Beruflich Dokumente

Kultur Dokumente

B31.3 Process Piping Course - 07 Layout and Support

Hochgeladen von

Binodh DanielCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

B31.3 Process Piping Course - 07 Layout and Support

Hochgeladen von

Binodh DanielCopyright:

Verfügbare Formate

ASME B31.3 Process Piping Course 7.

Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 1

ASME B31.3 Process Piping

Charles Becht IV, PhD, PE

Don Frikken, PE

Instructors

BECHT ENGINEERING COMPANY, INC. Layout and Support - 2

1. Establish applicable system standard(s)

2. Establish design conditions

3. Make overall piping material decisions

Pressure Class

Reliability

Materials of construction

4. Fine tune piping material decisions

Materials

Determine wall thicknesses

Valves

5. Establish preliminary piping system layout & support

configuration

6. Perform flexibility analysis

7. Finalize layout and bill of materials

8. Fabricate and install

9. Examine and test

Piping Development Process

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 3

7. Layout and Support

General Considerations

Support Spacing

Support Locations

Support Elements

BECHT ENGINEERING COMPANY, INC. Layout and Support - 4

The Material in This Section is

Addressed by B31.3 in:

Chapter II - Design

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 5

General Considerations

Access for operation (valves)

Access for maintenance of in-line devices

instrumentation

Traps

strainers, etc.

Avoiding interference with other activities

Removing heat exchanger bundles

Clearance for pump maintenance, etc.

Appearance

BECHT ENGINEERING COMPANY, INC. Layout and Support - 6

General Considerations

Drainage (slope) requirements

Pressure drop

Cost of piping, including maximizing use

of existing supports

Avoiding interference with other piping

Clearance for application of insulation

Clearance for piping displacement, etc.

Provisions for future additions

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 7

Support Spacing

Loads to consider

Dead Weight

Pipe

Insulation

Valves, specialty

items and

instruments

Live loads

Pipe contents

Ice, snow

People

BECHT ENGINEERING COMPANY, INC. Layout and Support - 8

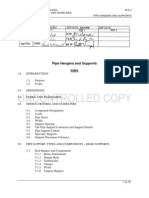

Support Spacing

Two principal sources:

1. Recognized codes & standards

ASME B31.1

MSS SP-69: Pipe Hangers and Supports

Selection and Application

2. Owner or designer calculated values

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 9

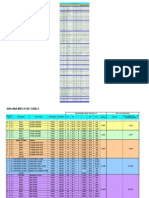

Support Spacing

10.4 34 6.1 22 10

11.0 36 7.0 23 12

9.8 32 5.8 19 8

9.1 30 5.2 17 6

7.9 26 4.3 14 4

6.1 20 3.0 10 2

4.3 14 2.1 7 1

m ft m ft

Typical Calculated MSS SP-69

NPS

BECHT ENGINEERING COMPANY, INC. Layout and Support - 10

Support Spacing

Usually based on simplifying assumptions

Combination of pipe material and wall

thickness used in the facility that gives the

shortest spans

Contents specific gravity, usually 1.0

Typical insulation thickness and density

Person walking on pipe for larger sizes

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 11

Support Spacing

L

w

L

w

Two Models Frequently Used

BECHT ENGINEERING COMPANY, INC. Layout and Support - 12

Support Spacing

S

L

= stresses caused by bending

moment and pressure

= M/Z + PD/4t

= (wL

2

+ 2HL) / (8Z) + PD/4t

H

L

w

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 13

Support Spacing

S

L

= (wL

2

+ 2HL) / (8Z) + PD/4t

Where

D = pipe outside diameter

H = concentrated load (people)

L = trial length for support spacing

M = bending moment

P = design pressure

t = pipe wall thickness nominal wall thickness less

mechanical, corrosion and erosion allowances

w = uniform load due to pipe, contents & insulation

Z = pipe section modulus

BECHT ENGINEERING COMPANY, INC. Layout and Support - 14

Support Spacing

Some designers limit support spacing using an

arbitrary deflection criterion. 0.5 in. (12 mm) is

frequently used.

H

L

w

max

= (5wL

4

/ 384EI) + (HL

3

/ 48EI)

Where

E = pipe material elastic modulus

I = pipe moment of inertia

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 15

Support Spacing

This calculation method is only applicable

to straight pipe with more-or-less

uniformly spaced supports.

Using the simply supported beam model

versus the fixed beam supported model

adds some conservatism to the

calculation.

Other models that can be used are shown

on succeeding slides.

BECHT ENGINEERING COMPANY, INC. Layout and Support - 16

M = wL

2

/8

max

=

5wL

4

/384EI

Uniform load

M = HL/4

max

= HL

3

/48EI

Concentrated

load

Support Spacing

Assuming simply supported ends

H

L

L

w

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 17

Support Spacing

Assuming Fixed ends

M = wL

2

/12

max

=

wL

4

/384EI

Uniform load

M = HL/8

max

=

HL

3

/192EI

Concentrated

load

H

L

L

w

BECHT ENGINEERING COMPANY, INC. Layout and Support - 18

Support Locations

Supports must be located such that S

L

S

h

.

Following these rules of thumb will help:

Piping running up the side of vessels should

be supported from the vessel, generally near

the top of the run.

Locate concentrated loads (e.g. valves) near

supports.

Use rigid supports (i.e. not spring supports) at

safety valves.

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 19

Support Locations

Following these rules of thumb will help

when doing the flexibility analysis:

As much as possible, attach supports to

straight pipe rather than elbows or other

fittings.

Provide space for adding loops to piping near

load sensitive equipment, e.g. in pump suction

lines.

Consider the need to add friction reducing

slides between the piping and support steel.

BECHT ENGINEERING COMPANY, INC. Layout and Support - 20

Support Locations

Following these rules of thumb will help

operation and maintenance:

Attach supports to pipe, not valves, flanges or

instruments.

Provide supports near instruments, and other

devices that are likely to be removed for

maintenance.

Support piping such that spools to be removed

for equipment maintenance can be removed

without adding temporary supports.

Minimize the use of spring hangers.

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 21

Support Elements

Support elements are classified by the degree of restraint

provided to the piping

Restrains movement in all

directions (welded to

support steel)

Anchor

Restrains axial movement

(and sometimes vertical

movement as well)

Longitudinal

Pipe Restraint

Restrains lateral movement

(and sometimes vertical

movement as well)

Guide

Only provides vertical

restraint

Simple

Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 22

Simple Support

(from Anvil International)

(from Piping Technology & Products)

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 23

Simple Support

(from Anvil International)

(from Piping Technology & Products)

BECHT ENGINEERING COMPANY, INC. Layout and Support - 24

Guide

(from Anvil International)

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 25

Spring Hangers

(from Anvil International)

Variable Type

Constant Type

BECHT ENGINEERING COMPANY, INC. Layout and Support - 26

(from Anvil International)

Special Purpose Supports

Sway strut used to

prevent horizontal

movement.

Hydraulic snubber used

to prevent sudden

horizontal movement but

allow slowly applied

displacement.

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 27

Support Element Selection

Resting pipe directly on structural

steel should be avoided when:

Carbon steel pipe is in a wet

environment and failure by

corrosion is not tolerable

Stainless steel pipe would be in

contact with galvanized steel and

failure by liquid metal

embrittlement during a fire is not

tolerable

BECHT ENGINEERING COMPANY, INC. Layout and Support - 28

Support Element Selection

Support elements on outdoor insulated

piping should penetrate the insulation on the

bottom of the pipe.

(from Anvil International)

ASME B31.3 Process Piping Course 7. Layout and Support

BECHT ENGINEERING COMPANY, INC. Layout and Support - 29

Support Element Selection

Some solutions:

Use pipe shoes

Support outside

the insulation

BECHT ENGINEERING COMPANY, INC. Layout and Support - 30

Support Element Selection

In aggressive external

corrosion environments,

support should be via

structural steel under

the pipe rather than

hanger rods with

multiple threaded

connections that may

fail in a few years.

(from Anvil International)

Das könnte Ihnen auch gefallen

- B31.3 Process Piping Course - 09 ReactionsDokument0 SeitenB31.3 Process Piping Course - 09 ReactionsCarlos Del ToroNoch keine Bewertungen

- B31.3 Process Piping Course - 08 FlexibilityDokument23 SeitenB31.3 Process Piping Course - 08 Flexibilitydalianbouri100% (1)

- B31.3 Process Piping Course - 06 Flexibility Analysis For IntroDokument10 SeitenB31.3 Process Piping Course - 06 Flexibility Analysis For IntroJose BijoyNoch keine Bewertungen

- B31.3 Process Piping Course - 11 Designing With Expansion Joints PDFDokument15 SeitenB31.3 Process Piping Course - 11 Designing With Expansion Joints PDFSulist N WahyudieNoch keine Bewertungen

- 167 Pipe Support FailureDokument0 Seiten167 Pipe Support FailureKhaled AbdelbakiNoch keine Bewertungen

- Unlock-B31.3 Process Piping Course - 07 Layout and SupportDokument15 SeitenUnlock-B31.3 Process Piping Course - 07 Layout and SupportProkopNoch keine Bewertungen

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Von EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Noch keine Bewertungen

- Unlock-B31.3 Process Piping Course - 10 Flexibility Analysis MethodsDokument5 SeitenUnlock-B31.3 Process Piping Course - 10 Flexibility Analysis MethodsProkopNoch keine Bewertungen

- B31.3 Process Piping Course - 16 Category M Fluid Service PDFDokument8 SeitenB31.3 Process Piping Course - 16 Category M Fluid Service PDFRomner CordovaNoch keine Bewertungen

- B31.3 Process Piping Course - 12 Fabrication and InstallationDokument21 SeitenB31.3 Process Piping Course - 12 Fabrication and InstallationLuong AnhNoch keine Bewertungen

- Piping GuideDokument14 SeitenPiping Guideprince_lalNoch keine Bewertungen

- GF Piping Systems Contain-IT PLUSDokument12 SeitenGF Piping Systems Contain-IT PLUSRon Don jrNoch keine Bewertungen

- B31.3 Process Piping Course - 04 Pressure Design of MetalsDokument22 SeitenB31.3 Process Piping Course - 04 Pressure Design of MetalsEryl YeongNoch keine Bewertungen

- Piping Terms GlossaryDokument11 SeitenPiping Terms GlossaryJulio Moran MoranNoch keine Bewertungen

- Material Table - Piping StudyDokument3 SeitenMaterial Table - Piping Studypandy1604Noch keine Bewertungen

- Mechanical Engineering BookDokument38 SeitenMechanical Engineering BookMuanif0% (1)

- B31.3 Process Piping Course - 17 High Pressure PipingDokument12 SeitenB31.3 Process Piping Course - 17 High Pressure PipingpfpmatosNoch keine Bewertungen

- Piping TheoryDokument22 SeitenPiping TheoryDilip YadavNoch keine Bewertungen

- FelkerCatalog071406 WEBDokument57 SeitenFelkerCatalog071406 WEBbalarcmtNoch keine Bewertungen

- B31.3 Process Piping Course - 15 Nonmetallic PipingDokument0 SeitenB31.3 Process Piping Course - 15 Nonmetallic PipingAxel MoorNoch keine Bewertungen

- History b16 34Dokument5 SeitenHistory b16 34qazi12100% (1)

- Piping GuideDokument10 SeitenPiping GuidezenpraveenNoch keine Bewertungen

- Thermal BowingDokument22 SeitenThermal BowingPedro Dominguez DominguezNoch keine Bewertungen

- High-Temperature Characteristics of Stainless Steels: A Designers' Handbook Series N 9004Dokument47 SeitenHigh-Temperature Characteristics of Stainless Steels: A Designers' Handbook Series N 9004aemis2010Noch keine Bewertungen

- B31.3 Process Piping Course - 03 Materials PDFDokument19 SeitenB31.3 Process Piping Course - 03 Materials PDFNguyen Anh TungNoch keine Bewertungen

- TSSA Safety Info Bulletin SB12-01 - Venting-DischargeDokument3 SeitenTSSA Safety Info Bulletin SB12-01 - Venting-DischargemurigurNoch keine Bewertungen

- Pipe Stress Amp SupportDokument24 SeitenPipe Stress Amp SupportShilpa GanganNoch keine Bewertungen

- NSC Piping Supt ChecklistDokument3 SeitenNSC Piping Supt ChecklistzahoorNoch keine Bewertungen

- Astm B 366Dokument13 SeitenAstm B 366AVINASH CHAVANNoch keine Bewertungen

- FOAM GLASS UG Piping Insulation Underground BrochureDokument12 SeitenFOAM GLASS UG Piping Insulation Underground BrochureSethuraman SaravanakumarNoch keine Bewertungen

- Cat Hvac en PDFDokument49 SeitenCat Hvac en PDFThang TongNoch keine Bewertungen

- Liquid Process Piping, Part 3 Miscellaneous Piping Design PDFDokument23 SeitenLiquid Process Piping, Part 3 Miscellaneous Piping Design PDFosama alabsiNoch keine Bewertungen

- Use of Glass Reinforced Epoxy (GRE) Piping For Fire Water Applications - OffshoreDokument10 SeitenUse of Glass Reinforced Epoxy (GRE) Piping For Fire Water Applications - OffshoreMubeenNoch keine Bewertungen

- SP PI PP 001 (General Piping System)Dokument49 SeitenSP PI PP 001 (General Piping System)Ari IndrajayaNoch keine Bewertungen

- Improve Evaluation of Brittle-Fracture Resistance For VesselsDokument6 SeitenImprove Evaluation of Brittle-Fracture Resistance For VesselsHieuNoch keine Bewertungen

- Cleaver Brooks - Blowdown Separator & AftercoolerDokument10 SeitenCleaver Brooks - Blowdown Separator & AftercoolertylerstearnsNoch keine Bewertungen

- Temperature HandbookDokument136 SeitenTemperature HandbookGustavo SánchezNoch keine Bewertungen

- Stress Critical Line ListDokument1 SeiteStress Critical Line ListJitendraSurveNoch keine Bewertungen

- 2021 Key Changes Section VIII-1Dokument79 Seiten2021 Key Changes Section VIII-1Huddar100% (1)

- Water Hammer in Nuclear PlantsDokument92 SeitenWater Hammer in Nuclear PlantsMaritza Pérez UlloaNoch keine Bewertungen

- 23 22 00 - Steam and Condensate Piping and PumpsDokument6 Seiten23 22 00 - Steam and Condensate Piping and PumpsDiana SoareNoch keine Bewertungen

- High-Rise Fan - Coil - EngineerDokument15 SeitenHigh-Rise Fan - Coil - EngineerMIN GUINoch keine Bewertungen

- ASME B31.3 Piping Design - Part ADokument46 SeitenASME B31.3 Piping Design - Part AA_Uossef100% (1)

- Tube Expander Design UsageDokument19 SeitenTube Expander Design UsageJaroslaw PoplawskiNoch keine Bewertungen

- Heat Exchanger Inspection PDFDokument23 SeitenHeat Exchanger Inspection PDFInnasi Arokiasamy100% (2)

- Is Thicker Gasket Material Better Than ThinnerDokument2 SeitenIs Thicker Gasket Material Better Than ThinnerSteven LiparotoNoch keine Bewertungen

- Engineering Training Module 3 Water Hammer PDFDokument74 SeitenEngineering Training Module 3 Water Hammer PDFEnoch Twumasi100% (1)

- Piping ClassDokument2 SeitenPiping ClassDylan RamasamyNoch keine Bewertungen

- Whats Different in B31.1 PDFDokument30 SeitenWhats Different in B31.1 PDFhirenkumar patel100% (2)

- Fluid Sealing Standards For NMEJ StandardsDokument9 SeitenFluid Sealing Standards For NMEJ Standardsamol1321Noch keine Bewertungen

- 31.1 VS 31.3Dokument2 Seiten31.1 VS 31.3rkukgNoch keine Bewertungen

- B31.3 Process Piping Course - 13 Inspection, Examination and TestingDokument19 SeitenB31.3 Process Piping Course - 13 Inspection, Examination and TestingferooxidanNoch keine Bewertungen

- PLN-1200-3.07-01, Iss 01 - Product Catalogue PDFDokument12 SeitenPLN-1200-3.07-01, Iss 01 - Product Catalogue PDFsakscribNoch keine Bewertungen

- Pipe Support Systems (2 PDH) Course No. M-2018Dokument17 SeitenPipe Support Systems (2 PDH) Course No. M-2018arsssyNoch keine Bewertungen

- B31.3 Process Piping Course - 07 - LayoutandSupportDokument24 SeitenB31.3 Process Piping Course - 07 - LayoutandSupportlyesNoch keine Bewertungen

- M-2-3 Hangers and SupportsDokument214 SeitenM-2-3 Hangers and SupportsSeungmin PaekNoch keine Bewertungen

- Pipe Support Basic - Seminar III, G.palaniDokument67 SeitenPipe Support Basic - Seminar III, G.palaniAnonymous Xy309m9Sm9100% (2)

- Es 16 417Dokument8 SeitenEs 16 417agaricusNoch keine Bewertungen

- Design of Cold-Formed Steel Structures ASI PDFDokument104 SeitenDesign of Cold-Formed Steel Structures ASI PDFgerrydimayugaNoch keine Bewertungen

- SUB60039452-A Table of Revised ConditioDokument13 SeitenSUB60039452-A Table of Revised ConditiogerrydimayugaNoch keine Bewertungen

- Weld Detail 1Dokument1 SeiteWeld Detail 1gerrydimayugaNoch keine Bewertungen

- Eurocodes Worked ExamplesDokument185 SeitenEurocodes Worked ExamplesPaskal Drazhich100% (9)

- Design Capacity Tables For Structural Steel Hollow SectionsDokument180 SeitenDesign Capacity Tables For Structural Steel Hollow Sectionsdoshi7850% (2)

- Engineering Basis of NZS 3604 - Updated7 PDFDokument112 SeitenEngineering Basis of NZS 3604 - Updated7 PDFJeanette MillerNoch keine Bewertungen

- ProfileDCT Mar15 Web PDFDokument245 SeitenProfileDCT Mar15 Web PDFshazanNoch keine Bewertungen

- (For SHI-UNA RFQ) Latest Revised MTO For TUBES - For MaterialDokument1 Seite(For SHI-UNA RFQ) Latest Revised MTO For TUBES - For MaterialgerrydimayugaNoch keine Bewertungen

- EXCEL - How To Write Perfect VLOOKUP and INDEX and MATCH FormulasDokument29 SeitenEXCEL - How To Write Perfect VLOOKUP and INDEX and MATCH Formulasgerrydimayuga100% (1)

- Stress & SupportDokument23 SeitenStress & Supportkarthickmectr100% (1)

- Bolting and WeldingDokument73 SeitenBolting and Weldinggerrydimayuga100% (2)

- Notes of F.MDokument159 SeitenNotes of F.Mnidhalsaada100% (1)

- Water Heating: Types of Residential Water HeatersDokument9 SeitenWater Heating: Types of Residential Water HeatersgerrydimayugaNoch keine Bewertungen

- 13/14, 17 & 17T Series: Multichoice Valve Trim Installation Instructions Owners ManualDokument94 Seiten13/14, 17 & 17T Series: Multichoice Valve Trim Installation Instructions Owners ManualgerrydimayugaNoch keine Bewertungen

- FSGP & PT370 - Pipe FittingsDokument6 SeitenFSGP & PT370 - Pipe FittingsgerrydimayugaNoch keine Bewertungen

- (For SHI-UNA RFQ) MTO For Non-Pressure Parts (Plates and OtheDokument2 Seiten(For SHI-UNA RFQ) MTO For Non-Pressure Parts (Plates and OthegerrydimayugaNoch keine Bewertungen

- (For SHI-UNA RFQ) MTO For Non-Pressure Parts (Excluding PlateDokument14 Seiten(For SHI-UNA RFQ) MTO For Non-Pressure Parts (Excluding PlategerrydimayugaNoch keine Bewertungen

- Structural SpecificationDokument26 SeitenStructural SpecificationgerrydimayugaNoch keine Bewertungen

- (Shi-Una) Mto For Tubes-pipes-fins-Forge Roundbar - For MateriDokument5 Seiten(Shi-Una) Mto For Tubes-pipes-fins-Forge Roundbar - For MaterigerrydimayugaNoch keine Bewertungen

- Timber Structures: Donald W. Neal, P.EDokument58 SeitenTimber Structures: Donald W. Neal, P.EsunndaihannNoch keine Bewertungen

- 267 Pipe Stress Analysis ReportsDokument11 Seiten267 Pipe Stress Analysis ReportsRaymond MetselaarNoch keine Bewertungen

- Material Take-Off - Takuma 5r - FinalDokument42 SeitenMaterial Take-Off - Takuma 5r - FinalgerrydimayugaNoch keine Bewertungen

- Calculation of The Reaction ForceDokument3 SeitenCalculation of The Reaction Forceahmad_korosNoch keine Bewertungen

- Design Calculation Sheet: Chilled Water Secondary PumpsDokument2 SeitenDesign Calculation Sheet: Chilled Water Secondary PumpsgerrydimayugaNoch keine Bewertungen

- ASME B31 3 Calculator V2Dokument11 SeitenASME B31 3 Calculator V2gerrydimayuga100% (3)

- EXCEL - How To Write Perfect VLOOKUP and INDEX and MATCH FormulasDokument29 SeitenEXCEL - How To Write Perfect VLOOKUP and INDEX and MATCH Formulasgerrydimayuga100% (1)

- Stainless Steel For High Pressure Piping in SWRO Plants. Are There Any OptionsDokument6 SeitenStainless Steel For High Pressure Piping in SWRO Plants. Are There Any OptionsgerrydimayugaNoch keine Bewertungen

- Beam Design For Moment, Shear & TorsionDokument6 SeitenBeam Design For Moment, Shear & TorsiongerrydimayugaNoch keine Bewertungen

- Base Plate and Bolt DesignDokument6 SeitenBase Plate and Bolt DesigngerrydimayugaNoch keine Bewertungen