Pakistans gold

markets are closely linked to the international bullion markets.

The Pakistani goldsmiths have had a long tradition of mastering their arts.

Gemstone cutters have also had a long tradition of over 200 years. However, both

these trades have not kept pace with changing technology and as a result the

equipment used and their techniques have become outdated and they do not give

the quality required by the international markets.

According to industry experts the local market for cut and polished gemstones in

the country is estimated to be around US$50 million presently. This can increase

significantly with easy availability of better quality products.

2.6 PROPOSED MARKETING STRATEGY

Since majority of the local consumers who belong to middle and lower income

groups in Pakistan do not display a preference for high quality gemstones, the

Project will have to find international buyers for its products. The options which

are available to the Project include:

A joint venture with a leading dealer in Europe for selling the product

Setting up a gemstone sales centre in Europe

Selling the product in international gemstone exhibitions.

Using middle men to sell the production.

Using the web to sell directly to the final consumer.

Of all the possibilities which are available, the option of a joint venture should be

pursued most vigorously as it will enable the Project to produce the product which

is in demand internationally and will lead to reduced risks for the project.

14

2.7 PROPOSED PRODUCT MIX

As stated above, although Pakistan is fortunate to have a wide variety of

gemstones, based on current international trends in the gemstone industry, it is

proposed that initially the project should concentrate on the following gemstones:

Emeralds;

Rubies; and

Tourmalines.

The above product mix is being suggested keeping in mind availability of the raw

material and demand for finished product in the market. It is proposed to

concentrate on the high value addition product such as emeralds and rubies as

they fetch a high price in the international markets.

The product mix can be changed keeping in mind international trends and

availability of local raw material, however in the future, import of raw material

from other countries in the region may also be an option.

15

CHAPTER 3

TECHNICAL EVALUATION

The international trade in gems excluding diamonds is estimated at US$18.0

billion per annum. The value addition of the uncut gems maybe as high as 1:100

in certain cases. Pakistan has got significant deposits of emeralds, rubies,

sapphires, topaz, zircon, aquamarine, garnet, tourmaline, quartz, peridot etc.

Although Pakistan has the 5

th

or 6

th

largest deposits of gemstones, their

contribution to the exports of the country is negligible.

As most of the known deposits have already been transferred to the private sector,

and also keeping in mind that access to these mines is difficult, it is proposed to

establish the gemstone buying Lapidary Unit in Karachi which is the hub of

Pakistans gemstone trade.

3.1 LOCATIONAL ANALYSIS

The Gemstone Market in Saddar, Karachi is proposed for setting up the Gemstone

Lapidary unit for the following reasons:

A market for the sale and purchase of raw and uncut gems already exists in

Karachi.

Foreign buyers frequent the market to buy raw and polished gemstones

Mine owners and individual miners bring their gems to sell in this market.

Infrastructure for export like international airport already exists.

Karachi is Pakistans largest and most metropolitan city which makes it easier

for foreigners to work and stay in Karachi.

Karachi is well connected to different parts of the country.

Trained and experienced management is readily available in Karachi.

Lapidary labor is already available in Karachi, although the skill levels are

currently not very high about can be upgraded.

Because of higher levels of education workforce can be more easily trained.

16

Based on the above consideration, the proposed 50,000 carat per annum lapidary

unit is proposed to be located at the Gemstone Market in Saddar, Karachi.

3.2 GEMSTONE CUTTING AND POLISHING

The process of cutting and polishing gems is called gemcutting or lapidary,

while a person who cuts and polishes gems is called a gemcutter.

Gemstone material that has not been extensively cut and polished is referred to

generally as rough. Rough material that has been lightly hammered to knock off

brittle, fractured material is said to have been cobbed.

All gems are cut and polished by progressive abrasion using finer and finer grits

of harder substances. Diamond, the hardest naturally occurring substance, has a

Mohs hardness of 10 and is used as an abrasive to cut and polish a wide variety of

materials, including diamond itself. Silicon-carbide, a manmade compound of

silicon and carbon with a Mohs hardness of 9.5, is also widely used for cutting

softer gemstones. Other compounds, such as cerium oxide, tin oxide, chromium

oxide, and aluminum oxide, are frequently used in polishing gemstones.

Gemstone cutting and polishing is a highly sophisticated and precise activity

requiring not only high quality machinery, testing equipment but also worker skill

and dedication.

Following is a brief description of the major processes and equipment used for

cutting and polishing gemstones.

3.2.1 SAWING

In most gem sawing, a thin circular blade usually

composed of steel, copper, or a phosphor bronze alloy

impregnated along the outer edge with diamond grit and

rotating at several thousand surface feet per minute

17

literally scratches its way through a gemstone. A liquid such as oil or water is

used to wash away cutting debris and keep the stone and the saw blade from

overheating, which could cause damage to both the stone and the sawblade.

Several sizes of circular rock saws are frequently used by most gemcutters.

A slab saw, typically 16 to 24 inches in diameter, is used to cut stones of

several inches thickness into relatively thin slabs (often 1/8 to 3/8 inch thick).

A trim saw, typically 6 to 10 inches in diameter, is used to cut smaller stones

into thin slabs or to cut small sections out of slabs.

A faceter's trim saw, typically 4 inches in diameter, is used with a very thin

blade, to saw small pieces of expensive rough.

There are also jigsaws that employ either a reciprocating wire or a continuous thin

metal band. These are useful for cutting curved lines that are impossible with

circular saws. They are also useful in minimizing waste on extremely valuable

rough material.

3.2.2 GRINDING

Grinding, usually with silicon carbide wheels or

diamond-impregnated wheels, is used to shape gemstones

to a desired rough form, called a preform. As with

sawing, a coolant/lubricant (water or oil) is used to

remove debris and prevent overheating. Very coarse

diamond or silicon carbide, such as 60 grit, or mesh, (400 micron particles) or 100

grit (150 micron particles) is used for rapid removal of stone, and finer abrasive

(600 grit - 30 micron, or 1200 grit - 15 micron) is used for final shaping and

sanding.

3.2.3 SANDING

Sanding is similar to grinding but uses finer abrasives. Its purpose is to remove

deep scratches left by coarser abrasives during grinding. Since it removes material

18

less rapidly, it also allows more delicate control over final shaping of the stone

prior to polishing. For stones with rounded surfaces, a flexible surface such as a

belt sander is often used to avoid creating flat areas and promote smooth curves.

3.2.4 LAPPING

Lapping is very similar to grinding and sanding, except

that it is performed on one side of a rotating or

vibrating flat disk known as a lap, and it is used

especially to create flat surfaces on a stone (as in

faceting). Laps are often made of cast iron, steel, or a

copper-bronze alloy, but other materials can also be used.

3.2.5 POLISHING

After a gemstone is sawed and ground to the desired

shape and sanded to remove rough marks left by

coarser grits, it is usually polished to a mirror-like

finish to aid light reflection from the surface of the

stone (or refraction through the stone, in the case of

transparent materials). Very fine grades of diamond

(50,000 to 100,000 mesh) can be used to polish a wide

variety of materials, but other polishing agents work well in many instances.

Usually, these polishing agents are metal oxides such as aluminum oxide

(alumina), cerium oxide, tin oxide, chromium oxide, ferric oxide (jeweler's

rouge), or silicon dioxide (tripoli). Different stones are often very inconsistent in

their ease of polishing, particularly in the case of faceted stones, so gemcutters are

often very inventive in trying new combinations of polishing agents and polishing

surfaces -- often tin, tin-lead, lead, leather, felt, pellon, wood, or lucite laps for flat

surfaces such as facets. Rounded surfaces, such as on cabochons, are often

polished on felt, leather, cork, cloth, or wood. Polishing removes small quantities

of stone and can be used, especially when faceting small stones, to do ultrafine

shaping of the stone.

19

3.2.6 DRILLING

When a gemcutter desires a hole in or through a gemstone

(e.g., a bead), a small rotating rod or tube with a diamond

tip, or slurry of silicon carbide and coolant, is used to drill

through the stone. Ultrasonic, or vibrating, drills are also

very effective, but they tend to be costly and thus reserved

for high-volume commercial drilling.

3.2.7 TUMBLING

Large quantities of roughly shaped stones are often

tumbled, i.e., turned at a slow speed in a rotating barrel

with abrasives and water for extended periods (days or

weeks). By tumbling with progressively finer grades of

abrasive (usually silicon carbide) and washing carefully

between grades, the stones are gradually smoothed and

polished to serendipitous but often very attractive shapes. Tumbling barrels are

often hexagonal in outline in order to enhance the stirring action of barrel rotation.

An alternative to rotatory tumblers is a vibratory machine, often called a vibratory

tumbler, in which the containing barrel vibrates rather than rotates. The more

stationary arrangement of vibratory machines makes it much easier to examine

the progress of the stones inside, whereas standard tumblers must be halted in

order to check progress. In addition to polishing gemstones, tumbling is often

used to polish large quantities of metal jewelry.

3.3 GEMSTONE FORMS

Using the techniques given above, gemstones are fashioned into one of the

following forms:

CABOCHONS

One of the simplest lapidary forms is the cabochon, a stone that is smoothly

rounded and polished on top, relatively flattish, and either flat or slightly rounded

20

on the bottom (which may be either polished or sanded). This form of cutting is

often used for opaque or translucent stones, but is also frequently used for

transparent materials that contain too many inclusions to yield a good faceted

stone. Coloration and patterning provide the major interest in such stones.

Cabochon cutting, or cabbing, is often performed by simply holding the stone in

the fingers, but it is more commonly done by dopping (attaching with adhesive

wax or glue) the stone to a wooden or metal dopstick. This facilitates twirling the

stone to form smooth curves and avoid flat areas during grinding, sanding, and

polishing. A typical cabbing machine holds several wheels representing a

progressive series of diamond or silicon carbide grit, turned by a common arbor

and motor, and a water supply that provides a coolant/lubricant to wash away

debris and keep the stone from overheating as it is ground and sanded on

progressively finer wheels.

FACETATED STONES

Faceting is most often done on transparent stones. Flat facets are cut and polished

over the entire surface of the stone, usually in a highly symmetrical pattern. The

stone is dopped (usually with adhesive wax, epoxy, or cyanoacrylate glue) on a

metal dopstick, which is then inserted in a handpiece that allows precise control of

positioning. The cutting angle is adjusted vertically via a protractor and

rotationally via an index gear. The facets are then ground, sanded, and polished

on a rotating lap, while water or another liquid acts as a coolant and lubricant.

When one side (top or bottom) of the stone is finished, a jig is used to transfer the

stone to a dopstick on the opposing side.

A faceting machine usually employs a motor that turns a lap, a water supply, an

adjustable handpiece with index gears and a protractor, and an adjustable mast or

platform to hold the handpiece assembly. Most commercially available

gemcutting machines employ a mast, but a few employ a platform.

In recent years, innovative faceters have employed techniques such as concave

21

facets, grooves, and combinations of faceting and cabbing to produce new forms

in faceted stones.

BEADS & SPHERES

Spheres are initially sawed into cubes or dodecahedrons and then ground to shape

between two pipes or rotating concave cutters, allowing the stone to rotate freely

in any direction to form a perfect spherical shape. As with other lapidary

processes, gradually finer grades of abrasive are used to grind, sand, and polish

the stone. While beads may be faceted, they are more commonly cut and polished

as small spheres and then drilled to allow stringing. Bead mills are used to grind

and sand large quantities of beads simultaneously. They typically employ a

grooved lap and a flat lap between which the beads are rolled and worn to shape.

After shaping and sanding, beads are usually polished by tumbling.

INLAYS

In an inlay, a gemstone is cut to fit and glued into a hollow recess in another

material (metal, wood, or other stones) and then the top ground and polished flush

with the surrounding material. Stones most commonly used for inlay are strongly

colored, opaque stones such as black onyx, lapis lazuli, turquoise, tigereye, etc.

INTARSIAS AND MOSAICS

In both intarsia and mosaic work, small bits of different colored stones are fit

together and the top cut and polished to present a picture or other interesting

pattern. Strictly speaking, a mosaic is constructed on top of a flat base of another

material (usually stone), while an intarsia (also known as Florentine mosaic, or

pietre dure) is set flush into the surface of the base material. The finest intarsias

and mosaics were traditionally of Italian origin, but intarsia has enjoyed

something of a renaissance in recent years.

CAMEOS AND INTAGLIOS

Cameos and intaglios are similar in that both usually are carved portraits in stone

22

Purchase of

Raw Stones

Grading

Delivery to

Exports

Customers

Sale in Local

Market

Cutting

Polishing

or seashells. They differ in that cameos are raised portraits, while intaglios are

carved down into the surface of the material. Both typically take advantage of

different colored layers of material. The finest cameos and intaglios have

traditionally come from Italy (usually shell) or Germany (usually agate).

SCULPTURES

Gemstones can be carved, like other materials, into almost any form, limited only

by the talents of the sculptor. Carving is accomplished with a variety of diamond-

impregnated steel bits, saws, and grindstones.

3.4 PROCESS FLOW CHART

The process flow chart is shown below, raw uncut gemstones will be locally

purchased and sold after grading, cutting, finishing etc.

CHART - 1

PROCESS FLOW CHART FOR LAPIDARY UNIT

PURCHASE OF RAW STONES

Trained purchasers will be employed for purchasing the raw stones, every effort

will be made to ensure that the purchasing is done in a transparent manner and the

entire process will be watched over CCTV.

23

GRADING OF STONES

In this process the raw unfinished stones will be graded keeping in mind the final

product that is required. Grading reports will be circulated within the organization

so that purchasers can improve their buying skills.

CUTTING OF STONES

The stones will be cut using the modern machines like sawing, faceting etc. Every

effort will be made to control wastage as reduced wastage will lead to increased

profitability.

POLISHING OF STONES

State of the art buffing and polishing machines will be used to enhance the value

of the final product.

EXPORT AND LOCAL SALE OF FINAL PRODUCT

Internationally acceptable quality will be exported, while the leftovers and lower

quality gemstones will be sold in the local market.

3.5 PHYSICAL FACITLITIES

The Gemstone Lapidary unit will be located in the Gemstone Market in Saddar,

Karachi. The unit will require over 5,000 square feet of space and will include a

display centre, conference room, secure area for buying of raw gems, a strong

room, workshops for grinding, cutting and polishing of the gemstones. In addition

support facilities for the workers and office staff will also be provided. The whole

unit will have state-of-the art security and surveillance system

The Lapidary Unit will also have its own 100 KVA generator to provide 100

percent power back up.

24

3.6 MACHINERY & EQUIPMENT

The proposed lapidary unit to handle the proposed product mix given above will

require following machinery and equipment.

TABLE - 1

SUMMARY OF MACHINERY AND EQUIPMENT

S. No. Description of Machinery

1. Sawing Machinery

2. Machines for Faceted Stones

3. Calibrating Machines with Wheels

4. Polishing Machines

5. Machines for Processing of Cabochons

6. Buffing, Sanding & Polishing Sets

7. Generator

8. Security Equipment

9. CAD, CAM Machines with Software

10. Furniture & Fixture

11. Misc. Equipment

12. Workshop Equipment

3.7 ACQUISITON OF TECHNOLOGY

Lapidary is a highly sophisticated area which has experienced a lot of

technological advances during the recent years. It is strongly recommended that

technical collaboration may be made for the establishment and operations of the

unit.

Technology could be obtained from various machinery suppliers of the World.

The lapidary equipment manufacturers exist in USA, UK and in many countries

of EU such as Italy, Germany, France, Holland, Sweden, etc.. Before the lapidary

unit goes into operation, it will be necessary to get the staff trained on all the

selected machines. Adequate provision of funds has been made in the capital cost

of the Project for training of staff and workers.

25

CHAPTER 4

GOVERNANCE AND MANAGEMENT STRUCTURE

4.1 GOVERNANCE

The gemstone lapidary and marketing unit may be run by a special purpose

company (SPC) governed by a Board of Directors with a Chairman and Directors

and a Chief Executive Officer.

The business of the company is to be managed under the directions of the Board

of Directors. The Board will be responsible for establishing broad corporate

policies and for the overall performance of the company. The core responsibility

of the directors is to exercise their business judgment and act in what they

reasonably believe to be the best interests of the company.

Proposed corporate governance structure is presented in Chart -2.

CHART - 2

PROPOSED GOVERNANCE STRUCTURE

The Company

Share-Holders

Board of Directors

Chairman

Chief Executive

Officer

Corporate

Governance

Committee

Corporate Audit

Committee

General

Manager

Operation

Manager

Procurement

Manager

Marketing

Manager

Finance &

Admin.

Internal Auditor

& Quality

Assurance

26

The Boards Corporate Governance Committee reviews the principles and rules

regularly in the light of prevailing best practices and forwards suggestions for

improvement to the full Board for approval.

The Boards Corporate Governance Committee is responsible for considering

matters of corporate social responsibility and matters of significance in areas

related to corporate public affairs and the companys employees and stockholders.

The Boards job should be to create and maintain a structure that will ensure

harmony and cooperation between management and the employees in pursuing

the goals and objectives of the organization rather than simply rubber-stamping

the actions of management.

The Boards Audit Committee will have two fundamental responsibilities.

Internally, it will oversee the annual external audit to ensure the accuracy and

integrity of the financial statements as required by legislation. It will also ensure

that there are no breakdowns in corporate governance rules and procedures,

including the rules of ethical conduct and internal control. The Audit Committee

would also be a practical monitor for collecting information regarding corporate

misconduct and encouraging those with such information to come forward.

4.2 MANAGEMENT STRUCTURE

The paramount duty of the Board of Directors is to select a Chief Executive

Officer and to oversee the CEO and the other senior management for the

competent and ethical operation of the company.

The Board should identify, and periodically update, the qualities and

characteristics necessary for an effective CEO of the company. With these

principles in mind, the Board should periodically monitor and review the

development and progression of potential internal candidates against these

standards.

27

The Chief Executive Officer (CEO) is in charge of the day-to-day management of

operations, and is responsible for ensuring that the company and management

functions are organized, run and developed in accordance with the law, Articles of

Association and decisions adopted by the Board, and the Annual General Meeting

of the Shareholders.

The management structure, presented in Chart-3, comprises of Operational

Division located at the Plant and Audit, Administration & Procurement, Finance

and Marketing Departments at Corporate Office.

CHART - 3

PROPOSED MANAGEMENT STRUCTURE

The structure is characterized by a clear assignment of responsibilities as well as a

reduced number of interfaces.

The selected chief executive is responsible for delivering policy and performance

for customers, society, staff and the business.

Chief Executive

Officer

General Manager

Operation

Maintenance

Manager

Production

Supervisors

Manager

Quality Assurance

Manager

Finance &

Admin.

Internal Auditor

& Quality

Assurance

Manager

Marketing

Manager

Procurement

28

4.3 MANPOWER

The total manpower requirement for the Lapidary Unit is 105 as shown in the

table:

TABLE -2

HUMAN RESOURCE REQUIREMENT

Sr. # Designation No. of Posts

1. Chief Executive Officer 01

2. General Manger 01

3. Managers 06

4. Technical Supervisors 08

5. Support Staff 05

6. Skilled Workers 24

7. Semi- Skilled Workers 36

8. Security Staff 24

Total Staff 105

The skilled workers of the project will be specialists in various process of

Lapidary e.g:

Slab Saw mill operators. Operators for processing cabochons.

Multiple and gemstone Saw mills

operators.

Operators for making round beads.

Polishers.

Grinding machine operators.

Operators for facetting.

29

CHAPTER 5

FINANCIAL EVALUATION

5.1 CAPITAL COST

Total Capital Cost of the Project will be Rs.187.0 million including a provision of

Rs.10.0 million for Raw Material Inventory and Rs.9.0 million for Contingencies.

The break up of the Capital Cost is shown in the table below:

TABLE -3

TOTAL PROJECT COST

(Rs. in million)

Description Amount

Land & Civil Works 100.0

Cost of Machinery & Equipment 42.5

Utilities 2.0

Erection and Installation 1.5

Training 6.0

Prospecting & Identification of Supply Sources 1.5

International Marketing Expenses 2.5

Pre-production and Start-Up Costs 4.0

Vehicles, Furniture & Fixtures 5.0

Working Capital 2.5

Raw Material 10.0

Contingencies 9.0

Total Project Cost 186.5

It is proposed that the above capital cost may be financed through a debt equity

structure of 40:60. As such funds may be obtained as follows:

Long Term Loans 40% Rs. 75.0 million

Shareholders Equity 60% Rs.112.0 million

Total Rs.187.0 million

30

5.2 OPERATING RESULTS

The operating results of the Project are given in the table below:

TABLE -4

PROJECTED PROFIT & LOSS ACCOUNT FOR 5 YEARS

(Rs in thousand)

Description Year 1 Year 2 Year 3 Year 4 Year 5

Net Sales 1,595,000 1,675,000 1,754,000 1,857,000 1,939,000

Cost of Goods Sold 957,000 1,005,000 1,052,400 1,114,200 1,163,400

Gross Profit 638,000 670,000 701,600 742,800 775,600

Admin & Salary

Expenses 49,638 53,609 57,897 62,529 67,532

Operating Profit 588,362 616,391 643,703 680,271 708,068

Depreciation 8,500 8,500 8,500 8,500 8,500

Net Profit before Tax 579,862 607,891 635,203 671,771 699,568

Corporate Tax at 40% 231,945 243,156 254,081 268,708 279,827

Net Profit 347,917 364,735 381,122 403,062 419,741

The above operating results are based on the product mix described in Chapter 2

and as per following sales forecast.

Following a conservative accounting practice, the following are the Sales

Projections for the first five years:

TABLE - 5

YEARLY SALES PROJECTIONS IN CARATS

(in Carat)

Description Year 1 Year 2 Year 3 Year 4 Year 5

Emeralds 15,000 15,750 16,500 17,500 18,250

Rubies 5,000 5,250 5,500 5,775 6,100

Tourmaline 10,000 10,500 11,000 11,600 12,000

Total 30,000 31,500 33,000 34,875 36,350

31

TABLE - 6

YEARLY SALES PROJECTION IN RUPEES

(Rs in million)

Description Year 1 Year 2 Year 3 Year 4 Year 5

Emeralds 1,125 1,181 1,237 1,312 1,368

Rubies 350 368 385 405 427

Tourmaline 120 126 132 140 144

Total 1,595 1,675 1,754 1,857 1,939

Assumptions:

1. Average price taken for calculation purposes is 75% of the prevailing prices in the

local market, although gemstones produced will be far superior to what is

currently available for export.

2. Current prices are taken as being constant over the next five years.

3. Prices for calculation purposes are:

Emeralds Rs.75, 000 per carat

Rubies Rs.70, 000 per carat

Tourmaline Rs.12, 000 per carat

5.3 PROJECTED CASH FLOW

The projected cash flow of the project for five years is given as under:

TABLE 7

PROJECTED CASH FLOW

(Rs. in thousand)

DESCRIPTION YEAR 1 YEAR 2 YEAR 3 YEAR 4 YEAR 5

Operating Profit 588,362 616,391 643,703 680,270 708,068

Less: Cash outflows

Income Tax - 231,945 243,156 254,081 268,708

Total Cash Outflow - 231,945 243,156 254,081 268,708

Net cash 588,362 384,446 400,546 426,190 439,360

Cumulative Cash Flow 588,362 972,809 1,373,355 1,799,544 2,238,904

32

5.4 PROJECTED BALANCE SHEET

Five Years projected Balance Sheet for the project is given as under:

TABLE -8

PROJECTED BALANCE SHEET

(Rs. in thousand)

DESCRIPTION YEAR 1 YEAR 2 YEAR 3 YEAR 4 YEAR 5

CAPITAL

Equity Contribution 186,500 186,500 186,500 186,500 186,500

Accumulated Profit

& Loss

347,917

712,652

1,093,774

1,496,836

1,916,577

534,417 899,152 1,280,274 1,683,336 2,103,077

LIABILITY

Long Term Liability - - - - -

Tax Payable 231,945 243,156 254,081 268,708 279,827

TOTAL

EQUITY &

LIABILITIES

766,362

1,142,308

1,534,355

1,952,044

2,382,904

ASSETS

Capital Investment 178,000 169,500 161,000 152,500 144,000

Cash & Cash

Equivalent

588,362

972,809

1,373,355

1,799,544

2,238,904

TOTAL ASSETS 766,362 1,142,309 1,534,355 1,952,044 2,382,904

5.5 PAYBACK PERIOD

The payback period of the Project is 6 months.

TABLE -9

PAYBACK PERIOD

(Rs. in thousand)

DESCRIPTION Year 1 Year 2 Year 3 Year 4 Year 5

Net Profit 347,917 364,735 381,122 403,062 419,741

Add

Depreciation

8,500 8,500 8,500 8,500 8,500

Total 356,417 373,235 389,622 411,562 428,241

Total Investment 186.5 million

Pay back period 6 months

33

CHAPTER 6

CONCLUSION

On the basis of the above study and analysis it maybe concluded that a Lapidary Unit

maybe established in Saddar, Karachi. The proposed Unit having capacity to cut, polish

and finish 50,000 carats of locally available emeralds, rubies and tourmaline will be able

to have a payback of less than one year with a return on investment of over 300% per

year.

The total capital investment required is Rs.187 million. This includes adequate provisions

for training of workers and staff in latest skills of Lapidary and for international

marketing.

As this will be the first unit of its type in the country, it is proposed to acquire technology

from an international source. For marketing of finished products in the world markets it

has been proposed to enter into joint venture with an international marketing

organisation.

There are large deposits of gemstones in the country which need to be fully utilized and

marketed internationally. Through Lapidary, countrys present gemstone exports of

US$50 million can be increased 100 times.

i

ANNEXURE 1

PAKISTAN - A PROFILE

INTRODUCTION

Pakistan is located in South Asia. It borders Iran to the southwest, Afghanistan to the

northwest, China to the northeast and India to the east. The Arabian Sea marks Pakistans

southern boundary.

ii

The total area of Pakistan is 796,095 square kilometers and the country is divided

administratively into four provinces Balochistan, North-West Frontier Province, Punjab

and Sindh and numerous federally administrated areas. The disputed territory of Azad

J ammu & Kashmir lies to the north of Punjab.

iii

Pakistan has a diverse array of landscapes spread among nine major ecological zones

from north to south. It is home to some of the worlds highest peaks including K-2 which

at 8,611 meters above sea level is the worlds second highest peak. Intermountain valleys

make up much of the North-West Frontier Province, while the province of Balochistan in

the west is covered mostly by rugged plateaus. In the east, irrigated plains along the Indus

River cover much of Punjab and Sindh. In addition, both Punjab and Sindh have deserts,

Thal, Cholistan and Thar deserts respectively.

Most of Pakistan has a generally dry climate and receives less than 250 mm of rain per

year. The average annual temperature is around 27

o

C, but temperatures vary with

elevation from -30

o

C to -10

o

C during cold months in the mountainous and northern areas

of Pakistan to 50

o

C in the warmest months in parts of Punjab, Sindh and the Balochistan

Plateau. Mid-November to February is dry and cool; March and April bring sunny spring,

May to J uly is hot, with 25 to 50% relative humidity; Monsoons start in J uly and continue

till September; October- November is the dry and colourful autumn season.

Pakistan had an estimated population in 2005 of 160 million, 40% of this population was

less than 15 years of age. The major cities of Pakistan and their estimated populations

are; Karachi (16.0 million), Lahore (8.0 million), Faisalabad (6.0 million), Rawalpindi

(5.0 million), Multan (4.5 million), Hyderabad (3.0 million), Gujranwalla (1.8 million)

Peshawar (1.6) and Quetta (0.85). Islamabad, the Capital of the country, has a population

of around 750,000.

According to the 1973 Constitution, Pakistan is governed under a federal parliamentary

system with the President as head of state and a Prime Minister as head of government.

The legislature, or parliament, consists of the Lower House (National Assembly) and the

Upper House or Senate. Members of the National Assembly are directly elected for five-

year terms.

Executive power lies with the President and the Prime Minister. The Prime Minister is an

elected member of the National Assembly and is the leader of the majority party in the

iv

National Assembly. An electoral college consisting of members of the national and

provincial legislatures elects the president for a five-year term.

After the events of 9/11, Pakistan has become a key US ally in the war against terror.

This alignment is totally in-line with the views of the majority of Pakistanis who practice

and preach a moderate version of Islam. The Government of Pakistan fully realizes the

need for promoting Islam as a modern progressive religion. The Government has chosen

the difficult option of fighting the war against terror by clamping down on Taliban and

Al-Qaeda remnants along the border with Afghanistan. The people of Pakistan fully

support the Government in its efforts to promote the true face of Islam.

The US Government fully backs and supports Pakistan in this war against terror. US Aid

which was stopped after the 1998 Nuclear Test has been restored and Pakistan will

receive US$ 3.0 billion over the next 5 years, divided equally between economic and

military aid.

Pakistan follows a very active policy of regional alliances for trade and economic

development. It is an active member of the South Asian Association for Regional

Cooperation (SAARC) which groups Pakistan, India, Bangladesh, Sri Lanka, Nepal,

Bhutan and the Maldives. It is also an active member of the Economic Cooperation

Organization (ECO) comprising of Turkey, Iran, Pakistan, Afghanistan, and the six

Central Asian Republics. Pakistan has an observer status at the Gulf Cooperation Council

(GCC) as well as ASEAN and Shanghai Cooperation Organization. Being a member of

WTO it conforms to most of the international trade regimes.

ECONOMY

Pakistans economy has made significant progress in the last six years. This has been

possible because of the Governments policy of initiating growth through domestic and

foreign direct investment. The GDP growth rate has increased from 1.8% per annum in

2001 to 8.4% per annum in 2005. Despite the devastating earthquake in October 2005,

the economy is expected to grow at over 6.6% in 2006. Pakistans GDP in 2005 was

v

estimated at US$ 385.2 billion and its per capita GDP was US$ 2,400. The Countrys

credit rating has been upgraded by Moodys from Caa1 in 2002 to Ba3 i.e. stable in

2006.

Pakistan has over 3.5 million laborers working in various countries of the Middle East. In

addition, Pakistani technical and professional manpower is engaged in lucrative pursuits

in USA, UK, Canada, Malaysia, etc. These non-resident Pakistanis annually send over

US$ 4.0 billion in foreign remittances.

The Government of Pakistans policy of encouraging Foreign Direct Investment (FDI)

has seen it grow from a mere US$ 376.0 million in 1999 to more than US$ 1.5 billion in

2005 which is expected to grow to over US$ 3.0 billion in 2006.

In addition to Foreign Direct Investment, low domestic interest rates have meant that

there has been an upsurge in domestic investment; the weighted average rate of lending

has fallen from 16% in 1999 to approximately 8% in 2005.

The Governments economic policy has seen foreign currency deposits rise from US$ 1.7

Billion in 1999 to now US$ 13.0 billion in 2006; this has led to both low rates of inflation

and to a stable exchange rate.

With the Government of Pakistan targeting annual growth in the economy at 7.5% per

annum in the next 5 years, Pakistan is the country of choice for foreign and domestic

investors.

INFRASTRUCTURE

The National Highway Authority (NHA) has the responsibility for 17 of Pakistans major

inter provincial links called the National Highway including the Motorways, which are

access controlled and tolled highways. Total length of roads, under NHA, currently

stands at 8845 Kms.

vi

These roads account for only 3.5% of Pakistans entire road network but cater for 80% of

the commercial road traffic in the country. Improvement and extension of the existing

network is, therefore, essential to develop remote areas and provide better connection

between the economic centers of Pakistan. In addition a first class road network is

essential if Pakistan is going to connect its all-weather Arabian Seaports with the

landlocked Central Asian Republics and Western China. The Government has initiated

work on the North-South Trade Corridor with planned investment of over US$ 60 billion.

In order to further speed up the development of the road network, the Government is

actively seeking the participation of the private sector to implement road projects on a

Build-Operate-Transfer (BOT) basis. A number of projects are currently being

implemented under the BOT concept and others are in the identification stage. These

BOT projects cover the construction of new roads as well as the upgrading of existing

roads.

Pakistan has about 1062 km of coastline on the Arabian Sea running from the Indian

border to the Persian Gulf. The Karachi Port is the premier port of Pakistan and is

managed by the Karachi Port Trust (KPT). Karachi port handles about 75% of the entire

national cargo. It is a deep natural port with a 11 km long approach channel to provide

safe navigation up to 75,000 DWT tankers, modern container vessels, bulk carriers and

general cargo ships. The Karachi Port has 30 dry cargo berths including two Container

Terminals and 3 liquid cargo-handling berths. KPT intends to cater for 12-meter draught

ships, which are the most widely used container vessels. In order to facilitate

accommodate and fast turnaround time of mother vessels, the KPT is offering to the

private sector the opportunity to develop a terminal on BOT basis. In addition KPT has

plans to develop a Cargo Village on 100 acres. This Cargo Village shall serve as a

satellite to the port, integrating container, bulk and general cargo handling as well as

providing processing plants for perishable exports. With direct connection to the National

Highway Network, as well as National Railways Network the cargo village shall also

alleviate the problem of upcountry trade with cost effective storage/handling services in

the vicinity of the port. A master plan is under preparation and all the units within the

vii

village shall be allocated to the private sector on BOT and Build-Operate-Own (BOO)

basis within the next year.

Pakistans second Sea Port, Port Qasim is located 50 kilometers to the South East of

Karachi. It is the Countrys first industrial and multi-purpose deep-sea-port. Currently it

is handling 23% of Pakistans sea trade. Port Qasim has attractions and advantages for

investment both in port facilities and port-based industrial development. Port Qasim

Authority from the very beginning has actively sought the help of the private sector in the

development of its port structure. Some of the projects which have been completed with

private sector involvement include; dedicated oil terminal developed in private sector on

BOO basis at a cost of US$ 87 million to cater for oil imports with a handling capacity of

9 million tons per annum, a container terminal developed by P&G Group, Australia, at a

cost of US$ 35 million on BOO basis, for chemicals imports a facility in collaboration

with Vopak of Netherlands on BOT basis at a cost of US$ 67 million. Some of the

projects which the Port plans to develop with the private sector on the basis of BOT

include; establishment of a second oil jetty, establishment of a dedicated coal and

clinker/cement terminal and the establishment of a marine workshop and dry dock

facilities.

To encourage industrial development the Port Qasim Authority has reserved 300 acres of

land on a prime location in the Eastern Industrial Zone (EIZ) for allotment of plots to

Overseas Pakistanis to induce and encourage foreign investment and provide them an

opportunity to establish small size industries in Pakistan. Each plot is measuring 100

square yards at a very low cost on attractive terms and conditions. This is in addition to

existing 1,200 acres of industrial zone which houses a number of auto assemblers such as

Toyota, Suzuki, Chevrolet and the Textile City spread over 1,250 acres.

The Pakistan Merchant Marine Policy 2001, has deregulated the shipping sector and aims

to attract investment; both local and foreign, public and private, by offering a range of

incentives. The new policy in addition to offering duty-free import of ships, offers many

new incentives to local and foreign investors including Income Tax exemption till 2020.

viii

Pakistan's annual seaborne trade is about 45 million tons, just 5 per cent of which is

carried by the national carrier Pakistan National Shipping Corporation (PNSC), the

country's annual freight bill surpasses staggering $ 1.5 billion which is causing a colossal

drain on foreign exchange resources, the marine policy aims to reverse this situation to

some extent.

The Shipping Policy aims to revive and augment national ship-building/capacity to meet

20 per cent ship construction requirements of the country merchant marine and entire

requirements of support and ancillary crafts. The policy also aims to rejuvenate and

expand the ship repair potential to undertake the entire range of repairs and maintenance

of 50 per cent of Pakistani Flag ocean-going vessels and all ancillary sectors. The new

Shipping Policy offers many financial incentives for potential investors. It offers tax

exemptions and concessional tax measures backed by assurances. It also aims at

simplifying the rules by deregulating the sector.

To begin with, ships and floating crafts tugs, dredgers, survey vessels, and specialized

crafts purchased or bareboat chartered by a Pakistani entity flying the Pakistani flag

will be exempt from all import duties and surcharges till 2020. The policy accords shop-

building and ship-repair the status of an industry under the investment policy which is

entitled to all incentives contained therein.

To attract foreign investment, all port and harbor authorities in Pakistan will allow all

ships and floating crafts 10 per cent reduced berthing rates when the same are berthed for

purposes of repair and maintenance. Under the Policy, ships and all floating crafts are

considered bonafide collateral against which financing can be obtained from Banks and

Financial Institutions subject to policy of the financial institution.

There are 42 airports in the country managed by the Civil Aviation Authority (CAA). Out

of these, five airports; Lahore, Karachi, Islamabad, Peshawar and Quetta are international

airports. The CAA is planning to develop a new international airport at Islamabad for

ix

which land has been acquired and it is planed to fund the US$ 250-300 million on BOT

basis.

The Pakistan International Airlines (PIA) is the national flag carrier flying to 46

international and 36 local destinations. Other Pakistani airlines in the private sector

include, Aero Asia, Air Blue, Shaheen Air International and Pearl Air. In addition to

direct flights from most parts of the world, Pakistan can also be accessed through the

regional hubs of most international airlines, which operate through airports in the Gulf

countries.

The Pakistan Railways provides an important nation-wide mode of transportation in the

public sector. It contributes to the countrys economic development by catering to the

needs of large-scale movement of freight as well as passenger traffic. Pakistan railway

provides transport facility to over 70 million people and handles freight above 6 million

tons annually.

The Pakistan Railways Network was based on a total of 11,515 track kilometers

(including track on double line, yard & sidings) at the end of 2001-2002. This network

consists of 10,960 kilometers of broad-gauge and 555 kilometers of meter gauge.

Pakistan Railways has launched modernization activity with rehabilitation and

improvement plan both for its infrastructure and rolling stock including prime mover.

The ongoing schemes worth over US$ 500 million are progressing satisfactorily and have

brought a radical improvement in service. The railways is gearing up to the challenge of

providing improved connectivity to Iran, India, and link the upcoming Gwadar Port to

Afghanistan and onward to Turkmenistan.

Pakistan Telecommunication Limited (PTCL) dominated Pakistans telecommunications

market for the fixed-line services. Today the Pakistan Telecommunication Authority

(PTA) has the role of a regulatory body and is responsible for implementing the telecom

deregulation policy. For a long time, Pakistan lagged behind in the region as far as

x

telecom access is concerned. With cellular mobile revolution taking place, Pakistan's