Beruflich Dokumente

Kultur Dokumente

Application of FRP

Hochgeladen von

M.Saravana Kumar..M.EOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Application of FRP

Hochgeladen von

M.Saravana Kumar..M.ECopyright:

Verfügbare Formate

FIBER REINFORCED POLYMER COMPOSITES APPLICATIONS IN USA DOT - FEDERAL HIGHWAY ADMINISTRATION

Benjamin Tang, PE St !"t! a# Enginee HNG-$%, B i&ge S'e"ia#i(t G )!' *++ Se,ent- St eet, S.W. Rm. $%+$ Wa(-ingt)n, D.C. %+/0+ 1an!a 2 3, 4005

Published in the First Korea/U.S.A. Road Workshop Proceedings, January !" #, $##% Hi(t) 2 )n Fi6e Rein7) "e& P)#2me C)m')(ite( AAlthough the concept o& &iber rein&orced 'aterials can be traced back to the use o& stra( as rein&orce'ent in bricks 'anu&actured by the )srealites in !** +.,., and in 'ore recent ti'es to

the use o& short glass &iber rein&orce'ent in ce'ent in the United States in the early $#-*.s, &iber rein&orced resin 'atri/ 'aterials 0or &iber rein&orced co'posites as (e kno( the' today1 (ere not de2eloped until the early $#3*.s@ 4$5. )n this paper the ter' co'posites is used in the conte/t o& ad2anced &iber rein&orced poly'ers 0FRP=s1. A&ter World War )), US 'anu&acturers began producing &iberglass and polyester resin co'posite boat hulls and rado'es 0radar co2er1. 6he auto'oti2e industry &irst introduced co'posites into 2ehicle bodies in the early $#7*s. +ecause o& the highly desirable light (eight, corrosion resistance, and high strength characteristics in co'posites8 research e'phasis (ent into i'pro2ing the 'aterial science and 'anu&acturing process. 6hat e&&ort led to the de2elop'ent o& t(o ne( 'anu&acturing techni9ues kno(n as &ila'ent (inding and pultrusion, (hich helped ad2ance the co'posite technology into ne( 'arkets. 6here (as a great de'and by the recreation industry &or co'posite &ishing rods, tennis rackets, ski e9uip'ent and gol& clubs. 6he aerospace industry began to use co'posites in pressure 2essels, containers, and non"structural aircra&t co'ponents. 6he US :a2y applied co'posites in 'ine s(eeping 2essels, cre( boats and sub'arine parts. 6he do'estic consu'ers began installing co'posite bath tubs, co2ers, railings, ladders and electrical e9uip'ent. 6he &irst ci2il application in co'posites (as a do'e structure built in +engha;i in $#<!, and other structures &ollo(ed slo(ly. 6he ,o'posites )nstitute, that tracks the do'estic econo'y, reported the total consu'ption &igures &or $##3 and $##7 at 'ore than three billion pounds each year. =& the nine industries reported, the transportation industry clai'ed -$> o& the total 'arket, thus, being the biggest consu'er o& co'posites in both years. 6he preli'inary &igures &or $##3 (as #37.< 'illion pounds &ollo(ed by $##7 (ith #!3 'illion pounds. )t is predicted that orders &or co'posites in the transportation sector (ill e/ceed one billion pounds &or $##<. With the increasing de'and &or co'posites, ne( and i'pro2ed 'anu&acturing processes such as pultrusion, resin trans&er 'olding, and &ila'ent (inding (ere de2eloped and i'ple'ented in the early $##*s. With these enhance'ents in place, the current &ocus is to rebuild the US transportation in&rastructure using FRP co'posites &or 'aintenance and rehabilitation o& e/isting bridges as (ell as ne( construction. Ci,i# St !"t! a# A''#i"ati)n( U(ing C)m')(ite( ?any pedestrian bridge pro@ects ha2e been constructed throughout the United States using pultruded co'posite structural shapes. )n states 2ulnerable to high seis'ic acti2ity, concrete bridge colu'ns are being retro&itted (ith a co'posite &ila'ent (inding to increase ductility. Plate bonding using thin co'posite la'inates to strengthen concrete and steel bridge 'e'bers has been de'onstrated. ,o'posite prestressed piles are being applied to ci2il and 'arine structures in so'e o& the coastal states. 6he &irst US ad2anced co'posite 2ehicular bridge superstructure (as dedicated into ser2ice on Aece'ber 3, $##< in Russell, Kansas. 6he deck panels (ere shop"&abricated (ith co'posite honeyco'b cells (hich are sand(iched bet(een t(o &ace sheets. 6hese panels (ere then @oined together (ith epo/y in the &ield. Ae'onstration bridge pro@ects are being de2eloped in other states such as Aela(are, West Birginia and ,ali&ornia. ,ontinued research pro@ects using co'posite rein&orcing bars in concrete slabs are being studied in :e( Ca'pshire, Washington, A.,. and ?ichigan. ,o'posite prestressing tendons and stay cables are being de2eloped in Pennsyl2ania, ?ichigan, South Aakota and ,ali&ornia. Man!7a"t! ing P )"e((e( 6here are three basic 'anu&acturing techni9ues in producing co'posite structural products, (ith 'any 2ariations and patented processesD $1 6he pultrusion process in2ol2es a

continuous pulling o& the &iber ro2ings and 'ats through a resin bath and then into a heated die. 6he ele2ated te'perature inside the die cures the co'posite 'atri/ into a constant cross"section structural shape. 1 6he &ila'ent (inding process can be auto'ated to (rap resin"(etted &ibers around a 'andrel to produce circular or polygonal shapes. -1 6he layup process engages a hand or 'achine buildup o& 'ats o& &ibers that are held together per'anently by a resin syste'. 6his 'ethod enables nu'erous layers o& di&&erent &iber orientations to be built up to a desired sheet thickness and product shape. C-a a"te i(ti"( )7 C)m')(ite( 6he 'echanical properties o& co'posites depend on 'any 2ariables such as &iber types, orientations, and architecture. 6he &iber architecture re&ers to the pre&or'ed te/tile con&igurations by braiding, knitting, or (ea2ing. ,o'posites are anisotropic 'aterials (ith their strength being di&&erent in any direction. 6heir stress"strain cur2es are linearly elastic to the point o& &ailure by rupture. 6he poly'eric resin in a co'posite 'aterial, (hich consists o& 2iscous &luid and elastic solids, responds 2iscoelastically to applied loads. Although the 2iscoelastic 'aterial (ill creep and rela/ under a sustained load, it can be designed to per&or' satis&actorily. ,o'posites ha2e 'any e/cellent structural 9ualities and so'e e/a'ples are high strength, 'aterial toughness, &atigue endurance, and light (eight. =ther highly desirable 9ualities are high resistance to ele2ated te'perature, abrasion, corrosion, and che'ical attack. So'e o& the ad2antages in the use o& co'posite structural 'e'bers include the ease o& 'anu&acturing, &abrication, handling, and erection. Pro@ect deli2ery ti'e can be short. )t took the Russell county engineer one day to install the deck panels in the &irst 2ehicular co'posite bridge. ,o'posites can be &or'ulated and designed &or high per&or'ance, durability and e/tended ser2ice li&e. 6hey ha2e e/cellent strength"to"(eight ratios. )& durability can be pro2en to last %7 years, co'posites can be econo'ically @usti&ied using the li&e"cycle cost 'ethod. So'e o& the disad2antages in the use o& co'posites in bridges are high &irst cost, creep, and shrinkage. 6he design and construction re9uire highly trained specialists &ro' 'any engineering and 'aterial science disciplines. 6he co'posites ha2e a potential &or en2iron'ental degradation, &or e/a'ples, alkalis= attack and ultra2iolet radiation e/posure. 6here are 2ery little or none/istant design guidance and/or standards. 6here is a lack o& @oining and/or &astening technology. +ecause o& the use o& thin sections, there are concerns in global and local buckling. Although the light (eight &eature 'ay be an ad2antage in the response to earth9uake loading, it could render the structure areodyna'ically unstable. )n 'anu&acturing (ith the hand layup process, there is a concern about the consistency o& the 'aterial properties. W-at I( Rea##2 in C)m')(ite(8 As the na'e i'plies, ad2ance &iber rein&orced poly'er co'posites is 'ade o& &iber rein&orce'ents, resin, &illers, and additi2es. 6he &ibers pro2ide increased sti&&ness and tensile capacity. 6he resin o&&ers high co'pressi2e strength and binds the &ibers into a &ir' 'atri/. 6he &illers ser2e to reduce cost and shrinkage. 6he additi2es help to i'pro2e not only the 'echanical and physical properties o& the co'posites but also (orkability. 6he discussions that &ollo( i''ediately (ill e/plain the basic &unctions and beha2iors o& the constituents. Fi6e Rein7) "ement( 6he &iber is an i'portant constituent in co'posites. A great deal o& research and de2elop'ent has been done (ith the &ibers on the e&&ects in the types, 2olu'e &raction, architecture, and orientations. 6he &iber generally occupies -*> " %*> o& the 'atri/ 2olu'e in the co'posites. 6he &ibers can be chopped, (o2en, stitched, and/or braided. 6hey are usually

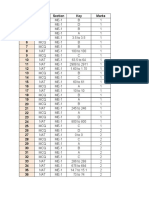

treated (ith si;ings such as starch, gelatin, oil or (a/ to i'pro2e the bond as (ell as binders to i'pro2e the handling. 6he 'ost co''on types o& &ibers used in ad2anced co'posites &or structural applications are the &iberglass, ara'id, and carbon. 6he &iberglass is the least e/pensi2e and carbon being the 'ost e/pensi2e. 6he cost o& ara'id &ibers is about the sa'e as the lo(er grades o& the carbon &iber. A=ther high"strength high"'odulus &ibers such as boron are at the present ti'e considered to be econo'ically prohibiti2e@ 4$35. Glass Fibers 6he glass &ibers are di2ided into three classes "" E"glass, S"glass and ,"glass. 6he E"glass is designated &or electrical use and the S"glass &or high strength. 6he ,"glass is &or high corrosion resistance, and it is unco''on &or ci2il engineering application. =& the three &ibers, the E"glass is the 'ost co''on rein&orce'ent 'aterial used in ci2il structures. )t is produced &ro' li'e"alu'ina"borosilicate (hich can be easily obtained &ro' abundance o& ra( 'aterials like sand. 6he &ibers are dra(n into 2ery &ine &ila'ents (ith dia'eters ranging &ro' to $- F $*"< '. 6he glass &iber strength and 'odulus can degrade (ith increasing te'perature. Although the glass 'aterial creeps under a sustained load, it can be designed to per&or' satis&actorily. 6he &iber itsel& is regarded as an isotropic 'aterial and has a lo(er ther'al e/pansion coe&&icient than that o& steel. 6ypical Properties Aensity 0g/c'-1 Houng=s ?odulus 0GPa1 6ensile Strength 0GPa1 6ensile Elongation 0>1 E"Glass .<* % $.% .3 6able $ 4Re&. 75 S"Glass .7* !% .7.#

Aramid Fibers 6hese are synthetic organic &ibers consisting o& aro'atic polya'ides. 6he ara'id &ibers ha2e e/cellent &atigue and creep resistance. Although there are se2eral co''ercial grades o& ara'id &ibers a2ailable, the t(o 'ost co''on ones used in structural applications are Ke2lar7$ # and Ke2lar7 3#. 6he Houng=s ?odulus cur2e &or Ke2lar7 # is linear to a 2alue o& !- GPa but then beco'es slightly conca2e up(ard to a 2alue o& $** GPa at rupture8 (hereas, &or Ke2lar7 3# the cur2e is linear to a 2alue o& $ 3 GPa at rupture 0see 6able 1. As an anisotropic 'aterial, it=s trans2erse and shear 'odulus are an order o& 'agnitude less than those in the longitudinal direction. 6he &ibers can ha2e di&&iculty achie2ing a che'ical or 'echanical bond (ith the resin. 6ypical Properties Aensity 0g/c'-1 Houng=s ?odulus 0GPa1 6ensile Strength 0GPa1 Ke2lar # $.33 !-/$** . % Ke2lar 3# $.33 $ 3 . %

$Ke2lar7 is a registered trade 'ark o& E.). du Pont de :e'ours I ,o.

6ensile Elongation 0>1

.! 6able 4Re&. 75

$.!

Carbon Fibers 6he graphite or carbon &iber is 'ade &ro' three types o& poly'er precursors "" polyacrylonitrile 0PA:1 &iber, rayon &iber, and pitch. 6he tensile stress"strain cur2e is linear to the point o& rupture. Although there are 'any carbon &ibers a2ailable on the open 'arket, they can be arbitrarily di2ided into three grades as sho(n in 6able -. 6hey ha2e lo(er ther'al e/pansion coe&&icients than both the glass and ara'id &ibers. 6he carbon &iber is an anisotropic 'aterial, and its trans2erse 'odulus are an order o& 'agnitude less than its longitudinal 'odulus. 6he 'aterial has a 2ery high &atigue and creep resistance. 6ypical Properties Aensity 0g/c'-1 Houng=s ?odulus 0GPa1 6ensile Strength 0GPa1 6ensile Elongation 0>1 Cigh Strength $.! -* .3! Cigh ?odulus $.# -%* $.%# Ultra"Cigh ?odulus .* " .$ 7 *"< * $.*- " $.-$ *.

$.$ *.7 6able - 4Re&. 75D

Since its tensile strength decreases (ith increasing 'odulus, its strain at rupture (ill also be 'uch lo(er. +ecause o& the 'aterial brittleness at higher 'odulus, it beco'es critical in @oint and connection details, (hich can ha2e high stress concentrations. As a result o& this pheno'enon, carbon co'posite la'inates are 'ore e&&ecti2e (ith adhesi2e bonding that eli'inates 'echanical &asteners. Re(in S2(tem( 6he resin is another i'portant constituents in co'posites. 6he t(o classes o& resins are the ther'oplastics and ther'osets. A ther'oplastic resin re'ains a solid at roo' te'perature. )t 'elts (hen heated and solidi&ies (hen cooled. 6he long"chain poly'ers do not che'ically cross link. +ecause they do not cure per'anently, they are undesirable &or structural application. ,on2ersely, a ther'osetting resin (ill cure per'anently by irre2ersible cross linking at ele2ated te'peratures. 6his characteristic 'akes the ther'oset resin co'posites 2ery desirable &or structural applications. 6he 'ost co''on resins used in co'posites are the unsaturated polyesters, epo/ies, and 2inyl esters8 the least co''on ones are the polyurethanes and phenolics. Unsaturated Polyesters 6he unsaturated polyester a'ounts to about %7> o& all polyester resins used in USA. )t is produced by the condensation poly'eri;ation o& dicarbo/ylic acids and dihydric alcohols. 6he &or'ulation contains an unsaturated 'aterial such as 'aleic anhydride or &u'aric acid (hich is a part o& the dicarbo/ylic acid co'ponent. 6he &or'ulation a&&ects the 2iscosity, reacti2ity, resiliency and heat de&lection te'perature 0CA61. 6he 2iscosity controls the speed and degree o& (et"out 0saturation1 o& the &ibers. 6he reacti2ity a&&ects cure ti'e and peak e/other' 0heat generation1 te'peratures. Cigh

e/other' is needed &or a thin section curing at roo' te'perature and lo( e/other' &or a thick section. Resiliency or &le/ible grade co'posites ha2e a higher elongation, lo(er 'odulus, and CA6. 6he CA6 is a short ter' ther'al property (hich 'easures the ther'al sensiti2ity and stability o& the resins. 6he ad2antages cited in the unsaturated polyester are its di'ensional stability and a&&ordable cost. =ther ad2antages include ease in handling, processing, and &abricating. So'e o& the special &or'ulations are high corrosion resistant and &ire retardants. 6his resin is probably the best 2alue &or a balance bet(een per&or'ance and structural capabilities. Epoxies 6he epo/ies used in co'posites are 'ainly the glycidyl ethers and a'ines. 6he 'aterial properties and cure rates can be &or'ulated to 'eet the re9uired per&or'ance. Epo/ies are generally &ound in 'arine, auto'oti2e, electrical and appliance applications. 6he high 2iscosity in epo/y resins li'its it use to certain processes such as 'olding, &ila'ent (inding, and hand lay"up. 6he right curing agent should be care&ully selected because it (ill a&&ect the type o& che'ical reaction, pot li&e and &inal 'aterial properties. Although epo/ies can be e/pensi2e, it 'ay be (orth the cost (hen high per&or'ance is re9uired. Vinyl Esters 6he 2inyl ester resins (ere de2eloped to take ad2antage o& both the (orkability o& the epo/y resins and the &ast curing o& the polyesters. 6he 2inyl ester has higher physical properties than polyesters but costs less than epo/ies. 6he acrylic esters are dissol2ed in a styrene 'ono'er to produce 2inyl ester resins (hich are cured (ith organic pero/ides. A co'posite product containing a 2inyl ester resin can (ithstand high toughness de'and and o&&er e/cellent corrosion resistance. Polyurethanes Polyurethanes are produced by co'bining polyisocyanate and polyol in a reaction in@ection 'olding process or in a rein&orced reaction in@ection 'olding process. 6hey are cured into 2ery tough and high corrosion resistance 'aterials (hich are &ound in 'any high per&or'ance paint coatings. Phenolics 6he phenolic resins are 'ade &ro' phenols and &or'aldehyde, and they are di2ided into resole and no2olac resins. 6he resoles are prepared under alkaline conditions (ith &or'aldehyde/phenol 0F/P1 ratios greater than one. =n the contrary, no2olacs are prepared under acidic conditions (ith F/P ratios less than one. Resoles are cured by applying heat and/or by adding acids. :o2olacs are cured (hen reacting che'ically (ith 'ethylene groups in the hardener. 6he phenolics are rated &or good resistance to high te'perature, good ther'al stability, and lo( s'oke generation. Fi##e ( Since resins are 2ery e/pensi2e, it (ill not be cost e&&ecti2e to &ill up the 2oids in a co'posite 'atri/ purely (ith resins. Fillers are added to the resin 'atri/ &or controlling 'aterial cost and i'pro2ing its 'echanical and che'ical properties. So'e co'posites that are rich in

resins can be sub@ect to high shrinkage and creep and lo( tensile strength. Although these properties 'ay be undesirable &or structural applications, there 'ay be a place &or their use. 6he three 'a@or types o& &illers used in the co'posite industry are the calciu' carbonate, kaolin, and alu'ina trihydrate. =ther co''on &illers include 'ica, &eldspar, (ollastonite, silica, talc, and glasses. When one or 'ore &illers are added to a properly &or'ulated co'posite syste', the i'pro2ed per&or'ance includes &ire and che'ical resistance, high 'echanical strength, and lo( shrinkage. =ther i'pro2e'ents include toughness as (ell as high &atigue and creep resistance. So'e &illers cause co'posites to ha2e lo(er ther'al e/pansion and e/other' coe&&icients. Wollastonite &iller i'pro2es the co'posites= toughness &or resistance to i'pact loading. Alu'inu' trihydrate i'pro2es on the &ire resistance or &la''ability ratings. So'e high strength &or'ulations 'ay not contain any &iller because it increases the 2iscosity o& the resin paste. Cigh 2iscosity resins 'ay ha2e a proble' (etting out co'pletely &or co'posite (ith hea2y &iber rein&orce'ent. A &iller should not be used (ith &iber 2olu'e greater than 7*> &or the sheet 'olding co'posite production 'ethod. A&&iti,e( A 2ariety o& additi2es are used in the co'posites to i'pro2e the 'aterial properties, aesthetics, 'anu&acturing process, and per&or'ance. 6he additi2es can be di2ided into three groups "" catalysts, pro'oters, and inhibitors8 coloring dyes8 and, releasing agents. 6heir roles are as si'ple as their na'es i'ply, and they need no &urther discussion here. De(ign C)n(i&e ati)n( Pro&essor Steenka'er and his coauthors at the Uni2ersity o& Aela(are stated it (ell (hen they (roteD A6he de2elop'ent o& a co'posite is a co'ple/ process that re9uires the si'ultaneous consideration o& 2arious para'eters such as co'ponent geo'etry, production 2olu'e, rein&orce'ent and 'atri/ types and relati2e 2olu'es, tooling re9uire'ents, process and 'arket econo'ics, etc. E2ery decision 'ade during the product de2elop'ent process is intricately related to a set o& three interacting decision=s areas 0i.e., 'aterials, processing, and con&iguration1@ 4!5. 6he de2elop'ent o& the ad2anced co'posite technology is an engineer=s drea' &or inno2ati2e design and application. 6he characteristics o& a co'posite can be tailored and designed to 'eet any desired speci&ications. ?ost o& the in&or'ation and design data a2ailable on co'posites are in the aerospace applications, but they are protected under the guise o& proprietary syste's and/or 'ilitary classi&ied docu'ents. Unlike con2entional isotropic 'aterials o& steel and concrete, there are no readily a2ailable design charts and guidelines to help the structural engineer. When it co'es to (orking (ith co'posites as opposed to con2entional 'aterials, as the author has disco2ered, the di&&erence can be as dra'atic as night and day. 6he challenge in applying co'posites is &or one to understand the beha2ior o& not only the constituents in the co'posites but also the co'pleted end product in the (ay they respond to an applied load. Since a separate design speci&ication &or co'posites bridges is not yet a2ailable, e/isting bridge design guidelines 'ay ha2e to be used (ith so'e caution. Under the current A'erican Association o& State Cigh(ay and 6ransportation =&&icials 0AASC6=1 JRFA bridge design speci&ications, the philosophy is one o& a probability"based li'it state approach. 6he &our basic li'it states that is applicable in bridge design (ith ad2anced co'posite 'aterials are the ser2ice, &atigue and &racture, strength, and e/tre'e e2ent. 6he ser2ice li'it states dictate the le2el o& de&or'ation and crack (idth under nor'al ser2ice conditions &or a bridge to per&or' satis&actorily during its ser2ice li&e. 6he &atigue and &racture li'it states restrict the stress range under nor'al ser2ice conditions (ithin an e/pected

nu'ber o& load cycles. 6hey are to li'it crack gro(th under repetiti2e loading and to pre2ent &racture during the design li&e o& a bridge. 6he strength li'it states are to ensure that both the global and local strength and stability are pro2ided to resist the statistically signi&icant load co'binations as e/perienced by a bridge during its design li&e. So'e o2erstress and structural da'age 'ay be ine2itable, but the o2erall integrity o& the structure (ill not be co'pro'ised. 6he e/tre'e e2ent li'it states ensure the structural sur2i2al o& a bridge during a 'a@or earth9uake or unusual collision &orce. +ased on so'e o& the design data obtained &ro' co'pleted co'posite bridge structures to date, the de&lection and/or local buckling go2ern co'posite design. With the inherent lo( section 'odulus o& a co'posite structural 'e'ber and critical high stress de'and in structural applications, a designer should consider the &ollo(ing &eatures care&ully in his designD A2oid abrupt thickness change in co'ponents 6ake ad2antage o& geo'etrical shapes 6ake ad2antage o& hybrid syste's Use bonded asse'blies and @oints Pro2ide good details &or connected @oints Avoid abrupt thickness change in components )n steel or concrete design, an increase in the plate or &lange thickness (ill usually keep the stresses under control. Although this concept also (orks &or co'posites, it is ine&&icient &or a co'posite 'e'ber to &ollo( suit by increasing its o2erall part thickness. +ecause co'posites are 2iscoelastic 'aterials, it is undesirable to create high stress risers. An understanding in the stress &lo( o& a structural 'e'ber (ill help a designer tailor the parts= thicknesses locally and a2oid abrupt changes in its geo'etry. Take advantage of geometrical shapes )n 'ost design using co'posites, the stress le2el is 2ery lo(. An opti'al design in co'posites balances the stress, de&lection, and stability (ith the use o& &langes, ribs, sti&&eners, honeyco'b or bo/"cells, or tubes to 'a/i'i;e the sti&&ness o& the section. +y placing &langes &arther apart at the top and botto' o& a hollo( core, the section 'odulus can be designed to span longer structures. +y proportioning and orienting the cells ade9uately, local buckling can be eli'inated and 'aterial sti&&ness can be increased. Take advantage of hybrid systems +y taking ad2antage o& the high sti&&ness in concrete and the high strength in co'posites, concrete &illed carbon co'posite tubes &or piles and 'ain superstructure 'e'bers in bridges are &ound to be 2ery cost e&&ecti2e. Structural ti'ber bea's rein&orced (ith co'posites in strategic locations ha2e de'onstrated an increase in the bea' capacity. Prestressing tendons in concrete bea's and decks are being studied in South Aakota and ?ichigan. Pultruded carbon FRP co'posite la'inates bonded to steel bea's and concrete slabs are being considered &or strengthening o& bridges. ,o'posite &iberglass rods replacing rein&orcing bars in concrete bridge decks are being studied in West Birginia. With any o& these hybrid syste's, the designer should account &or the di&&erence in the strains o& each 'aterial a&&ecting the co'patibility o& the total unit. Use bonded assemblies and joints ?uch (ork needs to be done in de2eloping good @oints to asse'ble the co'posite 'e'bers. 6he success&ul use o& the epo/y adhesi2e technology &ro' the aerospace

industry has been trans&erred to 'any recent ci2il structural applications. 6he concept o& using epo/ied shear trans&er toggle strips has been de'onstrated in t(o co'posite bridges in the United Kingdo'. Plate bonding using epo/y adhesi2e on thin la'inates to strengthen ci2il structures is seen as a pro'ising application. 6he colu'n (rapped (ith carbon to(s 0sheets1 (ill be as strong as the epo/y bonded o2erlapping splice. 6he ability to ad2ance the co'posite technology in ci2il structures (ill depend on the integrity and durability o& these @oints. Provide good details for connected joints Aiscontinuities (ithin a structural syste' can be a designer=s night'are. Special attention 'ust be gi2en to the local stress &lo(, o2erall load path, and @oint lines that create (eak links or porosity introduced during the 'anu&acturing process. =ther irregularities introduced during the cutting/drilling and &it up process 'ust be e2aluated. )t is i'portant to select proper &asteners. ,ertain co'posites (ith high &le/ural 'odulus are 2ery brittle and ha2e a tendency to granulate8 they (ould not be suitable (ith scre(s. 6he ability to connect the co'ponents into a structural syste' (ill enable co'posites to go &ar in ci2il applications. )t needs a technological breakthrough &ro' the current thinking o& using nuts and bolts to connect its 'e'bers.

C)n"#!(i)n 6here has been a great deal o& de2elop'ent in the co'posite technology. )t is an e/citing ti'e &or ci2il engineers to be in2ol2ed (ith co'posites. +oth the US Go2ern'ent and pri2ate institutions are &unding 'any de'onstration bridge pro@ects to sho( that ad2anced co'posite 'aterials can be applied to rebuilding our high(ay in&rastructure. 6here is 'uch to be learned about co'posites. ?anu&acturers, bridge o(ners, go2ern'ent o&&icials, acade'ia, researchers and contractors need to (ork together. 6rade secrets should be honored and respected to the e/tent that in&or'ation is pro2ided to bridge o(ners to understand and e2aluate the beha2ior o& their structures. 6he bridge o(ner has been and (ill continue to be held responsible &or the sa&ety o& the tra2eling public during the ser2ice li&e o& a structure. ,urrent la(s re9uire bridge o(ners to in2entory and rate their bridges. 6he o(ners need to kno( the pertinent in&or'ation and data that are used in bridge design, 'anu&acturing, and &abricating. 6he AASC6=, AS6?, and A'erican ,oncrete )nstitute ha2e established nu'erous technical co''ittees to de2elop design speci&ications, guidelines, standards, testing 'ethods and 'ethodologies. 6he ,o'posites )nstitute (hich represents the co'posite industry has been coordinating the industry=s e&&ort to de2elop product design 'anuals, i'pro2e 'anu&acturing processes, and collect test data. :u'erous uni2ersities are o&&ering research and design courses in co'posites. 6here are a'ple opportunities &or ci2il engineers to participate and contribute to this gro(ing technology.

Re7e en"e( 4$5 4 5 4-5 435 475 4<5 4%5 4!5 4#5 4$*5 4$$5 4$ 5 4$-5 4$35 S)E+JE, F. I KAR+CAR), B8 A paper titled Ad2anced ,o'posites &or ,i2il Engineering Applications in the United States, Uni2ersity o& ,ali&ornia, San Aiego, ,A. +AJJ):GER, ,raig8 K,o'posites poised to 'ake inroads as Cigh(ay Structural ?aterials,K 6he JournalD Roads and +ridges8 April $##3 )ssue, pp. 3*"33. S?)6C, W8 Resin Syste's8 Aela(are ,o'posites Aesign Encyclopedia 0A,AE1, Bolu'e -8 $##*. J):ASAH, Karen8 What is a ,o'positeL8 6he Journal on ,o'posites Aesign and Application, Fall $##7 )ssue8 pp #"-*. MWE+E:, ,.8 )ntroduction to ?echanical +eha2ior and Properties o& ,o'posites ?aterials8 A,AE, Bolu'e $8 $#!#. A+EREGG, Aale8 S?, Aesign Guidelines &or Structural Applications, 6he JournalD ,AA Su''er $##< )ssue8 pp . KPlastics and ,o'posites in ,onstruction,K 6he E:R Journal, :o2e'ber %, $##3. S6EE:KA?ER, A.A.8 W)JK):S, A.J.8 KAR+CAR), B.?.8 Resin 6rans&er ?oldingD Part $ " ?aterials and Pre&or'ing8 :o2. $## 8 ,,?, UAEJ, :e(ark, AE. A+EREGG, Aale, S?, Aesign Guidelines &or Structural Applications, 6he JournalD ,AA Su''er $##< )ssue, pp. . W=JFE, Joanne, 6ips &or Using Fasteners, 6he JournalD ,AA Su''er $##< )ssue, pp. -3. J):ASAH, Karen8 State"o&"the")ndustryD $##7"$##<8 6he JournalD ,AA February $##< )ssue, pp. $ "$<. FCWA 6raining ?anual in JRFA Aesign o& Cigh(ay +ridges, ?od@eski and ?asters, )nc. =ctober $##3. RE)S,C, ?arc S.8 Ad2anced Poly'er ,o'posite ?akers Jook 6o(ard )n&rastructure ?arket8 ?arch 7, $##<, , I E:. P=A=J:H, Walter, Jr.8 Winds o& ,hange and Paradig's o& =bsolescence8 Proc., 6he :ational Steel +ridge Sy'posiu', =ctober $7"$%, $##<, ,hicago, )llinois8 6he :ational Steel +ridge Alliance, ,hicago, )llinois.

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 2001 Ford F150 ManualDokument296 Seiten2001 Ford F150 Manualerjenkins1100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- VC AndrewsDokument3 SeitenVC AndrewsLesa O'Leary100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Corporate Restructuring Short NotesDokument31 SeitenCorporate Restructuring Short NotesSatwik Jain57% (7)

- MT-1 Full NotesDokument56 SeitenMT-1 Full NotesM.Saravana Kumar..M.ENoch keine Bewertungen

- Micro - Systemic Bacteriology Questions PDFDokument79 SeitenMicro - Systemic Bacteriology Questions PDFShashipriya AgressNoch keine Bewertungen

- Strength of Materials - Unit 2 - Week 1Dokument3 SeitenStrength of Materials - Unit 2 - Week 1M.Saravana Kumar..M.ENoch keine Bewertungen

- VerificationManual en PDFDokument621 SeitenVerificationManual en PDFurdanetanpNoch keine Bewertungen

- Effective Engineering Teaching in PracticeDokument4 SeitenEffective Engineering Teaching in PracticeM.Saravana Kumar..M.ENoch keine Bewertungen

- 2 & 3 - Institutional Vision, Mision, PO, PSO, PEODokument4 Seiten2 & 3 - Institutional Vision, Mision, PO, PSO, PEOM.Saravana Kumar..M.ENoch keine Bewertungen

- M.saravana Kumar Updated Co StatementDokument5 SeitenM.saravana Kumar Updated Co StatementM.Saravana Kumar..M.ENoch keine Bewertungen

- Scholar List MechDokument152 SeitenScholar List MechM.Saravana Kumar..M.ENoch keine Bewertungen

- NDT Syallbus Anna University ScribdDokument2 SeitenNDT Syallbus Anna University ScribdM.Saravana Kumar..M.ENoch keine Bewertungen

- Details Dr. V KhalkarDokument1 SeiteDetails Dr. V KhalkarM.Saravana Kumar..M.ENoch keine Bewertungen

- Laws of Thermodynamics - Unit 3 - Week 2 PDFDokument3 SeitenLaws of Thermodynamics - Unit 3 - Week 2 PDFM.Saravana Kumar..M.ENoch keine Bewertungen

- Laws of Thermodynamics - Unit 3 - Week 2Dokument3 SeitenLaws of Thermodynamics - Unit 3 - Week 2M.Saravana Kumar..M.ENoch keine Bewertungen

- Me1 PDFDokument2 SeitenMe1 PDFM.Saravana Kumar..M.ENoch keine Bewertungen

- Strength of Materials - Unit 6 - Week 5Dokument3 SeitenStrength of Materials - Unit 6 - Week 5M.Saravana Kumar..M.ENoch keine Bewertungen

- Project Report MiddleDokument5 SeitenProject Report MiddleM.Saravana Kumar..M.ENoch keine Bewertungen

- Modification and Optimization of Invert Vertical Drawing Machine IVD 800Dokument3 SeitenModification and Optimization of Invert Vertical Drawing Machine IVD 800M.Saravana Kumar..M.ENoch keine Bewertungen

- Machine StructureDokument8 SeitenMachine StructureM.Saravana Kumar..M.ENoch keine Bewertungen

- Project Report CompanyDokument4 SeitenProject Report CompanyM.Saravana Kumar..M.ENoch keine Bewertungen

- Drive Units in CNCDokument17 SeitenDrive Units in CNCM.Saravana Kumar..M.ENoch keine Bewertungen

- BA 4722 Marketing Strategy SyllabusDokument6 SeitenBA 4722 Marketing Strategy SyllabusSri GunawanNoch keine Bewertungen

- A2 UNIT 5 Culture Teacher's NotesDokument1 SeiteA2 UNIT 5 Culture Teacher's NotesCarolinaNoch keine Bewertungen

- Participatory EvaluationDokument4 SeitenParticipatory EvaluationEvaluación Participativa100% (1)

- Topic 1 - ICT Tools at USP - Theoretical Notes With Google AppsDokument18 SeitenTopic 1 - ICT Tools at USP - Theoretical Notes With Google AppsAvantika PrasadNoch keine Bewertungen

- National Employment Policy, 2008Dokument58 SeitenNational Employment Policy, 2008Jeremia Mtobesya0% (1)

- Zigbee Technology:19-3-2010: Seminor Title DateDokument21 SeitenZigbee Technology:19-3-2010: Seminor Title Dateitdep_gpcet7225Noch keine Bewertungen

- SahanaDokument1 SeiteSahanamurthyarun1993Noch keine Bewertungen

- GA Power Capsule For SBI Clerk Mains 2024 (Part-2)Dokument82 SeitenGA Power Capsule For SBI Clerk Mains 2024 (Part-2)aa1904bbNoch keine Bewertungen

- Corporate Tax Planning AY 2020-21 Sem V B.ComH - Naveen MittalDokument76 SeitenCorporate Tax Planning AY 2020-21 Sem V B.ComH - Naveen MittalNidhi LathNoch keine Bewertungen

- Universal and Commercial Banks in The PhilippinesDokument1 SeiteUniversal and Commercial Banks in The Philippinesjohngo888Noch keine Bewertungen

- Contemp Person Act.1Dokument1 SeiteContemp Person Act.1Luisa Jane De LunaNoch keine Bewertungen

- Heirs of Vinluan Estate in Pangasinan Charged With Tax Evasion For Unsettled Inheritance Tax CaseDokument2 SeitenHeirs of Vinluan Estate in Pangasinan Charged With Tax Evasion For Unsettled Inheritance Tax CaseAlvin Dela CruzNoch keine Bewertungen

- Course DescriptionDokument54 SeitenCourse DescriptionMesafint lisanuNoch keine Bewertungen

- Ankle Injury EvaluationDokument7 SeitenAnkle Injury EvaluationManiDeep ReddyNoch keine Bewertungen

- Key Performance Indicators - KPIsDokument6 SeitenKey Performance Indicators - KPIsRamesh Kumar ManickamNoch keine Bewertungen

- Business Plan: Muzammil Deshmukh, MMS From Kohinoor College, MumbaiDokument6 SeitenBusiness Plan: Muzammil Deshmukh, MMS From Kohinoor College, MumbaiMuzammil DeshmukhNoch keine Bewertungen

- ATAL Selected FDPs AY 2023 24Dokument15 SeitenATAL Selected FDPs AY 2023 24parthiban palanisamy100% (2)

- FDD Spindle Motor Driver: BA6477FSDokument12 SeitenFDD Spindle Motor Driver: BA6477FSismyorulmazNoch keine Bewertungen

- Hydraulics and PneumaticsDokument6 SeitenHydraulics and PneumaticsRyo TevezNoch keine Bewertungen

- Contigency Plan On Class SuspensionDokument4 SeitenContigency Plan On Class SuspensionAnjaneth Balingit-PerezNoch keine Bewertungen

- Catalogue of Archaeological Finds FromDokument67 SeitenCatalogue of Archaeological Finds FromAdrinaNoch keine Bewertungen

- Instruction Manual 115cx ENGLISHDokument72 SeitenInstruction Manual 115cx ENGLISHRomanPiscraftMosqueteerNoch keine Bewertungen

- Cheerios Media KitDokument9 SeitenCheerios Media Kitapi-300473748Noch keine Bewertungen

- ProjectDokument33 SeitenProjectPiyush PatelNoch keine Bewertungen

- Ward 7Dokument14 SeitenWard 7Financial NeedsNoch keine Bewertungen