Beruflich Dokumente

Kultur Dokumente

Diy Kit 2. Temperature Meter: Circuit Description

Hochgeladen von

Nedim NukicOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Diy Kit 2. Temperature Meter: Circuit Description

Hochgeladen von

Nedim NukicCopyright:

Verfügbare Formate

DIY Kit 2.

TEMPERATURE METER

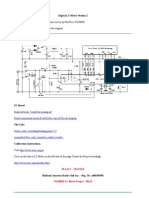

The Intersil chip 7106 is an amazing chip. We are so used to a constant stream of new and improved IC's that it is a surprise to find a chip which was launched in 1977, has remained unchanged during that time and yet sales of the chip today are actually increasing. What is the reason for this popularity? The 7106 was the first IC to contain all the active circuitry for a 3 1/2 digit panel meter (DPM) in a single chip. It was designed to interface directly to a liquid crystal display (LCD). (The 7107 IC is intended for LED - light emitting diode - displays.) So the chip contains BCD to seven segment decoders, display drivers, clock and a reference voltage as well as the necessary analog to digital (AD) circuitry to convert the input voltage to a digital form. The AD system also indicates the polarity of the input voltage. Voltage is the most frequently measured electrical quantity. In temperature meters, current meters, wind speed meters and resistance meters what is actually being measured is voltage, or more correctly, the potential difference between two points. After calibrating the meter for its particular purpose then the potential difference measured will give an accurate (digital) reading of the (variable analog) quantity being measured. With less than 10 external passive components the 7106 chip may be made into an easy to use meter for any of these purposes especially multiple range digital volt meters. See the Kit 127 documentation enclosed with this kit for more details. Digital displays have many advantages over analog meters which use a pointer and moving coil. Firstly they are easier to read especially by unskilled labour. In the majority of applications it is better hat the value displayed is exactly the value being measured, for example, 13.6V. To use an analog display with its many graduated scales (some going up and others going down) and switches requires considerable practice. But a simple LCD which reads '13.6' can be understood by everyone. Second, the DPM built using the 7106 is physically stronger and more robust than analog meters because it has no moving parts. Thirdly, for the manufacturer the assembly of the complete DPM unit can be done by relatively unskilled labour. Fourthly, the 7106 by its very nature can be adapted to so many uses at such a low cost that it has actually created markets for itself. All of these factors add up to a better, cheaper product which everyone can afford. In this kit we have supplied the 7106, the LCD and the components necessary to build it into a temperature meter. A printed circuit board (PCB) is supplied with the kit. It has a printed overlay on it so that the position of all the components is clearly indicated and construction only takes a few minutes. The PCB has a large breadboard area so that once you have become familiar with the module and used it as a temperature meter you can easily advance to build other metering devices such as a digital voltmeter, resistance meter, current meter and even an AC voltmeter. Used with a photodiode a light meter can be built. Applications are limited only by the availability of transducers and changing the circuit slightly to convert the external signals to a 0 to 199.9 mV DC signal. Copies of some ofthe circuits to do this are provided. The kit is constructed on a single-sided printed circuit board (PCB). A computer aided design (CAD) program is used to design the board. CIRCUIT DESCRIPTION The potential difference (PD) across a silicon diode is dependent on its temperature and current through it. Its temperature coefficient is negative, that is, the voltage falls with increasing temperature. This fall is approximately linear and is typically -2.2mV/oC. That is, there is the same drop in voltage when the diode cools from 88 oC to 87 oC as there is when it cools from 23 oC to 22 oC. Better sensors have better linear characteristics. In this Kit we have used a transistor as a diode (base and collector shorted together) which has a more linear temperature response over a bigger range than a diode does. The temperature meter measures the PD across the diode after an offset voltage which is available from pins 1 and 32 of the 7106 has been added. The two 100K 10-turn trimpots are used to calibrate the sensor at two known temperatures. The calibration is easily done using water with ice in it to calibrate zero degrees Centigrade and putting the sensor in a jet of steam from a boiling water kettle to calibrate for 100 oC. The decimal point has been hard-wired on. (The enclosed literature shows you circuits of how to obtain a variable decimal point.) ASSEMBLY INSTRUCTIONS There are several important points to watch. 1. The LCD (liquid crystal display) is mounted on two 40 pin IC sockets which you must cut apart using your side cutters. This allows the LCD to sit above the 7106 chip and save space. Make sure you get the LCD and the 7106 chip around the correct way. Look for the notch at one end of the LCD and match it to the notch shown on the PCB overlay (it goes to the lefthand side of the PCB.) Similarly, match the notch on the 7106 (opposite to the LCD notch it goes to the right.) These two components should be the last items added to the PCB. Use the filledin IC socket (if supplied) for the 7106 IC itself. 2. Mount POT 1 and R1 in the sockets provided and not directly into the PCB. Solder the single mounting socket pins into the PCB (After breaking them apart.). The values of these two components will change when the meter is used to build other projects. For the temperature meter R1 is 1M and POT1 is 100K (104). 3. It is best to attach the battery snap on the bottom side of the PCB so that the battery is contained inside the box.

DIY Kit 2. TEMPERATURE METER

4. Note the LINK to make on top of the PCB. The PCB has been marked on both sides to help you in using the kit to build other circuits. Abbreviations refer to the Intersil/Harris documentation. After the kit is assembled and the battery is connected the display should show some random readings or indicate out-of-range '1'. The unit now needs to be calibrated. You will need some ice and water to adjust the Zero Adjust pot to zero degrees centigrade and a jet of steam from boiling water to adjust the Scale Adjust pot to 100 degrees centigrade. The order of calibration does not matter. You may have to adjust both pots when you do the first calibration in order to get a reading other than '1'. If you hear a 'click, click' when you turn the trim pot then you are at one end of the winding and you should turn it the other way. Depending on the distance of the sensor from the meter you may need to use thin shielded coaxial cable between them. The 7106 has excellent noise limiting haracteristics. The sensor attached six inches from the PCB using the hookup wire provided should not have any noise roblems. The sensor transistor may be mounted on the breadboard area of the PCB with jumper leads connected from T+ and T- to it. WHAT TO DO IF IT DOES NOT WORK Poor soldering is the most likely reason. Check all solder joints carefully under a good light. Next check that all components are in their correct position on the PCB. Thirdly, follow the track with a voltmeter to check the potential differences at various parts of the circuit. A check list of other items includes: - did you add the jumper LINK on top of the PCB. - are the IC and LCD in the correct way. Check no pins are - bent up. This is very easy to do with a 40 pin IC. - is the battery flat. - is POT1 and the 1M resistor properly fitted into the sockets. WHAT TO LEARN FROM THIS KIT The Kit shows how much of electronics today can be contained in a single chip. Commercial low cost digital volt meters are nothing more than this kit, some switches and passive components and a nice plastic case. The main reason today for the failure of meters is more likely due to switch and mechanical failure rather than failure of the electronics itself. Our Kit 127 uses the 7106 and is a double-sided PCB version of Kit 2 without the breadboard area. It contains more information about how to use the 7106 in different types of meters. Get the documentation from The data sheet for the 7106 may be downloaded from the Intersil website at

www.intersil.com

or you can get it from our website at

www.kitsrus.com/pdf/7106.pdf

You can get the pinout information for the LCD at

www.kitsrus.com/pdf/vi302_dp.pdf

You may download a detailed Application Note for the 7106 at

www.kitsrus.com/pdf/7106_an1.pdf

This kit is basically the circuit shown in Figure 20 of this Application Note. (Documentation: November 2002) COMPONENTS Resistors 1% metal film: 1M brown black black yellow 22K red red black red 47K yellow violet black red 100K brown black black orange 220K red red black orange Capacitors: 100p 101 monoblok 220n 224 metallized 10n 103 mylar 100n 104 mylar 470n 474 metallized BC547 or BC548 10 turn trimpot 40 pin IC socket 7106 IC hookup wire 9V battery snap Box #2 and screws LCD VI302-DP-RC Kit 2 PCB

2 1 1 3 1

1 1 1 1 1 2 2 3 1 1 1 1 1

www.kitsrus.com/pdf/k127.pdf

Das könnte Ihnen auch gefallen

- Digital LED Thermometer with Microcontroller AVR ATtiny13Von EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Bewertung: 5 von 5 Sternen5/5 (1)

- Beginning Digital Electronics through ProjectsVon EverandBeginning Digital Electronics through ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Datasheet Humidity Sensor SHT21Dokument12 SeitenDatasheet Humidity Sensor SHT21Hernan VarelaNoch keine Bewertungen

- Voltmeter Using 7106+Dokument4 SeitenVoltmeter Using 7106+MahadevNoch keine Bewertungen

- Building Binary Clock z8Dokument23 SeitenBuilding Binary Clock z8Nat CasillanNoch keine Bewertungen

- Digital VoltmeterDokument7 SeitenDigital VoltmeterKrishna KithuNoch keine Bewertungen

- Water Heater ControlDokument17 SeitenWater Heater Controlsuhyb.awadallaNoch keine Bewertungen

- Dds 2016vmanualDokument11 SeitenDds 2016vmanualalirisad aliNoch keine Bewertungen

- Wa0002 PDFDokument18 SeitenWa0002 PDFuppulajashwanthNoch keine Bewertungen

- Ajay D - (MC & MP ASSIGN)Dokument7 SeitenAjay D - (MC & MP ASSIGN)Viswanath K ReddyNoch keine Bewertungen

- Test Bed para DinamometroDokument10 SeitenTest Bed para Dinamometropeccerini100% (1)

- Propeller Message Display With TemperatureDokument10 SeitenPropeller Message Display With Temperaturedivyanshu11111Noch keine Bewertungen

- Techincal Report Writing Short Project Report Section-ADokument7 SeitenTechincal Report Writing Short Project Report Section-AMuhammad UmairNoch keine Bewertungen

- Temperature Control - Project ReportDokument59 SeitenTemperature Control - Project ReportshivadocsNoch keine Bewertungen

- A Simple Digital Thermometer: ContentDokument13 SeitenA Simple Digital Thermometer: ContentKumar SamvatNoch keine Bewertungen

- DT 7107Dokument17 SeitenDT 7107Wilver Agustin CrisostomoNoch keine Bewertungen

- WS File 1Dokument13 SeitenWS File 1rhythm 2021Noch keine Bewertungen

- Applied Science Private UniversityDokument12 SeitenApplied Science Private UniversityRobin OhanyanNoch keine Bewertungen

- 7-Segmen Led Display Digital VoltmeterDokument8 Seiten7-Segmen Led Display Digital VoltmeterJoey TorresNoch keine Bewertungen

- 2.1.5 LCD Display: 2.1.7 GSM DeviceDokument9 Seiten2.1.5 LCD Display: 2.1.7 GSM DeviceHamza AliNoch keine Bewertungen

- Ir Thermometer: Presented By: Mustafa Ali Yassin Mohamed Fadel Alaa Khalil 2Nd Stage (Evening Study) Dr. Omar YoussefDokument17 SeitenIr Thermometer: Presented By: Mustafa Ali Yassin Mohamed Fadel Alaa Khalil 2Nd Stage (Evening Study) Dr. Omar YoussefAws FaeqNoch keine Bewertungen

- Ant Bms 20s Wiring Diagram Xebike DTDokument14 SeitenAnt Bms 20s Wiring Diagram Xebike DTEloan HerminNoch keine Bewertungen

- TEC-25V-20A-PID: Operating ManualDokument7 SeitenTEC-25V-20A-PID: Operating Manualmitio mitioniNoch keine Bewertungen

- Practical PIC ProjectsDokument14 SeitenPractical PIC ProjectsArdhika Dhennis Putra Ananda100% (1)

- v350 35 Ta24 Instal GuideDokument10 Seitenv350 35 Ta24 Instal GuideDejan IlievNoch keine Bewertungen

- Temperature and Humidity Sensor On An ArduinoDokument10 SeitenTemperature and Humidity Sensor On An ArduinoAlfred NeriNoch keine Bewertungen

- A Brief History of The 8051 FamilyDokument8 SeitenA Brief History of The 8051 FamilyAakash SheelvantNoch keine Bewertungen

- Adt 7311Dokument24 SeitenAdt 7311Elanchezhian VeeramaniNoch keine Bewertungen

- Digital LC Meter Version 2Dokument3 SeitenDigital LC Meter Version 2geraldino250Noch keine Bewertungen

- JulyDokument5 SeitenJulyapi-3707767Noch keine Bewertungen

- LCMeterHombrewmanual PDFDokument5 SeitenLCMeterHombrewmanual PDFwayan.wandira8122Noch keine Bewertungen

- Data SheetDokument8 SeitenData Sheetabolfazl1393Noch keine Bewertungen

- DC Motor CTRL Using Single SwitchDokument44 SeitenDC Motor CTRL Using Single SwitchAbhijeet NayakNoch keine Bewertungen

- An 023Dokument8 SeitenAn 023SoumitraNoch keine Bewertungen

- AVR Project - Remote Controlled Fan Regulator.Dokument23 SeitenAVR Project - Remote Controlled Fan Regulator.nadaratNoch keine Bewertungen

- LC MeterDokument10 SeitenLC MeterYenidir TeknoNoch keine Bewertungen

- Digital Fan RegulatorDokument31 SeitenDigital Fan RegulatorManoj GurralaNoch keine Bewertungen

- Ra 02Dokument35 SeitenRa 02Sina MahmoodiNoch keine Bewertungen

- Tips For Using Single Chip 3 12 Digit AD ConvertersDokument8 SeitenTips For Using Single Chip 3 12 Digit AD Converterslgrome73Noch keine Bewertungen

- An 052Dokument8 SeitenAn 052SoumitraNoch keine Bewertungen

- Lab Project ReportDokument18 SeitenLab Project ReportDebjit SarkarNoch keine Bewertungen

- D T S K: Igital Emperature Ensor ITDokument3 SeitenD T S K: Igital Emperature Ensor ITPhilip BullasNoch keine Bewertungen

- Z80 Microprocessor Kit Construction ManualDokument31 SeitenZ80 Microprocessor Kit Construction ManualAlfredo Meurer JuniorNoch keine Bewertungen

- Accident Detection SystemDokument62 SeitenAccident Detection SystemKarthik KingstarNoch keine Bewertungen

- Liquid Tank Monitring SystemDokument9 SeitenLiquid Tank Monitring Systemsyed_hafeez_2Noch keine Bewertungen

- Digital CounterDokument10 SeitenDigital Counterareej.fatima1298Noch keine Bewertungen

- Introduction Chapter 1Dokument20 SeitenIntroduction Chapter 1Kumaran SgNoch keine Bewertungen

- NEC Format RemoteDokument15 SeitenNEC Format RemoteMunish KaundalNoch keine Bewertungen

- Full Paper of Put Coin and Draw Power 2010Dokument9 SeitenFull Paper of Put Coin and Draw Power 2010Biswajit SarkarNoch keine Bewertungen

- Basic PIC 40 Development BoardDokument8 SeitenBasic PIC 40 Development BoardBasit Ahmad100% (3)

- Gilliam - Temp Sensors PDFDokument6 SeitenGilliam - Temp Sensors PDFKarthi SanNoch keine Bewertungen

- Sample FormatDokument18 SeitenSample FormatgetnetNoch keine Bewertungen

- ICL7106 and ICL7107 VoltmeterDokument16 SeitenICL7106 and ICL7107 VoltmeterAntonino ScordatoNoch keine Bewertungen

- ICL7106, ICL7107, ICL7107S: 3 / Digit, LCD/LED Display, A/D Converters FeaturesDokument16 SeitenICL7106, ICL7107, ICL7107S: 3 / Digit, LCD/LED Display, A/D Converters FeaturesStefano Romeu ZeplinNoch keine Bewertungen

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsVon EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNoch keine Bewertungen

- Manual D1750Dokument48 SeitenManual D1750Liaquat Najmi67% (3)

- 6 Hilux (Cont. Next Page) : Power Source Cruise Control (1KD-FTV W/o DPF)Dokument6 Seiten6 Hilux (Cont. Next Page) : Power Source Cruise Control (1KD-FTV W/o DPF)Alfian AkbarNoch keine Bewertungen

- Eaas0593 XaDokument24 SeitenEaas0593 XaAchmad AnugrahNoch keine Bewertungen

- WIBO-THINK Wi-Fi Robot Controller Module: 2-1: Pin DescriptionDokument13 SeitenWIBO-THINK Wi-Fi Robot Controller Module: 2-1: Pin DescriptionAbolfazl HabibiNoch keine Bewertungen

- TLE 8 Exploratory Computer System Servicing 1st Quarter ExamDokument3 SeitenTLE 8 Exploratory Computer System Servicing 1st Quarter ExamRubylinda100% (10)

- 1 1Z621144312 PDFDokument101 Seiten1 1Z621144312 PDFvijeshvijayanNoch keine Bewertungen

- ECZ Computer Studies P1 Past Paper 2015 2016 2017Dokument27 SeitenECZ Computer Studies P1 Past Paper 2015 2016 2017Bricious Mulimbi100% (2)

- User Manual 4009600Dokument3 SeitenUser Manual 4009600Ahmed ProlicNoch keine Bewertungen

- Ze Gcs04a20-Eng 247-270Dokument24 SeitenZe Gcs04a20-Eng 247-270ikrima BenNoch keine Bewertungen

- Allen-Bradley Manuals 2106Dokument25 SeitenAllen-Bradley Manuals 2106Diego Aparecido PereiraNoch keine Bewertungen

- CBSE UGC NET Electronic Science Paper 2 June 2007Dokument14 SeitenCBSE UGC NET Electronic Science Paper 2 June 2007Bhargav. GNoch keine Bewertungen

- Original SIWES Report WritingDokument25 SeitenOriginal SIWES Report Writingfalab toheeb100% (3)

- Minicore Rcm6700 Series: Application HighlightDokument2 SeitenMinicore Rcm6700 Series: Application HighlightCastrena AbadiNoch keine Bewertungen

- 555 Timer As Mono Stable Multi VibratorDokument8 Seiten555 Timer As Mono Stable Multi VibratorchrisgeclayNoch keine Bewertungen

- Aeng 514 FinalDokument722 SeitenAeng 514 FinalPaul GernahNoch keine Bewertungen

- Panasonic KX-TG1611 PDFDokument32 SeitenPanasonic KX-TG1611 PDFgrudva2Noch keine Bewertungen

- Continuous Assessement: 2019/2020 Academic Year: Course Title: Digital Control Systems. Course Code: Eeep3201Dokument3 SeitenContinuous Assessement: 2019/2020 Academic Year: Course Title: Digital Control Systems. Course Code: Eeep3201Danny JrNoch keine Bewertungen

- Computer Organization and Architecture (COA) May June Supply 2018 Solved Question PaperDokument32 SeitenComputer Organization and Architecture (COA) May June Supply 2018 Solved Question PapermaharshisanandyadavNoch keine Bewertungen

- Fleps23 CFP Web 03 E9038f7b56Dokument1 SeiteFleps23 CFP Web 03 E9038f7b56Shranish KarNoch keine Bewertungen

- Module 5 - Digital Techniques Electronic Instrument Systems PDFDokument42 SeitenModule 5 - Digital Techniques Electronic Instrument Systems PDFanilmathew244Noch keine Bewertungen

- IFM Speed Relay DD0203 Data SheetDokument2 SeitenIFM Speed Relay DD0203 Data SheetRaymund GatocNoch keine Bewertungen

- PHD78NQ03LT: N-Channel 30-V (D-S) MOSFETDokument8 SeitenPHD78NQ03LT: N-Channel 30-V (D-S) MOSFETNikolay ShkolkinNoch keine Bewertungen

- Limited Edition Limited Edition Limited EdDokument4 SeitenLimited Edition Limited Edition Limited EdWiNoch keine Bewertungen

- Lab1 Tranzistoare EngDokument11 SeitenLab1 Tranzistoare Engtoufik bendibNoch keine Bewertungen

- Bridge Axi AhbDokument22 SeitenBridge Axi Ahbkrishnaav100% (1)

- CRR 718 Ben FTTHDokument66 SeitenCRR 718 Ben FTTHanupkrajakNoch keine Bewertungen

- DTT IptvDokument9 SeitenDTT Iptvpeter mureithiNoch keine Bewertungen

- LAB 7: IIR Filter Design ObjectivesDokument13 SeitenLAB 7: IIR Filter Design Objectivesmjrahimi.eee2020Noch keine Bewertungen

- 1-Port Gigabit GPON/EPON Wireless-N ONU Router: Model No: iB-FONG11GWDokument1 Seite1-Port Gigabit GPON/EPON Wireless-N ONU Router: Model No: iB-FONG11GWFilesNoch keine Bewertungen

- 3GPP Newcomer Introduction & Overview of 5G Status: Georg Mayer, 3GPP SA ChairmanDokument57 Seiten3GPP Newcomer Introduction & Overview of 5G Status: Georg Mayer, 3GPP SA ChairmanSudipta DasNoch keine Bewertungen