Beruflich Dokumente

Kultur Dokumente

™ Aircraft - Engineer: Wooden Blades For V.P. Airscrews

Hochgeladen von

seafire47Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

™ Aircraft - Engineer: Wooden Blades For V.P. Airscrews

Hochgeladen von

seafire47Copyright:

Verfügbare Formate

February 24, 1938

Supplement to

AIRCRAFT ENGINEER

No. 145. XVI\

ENGINEERING SECTION

February 24, 1938

WOODEN BLADES FOR V.P. AIRSCREWS

Interesting Developments Now Taking Place May Have Far-reaching Effects

(Illustrated by " Flight " photographs) OR a great number of years the wooden airscrew held protective coverings which would withstand the effects of rain and hail, not to mention prolonged operation in humid undisputed sway. During the pioneer days of flying atmospheres, frequent spraying by sea-water, such as is wood was the ideal material for airscrews as well as associated with seaplane work, and so forth. One method for aeroplanes, its low cost and the ease with which in particular was evolved in Germany by the Schwarz it could be shaped making it particularly attractive for firm of Berlin. The British rights in this method were experimental work and for construction in small quantities. secured by the Airscrew Co., Ltd., of Weybridge, and In those days flying was done in fine weather only, and fixed-pitch wooden airscrews finished by the Schwarz prothus it did not matter that wooden airscrews were apt to ,cess are now used very extensively in the machines of the suffer severely from the effects of flying in rain or hail. Royal Air Force as well as in British civil aircraft. The As the art of flying developed, aircraft ventured out in process is well known, and consists in covering the wooden less favourable weather conditions, and the wooden airscrew blades with a layer of nitrocellulose, the material being was apt to suffer damage. Also, it was realised that its applied in sheet form and forced into the pores of the wood relatively thick blade sections were not quite as efficient under air pressure in autoclaves. as would be blades of thinner section, such as could be It was inevitable that when the variable-pitch airscrew manufactured of metal. Successful metal airscrews were introduced and gave excellent results in service. The wooden airscrew, in spite of fabric covering and/or varnished surfaces, could not compete from the point of view of durability, and its popularity began to wane. The next stage came when the speed range of aircraft had increased to such an extent that airscrews with controllable pitch were necessary if a good take-off were to be combined with high efficiency at operational speed. In view of the good service given by the fixed-pitch metal airscrew, it was natural that when the variable-pitch airscrew came to be developed it should have metal blades. Of variable-pitch airscrews with metal blades there are now several types in use and giving good service. In the meantime, the champions of the wooden airscrew had not been idle, and they had succeeded in discovering

The first stage. Impregnating a sheet of wood with synthetic resin.

Six blocks of wood being compressed under heat in the hydraulic press. Actually eight blocks can be compressed at a time.

Das könnte Ihnen auch gefallen

- Chris Damito - Rough Living - An Urban Survival GuideDokument175 SeitenChris Damito - Rough Living - An Urban Survival Guidesui pacha67% (3)

- Aircraft Structural ComponentsDokument32 SeitenAircraft Structural ComponentsLivil LyleNoch keine Bewertungen

- Koff Gas Turbine Technology Evolution A Designers PerspectiveDokument15 SeitenKoff Gas Turbine Technology Evolution A Designers PerspectiveTarun ChoudharyNoch keine Bewertungen

- Report No. 1 - PROPELLER CONSTRUCTIONDokument10 SeitenReport No. 1 - PROPELLER CONSTRUCTIONRev Xavier CruzNoch keine Bewertungen

- Selecting A Homebuilt Design 03Dokument4 SeitenSelecting A Homebuilt Design 03YvessNoch keine Bewertungen

- The Aircraft Engineer 1928Dokument130 SeitenThe Aircraft Engineer 1928Mark Evan SalutinNoch keine Bewertungen

- Developments of Morden Timber Structures - Timber in ConstructionDokument22 SeitenDevelopments of Morden Timber Structures - Timber in ConstructionPapa ConfiNoch keine Bewertungen

- Boeing 777 MaterialsDokument4 SeitenBoeing 777 MaterialsSaravanan AtthiappanNoch keine Bewertungen

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsVon EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsBewertung: 5 von 5 Sternen5/5 (1)

- Aluminium in ShipbuildingDokument11 SeitenAluminium in ShipbuildingHellery FilhoNoch keine Bewertungen

- Sailing Yacht DesignDokument61 SeitenSailing Yacht DesignMichal Sobczak100% (1)

- Composite Material 1 2Dokument1 SeiteComposite Material 1 2Sudhakar KarnanNoch keine Bewertungen

- 100 Years of SailplanesDokument24 Seiten100 Years of SailplanesEric RaymondNoch keine Bewertungen

- Composites REVOLUTIONISE AEDokument3 SeitenComposites REVOLUTIONISE AEmachit_xNoch keine Bewertungen

- Mechanicl EngineeringDokument981 SeitenMechanicl EngineeringBobby WaltersNoch keine Bewertungen

- SB2U VindicatorDokument11 SeitenSB2U Vindicatorseafire47100% (1)

- Bulkheads FinalDokument15 SeitenBulkheads Finalvikram5211Noch keine Bewertungen

- High-Speed Steel - The Development, Nature, Treatment, and use of High-Speed Steels, Together with Some Suggestions as to the Problems Involved in their UseVon EverandHigh-Speed Steel - The Development, Nature, Treatment, and use of High-Speed Steels, Together with Some Suggestions as to the Problems Involved in their UseNoch keine Bewertungen

- Scottish RotorDokument8 SeitenScottish Rotoraravisara5100% (1)

- 2016 KS1 English Reading Paper 1 Reading Prompt and Answer Booklet PDFADokument20 Seiten2016 KS1 English Reading Paper 1 Reading Prompt and Answer Booklet PDFABernard Chan100% (1)

- SandwichDokument23 SeitenSandwichGuillermo Angarita100% (1)

- History of Submarine CompositesDokument16 SeitenHistory of Submarine CompositesYakob Kher AldenNoch keine Bewertungen

- Global Food Waste Management Full Report PDFDokument145 SeitenGlobal Food Waste Management Full Report PDFJyothi MallyaNoch keine Bewertungen

- Pressure Vessel - WikipediaDokument11 SeitenPressure Vessel - Wikipediaramthecharm_46098467Noch keine Bewertungen

- Aerospace MaterialsDokument4 SeitenAerospace MaterialsJuan CastroNoch keine Bewertungen

- 01 - The History of Aircraft MaterialsDokument6 Seiten01 - The History of Aircraft MaterialsEsteban GuineaNoch keine Bewertungen

- I Tif: - L FillDokument1 SeiteI Tif: - L Fillseafire47Noch keine Bewertungen

- CL 404 Material Science Group 2Dokument30 SeitenCL 404 Material Science Group 2Akash PrasanthNoch keine Bewertungen

- Wood To MetalDokument5 SeitenWood To MetalSelvarajPichamuthu100% (1)

- The Aircraft Engineer: Die Head Bolster ContainerDokument1 SeiteThe Aircraft Engineer: Die Head Bolster Containerseafire47Noch keine Bewertungen

- Aluminum Alloys For AerospaceDokument2 SeitenAluminum Alloys For AerospaceNicholas Featherston100% (1)

- The Aircraft Engineer: Supplement ToDokument1 SeiteThe Aircraft Engineer: Supplement Toseafire47Noch keine Bewertungen

- Turcraft % . Engineer: Extrusion of Light AlloysDokument1 SeiteTurcraft % . Engineer: Extrusion of Light Alloysseafire47Noch keine Bewertungen

- Selection of MaterialsDokument9 SeitenSelection of MaterialsTaha KhanNoch keine Bewertungen

- Introduction To Aircraft and Structural Components - IDokument15 SeitenIntroduction To Aircraft and Structural Components - IVishal RajNoch keine Bewertungen

- Aircraft Materials HistoryDokument15 SeitenAircraft Materials Historymahaprabhu78Noch keine Bewertungen

- Material Impact Used in Aircraft Planes in Correlation To Flying PerformanceDokument12 SeitenMaterial Impact Used in Aircraft Planes in Correlation To Flying PerformanceFebwin VillaceranNoch keine Bewertungen

- Air Supported StructuresDokument12 SeitenAir Supported StructuresHalfred Hayes CatabasNoch keine Bewertungen

- The WheelDokument10 SeitenThe WheeldevoutoccamistNoch keine Bewertungen

- Bolted To The Wood. From Experience It Was Found, However,: DECEMBER 22, 1927Dokument1 SeiteBolted To The Wood. From Experience It Was Found, However,: DECEMBER 22, 1927Mark Evan SalutinNoch keine Bewertungen

- Determining The Young's Modulus REAL ISA CASE STUDY NEWDokument5 SeitenDetermining The Young's Modulus REAL ISA CASE STUDY NEWSerish HussainNoch keine Bewertungen

- The Aircraft Engineer: Saving WeightDokument1 SeiteThe Aircraft Engineer: Saving Weightseafire47Noch keine Bewertungen

- Common Aerospace Aluminum Grades: The Wright BrothersDokument9 SeitenCommon Aerospace Aluminum Grades: The Wright BrothersStephany SolísNoch keine Bewertungen

- Review Report of Blast Resistant Properties of Composite Structures in Naval Vessels.Dokument125 SeitenReview Report of Blast Resistant Properties of Composite Structures in Naval Vessels.Ali HassanNoch keine Bewertungen

- Composites and Advanced Material1Dokument2 SeitenComposites and Advanced Material1yogeshjeeterwalNoch keine Bewertungen

- Chapter 2Dokument35 SeitenChapter 2Febwin VillaceranNoch keine Bewertungen

- Foster-Miller, Inc. v. Babcock & Wilcox, 210 F.3d 1, 1st Cir. (2000)Dokument23 SeitenFoster-Miller, Inc. v. Babcock & Wilcox, 210 F.3d 1, 1st Cir. (2000)Scribd Government DocsNoch keine Bewertungen

- Aircraft Code Bolt2023r01Dokument14 SeitenAircraft Code Bolt2023r01Dinesh GanapathyNoch keine Bewertungen

- Metals Polymers Ceramics: U.S. Navy Ship New York Contains Steel From Ground ZeroDokument3 SeitenMetals Polymers Ceramics: U.S. Navy Ship New York Contains Steel From Ground ZeroAlejandroSalxixonNoch keine Bewertungen

- Chapter 1Dokument9 SeitenChapter 1Febwin VillaceranNoch keine Bewertungen

- Next Generation Thermal AirshipDokument17 SeitenNext Generation Thermal AirshipRalph BolzonaroNoch keine Bewertungen

- Piper PADokument22 SeitenPiper PAPokemon GoNoch keine Bewertungen

- The Aircraft Engineer January 30, 1931Dokument4 SeitenThe Aircraft Engineer January 30, 1931Mark Evan SalutinNoch keine Bewertungen

- Conc. Folded SlabDokument17 SeitenConc. Folded SlabBenedict CharlesNoch keine Bewertungen

- 1920 Metalsinaircraft00hanbrichDokument128 Seiten1920 Metalsinaircraft00hanbrichUlf Dunell100% (1)

- Leslie Built Like Bridges ArticleDokument29 SeitenLeslie Built Like Bridges ArticleneboNoch keine Bewertungen

- Security Barrier With Firebirck-ShamotDokument4 SeitenSecurity Barrier With Firebirck-Shamotalex dimoskiNoch keine Bewertungen

- Materials For Wind Turbine Blades - An OverviewDokument20 SeitenMaterials For Wind Turbine Blades - An OverviewDIBAL MUZANoch keine Bewertungen

- Group Two Presentation: Materials and Their Applications in Engineering: HelicopterDokument12 SeitenGroup Two Presentation: Materials and Their Applications in Engineering: HelicopterAjayi Olatunde RoCcNoch keine Bewertungen

- History of The PropellerDokument3 SeitenHistory of The PropellerMario VolpattiNoch keine Bewertungen

- Parametric Examination Including Brief Survey of Composite and Homogenous Closed Ended Cylindrical Pressure VesselsDokument26 SeitenParametric Examination Including Brief Survey of Composite and Homogenous Closed Ended Cylindrical Pressure Vesselsmirza_munir_baig995Noch keine Bewertungen

- 16 Shotcrete Support PDFDokument15 Seiten16 Shotcrete Support PDFAbdul KabasyNoch keine Bewertungen

- Bearings For Longer Shaft LifeDokument3 SeitenBearings For Longer Shaft LifeVito Digeo100% (1)

- Short S.20 Mercury SDokument3 SeitenShort S.20 Mercury Sseafire47Noch keine Bewertungen

- PH - Almond & Garlic Crusted Chicken With Cherry Tomato SaladDokument2 SeitenPH - Almond & Garlic Crusted Chicken With Cherry Tomato Saladseafire47Noch keine Bewertungen

- PH - Carolina's Chorizo Carbonara With Garden SaladDokument2 SeitenPH - Carolina's Chorizo Carbonara With Garden Saladseafire47Noch keine Bewertungen

- Gtsac : Flight Engineering SectionDokument1 SeiteGtsac : Flight Engineering Sectionseafire47100% (1)

- Shor BRQS.: of RochesterDokument1 SeiteShor BRQS.: of Rochesterseafire47Noch keine Bewertungen

- East To West Record: 13% HOURSDokument1 SeiteEast To West Record: 13% HOURSseafire47Noch keine Bewertungen

- 1938 - 2869Dokument1 Seite1938 - 2869seafire47Noch keine Bewertungen

- 1937 - 3487Dokument1 Seite1937 - 3487seafire47Noch keine Bewertungen

- 4 Worlds FairDokument5 Seiten4 Worlds Fairseafire47Noch keine Bewertungen

- "Mercury" Makes GoodDokument1 Seite"Mercury" Makes Goodseafire47Noch keine Bewertungen

- Commercial //V/At/On: Airlines AirportsDokument1 SeiteCommercial //V/At/On: Airlines Airportsseafire47Noch keine Bewertungen

- Second Parting: Short-Mayo Compo-Site Separated "In Public"Dokument1 SeiteSecond Parting: Short-Mayo Compo-Site Separated "In Public"seafire47Noch keine Bewertungen

- Flight.: Final Gliding Contest ResultsDokument1 SeiteFlight.: Final Gliding Contest Resultsseafire47Noch keine Bewertungen

- 598 Flight.: DECEMBER I 6, 1937Dokument1 Seite598 Flight.: DECEMBER I 6, 1937seafire47Noch keine Bewertungen

- 74-A-23 Se5a F938Dokument4 Seiten74-A-23 Se5a F938seafire47Noch keine Bewertungen

- 1937 - 3485Dokument1 Seite1937 - 3485seafire47Noch keine Bewertungen

- Percival Q4,6 1937 - 3486Dokument1 SeitePercival Q4,6 1937 - 3486seafire47Noch keine Bewertungen

- 8 Ross RS1 93Dokument4 Seiten8 Ross RS1 93seafire47Noch keine Bewertungen

- 203 Sample ArticleDokument8 Seiten203 Sample Articleseafire47Noch keine Bewertungen

- 7 Moundsville Lone Eagle 94Dokument9 Seiten7 Moundsville Lone Eagle 94seafire47Noch keine Bewertungen

- 95 Sample ArticleDokument5 Seiten95 Sample Articleseafire47Noch keine Bewertungen

- Wright Flyer 1903 EngineDokument3 SeitenWright Flyer 1903 Engineseafire47Noch keine Bewertungen

- Raid On Regensburg2Dokument8 SeitenRaid On Regensburg2seafire47100% (1)

- Designation OF USA AIRCRAFTDokument9 SeitenDesignation OF USA AIRCRAFTseafire47Noch keine Bewertungen

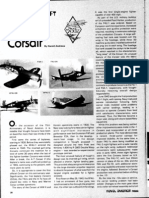

- VS-10001 GA 02 F4U-1 CorsairDokument0 SeitenVS-10001 GA 02 F4U-1 Corsairseafire47Noch keine Bewertungen

- Chance Vought F4u CorsairDokument6 SeitenChance Vought F4u Corsairseafire47100% (3)

- F4u 4Dokument8 SeitenF4u 4seafire47100% (1)

- Splash 1Dokument4 SeitenSplash 1seafire47100% (1)

- b47 v3Dokument4 Seitenb47 v3seafire47100% (1)

- Water Resources Planning in HP-1 Karnataka Surface WaterDokument48 SeitenWater Resources Planning in HP-1 Karnataka Surface WaterHydrologywebsiteNoch keine Bewertungen

- G29 Phạm Thị Sinh-Đề TA 10 theo mẫu 2025Dokument5 SeitenG29 Phạm Thị Sinh-Đề TA 10 theo mẫu 2025khanhhoi.clcNoch keine Bewertungen

- Steam TracingDokument72 SeitenSteam TracingMuzzamilNoch keine Bewertungen

- Lateral Thinking Worksheet 1Dokument3 SeitenLateral Thinking Worksheet 1vnskNoch keine Bewertungen

- English Grammar ExerciseDokument2 SeitenEnglish Grammar ExerciseCristian Rodrigo Flores MaldonadoNoch keine Bewertungen

- Sudhasindhu 6 BrihadaranyakaDokument398 SeitenSudhasindhu 6 BrihadaranyakaDr Suvarna NalapatNoch keine Bewertungen

- Ip-Xdr Verter-08 - 080610Dokument4 SeitenIp-Xdr Verter-08 - 080610flavioovalle100% (1)

- "Keep Your Chin Up," Tina Said.: Sequoia National ParkDokument5 Seiten"Keep Your Chin Up," Tina Said.: Sequoia National Parkbwhite1911Noch keine Bewertungen

- Sounding-Derived Parameters Associated With Severe Hail Events in RomaniaDokument14 SeitenSounding-Derived Parameters Associated With Severe Hail Events in RomaniaIstrate VasilicăNoch keine Bewertungen

- 7ci Sinif İngilis Dili SQ-2Dokument2 Seiten7ci Sinif İngilis Dili SQ-2hajiyeva.faridaNoch keine Bewertungen

- Ecology PacketDokument47 SeitenEcology Packetsabbate1994Noch keine Bewertungen

- 6 A.cotton, Coir, Kapok PDFDokument31 Seiten6 A.cotton, Coir, Kapok PDFanushkaNoch keine Bewertungen

- Topcon AT-B4A PDFDokument2 SeitenTopcon AT-B4A PDFKathe RpzNoch keine Bewertungen

- Semester 2013-2014Dokument12 SeitenSemester 2013-2014Rulita NianaNoch keine Bewertungen

- Single PackageDokument39 SeitenSingle PackageSilvio RomanNoch keine Bewertungen

- Articulo 1Dokument29 SeitenArticulo 1Cirene Guisell Bolaño JimenezNoch keine Bewertungen

- Future Tenses Model AnswersDokument4 SeitenFuture Tenses Model AnswersShaimaa HabibNoch keine Bewertungen

- Precipitation PresentationDokument39 SeitenPrecipitation Presentationengrmar91Noch keine Bewertungen

- SMP Mts English On Sky (K13) Chapter 10Dokument22 SeitenSMP Mts English On Sky (K13) Chapter 10PD.Lestari JayaNoch keine Bewertungen

- Q1 Reading Exercises Grade 1Dokument4 SeitenQ1 Reading Exercises Grade 1Swirly BitzNoch keine Bewertungen

- AM 4206M Dotocdogio PDFDokument2 SeitenAM 4206M Dotocdogio PDFtrungvuNoch keine Bewertungen

- 1 Ace - Get An "A" On A Test, Homework Assignment, Project, EtcDokument2 Seiten1 Ace - Get An "A" On A Test, Homework Assignment, Project, EtcLinda OmaNoch keine Bewertungen

- WIDGB1 AK Utest Skills 9Dokument1 SeiteWIDGB1 AK Utest Skills 9Анатолия РябченкоNoch keine Bewertungen

- 07 Chapter 2Dokument32 Seiten07 Chapter 2zahiraNoch keine Bewertungen

- Natural Disasters Animated Presentation Conversation Topics Dialogs Fun Activities Games o - 72285Dokument15 SeitenNatural Disasters Animated Presentation Conversation Topics Dialogs Fun Activities Games o - 72285Carlos GPNoch keine Bewertungen

- Weather Wheel Search and MatchDokument1 SeiteWeather Wheel Search and MatchDoreen Lee Ling LingNoch keine Bewertungen