Beruflich Dokumente

Kultur Dokumente

Fermentor Design

Hochgeladen von

tpchowoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fermentor Design

Hochgeladen von

tpchowoCopyright:

Verfügbare Formate

Fermenter

Design

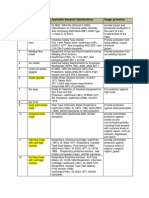

Utilitarianism, as defined by Jeremy Bentham (UCL) several assumptions that have to be made in order to solve an engineering problem, are acceptable !he first one "as the model ta#en for the scale$ up process !his "as the original %L fermenter used for the pilot scale of the & coli cells Assuming that a 1000L fermenter operating with 75% space efficiency (0.75) and 1 marine impeller (di=d !"). #he essel aspect ratio is ".5 that is Ah!d= ".5 and the fermenter is aerated at 0.75 m (that is 0.75 olumes of air per olume of li$uid per minute). #he gassed power re$uirement per m% is &g!'L= 1()0 *!m% as it was found from the model used for the scale+ up. ,sually the industrial motors are used to deli er 1+ % *!L (Lye et -agan./ "007). #herefore the 1.() *!L was chosen on the assumption that due to engineering cell modifications/ the 0.coli cells are not so ro1ust and thus e2tremely high power inputs should 1e a oided. #herefore the power input alue must 1e 3ept to a minimum. A 4ushton tur1ine four 1lade impeller is used as the a2ial flow type of impeller ensuring medium speed and ensuring medium growth rate 1ut also good mi2ing. 'hat does fermenter design means( *ell the importance of the design of the fermenter lies on the need to understand the 1roth5s 1eha iour during its mi2ing. Again/ we use the 5chocolate ca3e5 as the analogy. *e put the chocolate powder/ 1ased on a standard recipe (assumption) which in our case are the modified cells/ the mil3/ which is the o2ygen/ the sugar/ the 1utter and the eggs which are other crucial components for the success of our 5ca3e5 li3e the nutrients. 6econd step we mi2ed them all in a coo3ing pot/ which for the analogy used is the fermenter. 7ow/ you would not use a plastic pot/ as this would melt under high temperatures and you need to thin3 of your ingredients/ which opposed to cell 1roth/ are not acidic or anything li3e that/ 1ut you still need to thin3 of other factors that could cause leaching of the plastic/ leading to the conclusion that you would not use a &'8 one. 6o/ you may use a ceramic one/ again depending on what you coo39 pasta would go in a stainless steel one/ or a ca3e would go in a form with pro1a1ly some oil spraying for the ca3e to 1e remo ed easily upon coo3ing. 6imilarly/ the fermenter/ or 1ioreactor as it is also 3nown/ should 1e 6tainless steel. :oreo er/ when it comes to designing it/ of course you use some standard alues from literature/ as with a standard recipe for e2ample if you are coo3ing for 5 people the portion will differ significantly compared to a restaurant where the chefs coo3

for hundreds of people. #herefore/ the coo3ing apparatus differ in si.e. Also/ you need to critically thin3 a1out your recipe itself9 if you want to ma3e changes/ you can 1ase it on your e2perience/ on recommendations for e2perienced chefs as to on what ingredient goes with what. ;n a parallel way/ designing the e$uipment/ is 1ased on e2perience/ logic and some engineering calculations. :oreo er/ at some point/ you may ha e to close the lid/ so the fed 1atch mode where you could add other ingredients necessary during the <coo3ing process</ is switched to 1atch 1y closing the system5s input and letting the mi2ture get coo3ed. Also/ you ha e to control the temperature/ 1ecause o1 iously you do not want to 1urn your ca3e= #hat is why/ there is a need for a careful design of a fermenter/ with all the necessary pro1es/ to control the p>/ the temperature/ to ta3e out the first 1atch of <coo3ed ca3e< when is ready/ to see through a sight glass/ if the cells are growing+ or the ca3e is getting ready+ and control the fermentation process/ li3e a real coo3 does with the food.

)echanica

Design

of

%***L

Fermenter #his report was conducted to estimate the dimensions and the materials needed for the construction of a 1000L fermenter for the production of ?a1 fragments (fragmented antigen 1inding) are the regions of an anti1ody e2pressed and secreted in 0.coli cells. ?or the estimation of the dimensions of the fermenter empirical e$uations and rules of thum1s were e2ploited. #he dimensions and the fermenter properties li3e the diameter/ the height as well as the impellers speed/ the 1affles position and the dri eshaft si.e were estimated on a scale+ down model. #he material used for the fa1rication of the fermenter/ the head

end/ the ports and the pipes is stainless steel to resist corrosion and maintain a clean and sterile essel. #he diameter of the essel is 0.(m and the height is "m. #he thic3ness of the wall is )mm with a 0.15 m @ac3et surround it. #he impellerAs speed is %.% m!s and the impeller used is 4uston #ur1ine four 1lades/ suita1le for the growth of 0.coli cells. #herefore all the power re$uirements were satisfied ensuring the ia1ility of the design. ?i e spray 1alls were found to 1e enough for a sufficient cleaning of the fermenter with their %)0B co erage and placed on the inside of the torispherical head in a cross shape. #hen the flowrate in the pipes was predicted ena1ling the calculation of the diameter. -asically all the information specified for e ery single part of the fermenter was ta3en from recommendations/ ad ice from e2perts/ theoretical predictions as well as engineering @ustifications. Last 1ut not least emphasis is gi en on the importance of maintenance and annual shutdowns of the plant as well as regular chec3s to ensure its proper operation. #he 8omputational ?luid Cynamics (8?C) is the area of fluid mechanics that 1ased on e$uations/ simulates the flow pattern for a particular process. #hese are specific e$uations/ 3nown as 7a ier+6to3es e$uations/ which ena1le the understanding and prediction of the fluid flow that helps the 1etter design of the e$uipment e.g. impeller of the fermenter and optimisation of the conditions e.g. elocity/ in a way that yield the ma2imum 1enefit of the process e.g. achie e high yields and a oid dead olumes. ?or the 8?Cs (computational fluid dynamics) 8D:6DL :ultiphysics E.0a was used. #he modelling e$uations are the 7a ier+6to3es e$uations formulated in a rotating frame in the inner su1domain and in fi2ed coordinates in the outer one. 7o+slip 1oundary conditions apply at the 1ioreactor5s fi2ed walls and the 1oundary condition on the rotating impeller were set to rotate with the same elocity as the no+slip countercloc3wise rotation conditions.

?igure 1. #he computational fluid dynamics of the 1ioreactor using 8D:6DL :ultiphysics E.0a. showing that the shear rate reaches its ma2imum alue at the edges of the impeller and the 1affle. +avier$,to#es e$uations

-peration

Cycle

#he operation cycle for the fermenter in ol es start up/ where process water is fed from the process water port and media is fed from the feed port into the essel. #he le el of the li$uid is measured using the le el indicator pro1e. Dnce the re$uired le el is met then the ports close. Air is pumped through the air inlet to the sparger inside the fermenter. #here are three main modes of 1ioprocess operationF 1atch/ fed+1atch and continuous (Coran/ 1GGG). #he criticality of operating strategy is due to the significant impact is has upon the su1strate con ersion/ product concentration/ suscepti1ility to contamination and process relia1ility. ;nitially/ the reactor operation is fed+ 1atch. #hat means that the mi2ed reactor starts operating 1y intermittent or continuous feeding of nutrients which is necessary for the 1roth. #herefore/ additional fresh medium is allowed to enter the reactor with the flow rate and timing 1eing monitored and controlled 1y the dissol ed+ocygen le el or e2haust gas composition. #hen/ after all the medium is in the reactor at the conditions set/ we stop adding anything else in the reactor and the process ta3es place in a closed system. -atch processes operate in closed systems where there is no more su1strate addition 1ut only remo al of the end product (Coran/ 1GGG). #he most widely used reactor operation is 1atch with the classic reactor essel 1eing a stirred tan3.

?igure ". #he 8?C (8omputational fluid dynamics) of the 1ioreactor. As the simulation shows/ the regions where the 1roth is coming into direct contact with the 1affles and the impeller ha e greater speed. #he temperature is 1rought and maintained to the optimum temperature. #here are two pro1es in the fermenter which are at the greatest range i.e. opposite sides of the fermenter as shown in the drawing. #his is to ensure the distri1ution of heat is e en and the a erage of 1oth sensors should read %7B8. #he p> is maintained at a desired alue 1y the addition of acid and al3ali. #wo pro1es for measuring the p> are placed inside the fermenter at opposite ends to ensure there is good mi2ing as this would 1e indicated if there was little change 1etween the two pro1es. Dnce the optimum conditions ha e 1een achie ed the innocculum is fed through the innocculum port. Antifoam from the antifoam port is added to a oid foam formation which reduces the efficiency of the process. #he e2haust gases are released from the fermenter whilst in operation and the pressure is maintained. #he cells are grown for a

certain period of time and the process is regulated using a series of automatic control loops. ?inally there is shut down/ where the fermentation 1atch ends and in this step all the 1roth is collected into the har est port. After each operation cycle the fermenter will ha e to 1e cleaned and sterili.ed in place. 8;& will 1e performed using acid and 1ase detergents which will 1e pumped through the cleaning solution ports into the % spray 1alls. 6;& re$uires that the fermenter and all pipes are sterili.ed with steam at 1"1B8. #he steam will come from the acid/ 1ase and antifoam ports. 4egular and annual maintenance chec3s will ha e to 1e performed to ensure e erything is running correctly and as efficiently as possi1le.

Calculations

of

Bioreactor.s

/o"er 0e1uirements Calculations #he operating pressure of the essel was assumed to 1e %.5 1ar and the design pressure %.(5 1ar. #he operating temperature is %7B8 1ut the design temperature is E+ 1"1B8 allowing the introduction of steam to clean the essel.

?igure %. #he geometry of the 4ushton #ur1ine 1ioreactor/ as constructed with 8D:6DL :ultiphysics E.0a. 6tarting 1y assuming &g=0.E &g= (&g!'L)H 'L *ith &g usually 1etween 1+% *!L/ so &g! 'L= 1()0 *!m% (small scale) and need to find the properties of the 1000L fermenterF ''= 1000L= 1m% 'L= 0.75H 1m%= 0.75m% IJair='air!t=('LH m mK%)!()0 s) #he fermenter is aerated at 0.75 m/ i.e. 0.75 olumes of air per olume of li$uid per min #hen &g= 1()0 *!m% H 0.75m% which is the total gassed power input for the 1000L fermenter =L &g= 1%G5* #hen &ug= &g!0.E0Mrule of thum1N which is 1%G5*!0.E= %E((* #he aspect ratio of the essel height to the essel diameter could 1e from 1+% and according to e2perts (Oaco1s) for mammalian cells the alue of " is ad ica1le. AJh!d= ".5 =L h !d =".5 #hen usedF d =((E' )!(AJ(h!d) P))K(1!%) =L d =((EH1 mK%)! (%HP))K(1!%)=0.7515 mQ0.( m

6o h = ".5H 0.(m= "m #he minimum thic3ness re$uired can 1e calculated from the e$uation *ith f= 1%57!mm" for 150B8 (1"1B8 actually) &i= %.5 1ar= %.5H 105 &a/ Ci= 0.(m and f= 1%5H10) 7!m" #hen =L e= 1.0%H10+% m Q 0.001 m or 1mm #he minimum practical wall thic3ness of the essel though should 1e "mm. #he essel diameterAs is 0.(m and for essels of 1m diameter the minimum thic3ness should 1e 5mm (6innott/ "000). Jac#et #he space 1etween the @ac3et and the essel is estimated 1ased on the si.e of the @ac3et. According to 6innott ("000) the si.e of the @ac3et is 50mm for small essels and %00 mm for large essels. #he assumption made is that the @ac3etAs si.e should 1eF 150 mm for the 1000L fermenter. #he @ac3et surrounding the fermenter will 1e made out of stainless steel %0E and its thic3ness is the same as the fermenter. #he wall thic3ness of the fermenter was estimated to 1e )mm 1ased on rules of thum1 including an additional "mm allowance for corrosion.

2mpeller

,i3e

,peed

Calculation

and

+umber

&stimation

#hen the diameter of a2ial mi2ers was 1ased on the empirical statement (Lye/ "00)) that is o er 0.%% to 0.5 the tan3 diameter. 6o assumed to 1e 0.E5 timed the diameter of the essel/ that is dm= 0.E5H 0.(m= 0.%) m and the spacing is usually 1+" impeller diameters of 1 tan3 diameter (Lye/ "00)). 6o spacing/ 1ased on 1.5Hd#=0.%)H0.(m = 0.%m impeller spacing of one impeller from the other.

Driveshaft

Bl

ades

,i3e

calculation

#hen the impeller dri eshaft was decided to 1e 1ottom dri en as this is recommended in small industrial scale production where the shaft is shorter/ gi es 1etter power de elopment lea ing more space on top plate for ancillaries with only one draw1ac3 of a more difficult seal arrangement (Lye et -agan./ "007). ?igure E. #he elocity field of the 1ioreactor. #he shaft diameter was calculated 1y the ine$uality 1elowF ds L or = R((100HLH&ug ))!((PK"HSdiHf) )TK(1!%) #he shaft length was assumed to 1e 1.)5 m (slightly a1o e the li$uidAs le el). f is the design stress which is ta3en from literature which is 175 7!mm" for stainless steel %1)L wor3ing at %7B8. #he shaft diameter found is 0.07 m. #hen the 1lade thic3nessF d1t L or = R((G&Jug ))!((%"Pn7f) )TK(1!") where n is the num1er of impellers/ so n=1 d1t=0.00" m -lade width= 0."H di= 0.1)m -lade height= 0."5H di= 0."0m Cisc diameter= 0.75H di= 0.)0m Cisc thic3ness= -lade thic3ness= 0.0"m

Baffles

-rifice

,parger ;t was decided that four diametrically opposed 1affles would 1e put in the essel. #he si.e of each 1affle should 1e 0.1+ 0.05 tan3 diameter. #he assumption made here is that the 1affleAs diameter= 0.1Hd#= 0.1 H0.(m= 0.0(m or (cm. #he 1affle height is dependent on the gas holding or it accepted to 1e e$ui alent to the cylindrical height of the essel. ;n this case it was assumed to 1e slightly a1o e the li$uidAs le el. 6mall gap 1etween essel

and 1affle is recommended to stop 1iomass 1uild up/ enhance o2ygen transfer and cleaning solution (Lye et -agan./ "007). #he gap is 0.1 of the 1affle width fi2ed to the essel such that they can 1e remo ed. Also it is recommended that 1affles are placed at an angle as with were found from e2perts to enhance scouring (Lye et -agan./ "007). #he dimensions of the 1affles were estimated 1ased on empirical e$uations relating their si.e to the esselAs si.e.

?igure 5. #he cross sectional iew of the 1000L 1ioreactor. #herefore in the mechanical drawing the 1affles were drawn at an angle of 10B to the ertical pointing anti+ cloc3wise since the flow direction is cloc3wise. #hat was decided after some thought and with the preparation of a computational fluid dynamic model to predict the flow of the fluid. Also the 1ase of the cylindrical essel was chosen to 1e rounded at the edges since in this way it discourages the formation of stagnant regions. An orifice sparger was placed under the 1ottom impeller and its si.e was calculated to 1e 75% the impellers diameter that is %.%75 cm (E cm for easier design). #he holed on this circular ring must not e2ceed ) mm and therefore for design calculations their si.e was assumed to 1e 5 mm. A magnetic dri e was chosen as the dri eshaft seal as this is more common in non+ iscous fermentation 1roths li3e 0scherichia cell culture which is a ery dilute culture since the cell density is low.

Design

of

closure

of

the

fermenter

;t was decided to use a standard torispherical head since it is widely used in industry and can withstand operating pressure up to 15 1ar. #he 1ending and shear stresses were ta3en into consideration in the design of the heads. ?or the estimation of these stresses usually caused 1y dilations of the essel a 1asic e$uation used for a hemisphere was used. #he 3nuc3le and crown radii were found from empirical alues allowing the stress concentration alue determination that allowed with its turn the estimation of the thic3ness of the head. ?igure ). Cesign of the closure of the fermenter (plan iew).

8s= 1!E (%UV(4c!43 )) where 8s is the stress concentration factor ta3en to allow for the increased stress due to the discontinuity. 4c= crown radius (not to 1e more than the esselAs diameter) 43= 3nuc3le radius #he ratio 4c! 43 should not 1e less than )% (to a oid 1uc3ling). e= (&iH4cH8s)!("fOU&iH(8s+0.")) For formed heads (no joints in the head) J=1.0 &i is the internal pressure and f is the design stress (literature alue). #he design pressure= 110% of the operating pressure (8oulson and 4ichardson/ "000) ;n this case/ the fermenter is operating at %.5 1ar therefore the design temperature is %.(5 1ar. Dperating temperature= %7B8 mammalian cell culture/ cleaning solution EB8 for the cooling water and 1"1B8 for the steam (8;&) f= 1%5 7!mm" (stainless steel corresponding to operating temperature 150B8) 4c= 1.5 m hence 43= 0.0)H4c 6o 43=0.0G m 6o e= 7 mm (5mmU "mm for corrosion allowance) ?or design purposes it was assumed that the wall thic3ness and the end thic3ness are the same/ )mm. -asically/ the wall thic3ness has an impact on the o erall heat transfer coefficient while the end thic3ness affects the mi2ing characteristics of li$uid inside and since the essel is metal/ the alue of the thic3ness means it would aid cleaning. L&5&+D 6&7 5

7o A 8 C 0 ? W > ; O [ L : 7 D & I 4 6 #

7A:0 A8;C &D4# 6A:&L;7W &D4# 6#0A: ;7!*A#04 D,# :0C;A ?00C &D4# A8;C &D4# 8DDL;7W *A#04 ;7!8D7C076A#0 D,# -A60 &D4# A7#;?DA: &D4# >A4'06#;7W &D4# X C4A;7AW0 &;&0 6&4AY -ALL (Z5) :A;7 L;?#;7W L,W L;?#;7W L,W6 6;W># WLA66 ?D# &4D-0 #0:&04A#,40 &4D-0 &> &4D-0 L;I,;C L0'0L ;7C;8A#D4 &4066,40 &4D-0 0Z>A,6# A;4 A;4 ;7L0# #D 6&A4W04

Calculation

of

the

dead

"eight

of

the

fermenter

?or preliminary calculations/ the appro2imate weight of a cylindrical essel with domed ends and uniform wall thic3ness can 1e estimated with the following e$uationF * =8 H(PH\mHCmHg(> U0.(Cm)Ht *here * is the weight of essel 8 is a factor for the weight of no..les etc= 1.0( Cm= CiUt where Ci is the internal mean diameter of the essel ?or steel essels the a1o e formula 1ecomesF * ="E0H8 HCmH(> U0.(Cm)Ht All the ancillary e$uipment attached to a tall essel will su1@ect the essel to a 1ending moment if the centre of gra ity of the e$uipment does not coincide with the centre line of the essel according to 8oulson and 4ichardson. #he moment produced 1y small fittings e.g. ladders/ pipes and manway will 1e small and hence can 1e neglected. ?or this mechanical drawing though the moment e$uation is only 1eing mentioned. :e=*eHLo where :e is the moment/ *e is the dead weight of the e$uipment and Lo is the distance 1etween the centre of gra ity of the e$uipment and the column centre line. ?rom calculations/ * = %."1GE m% say %.% m% (%%00 L or %%00 3g). Fermentation ,upport "ith s#irt

#he choice of s3irt support was 1ased on that s3irt supports are used for tall/ ertical columns to carry the weight of the essel and contents. #herefore the essel support should 1e designed not to impose any locali.ed loads on the essel wall and to allow easy access to the essel and fittings for inspection and maintenance. A flange at the 1ottom of the s3irt transmits the load to the foundations. Last 1ut not least/ the s3irt that the fermenter will 1e placed in was chosen to 1e a conical one with the angles of the 1ase to 1e (0B as it is predicted to e$ually distri1ute the weight of the fermenter and ensure no collapse and 1alance of the whole e$uipment system. #he minimum thic3ness should not 1e less than 5mm. Assume to 1e Gmm. #he stresses in the s3irt can 1e found 1y calculating other outside parameters that influence the esselAs sta1ility 1esides the dead weight of the essel or the si.e of the essel with its contents li3e the wind loading and the earth$ua3e acceleration. #hese can 1e found 1y measuring the wind speed/ the density of air and hence calculating the pressure of the wind on the essel which in turn can 1e used to find the stress acting directly to the fermenter. ?or the purpose of this study though these parameters where neglected. ?igure 7. #he s3irt of the fermenter/ hand drawn. /ipe

dimensions

#he diameter of the pipes connected to the fermenter for the air supply/ air e2haust/ inocculum introduction and media feed as well as the ports for the introduction of acid/ al3ali and anti+ foam when necessary were calculated 1ased on predicted flowrate and on the 4eynolds 7um1er representing the type of flow needed for each case. Cue to the not so high operating pressure the process pipes are thin cylinders with a thic3ness of ".5 mm. ?or the determination of the pipe dimensions tur1ulent flow is assumed with the 4eynolds num1er to 1e L 10E to enhance good mi2ing of each fluid with the 1roth. As a rule of thum1/ li$uid elocities are usually in the range 1+% m!s in order to minimi.e the presence of stagnant unmi2ed poc3ets of fluids 1ut also to e2tend the lifetime of the systems (?arid/ "00)). #herefore assume = " m!s. #he mass flow/ 1ased on alues (?arid/ "00)) used in industry was assumed to 1e 10 3g!s.

/ressure

drop

calculation

(in

the

pipe)8

?riction loss per unit length/ fF 4e=(\H Hdp)!]= G000 ( L 10E therefore tur1ulent flow) #hen the a1solute roughness for commercial stainless steel pipe e= 0.0E)mm is found from ta1les (8oulson and 4ichardson/ "000) and hence the relati e roughness can 1e calculated. e!d= 0.0E)mm!70mm=).5(H(10K+E) ,se :oody chart to find the ?anning ?riction factorF f= 0.00"5

?igure (. :oody 8hart (6inott/ "000) #hen the wall thic3ness can 1e found 1yF t=(&Hd)!("0H^dU&)

#he wor3ing pressure is %.5 1ar and the design stress at the operating temperature of 1"1B8 which is the ma2imum wor3ing temperature (150B8 from the ta1le for stainless steel %1)L) is 1%5 7!mm" and 1 1ar= 105 &a. t=10+% mm -asically the process pipes can 1e considered as thin cylinders. Also allow "mm for corrosion. #hat is ".5mm as a standard pipe diameter.

,prayball

?or the 1000L fermenter it was decided that % spray 1alls of 75mm si.e each are suita1le for a satisfactory cleaning. #he height of the 1all with the connector is G0 mm and the shape of the 1all is the standard round shape pro ided 1y #ofte@org. #he spray1all has thic3 wall/ Emm/ offering more efficient cleaning and is made out of %1)L stainless steel to a oid corrosion caused 1y the cleaning solution. #here will 1e holes at the top/ at the sides and at the 1ottom of the 1all to ensure a %)0B co er of the fermenter.

?igure G. A typical 1ioreactor _ adopted 1y ;ndustrial ?ermentsF growing cells on a large scale 1y [eith >ic3s ("00G).

,ight

glass

#he placement sight glass placed on the fermenter is a way to loo3 into the actual process when it ta3es place. ,sually a 15 cm window is placed/ so for design purposes a 1).5 cm window was chosen. Also the height at which the sight glass was put was empirically predicted to 1e 15 cm outside the essel for a wider iew. #he glass will 1e surrounded 1y a stainless steel %0E collar which less e2pensi e compare to the %1) L since there is no need for it/ with a diameter of %0 cm. #hat is 1%.5 cm layer around the glass. Also a switch for L0C light is assumed to 1e needed to the sight glass for 1etter iewing. ?or the sight glass/ 1orosilicate is used due to its physical strength/ ma3ing it resistant to thermal shoc3 and chemical attac3 (6inott/ 1GGG). /orts

#here are se eral ports needed to 1e installed in the fermenter li3e pro1es/ acid/ 1ase and anti+ foam inlets which correct the p> when re$uired/ as well as outlet ports for drainage and their si.e ha e to 1e estimated 1efore the construction of the fermenter. ,sually a "5 mm port is used for pro1es and sampling while the %E mm is for some additional ports. #he decision made here was that a %E mm port would 1e the ideal si.e for all the ports with no e2ceptions and depending on the demand the flowrate of each component coming in or out of the fermenter will 1e ad@usted accordingly.

Choice

of

materials ?rom a detailed research of currently a aila1le fermenters in industry for the production of 1iopharmaceuticals/ the 1ioreactor will 1e made out of stainless steel %1)L (low car1on) since the use of clean steam causes corrosion to the essel and therefore it is e2tremely important to use clean steam for the mammalian cell culture. (Lydersen et al/ 1GGE). Also the choice of 66%1)L is suita1le for technical purposes li3e welding

characteristics. #he $uality of essel welds is to ensure the ma2imum possi1le smoothness and cleani1ility as well as to minimi.e corrosion. According to Lydersen et al (1GGE)/ the welding of an aseptic fermenter should 1e done under inert gas shielding to minimi.e o2idation and flu2 residue and to yield smoother welds. #herefore the use of a %1)L and not the %1) stainless steel reduced car1ide precipitation and conse$uent pitting near the welds. ?or the head end silicone will 1e used at the flange point and the for the other static D+ ring seals 0&C: (ethylene propylene diene monomer) as this is recommended from the -ioprocess 0ngineering 1oo3 for system/ e$uipment and facilities on the fermentor design section 1y Lydersen at al.

Jac#et,

,urfa

ce

treatment

/olishing #he space 1etween the @ac3et and the essel is estimated 1ased on the si.e of the @ac3et. According to 6innott ("000) the si.e of the @ac3et is 50mm for small essels and %00 mm for large essels. #he assumption made is that the @ac3etAs si.e should 1eF 150 mm for the 1000L fermenter. #he @ac3et surrounding the fermenter will 1e made out of stainless steel %0E and its thic3ness is the same as the fermenter. #he wall thic3ness of the fermenter was estimated to 1e )mm 1ased on rules of thum1 including an additional "mm allowance for corrosion. #he stainless steel fermenter is important to 1e cleaned and treated in a way so as corrosion will 1e pre ented during operation conditions. 6o there is an inside and outside surface finish that permits the easy and hygienic cleaning of the essel. Dn the stainless steel surface there is a microscopically thin/ in isi1ly chromium o2ide layer that pre ents

corrosion of the essel when the essel is clean and polished. #he surface finish is more for aesthetic purpose rather than for functional reasons. A mechanical surface treatment is used for the steel essel. #he smoothness and $uality of the mechanically treated surfaces are defined 1y 4a/ 4t or 4:6 alues which account for the roughness of the surface and usually in 1iotechnology surface $ualities of 4a around 0.) `m (""0 grit) is the minimum re$uirement. According to Lydersen et al/ the steel grade 1.EE0) (A;6; %1) L) gi es the 1est possi1le smoothness alue. #herefore a minimum finish of 0.51+ 0.)E `m is common and it for the 5500L of this pro@ect it was decided to go for a "E0 grit/ that is 0.%(+0.51 `m. #his polish num1er presented 1y the agritA term num1er is defined as the num1er of silicon car1ide particles per s$uare inch of a1rasi e pad or as the num1er of scratches per linear inch and a higher grit num1er means a smoother finish (Lydersen at al/ 1GGE). ;n addition to the mechanical polishing an electropolishing step remo es metal from the surface 1y anodic dissolution in a suita1le electrolyte with an applied current. #he ad antage of this treatment is that it is smoothes roughness in the surface area which cannot 1e seen with na3ed eye.

2nspection

and

)aintenance Access to the inside of the fermenter is re$uired for the super ision of the impellers/ the 1affles/ the dri eshaft/ to ensure that the magnetic coupling seal wor3s properly and that the orifice sparger wor3s without interruptions that would lead to product damage. ?or this reason a remo a1le domed end (torishperical head) was chosen. ;n addition to that it was thought that the addition of metallic lifting lugs would ma3e the dismantling remo al easier with the use of crane e$uipment. 6i2 different pro1es for temperature/ CD#/ pressure/ p> and o2ygen and car1on dio2ide le el indication each one along with " 1ac3 up indicators each in case of failure were put to the fermenter as well as a iewing sight glass while the inlet and outlet ports are used

for the addition or remo al of the necessary materials to ensure the proper opera1ility of the fermenter. :oreo er to ensure that sterility is maintained the use of D rings is assumed. ;t was decided that the D rings will 1e made of 0& (ethylenepolypropylene ru11er) since it is the most widely used and alidated material in 1iotechnology and food technology and the 0& seals range from +E0 to 1)0B 8/ are resistant to water/ steam and aging. ?or the stainless steel tu1ing sanitary clamp seals with flat gas3et are used in the ,.6.A. fi2ed with a #ri+ clampb (Lydersen et al/ 1GGE). 4egular chec3s on the pipes/ al es/ flanges points/ pro1es/ sparger/ control loops/ impeller/ @ac3et/ weld points is crucial to maintain the fermenter in a good condition for 1etter efficiency/ less money spent on replacing 1ro3en parts and e2tending its lifetime (although it is e2pected to wor3 for a1out 10 years). ;n addition to that/ an annual shutdown is re$uired to chec3 for degradation/ deformation of pipes/ fatigue of materials/ crac3s and nic3s inside or outside the fermenter. #ypically/ %+5% of fermentations in an industrial plant are lost due to failure of sterilisation procedures. >owe er in anti1iotic fermentations li3e in this pro@ect/ fewer than "% of production scale anti1iotic fermentations are lost through contamination 1y microorganisms or phage (Coran/ 1GGG). ;ndustrial fermenters are designed for in situ steam sterilisation under pressure. ?or effecti e sterilisation/ all air in the essel and pipe connections must 1e displaced 1y steam. After sterilisation/ all nutrient medium and air entering the fermenter must 1e sterile. :aintenance is re$uired to ensure the fermentation process is achie ing its goals/ to identify any pro1lems that may occur and ultimately 3eep the process wor3ing as efficiently as possi1le to sa e on costs. :aintaining the fermenter can significantly reduce the o erall operating cost as well as minimise the ris3 of any ha.ards. ?or maintenance/ the top of the fermenter can 1e remo ed to allow access of maintenance personnel for any repairs that may 1e re$uired. ?or large essels a domed construction at the top to allow access to personnel is less e2pensi e and so this has 1een chosen in the design (Coran/ 1GGG). Dnce the design has 1een 1uilt and appro ed 1y -ritish 6tandards 5500/ the fermenter can then start to operate (6inott/ 1GGG). :aintenance is crucial and the fermenter must 1e monitored at all times. :ost measurements can 1e made on+line through pro1es in the essel which are sensors that detect changes in many aria1les such as temperature and p>. >owe er/ whilst monitoring some alues there may always 1e a delay. ?or e2ample/ in a typical fermentation/ the time scale for change in p> and dissol ed+o2ygen tension is se eral minutes to ma3e sure they are all correctly cali1rated and functioning properly and as efficiently as possi1le. #his is to a oid any pro1lems that may 1e caused 1ecause of a false reading. ?or e2ample if the p> pro1e is not wor3ing properly and the p> is either too high or too low/ then the cells would die and also the product may denature. Also possi1le 1loc3ages in pipes or 1ro3en al es must 1e chec3ed regularly. D2ygen supply through 1ottom sparging should also 1e chec3ed regularly/ as cells die without it and that would mean a significant loss in time and money if the fermenter has 1een running for se eral days.

?igure 10. #he 1asic construction of the 1ioreactor/ using 8D:6DL :ultiphysics E.0a./ shows the 1affles/ the impeller/ the @ac3et and the essel wall clear geometry without any 1roth. #he fermenter re$uires annual shutdown to chec3 for possi1le corrosion on the internal surface and also on the impellers. 8orrosion may reduce the speed and efficiency of them impellers and the shaft too. #his needs to 1e maintained at a high standard to ensure good mi2ing in the fermenter for growth of cells and product. -affles also need to 1e chec3ed for to see the le el of corrosion. Also there may 1e possi1le fouling in the @ac3ets and general piping pro1lems/ such as 1loc3ages and lea3ages/ as well as o erall contamination in the system. As pre iously mentioned in the design a "mm allowance for corrosion had 1een added on the thic3ness of all e$uipment. #he annual chec3 would see how much all the e$uipment has 1een eroded and identify any pro1lems to resol e them. #he aim of the :echanical Crawing is to pro ide a detailed analysis of the construction and operation of the fermenter that is a technical way of presenting this piece of e$uipment. ;n this section the dimensions and materials of construction of a 1L fermenter were estimated. #he fermenter is used for the growth of 0scherichia coli cell culture for the production of therapeutic fragmented anti1odies.

Conclusion #he importance of carrying out a carefully designed fermenter lies to the fact that product safety (,6 term according to Oaco1s) is the num1er one demand. #herefore the $uality of the 1iopharmaceutical product is the factor that dri es all the operational re$uirements of the process. 6tarting from the 3nowledge of the culture itself defines the specifications re$uired to design a safe and opera1le piece of e$uipment. #herefore it is essential to specify all the parameters dri ing this process from the impeller power to the temperature indicator/ from a small detail such as the angle of the 1affles until the end closure of the essel/ as well the materials for the esselAs fa1rication found to 1e most suita1le from pre ious wor3 and industrial operations. 6ometimes in order to define the dimensions of the fermenter or parts of the system/ a rational analysis or a sound engineering @udgment is needed o er mathematical e$uations. ;t is 1elie ed that the purpose of this section was not to lead the future engineer how to loo3 for literature alues on the a1i1le of designA 1ut to de elop the critical thin3ing. Last 1ut not least regular inspections and maintenance is essential to ensure a safe operation of the fermentation step. #he cells are grown in a ery carefully controlled en ironment9 1y ad@usting the p>/ the acid as needed is aided to regulate the growth of the cells. :oreo er/ all pipewor3 connected to the fermenter is sterilised prior to fermentation. #he aero1ic fermentation process is dri en 1y the motor and the dri eshaft with the impellers on it/ which they continuously stirr the cell 1roth. :oreo er/ the @ac3et is re$uired to cool down the fermenter since the rise in temperature of the culture rises 1y more than 1B8 per hour 1ut a sharp rise in temperature could 3ill the micro1es if not cool. httpF!!"010.igem.org!#eamF,8LJLondon!?ermenterJ:echanics

Das könnte Ihnen auch gefallen

- Safety Concept Note For Ware HouseDokument3 SeitenSafety Concept Note For Ware HousetpchowoNoch keine Bewertungen

- Syllabus PDFDokument58 SeitenSyllabus PDFPrashant JagdaleNoch keine Bewertungen

- Industrial Safety Equipment StandardsDokument6 SeitenIndustrial Safety Equipment StandardstpchowoNoch keine Bewertungen

- Dotnet RemedyDokument1 SeiteDotnet RemedySantosh ChowdaryNoch keine Bewertungen

- Data AnalysisDokument19 SeitenData AnalysistpchowoNoch keine Bewertungen

- HelpDokument1 SeiteHelpAubrey AzaNoch keine Bewertungen

- List of PPE Is StandardsDokument2 SeitenList of PPE Is StandardstpchowoNoch keine Bewertungen

- Indian Pollution Control Board GuidelineDokument95 SeitenIndian Pollution Control Board GuidelineA.K. MAITINoch keine Bewertungen

- Student Slides M6Dokument14 SeitenStudent Slides M6niyo7Noch keine Bewertungen

- Is.2573.1986 GlovesDokument18 SeitenIs.2573.1986 Glovesraams_1973Noch keine Bewertungen

- India Salary Guide 2015Dokument60 SeitenIndia Salary Guide 2015ajay_chebrolu100% (1)

- SWL CalculationDokument4 SeitenSWL CalculationMohdNajib Mahmud93% (15)

- CLSS EWS LIG English Guidelines WBDokument36 SeitenCLSS EWS LIG English Guidelines WBAnurag BabuNoch keine Bewertungen

- Process Safety Basic DataDokument1 SeiteProcess Safety Basic DatatpchowoNoch keine Bewertungen

- PPEs StandardsDokument3 SeitenPPEs Standardstpchowo100% (1)

- Andhra Pradesh Building Rules 2012 GO - Ms.No.168 MA, Dated 07.04.2012Dokument373 SeitenAndhra Pradesh Building Rules 2012 GO - Ms.No.168 MA, Dated 07.04.2012info297287% (54)

- User Guide Nokia 3 User GuideDokument75 SeitenUser Guide Nokia 3 User GuidetpchowoNoch keine Bewertungen

- Atal Pension Yojana Application FormDokument1 SeiteAtal Pension Yojana Application FormRohit JainNoch keine Bewertungen

- IDBI Bank Homeloan Application FormDokument8 SeitenIDBI Bank Homeloan Application FormtpchowoNoch keine Bewertungen

- NF 1015 Applicable For Housing Loan Pradhan Mantri Awas Yojana 9pmayDokument9 SeitenNF 1015 Applicable For Housing Loan Pradhan Mantri Awas Yojana 9pmaytpchowo100% (1)

- Chap8 BioreactorDokument17 SeitenChap8 BioreactortpchowoNoch keine Bewertungen

- PMAY Annexure B and C SBI BankDokument6 SeitenPMAY Annexure B and C SBI BanktpchowoNoch keine Bewertungen

- 2016 17-Itr1 MNRDokument23 Seiten2016 17-Itr1 MNRvkbasavaNoch keine Bewertungen

- Pmay Self DeclarationDokument1 SeitePmay Self DeclarationtpchowoNoch keine Bewertungen

- Site For MsdsDokument1 SeiteSite For MsdstpchowoNoch keine Bewertungen

- 100CEPDokument0 Seiten100CEPtpchowoNoch keine Bewertungen

- Process Safety Basic DataDokument1 SeiteProcess Safety Basic DatatpchowoNoch keine Bewertungen

- HYSYS V8 TutorialDokument24 SeitenHYSYS V8 Tutorialpriyaprasad367792Noch keine Bewertungen

- Advanced HysysDokument210 SeitenAdvanced Hysystpchowo100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- SOP On LMO Tank 20210401 - USAID RISEDokument25 SeitenSOP On LMO Tank 20210401 - USAID RISEBoke BelayNoch keine Bewertungen

- Dextra Prestressing Bar Rev 11 Oct 2016Dokument14 SeitenDextra Prestressing Bar Rev 11 Oct 2016Natthawut CheencharoenNoch keine Bewertungen

- Arches: Theory of StructuresDokument20 SeitenArches: Theory of StructuresAravind BhashyamNoch keine Bewertungen

- Parker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016Dokument370 SeitenParker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016mds9185Noch keine Bewertungen

- Chapter 10 Solution Lecture Solution Ecture NotesDokument37 SeitenChapter 10 Solution Lecture Solution Ecture NotesLiew KahJiannNoch keine Bewertungen

- PCC Technova Series CPL Cylindrical ValvesDokument5 SeitenPCC Technova Series CPL Cylindrical ValvesAnju VijayanNoch keine Bewertungen

- Freeze Dryer Lyophilisation FishDokument4 SeitenFreeze Dryer Lyophilisation FishcouvrefeuNoch keine Bewertungen

- Fire Watch Training PDFDokument41 SeitenFire Watch Training PDFHamdi Rafiek83% (23)

- GTS-80 MQAP Rev 1.04Dokument6 SeitenGTS-80 MQAP Rev 1.04Tyler CurryNoch keine Bewertungen

- Reaction Mechanisms 1 MSDokument9 SeitenReaction Mechanisms 1 MSBeatrice MoyoNoch keine Bewertungen

- Schedule of Rates 2014Dokument10 SeitenSchedule of Rates 2014A. S. M. Elias ShahNoch keine Bewertungen

- Lesker FeedthroughsDokument39 SeitenLesker FeedthroughspericoNoch keine Bewertungen

- FME-2021-0403 Proof HiDokument41 SeitenFME-2021-0403 Proof HiAsif EqubalNoch keine Bewertungen

- Lec 6 Module 1Dokument18 SeitenLec 6 Module 1vedant chavanNoch keine Bewertungen

- BS en Iso 9712 Standard CodeDokument17 SeitenBS en Iso 9712 Standard CodeVilam Ndt100% (1)

- DIY Homemade HHO Hydrogen Generator - RMCyberneticsDokument6 SeitenDIY Homemade HHO Hydrogen Generator - RMCyberneticsharisaryono100% (1)

- Neil Dominic C. Mahusay Bsme-3 Module 1 Assignment: Military Body ArmorDokument4 SeitenNeil Dominic C. Mahusay Bsme-3 Module 1 Assignment: Military Body ArmorMahusay Neil DominicNoch keine Bewertungen

- Revised PT Program April-May 2021 30% Discount Metal TestingDokument2 SeitenRevised PT Program April-May 2021 30% Discount Metal TestingSaravanan PNoch keine Bewertungen

- Industrylist KolhapurDokument154 SeitenIndustrylist KolhapurYogarajaan DevarajNoch keine Bewertungen

- GTU BE Semester V Mass Transfer Operations I Exam Summer 2016Dokument2 SeitenGTU BE Semester V Mass Transfer Operations I Exam Summer 2016Shivam PanchalNoch keine Bewertungen

- ASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedDokument1 SeiteASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedAmanda Ariesta ApriliaNoch keine Bewertungen

- LNG Light Hydrocarbon Separation with Cryogenic Energy UtilizationDokument4 SeitenLNG Light Hydrocarbon Separation with Cryogenic Energy UtilizationphantanthanhNoch keine Bewertungen

- Fan - 2009 - 8 - ECTC 2009 - 2 RahimDokument5 SeitenFan - 2009 - 8 - ECTC 2009 - 2 RahimkraidonNoch keine Bewertungen

- BECHEM Special Lubricants For Open Gear Drives 2015 01Dokument11 SeitenBECHEM Special Lubricants For Open Gear Drives 2015 01satfas100% (1)

- Geotechnical Engineering QuantumDokument274 SeitenGeotechnical Engineering QuantumRitik SinghNoch keine Bewertungen

- Basics of Reinforced Concrete Design: OutlineDokument10 SeitenBasics of Reinforced Concrete Design: OutlineariNoch keine Bewertungen

- Styrene Acrylic FTIRDokument9 SeitenStyrene Acrylic FTIRDesi Rahma PrihandiniNoch keine Bewertungen

- Manual For ConcretingDokument43 SeitenManual For Concretinglwin_oo2435Noch keine Bewertungen

- Building TechnologyDokument3 SeitenBuilding TechnologyClaro III TabuzoNoch keine Bewertungen

- Reactive Wetting, Evolution of Interfacial and Bulk IMCs and Their Effect On Mechanical PDFDokument32 SeitenReactive Wetting, Evolution of Interfacial and Bulk IMCs and Their Effect On Mechanical PDFeid elsayedNoch keine Bewertungen