Beruflich Dokumente

Kultur Dokumente

FVC

Hochgeladen von

smileya_vp0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

153 Ansichten0 SeitenForged Vessel Connections (FVC) manufactures pressure vessel connection products including long welding necks, heavy barrel necks, and variable and full body connections. The document provides an overview of FVC's product offerings, manufacturing capabilities, quality assurance processes, and customer service. FVC stocks a wide range of standard connections and can custom design connections to meet specific needs. FVC utilizes quality materials and processes, precision machining, and thorough inspection to deliver high quality connection products to the oil and gas, petrochemical, and other industries.

Originalbeschreibung:

Originaltitel

fvc

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenForged Vessel Connections (FVC) manufactures pressure vessel connection products including long welding necks, heavy barrel necks, and variable and full body connections. The document provides an overview of FVC's product offerings, manufacturing capabilities, quality assurance processes, and customer service. FVC stocks a wide range of standard connections and can custom design connections to meet specific needs. FVC utilizes quality materials and processes, precision machining, and thorough inspection to deliver high quality connection products to the oil and gas, petrochemical, and other industries.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

153 Ansichten0 SeitenFVC

Hochgeladen von

smileya_vpForged Vessel Connections (FVC) manufactures pressure vessel connection products including long welding necks, heavy barrel necks, and variable and full body connections. The document provides an overview of FVC's product offerings, manufacturing capabilities, quality assurance processes, and customer service. FVC stocks a wide range of standard connections and can custom design connections to meet specific needs. FVC utilizes quality materials and processes, precision machining, and thorough inspection to deliver high quality connection products to the oil and gas, petrochemical, and other industries.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 0

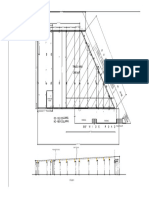

Pressure Vessel Connections

Long Welding Necks Heavy Barrel Type HB Necks

Variable Body Type V

1

, V

2

, V

3

Necks Full Body Type F Necks

Studding Outlets Custom Products Rough Forgings

Insert Type Q Nozzles

Table of Contents

Introduction to FVC .................................................................................. 4

FVC Standard and Variable Body Connections ......................................... 7

Introduction to Seamless Construction ................................................. 8

LWN, HB, F, V

1

, V

2

, and V

3

:

Class 150 ....................................................................................... 12

Class 300 ....................................................................................... 16

Class 400 ....................................................................................... 20

Class 600 ....................................................................................... 24

Class 900 ....................................................................................... 28

Class 1500 ..................................................................................... 32

Class 2500 ..................................................................................... 36

General Notes for FVC Connections .................................................... 40

FVC Studding Outlets ............................................................................. 41

Introduction to Studding Outlets ........................................................ 42

Class 150 ....................................................................................... 44

Class 300 ....................................................................................... 45

Class 600 ....................................................................................... 46

Class 900 ....................................................................................... 47

Class 1500 ..................................................................................... 48

Class 2500 ..................................................................................... 49

General Notes for FVC Studding Outlets ............................................ 50

FVC Custom Products ............................................................................. 53

Introduction to FVC Custom Product Capabilities ................................ 54

Technical Section .................................................................................... 57

Technical Table of Contents .................................................................... 58

Warranty and Terms ............................................................................... 80

MAILING ADDRESS:

P. O. Box 38421

Houston, TX 77238-8421

MAIN PLANT, DOMESTIC

AND INTERNATIONAL

SALES OFFICES:

2525 DeSoto St.

Houston, TX 77091

1-800-231-2701

1-713-688-9705

FAX: 1-713-688-7954

FAX: 1-713-688-7518

FAX: 1-713-688-1846

WEB PAGE:

http://www.fvc.cc

E-MAIL:

sales@fvc.cc

CANADA OPERATIONS:

WESTERN CANADIAN

SALES & DISTRIBUTION

7410A-5 Street S.E.

Calgary, Alberta T2H-2L9

1-800-382-3490

1-403-255-9011

FAX: 1-403-255-7239

E-MAIL:

wcanada@fvc.cc

Forged Vessel Connections

an AMERI-FORGE GROUP company

2

Forged Vessel Connections, Inc., FVC, was founded primarily to satisfy the

highly specialized needs of the pressure vessel fabrication industry with

products of unexcelled quality backed by dependable service. Dedication to

that purpose has enabled us to emerge as a major manufacturer of pressure

vessel components and related equipment in only a few, short years.

After organizing in the mid-1970s as a machining facility, it became increas-

ingly apparent that there was a need for more specialized forgings than those

readily available. Thus, operations were expanded to include in-house forging

capabilities with equipment and dies specifically selected to manufacture

seamless, self-reinforcing nozzles that would comply with the high standards

of performance our valued customers demand.

FVC has established a tradition of sound technology, quality assurance, pru-

dent economics, personalized service, and on-time delivery that has earned us

an enviable reputation in the industry.

Today, FVCs corporate, manufacturing, and storage facilities are situated on

approximately 15 acres. FVC offers total forging service from raw billet to the

finish machined product. These services also include custom design capabili-

ties as well as the full range of quality standard products outlined in this cata-

Forged Vessel Connections, Inc.

Let us serve your

pressure vessel

connection needs

log. This combination has allowed

FVC to fulfill a wide variety of

forging needs in many industries

worldwide. Some of these include:

Oil and gas exploration

Oil and gas processing

Petrochemical processing

Power generation

Cryogenic storage and

transportation

Pharmaceutical production

Through innovative design, sophisticated forging techniques, and versatility of

equipment, FVC is able to meet each customers exacting requirements effi-

ciently and economically. In addition, our attention to detail and dedication to

service is unequaled. Customer satisfaction is considered a necessity at FVC.

Savings

FVC products afford many fabrication advantages, not the least of which is

cost efficiency. The economics inherent in our one-piece, seamless construc-

tion versus built-up methods, allow the production of high quality nozzles at

minimal costs. Savings are effected through metallurgical control, maximum

utilization of input metals, machining efficiencies, and elimination of welds,

which enable our customers to meet critical delivery schedules.

Partial view of FVCs Houston

manufacturing factility.

3

A partial view of raw material inventory. Each billet is assigned an FVC heat number and

tested for chemical and physical properties by an independent test lab.

ABOVE: A large supply of carbon,

stainless, and alloy round bar is

maintained at FVC to provide our

customers with a quick turnaround

on all size products.

LEFT: Round bar, precisely cut to

size to forge FVC small necks, is

stocked and then forged in large

quantities.

Forging

All purchased steel used by FVC is

manufactured to fine grain practice

and is of excellent and exacting

quality. Each individual piece is

carefully prepared before processing

while strict identification control is

maintained. Forgings from each heat

of material are thoroughly tested

prior to the manufacture of produc-

tion items to insure compliance with

all required specifications. Sound

quality control practices are em-

ployed throughout manufacturing,

resulting in the finest quality forgings

available in carbon, alloy, and stain-

less steel grades.

Machining & Identification

Forging accuracy at FVC is such that

the profile of most rough forgings

closely conforms to the finished,

machined shape and size. Precision

machining then renders products to

the exact finish and tolerances neces-

sary for each application. Numerous

inspection points assure conformity

Forged Vessel Connections, Inc.

4

to all requirements. Before shipment, products are stamped in accordance with

applicable specifications for permanent traceability and then coated with a rust

inhibitor. In addition, the stamping includes the FVC work order number to

Forged Vessel Connections, Inc.

allow traceability to all manufactur-

ing steps and any special destructive

or non-destructive testing which may

have been performed on each indi-

vidual piece.

Versatility

The forging capabilities at FVC are

highly flexible. Stock items include

virtually every size ASME, LWN,

HB neck, and studding outlet used in

pressure vessel fabrication. Available

dies enable FVC to manufacture

many other standard flanges, such as

MSS-SP44, AWWA and API 605.

FVC can supply custom designed

nozzles to any size and reinforcement

configuration required to comply with applicable specifications. The extensive

inventory of dies and the capability for modifications to existing designs and

concepts minimize the need for special tooling. The economics arising from

such resourceful operation ultimately mean savings for you, the customer.

All dimensions shown in the catalog are typical dimensions. Any barrel size

with any bore can be furnished at standard price.

Layout and setup of bolt hole pat-

tern on one of FVCs radial arm

drilling machines.

A view of FVC semi-finished LWN forgings.

5

Service

FVC has developed an organization totally oriented to quality customer ser-

vice. Technical assistance in estimating and engineering is available, as well as

consultation on materials selection, reinforcement design, and special high

pressure flange design. FVCs single source savings assures excellent quality

control throughout manufacturing and on-time deliveries which enable you to

meet your all-important schedules. When you call FVC, you receive the high-

est quality products at fair, competitive prices accompanied by personalized

service every time!

Quality Assurance

At FVC, quality is built into each manufacturing step. Executive management

insists on strict adherence to its quality assurance program, which has been

established in compliance with ISO 9001 and ASME Boiler and Pressure

Vessel Code Sections I, II, and VIII Divisions 1 and 2. FVC utilizes many

additional in-house procedures, which further assures that its products will

meet or exceed our customers highest expectations.

Forged Vessel Connections, Inc.

ABOVE: Every part manufactured by FVC is carefully inspected during each

operation. Here FVC inspects an ASME RTJ facing to assure the close tolerances

outlined in B16.5 are maintainedthere is no spot-checking at FVC. To ensure

integrity, each part is stamped by the final inspector to indicate dimensional

accuracy and material verification.

LEFT: Complete material and product traceability data is stamped on each forging.

Optional destructive testing available

from FVC on applicable materials

includes:

Chemical analysis

Tensile testing (at ambient and/or

elevated temperatures)

Grain size (Metallographic Exami-

nation)

Hardness testing

Charpy impact testing

Nil-ductility testing to establish

transition temperature

HIC testing per NACE

Certificate Number: 30197

6

Optional non-destructive testing

available from FVC on applicable

materials includes:

Ultrasonic examination

Liquid penetrant examination

Dry or wet magnetic particle

examination

Positive material identification

FVC will administer any of the above

testing and/or provide test bars for

your own examinations. Please

specify with your order.

Custom Products

FVC is your single source for custom

products such as: stub ends, special

petroleum manway necks and covers,

full bore manways, well head compo-

nents, and custom reinforced nozzles.

FVC Type Q style nozzles as

shown in ASME Section VIII, Divi-

sion 1, Fig. UW 16.1 and Division 2,

Fig. AD-613.1 are used when

radiographable welds are required at

the nozzle-to-vessel junction.

FVC rough forgings are available, if

you prefer to perform your own

machining operations.

Forged Vessel Connections, Inc.

Bolt circles are checked before and bolt holes

after drilling to assure compliance to ASME

B16.5 dimensions and tolerances.

ABOVE RIGHT: FVC Insert Type

Q Nozzle for full penetration,

radiographed welding.

RIGHT: 42 x 300# V Nozzle

Manway made with SA-508 Grade

2 material.

80

1. Any Sales Tax, Manufacturers Tax, or Use tax imposed by Federal, State or Municipal Law is to be added

to the prices and assumed by purchaser.

2. Seller is not responsible for delays, defaults, or damages occasioned by any causes beyond sellers control

including, without limitation, governmental actions or orders, embargoes, strikes, fires and floods. In any

event, partial deliveries shall be permitted at sellers option.

3. Cancellations, of orders placed with and accepted by us, can be made only with our written consent. Upon

request to cancel, we will advise amount of cancellation charges, in addition to charges for dies, work in

process, products produced, including machine work, etc., and all liability for raw materials. Should you

change your material specification for your order after we have ordered or received the material, you are to

assume all liability for the material covered by your initial specification.

4. It is understood that dies, tools, and patterns required to produce the article quoted on shall remain the

property of FVC, Inc. Preparation charges or charges for dies, tools, and patterns represents only a portion

of cost. Payment of such charge does not give you any right, title, or interest in such dies, tools, or other

products of preparation.

5. Purchaser represents that purchaser is solvent and can and will pay for products delivered to purchaser in

accordance with the terms hereof. However, seller retains the right to require full payment in advance if in

sellers sole discretion the financial position of the purchaser so requires.

6. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

HEREOF EXCEPTING ONLY THAT EACH PRODUCT SOLD HEREUNDER IS WARRANTED TO BE

FREE FROM MANUFACTURING DEFECTS, AND IF DEFECTIVE, WILL EITHER BE REPAIRED OR

REPLACED WITHOUT CHARGE OR THE PURCHASE PRICE WILL BE REFUNDED, AT THE OP-

TION OF SELLER. SELLER MAKES NO OTHER WARRANTY, EITHER EXPRESS OR IMPLIED.

SELLERS LIABILITY IS LIMITED TO THE SALE PRICE OF THE PARTICULAR PRODUCT. IN NO

EVENT SHALL SELLER BE LIABLE FOR ANY CONSEQUENTIAL DAMAGES OR FOR EXPENSE

OCCASIONED BY THE USE OF DEFECTIVE PRODUCTS. SELLERS LIABILITIES AS ABOVE SET

OUT SHALL NOT BE EXTENDED BECAUSE OF ADVICE GIVEN BY SELLER IN CONNECTION

WITH THE DESIGN, INSTALLATION OR USE OF ANY PRODUCT. PURCHASER AGREES THAT IF

THE PRODUCTS SOLD HEREUNDER ARE BY PURCHASER RE-SOLD, PURCHASER WILL IN-

CLUDE IN THE CONTRACT FOR RE-SALE, PROVISIONS WHICH LIMIT RECOVERIES AGAINST

THIS SELLER IN ACCORDANCE WITH THIS PARAGRAPH.

7. Claims for shortages must be filed within ten days of receipt of shipment.

8. We assume no responsibility if the manufacture and sale to you of the items specified by you is an infringe-

ment of patent rights of other persons, you assume responsibility for and will protect us from such infringe-

ment liability, except as to our own manufacturing equipment and processes.

9. Stenographic or clerical errors are subject to correction.

10. Deferred deliveries are subject to FVC, Inc. written approval.

11. Purchases from us may not be returned without our written consent.

12. These terms and conditions shall control in any contract resulting from or arising out of this quotation, price

sheet, or acknowledgement, regardless of printed terms, conditions or provisions found in responses hereto

or documents giving rise hereto, all of such printed matters incorporated there in being deemed waived

insofar as the same differ from these terms and conditions, unless such differing terms, conditions or provi-

sions shall be specifically asserted for inclusion in written form other than printing and be specifically

accepted by seller as a change in these terms and conditions by express reference in writing. The applicabil-

ity of this paragraph is an express condition to any contract being formed between us.

13. Catalog product presentations including catalog dimensions, designs and specifications are representative

of product availability at time of publication only. Actual geometry dimensions and designs are subject to

designs and manufacturing changes without notice.

14. Material quoted as being available from stock is normally available for immediate shipment but subject to

prior sale.

15. The above and foregoing terms and conditions are the final expressions of the terms and conditions of the

contract which may be or is formed between us and they are intended also as a complete and exhaustive

statement of the terms and conditions of such agreement.

16. All published prices are/or may be subject to a surcharge to customers, who, by reason of current or prior

trade or business practices or course of dealings with FVC have increased or may increase marketing or

distribution costs.

FVC Terms and Warranty

Das könnte Ihnen auch gefallen

- Balaji S - Static Equipment Design - 7 Years - Resume - NEWDokument5 SeitenBalaji S - Static Equipment Design - 7 Years - Resume - NEWkanchanabalajiNoch keine Bewertungen

- Nozzle LoadDokument8 SeitenNozzle LoadDam VoNoch keine Bewertungen

- Tanky 53 KL Rev.1Dokument187 SeitenTanky 53 KL Rev.1Priyo Jati WahyonoNoch keine Bewertungen

- TQ - Air Fin Cooler (CS) - ModificationDokument6 SeitenTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNoch keine Bewertungen

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDokument5 SeitenASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNoch keine Bewertungen

- LWN FlangesDokument8 SeitenLWN Flangesfranckx1960Noch keine Bewertungen

- SP-2069 Specification For Pressure VesselsDokument68 SeitenSP-2069 Specification For Pressure Vesselsarjunprasannan7Noch keine Bewertungen

- Pump Material SpecificationDokument6 SeitenPump Material SpecificationshripaddixitNoch keine Bewertungen

- Astm F436.04 PDFDokument6 SeitenAstm F436.04 PDFWelington Volpatto MoraisNoch keine Bewertungen

- PV Elite BrocDokument6 SeitenPV Elite BrocprasadgssNoch keine Bewertungen

- Calgary 2011 Nozzle Loads PresentationDokument10 SeitenCalgary 2011 Nozzle Loads PresentationpexyNoch keine Bewertungen

- Design and Analysis of Spherical Pressure Vessel UsingDokument14 SeitenDesign and Analysis of Spherical Pressure Vessel UsingADitya JenaNoch keine Bewertungen

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFDokument13 SeitenComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFruponline1Noch keine Bewertungen

- Basket StrainersDokument19 SeitenBasket StrainersDiana CalderónNoch keine Bewertungen

- Load Case Explanation in PV EliteDokument2 SeitenLoad Case Explanation in PV ElitekuselanmlNoch keine Bewertungen

- BP GS162-1 Valves PDFDokument24 SeitenBP GS162-1 Valves PDFMohd Khairul100% (1)

- Mechanical EquipmentDokument3 SeitenMechanical EquipmentRameshBMNoch keine Bewertungen

- L&T Aquaseal Butterfly Check Valves PDFDokument28 SeitenL&T Aquaseal Butterfly Check Valves PDFSanjay SahulNoch keine Bewertungen

- WRC 107 WRC 297 Co MP PDFDokument11 SeitenWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

- Questions Flange Breaking ContainmentDokument2 SeitenQuestions Flange Breaking ContainmentMicky PlumbNoch keine Bewertungen

- Checklist For Stress Analysis: PEC-EN-FRM-Y-08927Dokument1 SeiteChecklist For Stress Analysis: PEC-EN-FRM-Y-08927Yusri FakhrizalNoch keine Bewertungen

- Data Teknis WILO 100lps @40mDokument4 SeitenData Teknis WILO 100lps @40mAnonymous dr93RjfPEY100% (1)

- Control Flownex SimulinkDokument8 SeitenControl Flownex SimulinkSrashmiNoch keine Bewertungen

- A 1 KDokument5 SeitenA 1 KSumantrra ChattopadhyayNoch keine Bewertungen

- IR HL Heatless DryerDokument1 SeiteIR HL Heatless DryerYing Kei ChanNoch keine Bewertungen

- Jacketed PipingDokument4 SeitenJacketed Pipingbinukumar100Noch keine Bewertungen

- BP Variable Catalog 09VDokument52 SeitenBP Variable Catalog 09VPetros IosifidisNoch keine Bewertungen

- 4139M06017 Default 000Dokument1 Seite4139M06017 Default 000gopi krishnaNoch keine Bewertungen

- Wall Thickness Calculations - Using B31.4 Code: T P D S FDokument1 SeiteWall Thickness Calculations - Using B31.4 Code: T P D S FRamalingam PrabhakaranNoch keine Bewertungen

- What Is Design Interpretation?Dokument17 SeitenWhat Is Design Interpretation?Qaisir MehmoodNoch keine Bewertungen

- Comparison ASME KTADokument7 SeitenComparison ASME KTAAndres_Pastor1987Noch keine Bewertungen

- ProcessBuildingVentilationSystemDesignDescription - CM A ME 001 R6 PDFDokument37 SeitenProcessBuildingVentilationSystemDesignDescription - CM A ME 001 R6 PDFShaimaa SaadNoch keine Bewertungen

- Mechanical HVAC Design & DraftingDokument2 SeitenMechanical HVAC Design & DraftingSuvidya Institute of TechnologyNoch keine Bewertungen

- Pressure Vessel RT TestDokument3 SeitenPressure Vessel RT TestAriq FauzanNoch keine Bewertungen

- WI06-0260 Calculations For Obround Nozzle ConnectionsDokument4 SeitenWI06-0260 Calculations For Obround Nozzle ConnectionskumarNoch keine Bewertungen

- Cast - Basket Strainers - 2nd EditionDokument27 SeitenCast - Basket Strainers - 2nd EditionmartinnovelNoch keine Bewertungen

- Flange Leakage Check: Equivalent Pressure / Kellogg MethodDokument3 SeitenFlange Leakage Check: Equivalent Pressure / Kellogg Methodtom hNoch keine Bewertungen

- ASME UM Audit Preparation ListDokument2 SeitenASME UM Audit Preparation ListMd Anamul Hoque100% (1)

- Stiffening Rings EvaluationDokument4 SeitenStiffening Rings EvaluationHomer SilvaNoch keine Bewertungen

- Thermowell Calculation Guide V1.3Dokument19 SeitenThermowell Calculation Guide V1.3AymanelorbanyNoch keine Bewertungen

- ASME Standards Technology, LLC: New PublicationsDokument5 SeitenASME Standards Technology, LLC: New PublicationsTrushar ParmarNoch keine Bewertungen

- BS 5500 Appendix K and DDokument14 SeitenBS 5500 Appendix K and DCRISTIAN SILVIU IANUCNoch keine Bewertungen

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDokument1 SeiteTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1Noch keine Bewertungen

- Conversion ASME Unit ConversionDokument3 SeitenConversion ASME Unit ConversionMohdBadruddinKarimNoch keine Bewertungen

- Tube Expander-Tools PDFDokument120 SeitenTube Expander-Tools PDFmarceilinus devaluantoNoch keine Bewertungen

- How To Use Code Case in PV EliteDokument2 SeitenHow To Use Code Case in PV EliteMukeshChopraNoch keine Bewertungen

- Code Case 2695 in PV Elite - How To Use It PDFDokument2 SeitenCode Case 2695 in PV Elite - How To Use It PDFMukeshChopra100% (1)

- T12026 SACM 0002 N 0 - ProposalDokument81 SeitenT12026 SACM 0002 N 0 - ProposalSubrata DasNoch keine Bewertungen

- Norsok Pipe Details PDFDokument41 SeitenNorsok Pipe Details PDFAli BariNoch keine Bewertungen

- Easyheat s27 - 02 SarcoDokument8 SeitenEasyheat s27 - 02 SarcoMarcelo ResckNoch keine Bewertungen

- PED 2014-68-EU Guidelines EN v4Dokument235 SeitenPED 2014-68-EU Guidelines EN v4Nav TalukdarNoch keine Bewertungen

- PV EliteDokument6 SeitenPV ElitevikrantgulhaneNoch keine Bewertungen

- FVC Catalog - UnlockedDokument80 SeitenFVC Catalog - UnlockedhumbubbleNoch keine Bewertungen

- FVC CatalogueDokument80 SeitenFVC CatalogueAnonymous qUMJ27ITQsNoch keine Bewertungen

- FVC Catalogue Forgings NozzleDokument80 SeitenFVC Catalogue Forgings NozzleChristian ApfelmannNoch keine Bewertungen

- Catalog FVCDokument36 SeitenCatalog FVCSebastian Xavier MaidanaNoch keine Bewertungen

- Catalog LWNDokument36 SeitenCatalog LWNPralhadNoch keine Bewertungen

- Flange FVC DataDokument36 SeitenFlange FVC DataachillesntroyNoch keine Bewertungen

- Ameriforge Group Catalogue 030199 - 4Dokument0 SeitenAmeriforge Group Catalogue 030199 - 4Ismael ZavalaNoch keine Bewertungen

- Hartford Stadium Collapse: Why Software Should Never Be More Than A Tool To Be Used WiselyDokument3 SeitenHartford Stadium Collapse: Why Software Should Never Be More Than A Tool To Be Used WiselynevinkoshyNoch keine Bewertungen

- Insert Plates Splice Bolt CalculationDokument1 SeiteInsert Plates Splice Bolt Calculationsmileya_vpNoch keine Bewertungen

- Job Title: Client: EngineerDokument1 SeiteJob Title: Client: Engineersmileya_vpNoch keine Bewertungen

- TRUSS PROFILE AND LEVELS-ModelDokument1 SeiteTRUSS PROFILE AND LEVELS-Modelsmileya_vpNoch keine Bewertungen

- 302 - Nozzle Design Tool Ver E4.01Dokument2 Seiten302 - Nozzle Design Tool Ver E4.01Honey TiwariNoch keine Bewertungen

- Nozzle Lenght CalculationDokument2 SeitenNozzle Lenght Calculationsmileya_vpNoch keine Bewertungen

- Welding Inspection CSWIP GudDokument637 SeitenWelding Inspection CSWIP GudAbdul Muneer A75% (4)

- M24316-HS01 - Experion HS R51XDokument3 SeitenM24316-HS01 - Experion HS R51XwagnerpNoch keine Bewertungen

- Satellogic Albania Government Master Servicdes AgreementDokument33 SeitenSatellogic Albania Government Master Servicdes AgreementTettsNoch keine Bewertungen

- Public Services (Management) Act 1995 (Consolidated To No 24 PDFDokument33 SeitenPublic Services (Management) Act 1995 (Consolidated To No 24 PDFdesmond100% (1)

- Amrit Banaspati CoDokument13 SeitenAmrit Banaspati Cotanishkasingh.ballbNoch keine Bewertungen

- Reliance General Insurance Company Limited: "A" Policy For Act Liability Insurance (Two Wheeler) - Policy ScheduleDokument5 SeitenReliance General Insurance Company Limited: "A" Policy For Act Liability Insurance (Two Wheeler) - Policy Schedulenabaghan dashNoch keine Bewertungen

- G.R. No. 134685Dokument2 SeitenG.R. No. 134685sherwincincoNoch keine Bewertungen

- Bates V Post Office Elaine Ridge Witness StatementDokument5 SeitenBates V Post Office Elaine Ridge Witness StatementNick WallisNoch keine Bewertungen

- Alcantara Vs AlcantaraDokument2 SeitenAlcantara Vs Alcantarakarl doceoNoch keine Bewertungen

- Contract Law 2 0 Smart Contracts As The Beginning of The End of Classic Contract LawDokument20 SeitenContract Law 2 0 Smart Contracts As The Beginning of The End of Classic Contract LawDaniel WongNoch keine Bewertungen

- Pacific Merchndising Corp., Consolacion Insurance & Surety Co., 73 SCRA 564Dokument3 SeitenPacific Merchndising Corp., Consolacion Insurance & Surety Co., 73 SCRA 564Dara CompuestoNoch keine Bewertungen

- UntitledDokument24 SeitenUntitledFlorz GelarzNoch keine Bewertungen

- BSC6900 UMTS V900R021C10 Performance Counter ListDokument517 SeitenBSC6900 UMTS V900R021C10 Performance Counter ListAhmedMa'moonNoch keine Bewertungen

- Help Them Help You: TritonDokument12 SeitenHelp Them Help You: TritonReview Editor In ChiefNoch keine Bewertungen

- Company Law Notes-LLB III Semester - Companies Act 1956Dokument44 SeitenCompany Law Notes-LLB III Semester - Companies Act 1956Aajit Dhiyya100% (1)

- IFRS 16 2022 ExamplesDokument15 SeitenIFRS 16 2022 ExamplesSergiu BoldurescuNoch keine Bewertungen

- MAN D2840 LE301 Operating InstructionDokument94 SeitenMAN D2840 LE301 Operating Instructionabdul muslim93% (15)

- Universal v. ResourcesDokument2 SeitenUniversal v. ResourcesKalliah Cassandra CruzNoch keine Bewertungen

- Morigo y Cacho Vs People 422 SCRA 376Dokument7 SeitenMorigo y Cacho Vs People 422 SCRA 376Myco MemoNoch keine Bewertungen

- Contracts ExerciseDokument3 SeitenContracts ExerciseSofia LucasNoch keine Bewertungen

- Best Practices Procurement Law - Consolidated Handout VersionDokument234 SeitenBest Practices Procurement Law - Consolidated Handout Versionkulafu 12Noch keine Bewertungen

- Metropolitan Bank and Trust Co vs. Pascual, 547 SCRA 246Dokument5 SeitenMetropolitan Bank and Trust Co vs. Pascual, 547 SCRA 246FranzMordenoNoch keine Bewertungen

- Economics, A Science or An Art?: Relationship To Law and Economics and ApproachesDokument3 SeitenEconomics, A Science or An Art?: Relationship To Law and Economics and ApproachesOnindya MitraNoch keine Bewertungen

- Ministerial Decision: Minister's Office 1/ Outbound Ref. 179196 Date: 24/09/1442 H Encl.: 1 RegulationDokument12 SeitenMinisterial Decision: Minister's Office 1/ Outbound Ref. 179196 Date: 24/09/1442 H Encl.: 1 Regulation贾文博Noch keine Bewertungen

- Tan V Valdehueza, 160 Phil 760, 767Dokument5 SeitenTan V Valdehueza, 160 Phil 760, 767Ann MarinNoch keine Bewertungen

- Henthorn V Fraser (1892) - 2-Ch.-27Dokument11 SeitenHenthorn V Fraser (1892) - 2-Ch.-27nabila14Noch keine Bewertungen

- Faculty of Law, MSU, Vadodara - PetitionerDokument15 SeitenFaculty of Law, MSU, Vadodara - PetitionerHafija Shekh100% (3)

- Extensions of Time ClaimsDokument21 SeitenExtensions of Time ClaimsFrankie FanNoch keine Bewertungen

- SMI 101 JanFeb 2023 PDFDokument108 SeitenSMI 101 JanFeb 2023 PDFHarman SandhuNoch keine Bewertungen

- Essentials of Business Law - Test Review Chapter 6-12 Key TermsDokument6 SeitenEssentials of Business Law - Test Review Chapter 6-12 Key TermsbrendaNoch keine Bewertungen

- Specpro Digest 2Dokument5 SeitenSpecpro Digest 2Jason AmpongNoch keine Bewertungen