Beruflich Dokumente

Kultur Dokumente

10 TMSS 05 R0

Hochgeladen von

renjithas2005Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

10 TMSS 05 R0

Hochgeladen von

renjithas2005Copyright:

Verfügbare Formate

TRANSMISSION MATERIALS STANDARD SPECIFICATION

10-TMSS-05, Rev. 0

PAGE NO. 2 OF 11 10TMSS05R0/MAA

Date of Approval: March 13, 2006

TABLE OF CONTENTS

1.0 SCOPE

2.0 CROSS REFERENCES

3.0 APPLICABLE CODES AND STANDARDS

4.0 DESIGN AND CONSTRUCTION REQUIREMENTS

4.1 General

4.2 Ratings

4.3 Materials

4.4 Fabrication

4.5 Diameter and Permissible Variations

4.6 Reel Design

4.7 Markings

5.0 TESTS

6.0 DATA SCHEDULE

TRANSMISSION MATERIALS STANDARD SPECIFICATION

10-TMSS-05, Rev. 0

PAGE NO. 3 OF 11 10TMSS05R0/MAA

Date of Approval: March 13, 2006

1.0 SCOPE

This Transmission Material Standard Specification (TMSS) specifies the minimum

technical requirements for design, engineering, manufacture, inspection, testing and

performance of Bare Copper-Clad Steel Grounding Conductor and Ground Rod to be

used for the grounding of transmission line structures in the overhead transmission line

system of Saudi Electricity Company (SEC), Saudi Arabia.

2.0 CROSS REFERENCES

This Material Standard Specification shall be read in conjunction with the latest

revision of SEC General Specification No. 01-TMSS-01, titled "General Requirements

for All Equipment/Materials" which shall be considered as an integral part of this

TMSS.

This TMSS shall also be read in conjunction with SEC Purchase Order or Contract

Schedules for project, as applicable.

3.0 APPLICABLE CODES AND STANDARDS

The latest amendments/revision of the following Code and Standard shall be

applicable for the equipment/material covered in this TMSS. In case of conflict, the

vendor/manufacturer may propose equipment/material conforming to Industry Code

and Standard other than that quoted hereunder without jeopardizing the requirements

of this TMSS.

ASTM B910/B910M Standard Specification for Annealed Copper-Clad Steel

Wire

4.0 DESIGN AND CONSTRUCTION REQUIREMENTS

4.1 General

4.1.1 The copper-clad steel grounding conductor and copper-clad steel

ground rods shall be of manufacturer's standard design and shall meet

or exceed the requirements of this Specification in all respects.

4.1.2 The copper-clad steel grounding conductor shall be made from bare

round annealed copper-clad steel wires conforming to ASTM

B910/B910M.

4.1.3 The service conditions referenced in 01-TMSS-01 shall be regarded

as the basis of design criteria.

4.1.4 Manufacturer's drawings, as required in 01-TMSS-01 shall show the

outline of the copper-clad steel grounding conductor and copper-clad

TRANSMISSION MATERIALS STANDARD SPECIFICATION

10-TMSS-05, Rev. 0

PAGE NO. 4 OF 11 10TMSS05R0/MAA

Date of Approval: March 13, 2006

steel ground rod together with all pertinent dimensions. Any

variations in these dimensions due to manufacturing tolerances shall

be indicated.

4.2 Ratings

4.2.1 The copper-clad steel grounding conductor shall conform to the

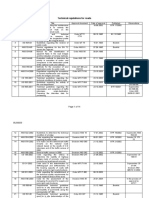

requirements of Table 1 below:

Table 1:

Nominal Diameter

Conductor

Size

Designation

Overall

Individual

Wire

Nominal

Total

Cross-

Section

Minimum

Rated

Tensile

Strength

DC

Resistance

at 20C

Fusing

Current

for 0.5

second

(approx.)

AWG (mm) (mm) (mm) (kN) (Ohm/km) (kA)

7 No. 10 7.77 2.588 36.83 10.28 1.2061 12

7 No. 9 8.71 2.906 46.44 12.95 0.9564 15

7 No. 8 9.78 3.264 58.57 16.34 0.7586 19

7 No. 7 11.00 3.665 73.87 20.60 0.6014 24

7 No. 6 12.34 4.115 93.10 25.97 0.4771 31

7 No. 5 13.87 4.620 117.42 32.75 0.3783 38

7 No. 4 15.57 5.189 148.04 41.30 0.3000 49

19 No. 8 16.31 3.264 158.97 44.36 0.2805 52

19 No. 7 18.31 3.665 200.45 55.92 0.2225 66

19 No. 6 20.57 4.115 252.71 70.50 0.1764 83

19 No. 5 23.11 4.620 318.71 88.89 0.1399 104

Note: The tensile load is taken as ninety percent (90%) of the sum of the

tensile loads of the individual wires and is based on minimum tensile

strength of 310 N/mm

2

as referred in ASTM B910/B910M.

4.2.2 The required size and diameter of copper-clad steel grounding

conductor shall be specified in the Data Schedule.

4.2.3 The copper-clad steel ground rods shall have a nominal diameter of

16mm (5/8 inches) and 19mm (3/4 inches) with a minimum length of

3 meter. The ground rods shall be of sectional type equipped with

suitable couplings and driving studs. The required diameter of the

ground rod shall be specified in the Data Schedule.

4.3 Materials

4.3.1 The copper-clad wire shall consist of a core of homogeneous open-

hearth, electric-furnace, or basic-oxygen low carbon steel with a

continuous outer cladding of copper thoroughly bonded to the core

throughout. The copper-clad wire shall be free from copper

TRANSMISSION MATERIALS STANDARD SPECIFICATION

10-TMSS-05, Rev. 0

PAGE NO. 5 OF 11 10TMSS05R0/MAA

Date of Approval: March 13, 2006

discontinuities and all imperfections not consistent with good

commercial practice.

4.3.2 The nominal conductivity of copper-clad steel wire shall be 40%

IACS (International Annealed Copper Standard).

4.3.3 The electrical resistivity of copper-clad steel wire at a temperature of

20C shall not exceed 0.04397 ohm.mm

2

/m.

4.3.4 All wires in the grounding conductor shall be of the same grade and

quality.

4.3.5 The ground rods shall be made from a high-strength steel (high

carbon steel). Pure electrolytic copper shall be uniformly molecularly

bonded onto the core to ensure corrosion resistance and eliminate

electrolytic action. The steel core shall have sufficient rigidity for

easy driving with hammer or mechanical drivers.

4.4 Fabrication

4.4.1 The copper-clad steel grounding conductors shall be constructed in

conventional concentric-lay-stranded type.

4.4.2 The copper-clad steel grounding conductors shall have left-hand lay

and the preferred lay is 13.5 times the diameter of that layer, but the

pitch of the strand shall not be less than 10 nor more than 16 times

this diameter.

4.4.3 All copper-clad steel wires in the conductor shall lie naturally in their

true positions in the completed conductor. They shall remain in

position when the conductor is cut at any point and shall permit re-

stranding by hand after being forcibly unraveled at the end of the

conductor.

4.4.4 Joints or splices may be made in the finished individual copper-clad

steel wires composing concentric- lay-stranded conductor but these

splices shall not decrease the strength of the finished conductor below

the minimum breaking strength specified in this specification.

4.4.5 These joints or splices shall not be closer than 15 meters to any other

joint in the same layer in the conductor.

4.4.6 The type of joints or splices in individual copper-clad steel wires shall

be of weld-annealed joints made by electric butt welding.

TRANSMISSION MATERIALS STANDARD SPECIFICATION

10-TMSS-05, Rev. 0

PAGE NO. 6 OF 11 10TMSS05R0/MAA

Date of Approval: March 13, 2006

4.5 Diameter and Permissible Variations

4.5.1 The actual diameter of the copper-clad steel wires forming the

conductor shall not vary from the specified diameter by more than

1.5% expressed to the nearest 0.003 mm.

4.5.2 The cross sectional area of the completed conductor shall not be less

than 98% of the area specified. The cross sectional area of a

conductor shall be considered to be the sum of the cross-sectional

areas of its component wires at any section when measured

perpendicularly to their individual axis.

4.5.3 The minimum copper thickness due to eccentricity shall not be less

than 5% of the individual wire diameter (10% of the wire radius) as

shown in Table-2:

Table 2:

Nominal

Individual Wire

Diameter

(mm)

Minimum

Copper Thickness

(mm)

2.588 0.1294

2.906 0.1453

3.264 0.1632

3.665 0.1832

4.115 0.2057

4.620 0.2310

5.189 0.2594

4.5.4 The minimum thickness of copper for copper-clad steel ground rod

shall not be less than 0.25 mm at any point.

4.5.5 The actual diameter of the copper-clad steel ground rod shall not be

less than 14.3mm and 17.1mm (unthreaded) for 16mm and 19mm

nominal diameter ground rods respectively.

4.6 Reel Design

4.6.1 Reel shall be of non-returnable wood.

4.6.2 The length of copper-clad steel grounding conductor per reel shall be

2000 meters with a permissible variation of 5%, unless otherwise

different lengths are required as per actual site requirements or as

agreed between SEC and the manufacturer.

TRANSMISSION MATERIALS STANDARD SPECIFICATION

10-TMSS-05, Rev. 0

PAGE NO. 7 OF 11 10TMSS05R0/MAA

Date of Approval: March 13, 2006

4.7 Markings

4.7.1 Each end of the copper-clad steel grounding conductor in the reel

shall bear a non-corroding tag identifying the following:

a. Grade of grounding conductor

b. Diameter/Size of grounding conductor

c. Average Breaking Strength

d. Length of grounding conductor

e. Stranding

4.7.2 Each reel shall be stenciled to show all information under paragraph

4.7.1 plus additional information as follows:

a. Manufacturer's Name and Country of Origin

b. Year of Manufacture

c. Serial Number

d. Size of Reel

e. Gross Weight

f. SEC Purchase Order Number/Contract Number.

g. SEC Material Item Number

h. Consignee Address

i. Direction of Rolling

j. 10-TMSS-05, Rev.0

4.7.3 All markings shall appear on both sides of the reel.

5.0 TESTS

All test results shall be provided for review and acceptance by SEC.

5.1 Tests for electrical and physical properties of copper-clad steel wires

composing concentric-lay-stranded conductors made from copper-clad steel

wire shall be made before stranding.

5.2 The routine test shall not be required after stranding.

5.3 The copper-clad steel wire shall withstand without fracture not less than 20

twists in a length equivalent to 100 times the nominal diameter of the

specimen. The specimen shall be twisted by rotating on the wires at a rate of

approximately 15 twists per minute in the same direction until fracture occurs.

5.4 The copper-clad steel wire after twisting to destruction shall not reveal any

seams, pits, slivers or other imperfection of sufficient magnitude to indicate

inherent defects or imperfections. Examination of the wire at the break with the

unaided eye shall show no separation of the copper from the steel.

TRANSMISSION MATERIALS STANDARD SPECIFICATION

10-TMSS-05, Rev. 0

PAGE NO. 8 OF 11 10TMSS05R0/MAA

Date of Approval: March 13, 2006

5.5 The electrical resistivity of the material shall be determined in accordance with

ASTM B193 Test Method for Resistivity of Electrical Conductor Materials.

5.6 Elongation shall be measured by means of an extensometer suitable for

measuring elongation in 250 mm in accordance with the testing requirements

specified in ASTM B910/B910M. It shall be attached to the test specimen at a

tension load of approximately ten percent (10%) of rated strength, and shall be

recorded as zero length.

The elongation shall be observed while applying tension load to the specimen

and the reading shall be taken when fracture occurs. The elongation of the

specimen shall be not less than fifteen percent (15%).

The tests shall be disregarded, if the fracture occurs in or at the gripping jaws

of the machine and the extensometer shows a reading less than fifteen percent

(15%).

5.7 If upon testing a sample from any reel of wire, the results do not conform to the

tensile requirements prescribed in Table 1 and the elongation of specimen in

Clause 5.6, two additional samples shall be tested and the average of the two

tests shall determine the acceptance or rejection of the reel of wire.

TRANSMISSION MATERIALS STANDARD SPECIFICATION

10-TMSS-05, Rev. 0

PAGE NO. 9 OF 11 10TMSS05R0/MAA

Date of Approval: March 13, 2006

6.0 DATA SCHEDULE

BARE COPPER-CLAD STEEL GROUNDING CONDUCTOR AND GROUND ROD

SEC Enquiry No. Date:

SEC Purchase Order

No.

Date:

or Contract No.

SEC PTS No./Project Title with J.O. No.

REFERENCE

SECTION NO. DESCRIPTION 'A' 'B' 'C'

3.0 APPLICABLE CODES AND STANDARDS

ASTM B910/B910M *

4.0 DESIGN AND CONSTRUCTION REQUIREMENTS

4.2.2 Copper-Clad Steel Grounding Conductor

AWG Size

Nominal Cross-Section (mm)

Overall Diameter (mm)

Minimum Tensile Strength (kN) *

D.C. Resistance at 20C (/km) *

Fusing Current Rating for 0.5 second (kA) *

'A'- SEC SPECIFIED DATA/PARAMETERS

'B'- BIDDER/SUPPLIER/VENDOR/CONTRACTOR PROPOSED DATA/PARAMETERS

'C'- REMARKS SUPPORTING THE PROPOSED DEVIATION IN COLUMN 'B'

(*)- DATA/PARAMETERS TO BE PROVIDED/PROPOSED BY THE BIDDER/SUPPLIER/

VENDOR/CONTRACTOR IN COLUMN 'B'

TRANSMISSION MATERIALS STANDARD SPECIFICATION

10-TMSS-05, Rev. 0

PAGE NO. 10 OF 11 10TMSS05R0/MAA

Date of Approval: March 13, 2006

6.0 DATA SCHEDULE

BARE COPPER-CLAD STEEL GROUNDING CONDUCTOR AND GROUND ROD

REFERENCE

SECTION NO. DESCRIPTION 'A' 'B' 'C'

4.2.3 Copper-Clad Steel Ground Rod

Nominal Diameter (mm) 16/19

Actual Diameter (mm) 14.3/17.1

Minimum Length (mm) 3,000

4.3 Conductivity of Annealed Copper-Clad

Steel Wire (%IACS)

40

4.4 Direction of Lay left hand

4.5 Minimum Copper Thickness for:

Copper-Clad Steel Wire (mm) *

Ground Rod (mm) 0.25

4.6 Length of Grounding Conductor

Total Required Length (m) *

Maximum Length per Reel (m) 2,000

Tolerance in Length per Reel 5%

Type of Reel wooden

TRANSMISSION MATERIALS STANDARD SPECIFICATION

10-TMSS-05, Rev. 0

PAGE NO. 11 OF 11 10TMSS05R0/MAA

Date of Approval: March 13, 2006

6.0 DATA SCHEDULE

BARE COPPER-CLAD STEEL GROUNDING CONDUCTOR AND GROUND ROD

ADDITIONAL TECHNICAL INFORMATION OR FEATURES TO BE FURNISHED BY

SEC:

A.

ADDITIONAL SUPPLEMENTARY DATA OR FEATURES PROPOSED BY

BIDDER/VENDOR/SUPPLIER/CONTRACTOR:

B.

OTHER PARTICULARS TO BE FILLED UP BY BIDDER/VENDOR/SUPPLIER/

CONTRACTOR:

B.

Actual Manufacturer

of Equipment/Material

Vendor/Supplier/

Contractor

Name of the Company

Location and address

Name and Signature of

authorized

representative

and date

Official Seal/Stamp

of the Company &

Date

Das könnte Ihnen auch gefallen

- Ansi MSS SP-55-2011Dokument23 SeitenAnsi MSS SP-55-2011SivaNoch keine Bewertungen

- 10 TMSS 05 R1Dokument11 Seiten10 TMSS 05 R1Omar HijaziNoch keine Bewertungen

- Electric Boiler Design Calculations-ASME SEC.I, PART-PEB, EDITION 2019 PDFDokument48 SeitenElectric Boiler Design Calculations-ASME SEC.I, PART-PEB, EDITION 2019 PDFSuresh Damu BhadNoch keine Bewertungen

- 11 TMSS 01 R0Dokument0 Seiten11 TMSS 01 R0renjithas2005Noch keine Bewertungen

- As 1746-1991Dokument15 SeitenAs 1746-1991Quantudogon DangNoch keine Bewertungen

- 15 TMSS 05 R0Dokument0 Seiten15 TMSS 05 R0renjithas2005Noch keine Bewertungen

- Australian Standard: Methods For Sampling and Testing Aggregates Part 0: List of MethodsDokument6 SeitenAustralian Standard: Methods For Sampling and Testing Aggregates Part 0: List of MethodsTeerasak YaowaratNoch keine Bewertungen

- Lexicon Host BrochureDokument37 SeitenLexicon Host BrochureMile FetahuNoch keine Bewertungen

- 15 TMSS 02 R0Dokument0 Seiten15 TMSS 02 R0renjithas2005Noch keine Bewertungen

- 15 TMSS 04 R0Dokument0 Seiten15 TMSS 04 R0renjithas2005Noch keine Bewertungen

- 10 TMSS 01 R0Dokument0 Seiten10 TMSS 01 R0hasanmnhNoch keine Bewertungen

- 20 TMSS 02 R0Dokument0 Seiten20 TMSS 02 R0renjithas2005Noch keine Bewertungen

- 10 TMSS 02 R0Dokument0 Seiten10 TMSS 02 R0renjithas2005Noch keine Bewertungen

- 24 TMSS 01 R0Dokument0 Seiten24 TMSS 01 R0renjithas2005Noch keine Bewertungen

- 12TMSS02R0, Saudi Electriicity Company StandardsDokument0 Seiten12TMSS02R0, Saudi Electriicity Company StandardsMohammed NazeeruddinNoch keine Bewertungen

- 10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R2Dokument11 Seiten10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R2m3eenNoch keine Bewertungen

- 11-TMSS-02-R1-POWER CABLE, XLPE INSULATED, COPPER CONDUCTOR, SINGLE CORE, 110kV, 115kV, 132kV PDFDokument35 Seiten11-TMSS-02-R1-POWER CABLE, XLPE INSULATED, COPPER CONDUCTOR, SINGLE CORE, 110kV, 115kV, 132kV PDFUtkucan KILIÇNoch keine Bewertungen

- 01TMSS01R1Dokument22 Seiten01TMSS01R1zaheenvNoch keine Bewertungen

- 15 TMSS 01 R0Dokument0 Seiten15 TMSS 01 R0renjithas2005Noch keine Bewertungen

- 12 TMSS 10 R0Dokument0 Seiten12 TMSS 10 R0renjithas2005Noch keine Bewertungen

- 32TMSS01R2Dokument44 Seiten32TMSS01R2Mahmoud MoezNoch keine Bewertungen

- 10-Tmss-06-Conductor Bare, Bare, Overhead Line (Heat-Resistance, Aluminum Alloy Conductor) - R0Dokument15 Seiten10-Tmss-06-Conductor Bare, Bare, Overhead Line (Heat-Resistance, Aluminum Alloy Conductor) - R0m3eenNoch keine Bewertungen

- 12 TMSS 03 R0Dokument0 Seiten12 TMSS 03 R0renjithas2005Noch keine Bewertungen

- 48 TMSS 02 R0Dokument0 Seiten48 TMSS 02 R0renjithas2005Noch keine Bewertungen

- Iec 62219Dokument31 SeitenIec 62219boopathy1705Noch keine Bewertungen

- 51TMSS01R0Dokument21 Seiten51TMSS01R0Bijaya Kumar Mohanty100% (2)

- 48 TMSS 01 R0Dokument0 Seiten48 TMSS 01 R0renjithas2005Noch keine Bewertungen

- 23 TMSS 02 R0Dokument0 Seiten23 TMSS 02 R0renjithas2005Noch keine Bewertungen

- 10-TMSS-06-Heat-Resistant Aluminum Alloy Bare Conductors For Overhead LineDokument21 Seiten10-TMSS-06-Heat-Resistant Aluminum Alloy Bare Conductors For Overhead LineBilal Javaid100% (1)

- Rachem GuideDokument156 SeitenRachem GuideeliahudNoch keine Bewertungen

- 11kv Steel Line Materials Vol 2 Tech SpecsDokument45 Seiten11kv Steel Line Materials Vol 2 Tech SpecsManjula SrihariNoch keine Bewertungen

- Cellpack Product CatalogueDokument296 SeitenCellpack Product CatalogueLaurentiu CatalinNoch keine Bewertungen

- Doha Cables Profile 2015Dokument15 SeitenDoha Cables Profile 2015Ahmed Farouk100% (1)

- EP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..Dokument14 SeitenEP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..dimaomarNoch keine Bewertungen

- 50 TMSS 03 R0Dokument0 Seiten50 TMSS 03 R0renjithas2005Noch keine Bewertungen

- Cathodic Protection Systems and The NECDokument9 SeitenCathodic Protection Systems and The NECAnonymous uxilzxUkaINoch keine Bewertungen

- Olex Arial CatalogueDokument15 SeitenOlex Arial CatalogueMike WesleyNoch keine Bewertungen

- J910-YQ01-P0ANA-145013 - 2 - Lighting System Installation Notes & Details (Approved)Dokument14 SeitenJ910-YQ01-P0ANA-145013 - 2 - Lighting System Installation Notes & Details (Approved)Devy MangimbaNoch keine Bewertungen

- Composite Overhead ConductorsDokument21 SeitenComposite Overhead ConductorsEnrique Garcia100% (1)

- TCXD 27. 1991 / Installation of Electric Equipments in Dwellings and Public Building - Design StandardDokument20 SeitenTCXD 27. 1991 / Installation of Electric Equipments in Dwellings and Public Building - Design StandardtrungjindoNoch keine Bewertungen

- Associations and Reference StandardsDokument13 SeitenAssociations and Reference StandardsgaburrNoch keine Bewertungen

- DS-6 Intercom SystemDokument47 SeitenDS-6 Intercom SystemMinhQuânNoch keine Bewertungen

- Communication in Plants PDFDokument2 SeitenCommunication in Plants PDFAngelNoch keine Bewertungen

- 15 TMSS 01 R0Dokument12 Seiten15 TMSS 01 R0Khaja MoinNoch keine Bewertungen

- OHL Manual Vol.2 Drawings & Reference Info v3 July 2006Dokument190 SeitenOHL Manual Vol.2 Drawings & Reference Info v3 July 2006somchak2000100% (2)

- Cleveland CablesDokument144 SeitenCleveland CablesPhil PhilipNoch keine Bewertungen

- Compact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsDokument6 SeitenCompact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsThanh DangNoch keine Bewertungen

- XLPE Insulated CablesDokument32 SeitenXLPE Insulated CablesMalik DausNoch keine Bewertungen

- Practice For Mounting Buses & Joints-374561Dokument11 SeitenPractice For Mounting Buses & Joints-374561a_sengar1Noch keine Bewertungen

- 12-SDMS-02 REV. 02: Saudi Electricity CompanyDokument20 Seiten12-SDMS-02 REV. 02: Saudi Electricity CompanyMichael Camit EsoNoch keine Bewertungen

- Tes P 119 05 R0Dokument8 SeitenTes P 119 05 R0boopelectraNoch keine Bewertungen

- Draka Power and InstrumentationDokument33 SeitenDraka Power and Instrumentationnokaraju100% (1)

- MVCC-Tech SpecDokument3 SeitenMVCC-Tech Specvishnu ojhaNoch keine Bewertungen

- AS 1102.101-1989, Graphical Symbols For Electrotechnical Documentation - General Information and General IndexDokument2 SeitenAS 1102.101-1989, Graphical Symbols For Electrotechnical Documentation - General Information and General IndexSAI Global - APACNoch keine Bewertungen

- 10 TMSS 03Dokument0 Seiten10 TMSS 03hasanmnhNoch keine Bewertungen

- 10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R0Dokument11 Seiten10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R0m3eenNoch keine Bewertungen

- 20 TMSS 01 R0Dokument0 Seiten20 TMSS 01 R0renjithas2005Noch keine Bewertungen

- 10-Tmss-07-Substation Grounding Materials-R0Dokument17 Seiten10-Tmss-07-Substation Grounding Materials-R0m3een100% (1)

- Astm 510Dokument7 SeitenAstm 510Arnold Bohorquez Acevedo100% (1)

- 10TMSS04R1 OpgwDokument29 Seiten10TMSS04R1 OpgwesamcoNoch keine Bewertungen

- Draft Barbed Wire Is CodeDokument7 SeitenDraft Barbed Wire Is Codekavi_prakash6992Noch keine Bewertungen

- A640Dokument3 SeitenA640Wagner Santana100% (1)

- B5-11 Standard Specification For High Conductivity Tough-Pitch Copper Refinery Shapes PDFDokument5 SeitenB5-11 Standard Specification For High Conductivity Tough-Pitch Copper Refinery Shapes PDFislamakthamNoch keine Bewertungen

- ASTM A641 A641M 2003 Standard Specification For Zinc Coated Galvanized Carbon Steel Wire 26 PDFDokument5 SeitenASTM A641 A641M 2003 Standard Specification For Zinc Coated Galvanized Carbon Steel Wire 26 PDFRober Moises Chumbe SoveroNoch keine Bewertungen

- Control Systems EngineerDokument1 SeiteControl Systems Engineerrenjithas2005Noch keine Bewertungen

- Central Maintenance SupervisorDokument2 SeitenCentral Maintenance Supervisorrenjithas2005Noch keine Bewertungen

- Commercial Electricians NeededDokument1 SeiteCommercial Electricians Neededrenjithas2005Noch keine Bewertungen

- Education:: Date Posted Location Country Degree Required Job Type Min Experience Position Id Job DescriptionDokument2 SeitenEducation:: Date Posted Location Country Degree Required Job Type Min Experience Position Id Job Descriptionrenjithas2005Noch keine Bewertungen

- Apprentice Electrician - Required Immediately!: Job Order #: 5159923Dokument1 SeiteApprentice Electrician - Required Immediately!: Job Order #: 5159923renjithas2005Noch keine Bewertungen

- Fundamentals of Power System Protection and CoordinationDokument54 SeitenFundamentals of Power System Protection and Coordinationrenjithas2005100% (1)

- Saskatchewan: Toddler/Preschool Social ResumeDokument3 SeitenSaskatchewan: Toddler/Preschool Social Resumerenjithas2005Noch keine Bewertungen

- 3039 Type Test 66 KV 500sqmm Rev1 20060913Dokument8 Seiten3039 Type Test 66 KV 500sqmm Rev1 20060913renjithas2005Noch keine Bewertungen

- FAT For 132 KV Accesories MTSBDokument7 SeitenFAT For 132 KV Accesories MTSBrenjithas2005Noch keine Bewertungen

- Factory Test Procedure For AccessoriesDokument7 SeitenFactory Test Procedure For Accessoriesrenjithas2005Noch keine Bewertungen

- CONSORTIUM - GTC/5/2004: Sie-Gtc5/Dts/ Document Transmittal SheetDokument1 SeiteCONSORTIUM - GTC/5/2004: Sie-Gtc5/Dts/ Document Transmittal Sheetrenjithas2005Noch keine Bewertungen

- Short CT Calc Cu Tube 500 and 1000sqmmDokument2 SeitenShort CT Calc Cu Tube 500 and 1000sqmmrenjithas2005Noch keine Bewertungen

- Quality Plan For Elastimold ProductsDokument32 SeitenQuality Plan For Elastimold Productsrenjithas2005Noch keine Bewertungen

- Leed Certified Building in IndiaDokument19 SeitenLeed Certified Building in IndiaUma Agrawal100% (1)

- Tablas IncoperaDokument57 SeitenTablas IncoperaJuan Jose Ledesma GuerreroNoch keine Bewertungen

- 11 Mds FDM Ultem 1010 Resin 0520aDokument10 Seiten11 Mds FDM Ultem 1010 Resin 0520akaledioskoppNoch keine Bewertungen

- Nano Technology in Marine Coatings Paint (KCC)Dokument18 SeitenNano Technology in Marine Coatings Paint (KCC)No NameNoch keine Bewertungen

- Conceptual Development: Low Loss Precast Concrete Frame Buildings With Steel ConnectionsDokument13 SeitenConceptual Development: Low Loss Precast Concrete Frame Buildings With Steel ConnectionsZvonimir MajićNoch keine Bewertungen

- Theme: Technology in Chemistry Chapter: Polymer Title of Project: Stationery HolderDokument30 SeitenTheme: Technology in Chemistry Chapter: Polymer Title of Project: Stationery HolderTecky JerryNoch keine Bewertungen

- Design PhilosophyDokument49 SeitenDesign PhilosophyAnuj ChandiwalaNoch keine Bewertungen

- BrederoShaw PDS 3LPE PDFDokument2 SeitenBrederoShaw PDS 3LPE PDFErick HoganNoch keine Bewertungen

- Pipe Production Products - Plassim - English Catalog 2006Dokument6 SeitenPipe Production Products - Plassim - English Catalog 2006Israel ExporterNoch keine Bewertungen

- Blowdown Valves 6DB Series Rev 2 (MS-02-118)Dokument2 SeitenBlowdown Valves 6DB Series Rev 2 (MS-02-118)herysyam1980Noch keine Bewertungen

- (2022) Causes and Treatment Measures of Large Deformation and FailureDokument16 Seiten(2022) Causes and Treatment Measures of Large Deformation and FailureRajesh WanwadeNoch keine Bewertungen

- Technical Regulations For RoadsDokument14 SeitenTechnical Regulations For RoadsAlexe FloreaNoch keine Bewertungen

- Itp For Painting WorksDokument28 SeitenItp For Painting WorksAhmed saberNoch keine Bewertungen

- Construction 3d PrintingDokument24 SeitenConstruction 3d PrintingSyed HusamNoch keine Bewertungen

- Concrete Design DIN 1045-1Dokument82 SeitenConcrete Design DIN 1045-1danegeotehnika100% (4)

- Tutorial - 1-Design For Static and Fatigue StrengthDokument5 SeitenTutorial - 1-Design For Static and Fatigue StrengthSouradeepBhattacharya50% (2)

- 350R 89Dokument55 Seiten350R 89DIDIER ANGEL LOPEZ RINCONNoch keine Bewertungen

- Casting IntroDokument94 SeitenCasting IntroJith ViswaNoch keine Bewertungen

- Mill Housings Mangal SinghDokument5 SeitenMill Housings Mangal SinghGun SmithNoch keine Bewertungen

- Crystal DefectsDokument1 SeiteCrystal DefectsMATEO SEBASTIAN VARGAS HERNANDEZNoch keine Bewertungen

- KS-200 Kiosk Substation Fire Protection Guide Non Fire Rated EnclosureDokument1 SeiteKS-200 Kiosk Substation Fire Protection Guide Non Fire Rated EnclosureRickNoch keine Bewertungen

- Dust Control Measures For Construction Projects Rev. November 2009Dokument2 SeitenDust Control Measures For Construction Projects Rev. November 2009Janice Reyes De OcampoNoch keine Bewertungen

- Refernce Data Bellows Catalog Metal FlexDokument3 SeitenRefernce Data Bellows Catalog Metal FlexKrishna ChettyNoch keine Bewertungen

- Rascoflex - Flexible Hose SprinklerDokument4 SeitenRascoflex - Flexible Hose SprinklerPaulina CabreraNoch keine Bewertungen

- HES Heavy Engineered Restraint StrapDokument2 SeitenHES Heavy Engineered Restraint StrapMarko NakicNoch keine Bewertungen

- Process Specification For The Heat Treatment of Aluminum Alloys PDFDokument8 SeitenProcess Specification For The Heat Treatment of Aluminum Alloys PDFashokksamy100% (1)