Beruflich Dokumente

Kultur Dokumente

Blasting Abrasive S

Hochgeladen von

Abbas Rizvi0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten1 Seiteblasting book

Originaltitel

Blasting Abrasive s

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenblasting book

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten1 SeiteBlasting Abrasive S

Hochgeladen von

Abbas Rizviblasting book

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

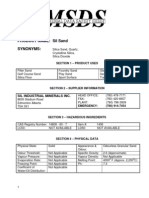

Blasting Abrasives

provided by Sil Industrial Minerals

N ANGULAR CUTTING ABRASIVES

ALUMINUM OXIDE: Widely used as a cutting abrasive. Produces excellent anchor or tooth patterns in preparation for recoating. Excellent for deburring, frosting glass and lettering stone. It is extremely fast cutting and can be reused many times. Manufactured from high-grade ore and is chemically inert. GARNET: This hard, fast cutting abrasive is manufactured from natural mineral. This naturally hard abrasive is ideal for the Blasting, Filtration and Waterjet cutting industries. Removes heavy material such as rust, weld scale, etc. Leaves uniform anchor pattern. METAL GRIT: The most popular type is made from chilled iron. Grit is angular and like thousands of tiny chisels and cutting tools, does a fast cleaning job. Produces an ideal surface for adherence of new coatings. Often the shot and the grit will be mixed to achieve different finishes. MINERAL GRIT: This silica-free abrasive combines high cutting power with low dust content. Applications are basically the same as sand. Prices are generally competitive, depending on location. SILICA SAND: Most commonly used with outdoor equipment, due to its low cost. Removes corrosion and old coatings from equipment and structures. Cleans concrete to expose aggregate. Not recommended for cabinet or room use, due to its rapid breakdown. SILICON CARBIDE: Used for cleaning extremely hard surfaces such as tungsten-carbide. This hard, sharp abrasive is extremely fast cutting.

G ROUND NON-CUTTING ABRASIVE

COB GRIT: Known as a soft-grit blasting. This natural cellulose grit is derived from corn cobs. Designed for removing light foreign matter, such as carbon, oil and dirt with no affect to surface. GLASS BEADS: One of the most popular abrasives used in cabinets today. Ideal for honing, polishing, peening, finishing and removing light burrs and foreign matter, such as carbon and surface residue from pistons and valves with no base metal removal or dimensional change. Produces bright satin finish. The applications are extensive, due to the wide range of screen sizes available. METAL SHOT: The most popular type of shot is made from chilled iron. Shot is a solid round particle causing a peening action and producing a smooth surface. Its heavy weight gives greater impact and hammering action for cleaning heavy forgings and removing heat-treating scale. PLASTIC: This relatively new dust-free abrasive is a special alloy of plastic material that has high tensile, compressive and flexural strength combined with comparatively low hardness. Used for deflashing plastic parts and cleaning molds, dies, electronic connections and circuit boards. It can effectively deburr machined iron castings, zinc or aluminum die castings and non-ferrous screw machine parts in addition to defacing molded plastic parts. WALNUT SHELLS: A soft nut shell material. Used in blasting processes for removal of foreign matter or coating from surface without etching, scratching or marring the cleaned areas. Examples would be cleaning molds, armatures and electric motors prior to rewinding.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- SA Garwin Epithermal Vein Presentation April2011Dokument94 SeitenSA Garwin Epithermal Vein Presentation April2011rahmanto98100% (3)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Metallography PDFDokument185 SeitenMetallography PDFDante GarzaNoch keine Bewertungen

- Astm A992Dokument2 SeitenAstm A992Saabir Gariire100% (1)

- Bs Steel CodeDokument14 SeitenBs Steel CodeA.K.A. HajiNoch keine Bewertungen

- Extractive Metallurgy of Rare EarthsDokument11 SeitenExtractive Metallurgy of Rare EarthsWilliam Jesus Cabrera Meza100% (1)

- CSWIP Question Answers PDFDokument32 SeitenCSWIP Question Answers PDFAnonymous SA40GK6100% (2)

- PorphyryDokument23 SeitenPorphyryJorge Sanchez100% (2)

- Astm A 781Dokument13 SeitenAstm A 781waleed4631Noch keine Bewertungen

- Preparation of High Purity Graphite From Alkali RoastingDokument3 SeitenPreparation of High Purity Graphite From Alkali RoastingEni Mece100% (1)

- Balst Furnace Iron Making - A.K BiswasDokument270 SeitenBalst Furnace Iron Making - A.K BiswasPukhraj Singh Grewal100% (5)

- Fabrication of Ceramic Matrix Composites by Liquid Phase InfiltrationDokument5 SeitenFabrication of Ceramic Matrix Composites by Liquid Phase InfiltrationyoukahoNoch keine Bewertungen

- III 08Dokument44 SeitenIII 08Abbas RizviNoch keine Bewertungen

- Website PaintsDokument7 SeitenWebsite PaintsAbbas RizviNoch keine Bewertungen

- 333Dokument2 Seiten333Abbas RizviNoch keine Bewertungen

- Plimbing Pump StandardDokument6 SeitenPlimbing Pump StandardAbbas RizviNoch keine Bewertungen

- Maintenance SteelDokument1 SeiteMaintenance SteelAbbas RizviNoch keine Bewertungen

- Pump Selection CriteriaDokument5 SeitenPump Selection CriteriaAbbas RizviNoch keine Bewertungen

- Essential handbooks, catalogues and textbooksDokument1 SeiteEssential handbooks, catalogues and textbooksAbbas RizviNoch keine Bewertungen

- API 653 Inspector Certification Training: Study SuggestionsDokument5 SeitenAPI 653 Inspector Certification Training: Study Suggestionsrizviabbas2012Noch keine Bewertungen

- Plain End Piping System For High Density Polyethylene Pipe: Product DescriptionDokument1 SeitePlain End Piping System For High Density Polyethylene Pipe: Product DescriptionAbbas RizviNoch keine Bewertungen

- Introduction To Fluid Mechanics - Ch01Dokument5 SeitenIntroduction To Fluid Mechanics - Ch01Nguyễn Hồng QuânNoch keine Bewertungen

- Inspector Calc Part 1Dokument10 SeitenInspector Calc Part 1Abbas RizviNoch keine Bewertungen

- Secret Doc P2066Dokument5 SeitenSecret Doc P2066Abbas RizviNoch keine Bewertungen

- Toolbox BrochDokument1 SeiteToolbox BrochAbbas RizviNoch keine Bewertungen

- 3000 FittingsDokument4 Seiten3000 FittingsAbbas RizviNoch keine Bewertungen

- Ms Ds Silica SandDokument3 SeitenMs Ds Silica SandAbbas RizviNoch keine Bewertungen

- ThyssenDokument0 SeitenThyssenAbbas RizviNoch keine Bewertungen

- Aws Cwi Laplace 05Dokument2 SeitenAws Cwi Laplace 05Abbas RizviNoch keine Bewertungen

- Air, Sand & Power Requirements: Orifice Pressure at The Nozzle (Psi)Dokument1 SeiteAir, Sand & Power Requirements: Orifice Pressure at The Nozzle (Psi)Abbas RizviNoch keine Bewertungen

- Profile Guide: 3.5-16/50 MESH 3.0 - 2.5 - 40/50 MESH (Mils) 2.0 - 60/80 MESH 1.5 - 1.0 - 0.5Dokument1 SeiteProfile Guide: 3.5-16/50 MESH 3.0 - 2.5 - 40/50 MESH (Mils) 2.0 - 60/80 MESH 1.5 - 1.0 - 0.5Abbas RizviNoch keine Bewertungen

- Conversion GuideDokument1 SeiteConversion GuideAbbas RizviNoch keine Bewertungen

- Turbine Duct WorkDokument4 SeitenTurbine Duct WorkAbbas RizviNoch keine Bewertungen

- Sand Blasting: Oil Removal from StructuresDokument1 SeiteSand Blasting: Oil Removal from StructuresAbbas RizviNoch keine Bewertungen

- Surface Finish SpecsDokument2 SeitenSurface Finish SpecsAbbas RizviNoch keine Bewertungen

- Silica XDokument21 SeitenSilica XAbbas RizviNoch keine Bewertungen

- Sil Topdressing Materials: Dry, Bagged Topdressing SandDokument1 SeiteSil Topdressing Materials: Dry, Bagged Topdressing SandAbbas RizviNoch keine Bewertungen

- Media GuideDokument3 SeitenMedia GuideAbbas RizviNoch keine Bewertungen

- Contractor Name City, State: Shop Standards Rectangular Duct ConstructionDokument2 SeitenContractor Name City, State: Shop Standards Rectangular Duct ConstructionAbbas RizviNoch keine Bewertungen

- Medium and High Pressure Duct WorkDokument4 SeitenMedium and High Pressure Duct WorkAbbas RizviNoch keine Bewertungen

- Bioleaching PDFDokument3 SeitenBioleaching PDFbioenvironNoch keine Bewertungen

- Nickel Alloy Fittings Standard SpecificationDokument13 SeitenNickel Alloy Fittings Standard SpecificationAVINASH CHAVANNoch keine Bewertungen

- AWS G 2.3M G2.3-2012 Guide For The Joining of Solid Solution Austenitic Stainless Steels - Part2Dokument50 SeitenAWS G 2.3M G2.3-2012 Guide For The Joining of Solid Solution Austenitic Stainless Steels - Part2estephan82Noch keine Bewertungen

- EP-June 30,2010Dokument7 SeitenEP-June 30,2010Bobby CalanogNoch keine Bewertungen

- Explosive WeldingDokument3 SeitenExplosive WeldingDarryl007Noch keine Bewertungen

- StruktoMaskinresurser Eng Web1 PDFDokument5 SeitenStruktoMaskinresurser Eng Web1 PDFmartinimartiini100% (1)

- Effect of Alloying Elements on Corrosion Resistance of Reinforcing Bar SteelDokument7 SeitenEffect of Alloying Elements on Corrosion Resistance of Reinforcing Bar SteelJosé AntonioNoch keine Bewertungen

- Data Sheet for 16.8.2 Welding Consumables for High Temperature 3XXH Stainless SteelsDokument5 SeitenData Sheet for 16.8.2 Welding Consumables for High Temperature 3XXH Stainless Steelsprabu prasadNoch keine Bewertungen

- 03 Sossego MineDokument32 Seiten03 Sossego MineJulio MendozaNoch keine Bewertungen

- Question-Answer For Degree of GalvanizingDokument7 SeitenQuestion-Answer For Degree of GalvanizingIFan SageNoch keine Bewertungen

- Investigation and Analysis of Cold Shut Casting Defect ReductionDokument3 SeitenInvestigation and Analysis of Cold Shut Casting Defect Reductionvivek1312Noch keine Bewertungen

- Selective Leaching (Dealloying) : Ib - Pt.Putra - Mahartana (2111100177) I Gede Brahmanda Aditya Paramartha (21111000146)Dokument12 SeitenSelective Leaching (Dealloying) : Ib - Pt.Putra - Mahartana (2111100177) I Gede Brahmanda Aditya Paramartha (21111000146)Idabagus Putu Putra MahartanaNoch keine Bewertungen

- Geology and Mineral Resources of Banswara District, RajasthanDokument24 SeitenGeology and Mineral Resources of Banswara District, Rajasthankanwaljeetsingh05Noch keine Bewertungen

- 20CrMnTi SteelDokument2 Seiten20CrMnTi Steelkannankriv0% (1)

- MdsDokument124 SeitenMdsAnonymous GE8mQqxNoch keine Bewertungen

- BS 970 SteelsDokument5 SeitenBS 970 SteelsPrapakaranNoch keine Bewertungen

- Physical Metallurgy 21 TH Lecture: MS&E 410 D.Ast Dast@ccmr - Cornell.edu 255 4140Dokument55 SeitenPhysical Metallurgy 21 TH Lecture: MS&E 410 D.Ast Dast@ccmr - Cornell.edu 255 4140Manikandan VijayanNoch keine Bewertungen

- Duplex SS HistoryDokument7 SeitenDuplex SS HistoryPedro CarneiroNoch keine Bewertungen

- Metal Casting TechniquesDokument81 SeitenMetal Casting TechniquesAshok PradhanNoch keine Bewertungen