Beruflich Dokumente

Kultur Dokumente

Bernoulli" Theormmem Lab

Hochgeladen von

Nur AfiqaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bernoulli" Theormmem Lab

Hochgeladen von

Nur AfiqaCopyright:

Verfügbare Formate

FLUID LABORATORY (BEC205)

Bernoullis theorem

Group B2

Table of Content

No

1.0 1.1 1.1.1 1.1.2 1.2 1.2.1 2.0 2.1 2.2 2.3 2.3.1 3.0 3.1 3.2 3.3

Titles

Introduction to Bernoulli Theorem Explanation of the Bernoullis equation. formula of STEADY FLOW ENERGY EQUATION Bernoullis equation has some restrictions in its applicability THE CONCEPT OF BERNOULLIS THEOREM THEORY Objective General Description Equipment Procedures General Shut-down Procedures Data and Analysis Calculation Discussion Conclusion Appendix

Pages

2 3 3 3 4 4-5 6 6-7 8 9 9-10 10 10-11 11 11 12

FLUID LABORATORY (BEC205)

Bernoullis theorem

Group B2

1.0 Introduction to Bernoulli Theorem :

In fluid dynamics, Bernoulli's principle states that for an in viscid flow, an increase in the speed of the fluid occurs simultaneously with a decrease in pressure or a decrease in the fluid's potential energy. Bernoulli's principle is named after the Dutch-Swiss mathematician Daniel Bernoulli who published his principle in his book Hydrodynamics in 1738. Bernoulli's principle can be applied to various types of fluid flow, resulting in what is loosely denoted as Bernoulli's equation. In fact, there are different forms of the Bernoulli equation for different types of flow. The simple form of Bernoulli's principle is valid for incompressible flows (e.g. most liquid flows) and also for compressible flows (e.g. gases) moving at low Mach numbers. More advanced forms may in some cases be applied to compressible flows at higher Mach numbers (see the derivations of the Bernoulli equation). Bernoulli's principle can be derived from the principle of conservation of energy. This states that, in a steady flow, the sum of all forms of mechanical energy in a fluid along a streamline is the same at all points on that streamline. This requires that the sum of kinetic energy and potential energy remain constant. Thus an increase in the speed of the fluid occurs proportionately with an increase in both its dynamic pressure and kinetic energy, and a decrease in its static pressure and potential energy. If the fluid is flowing out of a reservoir the sum of all forms of energy is the same on all streamlines because in a reservoir the energy per unit volume (the sum of pressure and gravitational potential g h) is the same everywhere. Bernoulli's principle can also be derived directly from Newton's 2nd law. If a small volume of fluid is flowing horizontally from a region of high pressure to a region of low pressure, then there is more pressure behind than in front. This gives a net force on the volume, accelerating it along the streamline. Fluid particles are subject only to pressure and their own weight. If a fluid is flowing horizontally and along a section of a streamline, where the speed increases it can only be because the fluid on that section has moved from a region of higher pressure to a region of lower pressure; and if its speed decreases, it can only be because it has moved from a region of lower pressure to a region of higher pressure. Consequently, within a fluid flowing horizontally, the highest speed occurs where the pressure is lowest, and the lowest speed occurs where the pressure is highest.

FLUID LABORATORY (BEC205)

Bernoullis theorem

Group B2

1.1 Explanation of the Bernoullis equation.

From the study of physics, it has been established that energy cannot be created nor destroyed. Energy can only be transformed from one from to another. In an ideal fluid, where is no viscosity by H at one point in a steady flow, must be equal to the total energy at any other point in the path of flow provided no energy is added to the fluid or taken from it. H= z+ +

Where H is the total head, z is the elevation head , head.

is the velocity head ,

is the pressure

1.1.1 formula of STEADY FLOW ENERGY EQUATION

1. Is a statement of the principle of conservation of energy along a streamline. 2. Is one of the most important/useful equations in fluid mechanics.

1.1.2 Bernoullis equation has some restrictions in its applicability:

Flow is steady. Density is constant (which also means the fluid is incompressible) Friction losses are negligible. The equation relates the states at two points along a single streamline, (not conditions on two different streamlines).

1.2 THE CONCEPT OF BERNOULLIS THEOREM:

3

FLUID LABORATORY (BEC205)

Bernoullis theorem

Group B2

Bernoulli's principle, sometimes known as Bernoulli's equation, holds that for fluids in an ideal state, pressure and density are inversely related: in other words, a slow-moving fluid exerts more pressure than a fast-moving fluid. Since "fluid" in this context applies equally to liquids and gases, the principle has as many applications with regard to airflow as to the flow of liquids. One of the most dramatic everyday examples of Bernoulli's principle can be found in the airplane, which stays aloft due to pressure differences on the surface of its wing; but the truth of the principle is also illustrated in something as mundane as a shower curtain that billows inward.

1.2.1 THEORY:

Bernoulli's law indicates that, if an in viscid fluid is flowing along a pipe of varying cross section, then the pressure is lower at constrictions where the velocity is higher, and higher where the pipe opens out and the fluid stagnates. Many people find this situation paradoxical when they first encounter it (higher velocity, lower pressure). The well-known Bernoulli equation is derived under the following assumptions:

1. 2. 3. 4.

fluid is incompressible ( density is constant ); flow is steady: flow is frictionless ( = 0); along a streamline;

Then, it is expressed with the following equation:

Where (in SI units): p = fluid static pressure at the cross section in N/m2. = density of the flowing fluid in kg/m3 g = acceleration due to gravity in m/s2 (its value is 9.81 m/s2 = 9810 mm/s2) v = mean velocity of fluid flow at the cross section in m/s

4

FLUID LABORATORY (BEC205)

Bernoullis theorem

Group B2

z = elevation head of the center of the cross section with respect to a datum z=0 h* = total (stagnation) head in m The terms on the left-hand-side of the above equation represent the pressure head (h), velocity head (hv ), and elevation head (z), respectively. The sum of these terms is known as the total head (h*). According to the Bernoullis theorem of fluid flow through a pipe, the total head h* at any cross section is constant (based on the assumptions given above). In a real flow due to friction and other imperfections, as well as measurement uncertainties, the results will deviate from the theoretical ones. In our experimental setup, the centreline of all the cross sections we are considering lie on the same horizontal plane (which we may choose as the datum, z=0), and thus, all the z values are zeros so that the above equation reduces to:

(This is the total head at a cross section). For our experiment, we denote the pressure head as hi and the total head as h*i, where i represents the cross section we are referring to. Bernoullis theorem is a consequence of the principle of conservation of energy, applied to ideal liquids in motion. The theorem states that: For the streamline flow of an ideal liquid, the total energy (sum of pressure energy, potential energy and kinetic energy) per unit mass remains constant at every cross-section, throughout the flow.

2.0 Objective

5

FLUID LABORATORY (BEC205)

Bernoullis theorem

Group B2

To demonstrate Bernoullis Theorem:

1. To investigate the validity of the Bernoulli equation when applied to the steady flow of water in a tapered duct. 2. To measure flow rates and both static and total pressure heads in a rigid convergent or divergent tube of known geometry for a range of steady flow rates.

2.1General Description

The unit is mounted on a base board which is to be placed on top of the hydraulic Bench. This base board has four adjustable feet to level the apparatus. The main test section is an accurately machined acrylic venture of varying circular crass section. It is provided with a number of side hole pressure tappings, which are connected to the manometer tubes on the rig. The test section incorporates two unions, one at either end, to Facilitate reversal for convergent or divergent as illustrated in figure 1 and 2.

A hypodermic tube, the total pressure head probe, is provided which may be positioned to read the total pressure head at any section of the duct. This total pressure head probe may be moved after slacking the gland nut; this nut should be re-tightened by hand after adjustment. An additional tapping is provided to facilitate setting up. All eight pressure tapings are connected to a bank of the monometer tubes. Pressurization of the manometers is facilitated by connecting any hand pump to the inlet valve on the manometer manifold.

FLUID LABORATORY (BEC205)

Bernoullis theorem

Group B2

The unit is connected to the hydraulic bench using flexible hoses. The hoses and the connections are equipped with rapid action couplings. The flexible hose attached to the outlet pipe which should be directed to the volumetric measuring tank on the hydraulics bench. A flow control valve is incorporated downstream of the section. Flow rate and pressure in the apparatus may be varied independently by adjustment of the flow control valve and the bench supply control valve.

Figure 2 Top view of Bernoullis Theorem Demonstration Unit.

2.2Equipment :

a. venture The venturi is made of transparent acrylic with the following specifications: Throat diameter : 16mm Upstream diameter : 26mm Designed flow Rate : 20 LPM

b. Manometer There are eight manometer tubes; each length 320mm, for statics pressure and total head measuring along the venture meter. The manometer tubes are connected to an air bleed screw for air release as well as tubes pressurization.

c. Baseboard The baseboard is epoxy coated and designed with 4 height adjustable stands to level the venture meter. d. Discharge valve

7

FLUID LABORATORY (BEC205)

Bernoullis theorem

Group B2

One discharge valve is installed at the venture discharge section for flow rate control. e. Connections Hose connections are installed at both inlet and outlet. f. Hydraulic Bench Sump tank : 120 litres Volumetric tank: 100 litres Centrifugal pump: 0.37KW, 50 LPM

2.3 Procedures:

1. The general Start-up Procedures in the above section is performed. 2. All manometer tubing is checked properly so that they are connected to the corresponding pressure taps and are air-bubble free. 3. The discharge valve is adjusted to a high measurable flow rate. 4. The water flow rate is measured using volumetric method after the level stabilizes. 5. The hypodermic tube (total head measuring) connected to manometer G is slide gently so that its end reaches the cross section of the Venturi tube at A. Wait for some time and the readings from manometer G and velocity heads, i.e. the total (or stagnation) head (h*), because the hypodermic tube is held against the flow of fluid forcing it to a stop (zero velocity). The reading in manometer #A measures just the pressure head (hi) because it is connected to the Venturi tube pressure tap, which does not obstruct the flow, thus measuring the flow static pressure. 6. Step 5 is repeated for other cross sections (A,B, C, D, E,F).

FLUID LABORATORY (BEC205)

Bernoullis theorem

Group B2

7. Step 3 to 6 is repeated with three other decreasing flow rates by regulating the venture discharge valve. 8. The velocity is calculated, ViB using the Bernoullis equation where; ViB =

2 g h8 hi

9. The velocity, ViC is calculated using the continuity equation where; ViC =

Q av Ai

10. Determined the difference between two calculated velocities.

2.3.1 General Shut-down Procedures

1. closes water supply valve and venture discharge valve.

2. Turn off the water supply pump. 3.Drain off water from the unit when not in use.

3.0 Data and Analysis

Cross section i Di (mm) h =h (mm)

* G

Using Bernoulli equation

Using equation

*

continuity

Difference

hi(mm)

ViB= [2 x g x (h h i)] (m/s)

Ai= Di2/4 (m )

2

ViC=Qav/Ai (m/s)

ViB-Vic (m/s)

Qav

A B C

26.0 21.6 16.0

122 119 117

120 118 115

0.198 0.140 0.198

0.000531 0.000366 0.000201

0.758 0.110 0.200

-0.56 0.03 -0.002

4.03 4.03 4.03

FLUID LABORATORY (BEC205)

Bernoullis theorem

Group B2

D E F

20.0 22.0 26.0

115 111 108

114 110 106

0.140 0.140 0.198

0.000314 0.000380 0.000531

0.128 0.106 0.076

0.012 0.034 0.072

4.03 4.03 4.03

3.1 Calculation:

Water volume (V) = 5 litres

Time(T) =2m04s =124s Q = = 0.4 or 4

ViBA = [2 x g x (h* h i)] = 2 9.81 =0.198(m/s) Where g is 9.81 Ai = Di2 / 4 = (0.026)2 / 4 Ai = 0.000531 m2. ViC=Qav/Ai (m/s) = = 0.076 m/s. ViB-Vic (m/s)

122-120)

3.2Discussion:

10

FLUID LABORATORY (BEC205)

Bernoullis theorem

Group B2

We can see that the difference of the velocity is not very large. The difference between the velocities is caused due to the difference in the cross sectional area of the water channels. The difference of the velocity is also caused due to the inner surface frictional losses. In our case, the air bubble inside the tube is fail to remove, it cause some error to the result taken. The smaller cross sectional area have a larger velocity value. Therefore, the water pressure in this area is higher than the others.

3.3Conclusion:

By doing this lab experiment, we learned practically the theorem of Bernoulli. The theory that stated in Bernoulli theorem, we see practically in this demonstration experiment. Bernoullis theorem. This

experiment also proves that the smallest section in area having a largest velocity which is stated in the

Appendix

11

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Student Handout Graphing TidesDokument2 SeitenStudent Handout Graphing TidesNur AfiqaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- New Catchment For Drainage-ModelDokument1 SeiteNew Catchment For Drainage-ModelNur AfiqaNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- 5.1 General Subsurface ProfileDokument2 Seiten5.1 General Subsurface ProfileNur AfiqaNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Introduction Company Involved Objective of Bertam MelakaDokument4 SeitenIntroduction Company Involved Objective of Bertam MelakaNur AfiqaNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Price List: Jadual Kadar Sewa Loji 2003Dokument9 SeitenPrice List: Jadual Kadar Sewa Loji 2003Nur AfiqaNoch keine Bewertungen

- The Eutrophication Process Occurred in A Lake and Its EffectsDokument3 SeitenThe Eutrophication Process Occurred in A Lake and Its EffectsNur AfiqaNoch keine Bewertungen

- Civil Engineering Department: CC607 Water and Wastewater Engineering Assignment 2 DKA5S3Dokument1 SeiteCivil Engineering Department: CC607 Water and Wastewater Engineering Assignment 2 DKA5S3Nur AfiqaNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Mechanical Engineering Department: Workshop Technology 2Dokument2 SeitenMechanical Engineering Department: Workshop Technology 2Nur AfiqaNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Depth (MM) vs. Cumulative No. of BlowsDokument1 SeiteDepth (MM) vs. Cumulative No. of BlowsNur AfiqaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- 3.1 Services Provided in Politeknik Port Dickson Student 'S Affair DepartmentDokument8 Seiten3.1 Services Provided in Politeknik Port Dickson Student 'S Affair DepartmentNur AfiqaNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Mechanical Engineering Department: JJ 207-Thermodynamics 1 (End of Chapter 1)Dokument2 SeitenMechanical Engineering Department: JJ 207-Thermodynamics 1 (End of Chapter 1)Nur AfiqaNoch keine Bewertungen

- Table of Content PrintDokument1 SeiteTable of Content PrintNur AfiqaNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- FlakyflakyyyDokument1 SeiteFlakyflakyyyNur AfiqaNoch keine Bewertungen

- Group Discussion 1: Area of Irregular Shapes (Clo 2) : DX X XDokument1 SeiteGroup Discussion 1: Area of Irregular Shapes (Clo 2) : DX X XNur AfiqaNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- 2011 - Engine - KlammerDokument23 Seiten2011 - Engine - KlammerTiago HenriquesNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Line Sizing and Pressure Drop PhilosophyDokument30 SeitenLine Sizing and Pressure Drop PhilosophyBelos SahajiNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

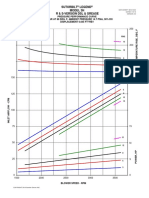

- Sutorbilt Legend Model 3H R & S-Version DSL & GreaseDokument1 SeiteSutorbilt Legend Model 3H R & S-Version DSL & GreaseJosue UrgilésNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Proven Upgrade SGT5-4000FDokument9 SeitenProven Upgrade SGT5-4000FThanapaet Rittirut100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- TAM-EN-1100 Tank MaintenanceDokument46 SeitenTAM-EN-1100 Tank MaintenanceJack Michaels100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Mroy Pump Catalogue PDFDokument6 SeitenMroy Pump Catalogue PDFTitus FelixNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Methanol Formation in The Water Gas Shift Reaction Over Copper Containing CatalystsDokument2 SeitenMethanol Formation in The Water Gas Shift Reaction Over Copper Containing CatalystsDAYAMOY APLNoch keine Bewertungen

- Product Information VDROO20-10: Project Name Item NODokument7 SeitenProduct Information VDROO20-10: Project Name Item NODado FahssaNoch keine Bewertungen

- Dryer Data Sheet Refrigerant Dryers Model DataDokument21 SeitenDryer Data Sheet Refrigerant Dryers Model Dataroni kurniawanNoch keine Bewertungen

- L Inverted Siphon 3rd CDokument6 SeitenL Inverted Siphon 3rd CPreston VargheseNoch keine Bewertungen

- Energy Conservation in Reciprocating CompressorDokument5 SeitenEnergy Conservation in Reciprocating CompressorRuturaj UmaranikarNoch keine Bewertungen

- Orifice Plate Specification: Client Project Unit LocationDokument1 SeiteOrifice Plate Specification: Client Project Unit Locationrufino.perea.1000Noch keine Bewertungen

- Reciprocating Compressor - SizingDokument36 SeitenReciprocating Compressor - SizingchaitanyaNoch keine Bewertungen

- ESA 11-18 GD - Rev1 - EngDokument36 SeitenESA 11-18 GD - Rev1 - EngaircenterNoch keine Bewertungen

- 8 PDFDokument8 Seiten8 PDFNicandroGonzalesNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Sir Nasim NotesDokument104 SeitenSir Nasim NotesMuhammad Arsalan100% (1)

- Differences Between A Thermostatic Expansion Valve and An Electronic Expansion ValveDokument4 SeitenDifferences Between A Thermostatic Expansion Valve and An Electronic Expansion Valvexuyen tran100% (1)

- Project Name: EMS APPARELS LIMITED. Area Reference: MOST REMOTE AREA 5th Floor (1500SQFT) OHG2Dokument8 SeitenProject Name: EMS APPARELS LIMITED. Area Reference: MOST REMOTE AREA 5th Floor (1500SQFT) OHG2NOMANNoch keine Bewertungen

- Basic Law of PercolationDokument13 SeitenBasic Law of PercolationMuneeb AhmadNoch keine Bewertungen

- Technical Catalogue: Air-Cooled Liquid Chillers With Screw CompressorsDokument40 SeitenTechnical Catalogue: Air-Cooled Liquid Chillers With Screw CompressorsEddieNoch keine Bewertungen

- Amao Temitope Laboratory Report 2012Dokument25 SeitenAmao Temitope Laboratory Report 2012jidefkNoch keine Bewertungen

- Thermofluid Final RevisionDokument3 SeitenThermofluid Final RevisionKaitou KiddoNoch keine Bewertungen

- JURNAL SandraDokument8 SeitenJURNAL Sandrania kurnianingsihNoch keine Bewertungen

- Hydrotest ProcedureDokument2 SeitenHydrotest ProcedureVarun MalhotraNoch keine Bewertungen

- Gei 41040MDokument28 SeitenGei 41040MPhong leNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- PurifierDokument29 SeitenPurifierRaghvendra Pratap Singh100% (1)

- Unit 4 Conventional and Non Conventional Energy NotesDokument17 SeitenUnit 4 Conventional and Non Conventional Energy NotesSujal GuptaNoch keine Bewertungen

- Quiz 2 Oil & GasDokument5 SeitenQuiz 2 Oil & GasNaumanTahirNoch keine Bewertungen

- كاتالوج لابيساDokument56 Seitenكاتالوج لابيسامحمود من فارس للبترولNoch keine Bewertungen

- E38 Fuel Supply SystemDokument4 SeitenE38 Fuel Supply SystemNorizwad Shah NasharudinNoch keine Bewertungen