Beruflich Dokumente

Kultur Dokumente

Media Guide

Hochgeladen von

Abbas RizviCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Media Guide

Hochgeladen von

Abbas RizviCopyright:

Verfügbare Formate

Media Guide

Material

Mesh

Size

Density

lbs/ft

Mohs

Friability

Silica Sand

6-270

100

5.0-6.0

high

20-90

nat

Outdoor blast cleaning

Mineral Slag

8-80

85-112

7.0-7.5

high

20-90

b-p

Outdoor blast cleaning

Steel Grit

10-325

230

8.0

low

20-90

mfg.

Removing heavy scale

Steel Shot

8-200

280

8.0

low

20-90

mfg.

Cleaning, peening

Aluminum

Oxide

12-325

125

8.0-9.0+

med

20-90

mfg.

Cleaning, finishing

deburring, etching

Glass Bead

10-400

85-90

5.5

med

20-55

mfg.

Cleaning, finishing

Plastic

12-80

45-60

3.0-4.0

low/med

20-60

mfg.

Paint stripping, deflashing,

cleaning

Wheat Starch

12-50

90

2.8-3.0

high

10-40

b-p

Paint stripping, cleaning

Corn Cob /

Walnut Shell

8-40

35-45

2.0-4.5

med

10-40

b-p

Removing paint from delicate

surfaces

nat. = Natural

Typical Blast

Source

Pressure (psi)

b-p = By Product

Typical Applications

mfg. = Manufactured

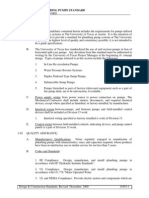

System Sizing Chart-Portable Blaster

(at 100 psi nozzle pressure)

Nozzle

Hose I.D.

(No.)

(I.D.)

(Blast)

(Air Supply)

Optimum

Vessel Size

#2

1/8"

1/2"

3/4"

#3

3/16"

1/2" to 3/4"

#4

1/4"

#5

Minimum Compressor Size

Approximate

Blast Time Media Use

(Min)

(lbs/hr)

(SCFM)

(HP)

100 / 150

20

35/50

175

1"

150 / 350

45

10

24/45

250

3/4" to 1"

1 to 1-1/4"

350

81

18

45

500

5/16"

1 to 1-1/4"

1-1/4"

650

137

30.5

50

800

#6

3/8"

1 to 1/4"

1-1/2"

650 / 1050

196

44

35/55

1150

#7

7/16"

1-1/2"

2"

1050

254

56.5

40

1600

#8

1/2"

1-1/2"

2"

1050

338

75

30

2000

#10

5/8"

1-1/2"

3"

1050

548

122

20

3300

Air Requirements & Media Consumption Chart

Nozzle

No.

#3

#4

I.D.

3/16"

1/4"

PSI

60

70

80

90

100

120

Air (CFM)

30

33

38

41

45

--

Horsepower

7.0

7.5

8.5

9.5

10.0

--

Media (lbs/hr)

171

196

216

238

264

--

Air (CFM)

54

61

68

74

81

97

Horsepower

12.0

13.5

15.0

16.5

18.0

21.5

#5

#6

#7

#8

#10

5/16"

3/8"

7/16"

1/2"

5/8"

Media (lbs/hr)

312

354

408

448

494

582

Air (CFM)

89

101

113

126

137

152

Horsepower

20.0

22.5

25.5

28.0

30.5

34.0

Media (lbs/hr)

534

604

672

740

812

912

Air (CFM)

126

143

161

173

196

220

Horsepower

28.0

32.0

36.0

38.5

44.0

49.0

Media (lbs/hr)

764

864

960

1,052

1,152

1,320

Air (CFM)

170

194

217

240

254

300

Horsepower

38.0

43.5

48.5

53.5

56.5

67.0

Media (lbs/hr)

1,032

1,176

1,312

1,448

1,584

1,800

Air (CFM)

224

252

280

309

338

392

Horsepower

50.0

56.0

62.5

69.0

75.0

87.5

Media (lbs/hr)

1,336

1,512

1,680

1,856

2,024

2,352

Air (CFM)

356

404

452

504

548

611

Horsepower

79.5

90.0

100.5

112.0

122.0

136.0

Media (lbs/hr)

2,136

2,424

2,712

3,024

3,288

3,668

Pressure Loss in Air Hose

I.D.

Pressure Loss

Production Loss

3/4"

11.1 psi

16.6%

1"

2.4 psi

3.6%

1-1/4"

0.7 psi

1.0%

1-1/2"

.02 psi

0.3%

Based on 150 cfm @ 100 psi through 50 feet of compressor air hose

For maximum efficiency, provide large air lines from the compressor to the blast

machines. Place the compressor as near as possible to the blast operation. Use the

largest air hose available.

System Air Volume Requirements at 100 Psi

Nozzle

Size of Orifice Volume of Air

Plus Helmet

Plus 50%

(reserve)

Minimum Air Required

No. 4

1/4"

6.5mm

81

2.3

20

0.5

50

1.4

No. 5

5/16"

8.0mm

137

3.9

20

0.5

79

2.2

236 cfm

6.6 m/min

No. 6

3/8"

9.5mm

196

5.5

20

0.5

108

3.0

324 cfm

9.0 m/min

No. 7

7/16"

11.0mm

254

7.2

20

0.5

137

3.9

411 cfm

11.6 m/min

No. 8

1/2"

3338

20

179

537 cfm

151 cfm

4.2 m/min

12.5mm

9.6

0.5

5.0

16.1 m/min

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Bs Steel CodeDokument14 SeitenBs Steel CodeA.K.A. HajiNoch keine Bewertungen

- Chapter 3 - Global Analysis EquationsDokument54 SeitenChapter 3 - Global Analysis EquationsCarl Chester RagudoNoch keine Bewertungen

- SSC JE Mechanical Study Material Strength of Materials PDFDokument13 SeitenSSC JE Mechanical Study Material Strength of Materials PDFSameer ShahNoch keine Bewertungen

- Website PaintsDokument7 SeitenWebsite PaintsAbbas RizviNoch keine Bewertungen

- 333Dokument2 Seiten333Abbas RizviNoch keine Bewertungen

- Pump Selection CriteriaDokument5 SeitenPump Selection CriteriaAbbas RizviNoch keine Bewertungen

- Maintenance SteelDokument1 SeiteMaintenance SteelAbbas RizviNoch keine Bewertungen

- III 08Dokument44 SeitenIII 08Abbas RizviNoch keine Bewertungen

- Plimbing Pump StandardDokument6 SeitenPlimbing Pump StandardAbbas RizviNoch keine Bewertungen

- Introduction To Fluid Mechanics - Ch01Dokument5 SeitenIntroduction To Fluid Mechanics - Ch01Nguyễn Hồng QuânNoch keine Bewertungen

- Plain End Piping System For High Density Polyethylene Pipe: Product DescriptionDokument1 SeitePlain End Piping System For High Density Polyethylene Pipe: Product DescriptionAbbas RizviNoch keine Bewertungen

- 3000 FittingsDokument4 Seiten3000 FittingsAbbas RizviNoch keine Bewertungen

- Titles of Handbooks, Catalogues and TextbooksDokument1 SeiteTitles of Handbooks, Catalogues and TextbooksAbbas RizviNoch keine Bewertungen

- Secret Doc P2066Dokument5 SeitenSecret Doc P2066Abbas RizviNoch keine Bewertungen

- Toolbox BrochDokument1 SeiteToolbox BrochAbbas RizviNoch keine Bewertungen

- Inspector Calc Part 1Dokument10 SeitenInspector Calc Part 1Abbas RizviNoch keine Bewertungen

- Ms Ds Silica SandDokument3 SeitenMs Ds Silica SandAbbas RizviNoch keine Bewertungen

- ThyssenDokument0 SeitenThyssenAbbas RizviNoch keine Bewertungen

- Aws Cwi Laplace 05Dokument2 SeitenAws Cwi Laplace 05Abbas RizviNoch keine Bewertungen

- Profile Guide: 3.5-16/50 MESH 3.0 - 2.5 - 40/50 MESH (Mils) 2.0 - 60/80 MESH 1.5 - 1.0 - 0.5Dokument1 SeiteProfile Guide: 3.5-16/50 MESH 3.0 - 2.5 - 40/50 MESH (Mils) 2.0 - 60/80 MESH 1.5 - 1.0 - 0.5Abbas RizviNoch keine Bewertungen

- SandDokument1 SeiteSandAbbas RizviNoch keine Bewertungen

- API 653 Inspector Certification Training: Study SuggestionsDokument5 SeitenAPI 653 Inspector Certification Training: Study Suggestionsrizviabbas2012Noch keine Bewertungen

- Conversion GuideDokument1 SeiteConversion GuideAbbas RizviNoch keine Bewertungen

- Silica XDokument21 SeitenSilica XAbbas RizviNoch keine Bewertungen

- Surface Finish SpecsDokument2 SeitenSurface Finish SpecsAbbas RizviNoch keine Bewertungen

- Sil Topdressing Materials: Dry, Bagged Topdressing SandDokument1 SeiteSil Topdressing Materials: Dry, Bagged Topdressing SandAbbas RizviNoch keine Bewertungen

- Medium and High Pressure Duct WorkDokument4 SeitenMedium and High Pressure Duct WorkAbbas RizviNoch keine Bewertungen

- Turbine Duct WorkDokument4 SeitenTurbine Duct WorkAbbas RizviNoch keine Bewertungen

- Air, Sand & Power Requirements: Orifice Pressure at The Nozzle (Psi)Dokument1 SeiteAir, Sand & Power Requirements: Orifice Pressure at The Nozzle (Psi)Abbas RizviNoch keine Bewertungen

- Blasting Abrasive SDokument1 SeiteBlasting Abrasive SAbbas RizviNoch keine Bewertungen

- Contractor Name City, State: Shop Standards Rectangular Duct ConstructionDokument2 SeitenContractor Name City, State: Shop Standards Rectangular Duct ConstructionAbbas RizviNoch keine Bewertungen

- EM Paper 1Dokument1.156 SeitenEM Paper 1sCience 123Noch keine Bewertungen

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDokument9 SeitenEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureJovanni RodriguezNoch keine Bewertungen

- CFD Study Heat PipeDokument8 SeitenCFD Study Heat PipeSalman Chowdhury ShawonNoch keine Bewertungen

- Report CMTDokument5 SeitenReport CMTKhalil FurioNoch keine Bewertungen

- Ec8252-Electronic Devices: Jothibasu M Ap (SR - GR) /ece PsgitechDokument27 SeitenEc8252-Electronic Devices: Jothibasu M Ap (SR - GR) /ece PsgitechJothibasu MarappanNoch keine Bewertungen

- Testing of The Mechanical Properties For 15mo3 SteelDokument2 SeitenTesting of The Mechanical Properties For 15mo3 SteelavenclNoch keine Bewertungen

- Introduction To A Real-Time Weather ForecastingDokument20 SeitenIntroduction To A Real-Time Weather ForecastingjjjdklcfjsdcfNoch keine Bewertungen

- TPFT IG1 Jan 2020 PDFDokument6 SeitenTPFT IG1 Jan 2020 PDFrehanNoch keine Bewertungen

- Q1) Choose The Correct Answer (2 Marks For Each Branch)Dokument16 SeitenQ1) Choose The Correct Answer (2 Marks For Each Branch)abdulkaderNoch keine Bewertungen

- Water TankDokument89 SeitenWater TankDenishmakvanaNoch keine Bewertungen

- Mig Guide From Zero PDFDokument10 SeitenMig Guide From Zero PDFHugo SalazarNoch keine Bewertungen

- Pharmaceutical Formulations-Suspensions and Solutions PDFDokument4 SeitenPharmaceutical Formulations-Suspensions and Solutions PDFERICA LILIAN ESGUERRA GILNoch keine Bewertungen

- Difference Between Pressure Vessel and ColumnDokument1 SeiteDifference Between Pressure Vessel and ColumnDarshit GolwalaNoch keine Bewertungen

- Dry Gas Versus Wet Gas Compressor SealsDokument5 SeitenDry Gas Versus Wet Gas Compressor Sealsasimozma100% (1)

- Section 13 Fatigue 13.1 General This Section Applies To The Design of Structures and Structural ElementsDokument16 SeitenSection 13 Fatigue 13.1 General This Section Applies To The Design of Structures and Structural ElementslakshayNoch keine Bewertungen

- Duratherm XLT-120Dokument4 SeitenDuratherm XLT-120Goh Kok SweeNoch keine Bewertungen

- How To Extract The Maximum Information From Dma TestsDokument13 SeitenHow To Extract The Maximum Information From Dma TestsGyörgy BánhegyiNoch keine Bewertungen

- Jee Advanced Check List Set 1Dokument1 SeiteJee Advanced Check List Set 1Pulkit BaghelNoch keine Bewertungen

- Gauss Law Lab ExampleDokument6 SeitenGauss Law Lab ExampleAnthony MajinianNoch keine Bewertungen

- R.N. Swamy (Editor) - B. Barr (Editor) - Fibre Reinforced Cement and Concretes - Recent developments-CRC Press (1990)Dokument715 SeitenR.N. Swamy (Editor) - B. Barr (Editor) - Fibre Reinforced Cement and Concretes - Recent developments-CRC Press (1990)Gardener Ayu0% (1)

- Hasselblad 503cwDokument6 SeitenHasselblad 503cweternal_harpyNoch keine Bewertungen

- Kinetic Particle Theory For Year-8 - Final ExamsDokument17 SeitenKinetic Particle Theory For Year-8 - Final ExamsJihan KhanNoch keine Bewertungen

- SodaPDF-merged-Merging Result-2Dokument258 SeitenSodaPDF-merged-Merging Result-2ermiasNoch keine Bewertungen

- Transverse and LongitudinalWavesDokument8 SeitenTransverse and LongitudinalWavesDebasish TNoch keine Bewertungen

- Measurements Lab Final-2Dokument19 SeitenMeasurements Lab Final-2Lance ShahNoch keine Bewertungen

- R0-Sliding Gate, Fence, LadderDokument90 SeitenR0-Sliding Gate, Fence, LadderMariam MousaNoch keine Bewertungen

- ManualDokument7 SeitenManualAsri GaniNoch keine Bewertungen