Beruflich Dokumente

Kultur Dokumente

11

Hochgeladen von

vishiwizardOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

11

Hochgeladen von

vishiwizardCopyright:

Verfügbare Formate

General Settings Specifications Supply type Supply voltage Synchronous speed Rated slip Global Outer diameter Air

gap thickness Stack length Description Protected dimension method Rotor Rotor type Number of bars Stator Stator type Number of phases Number of poles Number of slots Number of slots per pole Mechanical Losses Friction loss Windage loss Stray loss factor Rotor (Flat back bars with parallel teeth) General Skew Skew angle Protected dimensions Bars Bar area Bar back width Bar bridge angle Bar depth Bar inset Bar spacing Bridges Bridge depth Bridge gap width Core

Bifurcation radius Core thickness Diameters Inner diameter Outer diameter Fillets Bar radius Bridge radius A Bridge radius B Rotor End Ring End Effects End effects input method End ring inner diameter End ring outer diameter End ring thickness Overhang distance End ring inductance End ring resistance Overhang inductance Overhang resistance Stator (Round) General Skew Skew angle Protected dimensions Diameters Back iron depth Inner diameter Outer diameter Teeth Bifurcation radius Shank length Slot area Slot depth Tooth edge inset Tooth gap angle Tooth gap width Tooth tang angle Tooth tang depth Tooth width Fillets Bottom shaft radius

Tooth tang radius Stator Windings Drive Connection type Number of parallel paths Diode voltage drop Switch voltage drop Sampling frequency Switching frequency Coil Cross Section Coil placement method Slot liner thickness Coil separator thickness Slot wedge thickness Wire Wire size method Fill factor Layout Layout method Winding type Number of coils per set Coil span Number of layers Phase offsets Automatic layout Number of turns Manual Layout Phase B offset Phase C offset Number of phase A coils Number of phase B coils Number of phase C coils

Layout of phase A

Layout of phase B

Layout of phase C

Stator End Windings End Effects End winding gap Inner inset End winding outer diameter End winding axial extent End winding fill factor

End turn length End winding resistance End winding inductance Materials Rotor Materials Rotor back iron material Rotor tooth material Rotor bar material End ring material Rotor stacking factor Rotor iron loss adjustment factor Stator Materials Stator back iron material Stator tooth material Stator coil material Stator slot liner material Stator stacking factor Stator iron loss adjustment factor Shaft & Hub Materials Shaft material Hub material Include shaft & hub in magnetic analysis Thermal Settings General Ambient temperature Steady-state temperature mode Housing Housing Housing thickness Left endregion width Right endregion width End Plates Left end plate thickness Right end plate thickness Flanges Left flange thickness Left flange diameter Right flange thickness Right flange diameter Shaft & Bearing Shaft diameter Left shaft extension

Right shaft extension Left bearing thickness Right bearing thickness Left bearing width Right bearing width Interface Gaps Interface Gap Thicknesses Rotor - bar gap thickness Rotor - endring gap thickness Rotor - hub gap thickness Stator - housing gap thickness Housing - left end plate gap thickness Housing - right end plate gap thickness Left flange - left end plate gap thickness Right flange - right end plate gap thickness Left bearing effective gap thickness Right bearing effective gap thickness Cooling General Motor orientation Cooling method Coolant temperature Left face temperature Right face temperature Duct coolant inlet temperature Spray Cooling Parameters Spray cooling type Emissivities Housing emissivity Left face emissivity Right face emissivity Left endregion emissivity Right endregion emissivity Convection Adjustment Factors Housing convection adjustment factor Air gap convection adjustment factor Left face convection adjustment factor Right face convection adjustment factor Left endregion convection adjustment factor Right endregion convection adjustment factor Left bearing convection adjustment factor Right bearing convection adjustment factor

Thermal Materials Coolant Materials Surrounding material Rotor Materials Rotor core filler material Stator Materials Stator core filler material Stator coil filler material Housing Materials Housing material Left end plate material Right end plate material Left bearing material Right bearing material Left flange material Right flange material Air Gap Materials Air gap material Interface Gap Materials Rotor - bar gap material Rotor - endring gap material Rotor - hub gap material Stator - housing gap material Housing - left end plate gap material Housing - right end plate gap material Left flange - left end plate gap material Right flange - right end plate gap material

Induction Motor

Voltage driven 72 2200 3 V rpm

180 0.5 170

mm mm mm

Automatic

Flat back bars with parallel teeth 40

Round 3 4 36 9

0 0 0

kW kW

1 10 Bar back width, Bar bridge angle, Bar spacing, Bridge depth, Bridge gap width, Inner diameter

59.7 1.5 30 20.5 0 2.9

mm mm mm mm mm

0.5 1

mm mm

0 14

mm mm

28 97

mm mm

0.5 1.48 0

mm mm mm

Automatic 58 90 10 0 0.0000145 0.000000739 0 0 mm mm mm mm mH mH

0 0 Back iron depth, Tooth gap width, Tooth tang angle, Tooth tang depth, Tooth width

11 98 180

mm mm mm

0 28.3 228 30 0 2.34 2 4.95 1.5 2.8

mm mm mm mm mm mm mm mm

mm

mm

Delta (Mesh) 2 0.6 0.2 V V

6000

Hz

Over-under 0.15 0.2 0.32 mm mm mm

Fill factor 45

Automatic Lap 2 9 2 6 94% (1 2 -9 19 20 -27) 6

6 6 12 12 12

Coil # | Go | Return | # of Turns1

| 1

| 10

| 62

| 2

| 11

| 63

| 2

| 11

| 64

| 3

| 12

Coil # | Go | Return | # of Turns1

| 7

| 16

| 62

| 8

| 17

| 63

| 8

| 17

| 64

| 9

| 18

Coil # | Go | Return | # of Turns1

| 13 | 22

| 62

| 14 | 23

| 63

| 14 | 23

| 64

| 15 | 24

0 0 158 53 47.7

mm mm mm mm

145 0.0126 0.0182

mm mH

M-36 26 Ga M-36 26 Ga Copper: 98% IACS Copper: 98% IACS 0.95 0.91

M-36 26 Ga M-36 26 Ga Copper: 98% IACS Epoxy resin 1 1

CR10: Cold rolled 1010 steel Non-magnetic No

65 Automatically calculated

5 5 5

mm mm mm

5 5

mm mm

5 120 5 120

mm mm mm mm

8 0

mm mm

20 8 8 8 8

mm mm mm mm mm

0 0 0.037 0.037 0 0 0 0 1 1

mm mm mm mm mm mm mm mm mm mm

Horizontal Totally Enclosed Non-Ventilated (TENV)

None

0.85 0.85 0.85 0.85 0.85

1 1 1 1 1 1 1 1

AIR

Epoxy resin

Epoxy resin Epoxy resin

CR10: Cold rolled 1010 steel CR10: Cold rolled 1010 steel CR10: Cold rolled 1010 steel CR10: Cold rolled 1010 steel CR10: Cold rolled 1010 steel CR10: Cold rolled 1010 steel CR10: Cold rolled 1010 steel

AIR

Virtual Air Virtual Air Virtual Air Virtual Air Virtual Air Virtual Air Virtual Air Virtual Air

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hardware Inloop Simulation IEEE LabVIEWDokument1 SeiteHardware Inloop Simulation IEEE LabVIEWvishiwizardNoch keine Bewertungen

- Op - XT546 246 346 - Op288 V03Dokument2 SeitenOp - XT546 246 346 - Op288 V03vishiwizardNoch keine Bewertungen

- ACM2 TAU Datasheet enDokument5 SeitenACM2 TAU Datasheet envishiwizardNoch keine Bewertungen

- Part Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisDokument6 SeitenPart Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisIjabiNoch keine Bewertungen

- Maxwell 2dDokument7 SeitenMaxwell 2dvishiwizardNoch keine Bewertungen

- Engineered PlasticsDokument61 SeitenEngineered Plastics고병석Noch keine Bewertungen

- LJLVJK LVJJV LKJVDokument5 SeitenLJLVJK LVJJV LKJVvishiwizardNoch keine Bewertungen

- 50 SCS Automotive Coatings - Rev0913Dokument4 Seiten50 SCS Automotive Coatings - Rev0913vishiwizardNoch keine Bewertungen

- Electric Vehicle Motor Design NotesDokument131 SeitenElectric Vehicle Motor Design NotesvishiwizardNoch keine Bewertungen

- TRL Definitions PDFDokument1 SeiteTRL Definitions PDFBHARadwajNoch keine Bewertungen

- ReadmeDokument4 SeitenReadmevishiwizardNoch keine Bewertungen

- FAB Resistivity White PaperDokument8 SeitenFAB Resistivity White PapervishiwizardNoch keine Bewertungen

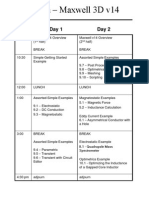

- Maxwell 3D v14 Training AgendaDokument1 SeiteMaxwell 3D v14 Training AgendavishiwizardNoch keine Bewertungen

- 5 SmanualDokument16 Seiten5 SmanualMark ThomasNoch keine Bewertungen

- Recent Advances in Materials For Use in Permanent Magnet Machines - A ReviewDokument7 SeitenRecent Advances in Materials For Use in Permanent Magnet Machines - A ReviewvishiwizardNoch keine Bewertungen

- Jeas 1012 787Dokument5 SeitenJeas 1012 787vishiwizardNoch keine Bewertungen

- Electrical Resin BenefitsDokument2 SeitenElectrical Resin BenefitsvishiwizardNoch keine Bewertungen

- Nit 3600 1Dokument5 SeitenNit 3600 1vishiwizardNoch keine Bewertungen

- Lit Survey RamamurthyDokument9 SeitenLit Survey RamamurthyvishiwizardNoch keine Bewertungen

- Wittich2011 SonkusaleVanderveldeDokument1 SeiteWittich2011 SonkusaleVanderveldevishiwizardNoch keine Bewertungen

- Presentation 1Dokument1 SeitePresentation 1vishiwizardNoch keine Bewertungen

- Big Energy Series 11.5.2012 Qing-Chang ZhongDokument1 SeiteBig Energy Series 11.5.2012 Qing-Chang ZhongvishiwizardNoch keine Bewertungen

- Brushless Motor FundamentalsDokument13 SeitenBrushless Motor FundamentalsvishiwizardNoch keine Bewertungen

- Sensors Used in HEVDokument4 SeitenSensors Used in HEVvishiwizard100% (1)

- How to Check a MOSFETDokument2 SeitenHow to Check a MOSFETvishiwizardNoch keine Bewertungen

- FTF Aut f0234Dokument38 SeitenFTF Aut f0234vishiwizardNoch keine Bewertungen

- Cam DesignDokument13 SeitenCam DesignvishiwizardNoch keine Bewertungen

- A Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesDokument1 SeiteA Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesvishiwizardNoch keine Bewertungen

- Motor Primer1Dokument2 SeitenMotor Primer1vishiwizardNoch keine Bewertungen

- Sona SPEED CatalogueDokument13 SeitenSona SPEED CataloguevishiwizardNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ac Machines ModuleDokument42 SeitenAc Machines ModuleFranzon MelecioNoch keine Bewertungen

- Tamturbo Brochure 210x280 ENG 2019 12-31 PDFDokument16 SeitenTamturbo Brochure 210x280 ENG 2019 12-31 PDFSergio R. BahenaNoch keine Bewertungen

- Magnet Skew in Cogging Torque Minimization of Axial Gap Permanent Magnet MotorsDokument6 SeitenMagnet Skew in Cogging Torque Minimization of Axial Gap Permanent Magnet MotorsaugustoNoch keine Bewertungen

- Stamford Ucdi274kDokument7 SeitenStamford Ucdi274kSilver SilverNoch keine Bewertungen

- Jang, Cho, Choi - 2007 - Design and Analysis of A High-Speed Brushless DC Motor For Centrifugal CompressorDokument3 SeitenJang, Cho, Choi - 2007 - Design and Analysis of A High-Speed Brushless DC Motor For Centrifugal CompressormitulNoch keine Bewertungen

- Ac Motor Coupled With DC GeneratorDokument1 SeiteAc Motor Coupled With DC GeneratorVirender RanaNoch keine Bewertungen

- The Key Reactances of Synchronous MachinesDokument22 SeitenThe Key Reactances of Synchronous MachinesAnonymous UZ5xA8Noch keine Bewertungen

- KenSaveth Failure AnalysisDokument28 SeitenKenSaveth Failure AnalysisAnyone KnowingNoch keine Bewertungen

- Saturn DriveDokument21 SeitenSaturn DrivefreddyjoertyNoch keine Bewertungen

- Curva de Capacidade PDFDokument6 SeitenCurva de Capacidade PDFAnonymous sXjtR7PanNoch keine Bewertungen

- Chapter 3Dokument26 SeitenChapter 3Rodel Martin ConsueloNoch keine Bewertungen

- Nidec CPLS MotorsDokument68 SeitenNidec CPLS MotorsTraian SerbanNoch keine Bewertungen

- Design and Optimization of Outer-Rotor Permanent Magnet Fluxswitching Motor Using Transverse Segmental Rotor Shapefor Automotive ApplicationsDokument10 SeitenDesign and Optimization of Outer-Rotor Permanent Magnet Fluxswitching Motor Using Transverse Segmental Rotor Shapefor Automotive ApplicationsGeorge LazarNoch keine Bewertungen

- BA Spring-Operated Brake BFK458 v1!0!0199 enDokument48 SeitenBA Spring-Operated Brake BFK458 v1!0!0199 enGuillermo Osvaldo Rivera MelladoNoch keine Bewertungen

- ECCE.2009.Impact of The Supply Voltage On The Stray Load Losses in Induction MotorsDokument6 SeitenECCE.2009.Impact of The Supply Voltage On The Stray Load Losses in Induction MotorsBorislav BrnjadaNoch keine Bewertungen

- Nanoenergyadv 02 00013 v2Dokument24 SeitenNanoenergyadv 02 00013 v2Muhamad Praja DewanataNoch keine Bewertungen

- Nippon Pulse 2011 CatalogDokument98 SeitenNippon Pulse 2011 CatalogElectromateNoch keine Bewertungen

- ST SERIES Single-Phase AC Synchronous GeneratorDokument8 SeitenST SERIES Single-Phase AC Synchronous Generatorlonski2k100% (1)

- Elec 4 Synchronous Genrators PPT 2Dokument37 SeitenElec 4 Synchronous Genrators PPT 2Jamir CalNoch keine Bewertungen

- Cip0340 CHECKING VVT SENSOR PDFDokument5 SeitenCip0340 CHECKING VVT SENSOR PDFDoDuyBacNoch keine Bewertungen

- Questions On Efficiency and RegulationDokument29 SeitenQuestions On Efficiency and Regulationkibrom atsbhaNoch keine Bewertungen

- Kannur University BTech EE VIII Sem SyllabusDokument14 SeitenKannur University BTech EE VIII Sem SyllabusManu K M100% (1)

- Paper Review 1234Dokument18 SeitenPaper Review 1234Gedef YirgalemNoch keine Bewertungen

- 3 ExperimentsDokument100 Seiten3 ExperimentsSaravanan T YNoch keine Bewertungen

- Problem 2.9 The Source MMF in The Magnetic Structure of Fig. 2.46 Is Fixed at 200 At. The TwoDokument8 SeitenProblem 2.9 The Source MMF in The Magnetic Structure of Fig. 2.46 Is Fixed at 200 At. The TwoDiego BustosNoch keine Bewertungen

- Whitepaper Slot Fill WindingsDokument7 SeitenWhitepaper Slot Fill WindingsSnowdenKonanNoch keine Bewertungen

- Current Signature AnalysisDokument7 SeitenCurrent Signature Analysisliepan_bara75% (4)

- Vibration Monitoring For Fault Motors Diagnosis PDFDokument8 SeitenVibration Monitoring For Fault Motors Diagnosis PDFuuur35100% (1)

- Thesis Design and Implementation of A Three Phase Induction Motor Control Scheme PDFDokument93 SeitenThesis Design and Implementation of A Three Phase Induction Motor Control Scheme PDFCHRISTIANNoch keine Bewertungen