Beruflich Dokumente

Kultur Dokumente

Detecting Bearing Faults

Hochgeladen von

Hamza NoumanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Detecting Bearing Faults

Hochgeladen von

Hamza NoumanCopyright:

Verfügbare Formate

Detecting Bearing Faults

By Jason Tranter This article is the first in a series of four. In this article we will provide an overview of how vibration analysis can be used to detect bearing faults. We will only consider the typical failure mode where a spall develops in the bearing and the fault slowly worsens until the bearing ultimately fails. In the next article we will explore how techniques such as enveloping, ea!"ue, #hoc! ulse, time waveform, and spectrum analysis can be used to detect bearing wear. In future articles we will explore additional fault conditions $coc!ed bearing, %&', s!idding and other conditions(, and in the final article we will examine what the vibration analyst can do to extend the life of the bearing through acceptance testing, correction of unbalance and other conditions, and root cause failure analysis. Your job relies on accurate fault detection There is no doubt that the primary focus for most vibration analysts is the detection of rolling element bearing fault conditions. When a bearing fails unexpectedly it costs a great deal of money $downtime, secondary damage, etc.( and it is a blac! mar! on your name and your department. )or all the successes you may have achieved, missing *ust one bearing failure can set your reputation bac! months.

Dryer Fan Then again, the opposite is also true. If you report that a bearing has a defect and must be replaced, yet it is found to be in good condition, you also don+t loo! good. eople lose confidence in your s!ills and in the technology. #o what is the solution, I guess that+s obvious- don+t ma!e mista!es. If only it were that easy . . .

Its actually not that hard to detect faults . . . &etecting rolling element bearing defects is not as difficult as it may seem/I bet you did not expect me to say that. With a good screw driver and frequent trips around the machines, most people would be able to detect that a bearing needs to be replaced. There are, of course, a few issues with this approach. )irst, it is hardly a safe practice. #econd, the greatest benefits are achieved when the maintenance and production group have more than a few days warning that a machine needs to be stopped to replace a bearing. The earlier the better The challenge is to correctly assess the nature and severity of the defect and the life of the bearing. If you could confidently detect a bearing fault wee!s or months before the bearing needs to be replaced, then the wor! can be planned to minimi0e the impact of the bearing change. 1ou may even be able to extend the life of the bearing by correcting the root cause of the fault condition $unbalance, misalignment, poor lubrication, etc.(. There is some good news The good news is that the design of rolling element bearings ma!es it much easier to detect fault conditions at an early stage. Than!s to the geometry of the bearing $and their unique 2defect frequencies3( it is easy to distinguish bearing vibration from other vibration generated by the machine. 4nd than!s to the high frequencies generated in the early stage of wear, again it is easy to distinguish from other fault conditions. 4rmed with this information we *ust need to measure the vibration correctly and analy0e the data correctly, and we can be very successful. 56, I may have made it sound too easy. In truth there are a number of challenges to overcome. But understanding the challenges and their solutions is the !ey to success. Key # ! "easure the #ibration correctly 4ssuming the goal is to detect the bearing fault as early as possible, the first thing you have to do is recogni0e that the way you measure the vibration is absolutely !ey to success. In the earliest stage of bearing wear, the frequency of the vibration is very high and the amplitude is very low. I don+t care who you are- you *ust can+t hear it. 4nd if you use 2conventional3 sensor mounting techniques, you cannot capture these high frequencies.

Techniques such as ultrasound, #hoc! ulse, enveloping $demodulation(, #pi!e %nergy and ea!"ue are designed to detect high frequency, low amplitude vibration. Without getting into the details, these techniques wor! by first removing the high amplitude, low frequency vibration, then listening carefully to the high frequency vibration for the telltale signs of bearing wear, then transforming that vibration into a form that is easy to analy0e. We+ll examine these techniques more closely in the next article. $ little bit of bac%ground . . . When a defect is first initiated, the surface of the bearing may not actually be damagedthe damage may be subsurface. %ven when the damage does extend to the surface, the vibration generated is still wea!. 4s the balls or rollers move around the bearing and there is contact at the point where the damage exists, two things will happen7 there will be a shoc! wave $also called a stress wave(- and the bearing may vibrate $or resonate(. The shoc! wave ripples out from the point of contact very quic!ly. The vibration that results will be very wea!, and thus difficult to detect.

Bearing Series We can calculate, or search bearing databases for the telltale frequencies7 the ball/pass inner race frequency, ball/pass outer race frequency, ball $or roller( spin frequency, and cage $or fundamental train( frequency. If you can visuali0e the shaft turning inside the bearing, and the balls rolling around, there will be a fixed time between each impact. The time will be different depending upon where the bearing is damaged- on the inner race, the outer race, or on the rolling elements themselves.

&ood news' The good news is that this frequency will always be non/synchronous- it will never be exactly 8.9, :.9, ;.9 $or any other integer( times the turning speed of the shaft. It will be a non/integer number such as :.9<, =.>?, or ??.;: times the speed of the shaft. That+s the good news. It ma!es it easier to distinguish these sources of vibration from the numerous sources of vibration that occur at exact integer multiples of the running speed/from rotating elements such as pump vanes, fan blades, gear teeth, and so on. "ore good news' 4nother piece of good news is that when these impacts occur, the vibration that results is not smooth- the vibration will suddenly spi!e in amplitude before it settles again. That causes harmonics to appear in the spectrum. 4nd even more good news is that under certain conditions the amplitude of those spi!es will rise and fall $as a spall on the inner race of the bearing, or the damaged rolling elements, move in and out of the load 0one(. That causes sidebands to appear in the spectrum. 4ll of these telltale signs, which we can loo! for even if we do not !now which bearing is installed in the machine, provide an early warning that the bearing is damaged. We can loo! for these signs well before we would ever hear a change in vibration, even with the best screwdriver. (ome bad news . . . The bad news is that in the earliest stage of bearing wear, we will not be able to see pea!s at these telltale frequencies in the standard velocity spectrum when it is displayed in the linear format that most people use. $In truth, we might see them in a logarithmic spectrum

or in an acceleration spectrum.( #o we have to loo! elsewhere. 4nd that+s where enveloping $and the other techniques listed previously( can be put to good use. (o) what is the solution* There are a few ways to tac!le this challenge. ?. There are simple meters that focus on higher frequencies can be used to get an indication that a fault exists. @owever, other fault conditions can be confused with bearing faults. 8. #hoc! ulse meters are specifically designed to detect bearing faults. When used properly they provide an affordable way to get started. :. Altrasound meters allow you to listen for the presence of high frequencies. It is possible to detect lubrication problems and bearing defects. 4gain, they offer an affordable way to get started. ;. If you rely on 2standard3 velocity spectra $in linear format( then you will find it difficult to detect the fault until the fault has become more severe. #witching to log can help, and using units of acceleration and setting a higher )max will help. B. The best solution is to use more sophisticated techniques such as enveloping $also !nown as demodulation(, #hoc! ulse $with access to the spectra and time waveforms(, #pi!e %nergy, and ea!"ue. We+ll discuss these techniques in the next article. In the next article we will explore the techniques described in item B above. I hope this article has given you a better understanding of how the vibration changes as a defect grows, and the challenges involved with detecting the fault at the earliest stage.

Jason Tranter is the founder of Mobius Institute and author of iLearnVibration and other training materials and products. Jason has been involved in vibration analysis in the USA and his native Australia since !"#. $efore starting Mobius Institute Jason %as involved in vibration consulting and the development of vibration monitoring systems. %%%.mobiusinstitute.com This article is the second in a series of four. The first article provided a summary of how the vibration patterns change as the bearing fails. 4fter very briefly recapping the basics, this article will discuss the detection and analysis tools that can be used to determine the

nature and severity of the bearing fault7 ultrasound, #hoc! ulse, ea!"ue, enveloping, and spectrum and time waveform analysis.

&Metal'to'metal contact sets off a ripple effect( A stress %ave races through the metal components) causing the components to vibrate due to resonance*. @ow 'uch of a Cis! 4re 1ou Willing to Ta!e, What are your goals, &o you want to !now that a bearing may fail *ust days before it is li!ely to fail, with no prior warning, 5r would you li!e to !now that a bearing has been poorly lubricated, or has a minor defect that will develop into a ma*or fault, With the techniques described in this article you could learn these things months $certainly wee!s( before the bearing is li!ely to fail. With that extra time you could change the lubrication, order parts, organi0e the labor, and loo! for the best opportunity to perform the bearing replacement. The result is a safer plant with less downtime, less stress, and higher profits. Brief +eca, In the previous article, a few important points were made that are pertinent to this article7 ?. 4s bearings begin to fail, the vibration is very low in amplitude, and the frequency is very high $beyond your ability to hear, even with the best screw driver(. 8. #imple spectrum analysis will not reveal the fault until it has developed to stage three, unless you ta!e special precautions $listed later in the article(. :. To measure high frequency vibration you must mount the sensor correctly. Beyond Your -earing! .ltrasound

The ultrasound technique is very easy to implement. The measurement tool listens for very high frequency vibration and provides an indication of amplitude. It also amplifies the vibration and shifts $heterodynes( the frequency so that you can hear it through headphones. Therefore, you can listen for the telltale sounds of poor lubrication and bearing distress. When used correctly and appropriately, ultrasound instruments can be very complimentary to the other techniques described in this article. /hat $re 0(tress /a#es)1 and /hy (hould I 2are* Before describing the next two techniques it is important to briefly introduce the concept of the stress wave $also !nown as shoc! pulse(. 'etal/to/metal contact sets off a ripple effect7 a stress wave races through the metal components, causing the components to vibrate due to resonance. The stress wave is a very short/duration, low/amplitude, high/ frequency wave. %very time the rolling elements roll over the damaged area on the inner andDor outer race $or as the damaged areas on the rolling elements contact the raceways(, a stress wave will be generated. We can see! to detect that wave with techniques such as #hoc! ulse, ea!"ue, and #W4E $#tress Wave 4Ealysis, not discussed further in this brief article(. The vibration that results can also be detected via the envelope method, and as the fault develops further, via the time waveform and spectrum. There is one very !ey point you must be aware of7 we are tal!ing about very high frequencies, and as such the vibration sensor must be mounted correctly. Anless specifically designed for the purpose $e.g., #hoc! ulse(, a handheld probe is horribly inadequate. %ven a two/pole magnet mounted directly to the machine surface is not adequate. 4ll of the analy0er vendors will tell you, you must properly prepare the surface and use an attachment pad $or stud mount( in order to achieve the best results. It is also important to note that there are other defects that will generate stress waves and high/frequency vibration, including looseness, gear wear, and cavitation. That can help us to detect those conditions, but it can confuse our attempts to detect bearing and lubrication faults. (hoc% 3ulse The vibration sensors provided by # ' and CF)T%G@EI6 are designed to amplify $through resonance( high/frequency vibration $at approximately :B !@0(. 4s noted earlier, lubrication and physical defects $including wearDspalls( will generate vibration around this frequency. The vibration can be displayed as an amplitude to be trended, or a spectrum can be displayed in order to better understand the specifics of the defect7 inner race, outer race, etc. (,i%e 4nergy The #pi!e %nergy $units of g#%( technique aims to utili0e the accelerometer+s mounted resonance to amplify the high frequency vibration. @owever, in more recent years, the accelerometers provided have not been manufactured to have a repeatable resonance

characteristic. What that means is that when you change your accelerometer, the amplitudes will change. 3ea%5ue The ea!"ue technique, developed by %merson rocess 'anagement $G#i &ivision(, is also designed to detect the stress wave- however, it is performed in a different way. The signal from the accelerometer is digitally sampled $converted from analog voltages to digital numbers( at a very high rate so that the very short duration stress waves can be detected and quantified. The ea!"ue waveform and spectrum provide an indication of the bearing defect. 4s with all of the techniques, the accelerometer must be mounted correctly, and the filter settings $used to 2tune in3 to the bearing vibration( must be set correctly. 4n#elo,ing 4lso !nown as 2demodulation,3 the enveloping technique, which is used by a large number of vibration analy0er vendors, has been optimi0ed to measure the low/amplitude, high/frequency bearing vibration. #ee )igure ?. The envelope spectrum is then chec!ed for signs of the fault condition. #imilar to the spectrum that results in the #hoc! ulse, #pi!e %nergy, and ea!"ue systems, we are loo!ing for pea!s, sidebands, and harmonics that are related to the four characteristic bearing frequencies7 Ball ass )requency 5uter race $B )5(, Ball ass )requency Inner race $B )I(, Ball $or roller( #pin )requency $B#)(, and )undamental Train $or cage( )requency $)T)(. #ee )igure 8 for a summary of the progression we expect to see. The #pi!e %nergy $units of g#%( technique aims to utili0e the accelerometer+s mounted resonance to amplify the high frequency vibration. @owever, in more recent years, the accelerometers provided have not been manufactured to have a repeatable resonance characteristic. What that means is that when you change your accelerometer, the amplitudes will change. #ee )igure ?. The envelope spectrum is then chec!ed for signs of the fault condition. #imilar to the spectrum that results in the #hoc! ulse, #pi!e %nergy, and ea!"ue systems, we are loo!ing for pea!s, sidebands, and harmonics that are related to the four characteristic bearing frequencies7 Ball ass )requency 5uter race $B )5(, Ball ass )requency Inner race $B )I(, Ball $or roller( #pin )requency $B#)(, and )undamental Train $or cage( )requency $)T)(. #ee )igure 8 for a summary of the progression we expect to see.

(,ectrum $nalysis If we do not use one of these techniques and simply view a spectrum, then we may have limited success unless we ta!e precautions7 ?. 4cceleration is most sensitive to high/frequency vibration, so if we view the spectrum in units of acceleration $Hs or mmDs8( and have a high )max $>9I or higher( and, better yet, we view the spectrum in logarithmic format, then we will achieve the best results $with a spectrum alone(. 8. If we view the spectrum in units of velocity $inDsec or mmDs(, then we may need to wait until the bearing is at stage three until we see positive signs of the fault. Increasing the )max and viewing the spectrum in logarithmic format will help significantly. When viewing the velocity or acceleration spectrum $or any spectrum from ea!"ue, enveloping, etc.( there are a few techniques that help to achieve the best results7 ?. Joo! for pea!s at frequencies that are non/integer multiples of the shaft speed $e.g., :.9<I, ;.=BI, >.K<I, etc.(. 8. There should be harmonics of those frequencies $e.g., pea!s at :.9<I, =.?KI, <.8>I, etc.(. :. Ghec! for sidebands of the turning speed of the shaft. If they exist, then suspect a fault on the inner race. If there are no sidebands, suspect an outer race fault. ;. Ghec! for sidebands of the fundamental train frequency $slightly less than half the turning speed of the shaft(. If they exist, then suspect a fault on the rollersDballs.

Time wa#eform analysis It is typically possible to view the time waveform from the #hoc! ulse, ea!"ue, and envelope process, but I+ll focus on the raw waveform from the accelerometer. In the early stages of the fault condition it will be very difficult to detect the fault with a time waveform. @owever, as the fault develops, an acceleration waveform can reveal the fault, especially when ta!en from low/speed machinery. 4s the fault develops, the waveform will have characteristic 2pulses3 and patterns that indicate the condition of the bearing fault. In the later stages of the fault, a waveform in velocity units can display the defect quite clearly.

+haracteristic &modulated* pattern in the acceleration %aveform ,often called the &angel fish* pattern-.

&Spi.es* in the velocity %aveform indicate the presence of a severe fault. 2onclusion I hope this article has helped to provide a basic understanding of these techniques. They have all been used for many years to successfully detect bearing faults at a very early stage. The !ey is to mount the sensor correctly, choose the correct settings, and analy0e the data correctly.

Jason Tranter is the founder of 'obius Institute and author of iJearn"ibration and other training materials and products. Jason has been involved in vibration analysis in the A#4 and his native 4ustralia since ?<K;. Before starting 'obius Institute Jason was involved in vibration consulting and the development of vibration monitoring systems. www.'obiusInstitute.com

Detecting Bearing Faults 6 3art 7

4dd comment "iew comments rint by Jason Tranter In the two previous articles $&ecDJan 89??, 4prD'ay 89??(, the focus has been on how the vibration changes when a 2typical3 bearing fault develops. We have explored spectrum analysis, time waveform analysis, and a raft of high frequency detection techniques. But there are a number of fault conditions related to rolling element bearings that will not necessarily change the vibration patterns in the ways described thus far. Thus, in this article we will explore fault conditions that relate to poor installation $coc!ed on the shaft or on in the housing(, current flow through the bearing $%&' damage(, s!idding, and slipping. 3oor installation! coc%ed bearing Bearing installation is very important. If a hammer is used to pound a bearing into place, the rolling elements and raceways can be, and almost surely will be, damaged. oor installation can also damage the shaft or the raceways via surface gouging or scratching. Those damaged areas will cause the vibration to change in ways described in the previous two articles- periodic stress waves and vibration will be detected at the !ey forcing frequencies $depending on the damage inflicted on the bearing(. @owever, if the outer race of the bearing is coc!ed in the housing, or the inner race is coc!ed on the shaft $i.e. there is an angle between the outer race and the housing or between the inner race and the shaft(, then with time the additional load on the rolling elements and raceways will cause excessive wear and premature failure of the bearing. But we can detect this situation so that it can be corrected before damage is done. "ibration amplitude will be higher than normal in the axial direction- however, instead of generating vibration at the bearing defect frequencies $B )I, B )5, B#), and )T(, the vibration will be generated at the speed of rotation, i.e. ?I. The vibration at twice running speed $8I( and at harmonics can also increase in amplitude. The only problem is

that vibration at these frequencies can be elevated for other reasons, including unbalance, misalignment, and a bent shaft. $)igures ? and 8(

hase analysis can aid in this diagnostic process. In the case of the bearing coc!ed on the shaft, with each rotation you have a 2wobble3 motion. hase analysis would reveal that as you move an accelerometer around the face of the bearing at different cloc! positions, the phase reading would change accordingly. )or example, if the phase reading $compared to a tachometer reference or a second accelerometer( was 9 degrees at the ?8 o+cloc! position, the reading would be approximately <9L $or 8>9L( at :799, ?K9L at =799, and 8>9L $or <9L( at the <799 position. $)igure :(

If the outer race is coc!ed in the housing, the phase readings will depend on how it is coc!ed $i.e. which point on the bearing is furthest from the machine face, and which is closest(. By moving the accelerometer around $safely(, the analyst would find a ?K9L phase difference between those two points. $)igure ;(

Fluting or 4D" If current flows between the inner race and outer race, through the rollers or balls, a fluting pattern will be etched onto the bearing surfaces. The pattern is quite unusual, although very recogni0able, as shown in the photograph. $)igure B(

Gurrent flow can occur for a variety of reasons $including poor grounding when welding is performed, insulation brea!down, brush problems on &G drives, and other reasons(. The fault condition is common in &G motors, and it is now increasingly common to see this problem on variable frequency drives. Because of the 2washboard3 pattern on the bearing surfaces, a series of pea!s is often seen clustered together up in a high/frequency band, typically between ?99,999 G ' and ?K9,999 G '. It is believed that the pea!s appear in this range because they are exciting a bearing resonance- therefore, where they actually appear will depend upon the bearing. The pea!s may be separated by B )5, B )I, or sometimes B#)- however, they are often not observed in the lower frequencies $i.e. at B )5, B )I, etc.(. $)igure =(

(%idding If a bearing is correctly selected for its application, the lubricant is functioning correctly, and there is adequate load on the rolling elements, then the rolling elements should continuously roll around the raceways. @owever, it is not uncommon for the rolling elements to slide or s!id from time to time when these conditions are not met. This is more common on non/drive/end bearings, especially on vertical machines, and far more commonly with cylindrical roller bearings $as against deep groove ball bearings(. In many cases, when s!idding is observed, a shot of grease may stop the bearing from s!idding, but minutes or hours later the s!idding will resume. In some cases the s!idding will occur when the machine is started, or on cold days because the lubricant is more viscous. There are actually a number of situations in which s!idding, sliding, or smearing can occur, but for now the focus is where the rolling elements s!id through the unloaded portion of the bearing $i.e. opposite the load 0one(. I thin! it goes without saying that s!idding is very harmful to the bearing. The metal/to/metal contact causes excessive wear, and heat is also generated. In more than one case fire andDor explosions have resulted. The vibration pattern will change when a bearing is s!idding. The recording must be ta!en, however, when the s!idding is occurring $which can be intermittent(. It is common to be able to hear a high/pitched sound from the bearing when s!idding occurs. That should be enough to get your attention- however, an acceleration time waveform also will show high H levels- often above ?9 Hs. @igh/frequency 2noise3 is generated, which will excite the bearing resonance $as described when fluting occurs(- however, in this case we may expect to see a 2hump3 in the spectrum, li!e a mountain. It is not uncommon for pea!s to emerge out of the hump that are separated by B )5.

If the surface is damaged, pea!s may be observed at the defect frequencies. 1ou may notice that the pea!s become 2smeared3 $broader and shorter(, because the frequency of vibration is not consistent. (liding and loose fit 4nother fault condition you may encounter is where the inner race slides on the shaft, or the outer race slides in the housing, due to a loose fit. It is not uncommon to see a :I pea! $and harmonics( rise in amplitude when the bearing is slipping on the shaft, and you may also witness an increase in the ;I pea! when the bearing is loose in the housing. 8bser#e the bearing It is highly recommended that you loo! closely at the surface of a bearing when it is removed from the machine. It will tell you a great deal about the failure mode. 4ll of the ma*or bearing suppliers offer application notes with images that allow you to recogni0e the mar!ings on the bearing surfaces, helping you to determine the root cause. If a bearing is slipping on a shaft or is loose in the housing, or if the rollers are s!idding, the surfaces of the bearing will provide tell/tale signs. $)igure >(

.sing a strobosco,e If the cover of the bearing can be safely removed so that the rolling elements can be observed, a stroboscope can help to diagnose the slipping and s!idding faults conditions discussed in this article. If you synchroni0e the strobe to the shaft speed, you should not see relative movement between the inner race and the shaft. If the strobe is synchroni0ed

to the cage frequency, the cage should appear to be stationary, unless s!idding occurs. The relative position of the outer race to the housing should not change. 2onclusion There are a number of fault conditions related to rolling element bearings that can be detected with vibration analysis. 4s always, serious thought must be given to the root cause of these fault conditions. 1ou need a good vibration monitoring program, but you also need to adopt precision maintenance practices. In the fourth and final article $Goming out 5ctDEov ??( we will explore how vibration analysts can contribute to reliability improvement.

Jason Tranter is the founder of Mobius Institute and author of iLearnVibration and other training materials and products. Jason has been involved in vibration analysis in the USA and his native Australia since !"#. $efore starting Mobius Institute) Jason %as involved in vibration consulting and the development of vibration monitoring systems. %%%.mobiusinstitute.com

Detecting Bearing Faults 6 3art 9

4dd comment "iew comments rint by Jason Tranter This is the final part of the series on dealing with rolling element bearing defects. In previous articles, we loo!ed at how vibration analysis can be used to detect a range of faults conditions, including lubrication problems- wear, spalls, crac!s and other defectsand problems that relate to poor installation practices. In this article, we will discuss how the vibration analyst $and others within the maintenance and operations group( can minimi0e the number and severity of bearing faults. This is arguably the most important of the four articles.

If you as!ed most people whether vibration analysis improved reliability, they would answer, 21es.3 But I would disagree.

/hat is your definition of reliability* If your definition of 2reliability3 is whether or not bearings are failing catastrophically and unexpectedly, then it would be true to say that vibration analysis does improve reliability. But let+s draw a parallel with your car for a moment. -ow would you feel if your car failed as often as most rotating machines* If you found that every three months your car engine failed and thus you often found yourself stranded on the side of the road, then you would correctly say that your car is unreliable. But if the mechanics added a red light to your car+s dashboard that warned of imminent failure so you could avoid being stranded on the side of the road, you would feel li!e that was a step in the right direction. But if the red light comes on every three months, you would still feel as if your car is unreliable. 1ou would be within your rights to as! the mechanics to ma!e a change so that your car would run six years / or much longer / without the red light coming on. /e need red lights on our motors and ,um,s The same is true with your rotating machinery. In most plants, the vibration analysts are the 2red light3 on the dashboard. They ta!e readings, see that there is a problem, then wave their hands to say, 2you need to ta!e action because the bearing is about to fail.3 If the vibration analyst does a good *ob, then there will be more time between the red light coming on and the machine failing. 4s a result, the maintenance department will have more time to deal with the repair7 order the parts, find the most convenient time to shut the machine down, operate the machine through a critical period, operate the machine more safely, etc.

But there is much more that the vibration analyst and the maintenance and operations departments can do. The goal has to be to increase the life of the bearing / that+s what ma!es a machine more reliable. -ow can you im,ro#e reliability* There are four !ey components to improving the reliability of rotating machinery. 3urchase and design Cotating machinery and its support structures should be designed and purchased with reliability in mind. The lifetime costs should be prioriti0ed over the up/front purchase price. "ibration analysts can contribute to the design and selection process by referencing the experience gained from similar machines / that is, if a certain design has proven to have problems, do not use it again. "ibration analysts can also contribute by performing 2acceptance testing3 $incoming inspections( of new and overhauled machines to ensure that they are fit for your company+s use. 8,eration If a machine is operated correctly, there are less stresses on the components $bearings, shaft, seals, etc.(. It is primarily up to the operators to ensure a machine is operating correctly, but the vibration analyst and other condition monitoring technicians can perform tests to verify that it is operating properly. "aintenance #imilarly, if a machine runs more smoothly, there will be less stress on the components and it will be more reliable. The maintenance department has an important role to play. The bearings and gears should be lubricated correctly. In addition, the shafts should be precision aligned- there should be no soft foot- the rotating elements should be correctly balanced- there should be minimal resonance- the bearings should be installed correctlyand so on. If the maintenance department gets all of the fundamental maintenance issues right, then the machine will be far more reliable. 4s a result, the vibration analyst should see very few fault conditions develop. #o what is the role of the vibration analyst, The vibration analyst may be involved in precision alignment and should be involved with field balancing. The vibration analyst can certainly ta!e the required readings to chec! for misalignment, soft foot, lubrication problems, bearing installation problems, unbalance, looseness, resonance, flow problems, and so on. If these tests are performed correctly and the conditions are corrected quic!ly, the machine will provide many years of reliable operation. 1es, it will ta!e cooperation between maintenance and the condition monitoring group, and it will require the vibration analyst to master all the necessary s!ills, but it is definitely worth it.

2ontinuous im,ro#ement %ven with the best intentions, there will still be failures. The important factor is to learn from failure. Coot cause failure analysis can be used to determine why a machine failed / but it is important to go bac! and ma!e changes so that the failure does not occur again. 4 vibration analyst can play a very important role. The vibration data can hold the clue as to why a machine failed. It may be that a bearing failed, for example, but careful examination of the data may identify a condition $unbalance, misalignment, resonance, etc.( that led to the failure. When the bearing is removed from the machine, it should be examined to determine why the failure occurred. In the example in )igure ?, the pump was in standby mode for long periods and experiencing vibration from a second unit, thus 2false brinelling3 occurred.

/igure ' This bearing has failed due to false brinelling. Image adapted from /A0 1ubl. 2o. 3L "4 5464 78 -ow do you ma%e all this ha,,en* The answer is training and communication. Anless you have buy/in at all levels in the organi0ation, reliability will always be a seemingly impossible dream. %veryone must believe that reliability is a very high priority $safety may be a higher priority, but reliable plants are safer plants(. Celiability adds to the bottom line of the balance sheet. While there will be an initial investment $training, instrumentation, design modifications, etc.(, the improvements in production, quality and energy efficiency, and the reduction in maintenance costs $parts and labor( and safety incidences will result in a very fast return on investment. /hat ty,e of training is re:uired* In this author+s opinion, you need three types of training7 awareness, management and practitioner.

4wareness7 5perators, millwrights and everyone up through to management need to have basic training on the concept of reliability, condition/ based maintenance and the condition monitoring technologies. eople should not feel threatened by the technologyand everyone should be pulling in the same direction. 4nd they should all believe in the philosophy so that when recommendations for repairs and changes to procedure are made, they are followed without question. 'anagement7 'anagers, engineers and purchasing personnel need a deeper understanding of the same three areas $reliability, condition/based maintenance and the condition monitoring technologies( so the program can be run correctly and all design and repair decisions are made with reliability in mind. ractitioner7 It may seem obvious that the vibration analysts, aligners, balancers, lubricators, bearing installers and other people need training to do their *ob properly, but you would be surprised at how few actually have adequate training. 4ssumptions are made about a person+s !nowledge- sadly each person learns the same mista!es from their fellow wor!ers. Gompanies may buy modern vibration analy0ers, state/of/the/art laser alignment systems and other high/tech equipment, but without adequate training, the money is wasted $and the opportunity is lost(. #ee )igure 8.

/igure 4 ' Laser alignment systems are great) but %ithout ade9uate training) they %ill be misused 2onclusion 4 good vibration analyst will detect a bearing defect before it fails. 4 better analyst will detect the defect earlier and communicate the status so action can be ta!en to minimi0e the cost of repair. But the best vibration analysts do everything possible to reduce the li!elihood that the bearing will ever develop a defect in the first place.

Jason Tranter is the founder of Mobius Institute and author of iLearnVibration and other training materials and products. Jason has been involved in vibration analysis in the USA and his native Australia since !"#. $efore starting Mobius Institute) Jason %as involved in vibration consulting and the development of vibration monitoring systems. %%%.mobiusinstitute.com

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Replacing An Engine Drive BeltDokument5 SeitenReplacing An Engine Drive BeltHamza NoumanNoch keine Bewertungen

- CV Hamza wORKSHOP eNGINEERDokument3 SeitenCV Hamza wORKSHOP eNGINEERHamza NoumanNoch keine Bewertungen

- Direction On How To Replace A Fuel Filter.Dokument5 SeitenDirection On How To Replace A Fuel Filter.Hamza NoumanNoch keine Bewertungen

- List of Documetns, Rev-2, 29-09-2012Dokument4 SeitenList of Documetns, Rev-2, 29-09-2012Hamza NoumanNoch keine Bewertungen

- List of Workshop Machines, 2011 RevisedDokument3 SeitenList of Workshop Machines, 2011 RevisedHamza Nouman100% (1)

- Quality Plan For WorkshopDokument1 SeiteQuality Plan For WorkshopHamza NoumanNoch keine Bewertungen

- Scaffolding: "It's Big, It's Ugly, It's There,"Dokument2 SeitenScaffolding: "It's Big, It's Ugly, It's There,"Hamza NoumanNoch keine Bewertungen

- Muhammad Rehan Khan Maintenance EngineerDokument13 SeitenMuhammad Rehan Khan Maintenance EngineerHamza NoumanNoch keine Bewertungen

- Scaffold 2Dokument2 SeitenScaffold 2Hamza NoumanNoch keine Bewertungen

- Guidelines For Access ScaffoldingDokument28 SeitenGuidelines For Access ScaffoldingHamza Nouman100% (1)

- GRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Dokument5 SeitenGRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Hamza NoumanNoch keine Bewertungen

- ER-Format (Version 1)Dokument1 SeiteER-Format (Version 1)Hamza NoumanNoch keine Bewertungen

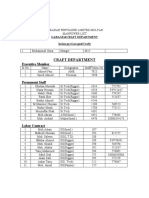

- Craft Department: Executive MemberDokument2 SeitenCraft Department: Executive MemberHamza NoumanNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Proposal: Analysis of A Double Wishbone Suspension SystemDokument11 SeitenProposal: Analysis of A Double Wishbone Suspension SystemSebastianTamayoNoch keine Bewertungen

- Table 1 - Loads To Be Taken in Each Combination With AppropriateDokument2 SeitenTable 1 - Loads To Be Taken in Each Combination With AppropriateAdi HamdaniNoch keine Bewertungen

- Newtons Rings Formal ReportDokument8 SeitenNewtons Rings Formal ReportSammy BennettNoch keine Bewertungen

- Ruukki Double Grade S420MH S355J2H RectangularDokument6 SeitenRuukki Double Grade S420MH S355J2H Rectangularhooky1Noch keine Bewertungen

- Syllabus: M. Tech. Energy Management (Regular)Dokument28 SeitenSyllabus: M. Tech. Energy Management (Regular)Digvijay SinghNoch keine Bewertungen

- 105mm Enhanced GunDokument38 Seiten105mm Enhanced Gungrindormh53100% (1)

- Lecture-10 - Sesmic Data ProcessingDokument13 SeitenLecture-10 - Sesmic Data ProcessingusjpphysicsNoch keine Bewertungen

- Micro X Ray Fluorescence Spectroscopy First Edition PDFDokument31 SeitenMicro X Ray Fluorescence Spectroscopy First Edition PDFAlberto Núñez CardezoNoch keine Bewertungen

- Almost Final Draft ProjectDokument67 SeitenAlmost Final Draft ProjectGanesh V IyerNoch keine Bewertungen

- Understanding Neutron Radiography Post Exam Reading IX-ADokument231 SeitenUnderstanding Neutron Radiography Post Exam Reading IX-ACharlie Chong100% (3)

- Samrat - Chem QP Unit Test XIDokument3 SeitenSamrat - Chem QP Unit Test XIPriyam PandaNoch keine Bewertungen

- CSIR NET June 2021 Organic ChemistryDokument99 SeitenCSIR NET June 2021 Organic ChemistrySankar AdhikariNoch keine Bewertungen

- 11.4 Diffusion & EffusionDokument3 Seiten11.4 Diffusion & EffusionOmar AlwaerNoch keine Bewertungen

- Daiseikai Owners ManualDokument31 SeitenDaiseikai Owners ManualhunabhiNoch keine Bewertungen

- Optimizing Materials Cost and MechanicalDokument8 SeitenOptimizing Materials Cost and MechanicalKaleem UllahNoch keine Bewertungen

- ME5506 Make-Up Quiz 2Dokument6 SeitenME5506 Make-Up Quiz 2Wai-Yen Chan100% (1)

- Atomic ResearchDokument21 SeitenAtomic ResearchPrashant DoundNoch keine Bewertungen

- Gen. Chem Colligative PropertiesDokument50 SeitenGen. Chem Colligative PropertiesKath Del CastilloNoch keine Bewertungen

- Polapak Condensing Unit: PPC Ver2.0Dokument44 SeitenPolapak Condensing Unit: PPC Ver2.0Lai WeikinNoch keine Bewertungen

- Boe Exam Paper Oct 2012Dokument10 SeitenBoe Exam Paper Oct 2012Sandip WarbheNoch keine Bewertungen

- 7.7 High Pressure Vapour Liquid Equilibria: V L I IDokument7 Seiten7.7 High Pressure Vapour Liquid Equilibria: V L I IayushNoch keine Bewertungen

- Nozzle TestDokument9 SeitenNozzle TestDarshan PanchalNoch keine Bewertungen

- Compression After ImpactDokument22 SeitenCompression After ImpactviswanathyakkalaNoch keine Bewertungen

- The Nature and Properties of Light PDFDokument19 SeitenThe Nature and Properties of Light PDFB VIDATTE VILLANIEVANoch keine Bewertungen

- Determining Wicking of Fibrous Glass Fiber Blanket Insulation (Aircraft Type)Dokument3 SeitenDetermining Wicking of Fibrous Glass Fiber Blanket Insulation (Aircraft Type)Ahmed AlzubaidiNoch keine Bewertungen

- Aits 1718 PT Iii Jeea Paper 2 Sol PDFDokument19 SeitenAits 1718 PT Iii Jeea Paper 2 Sol PDFAaryan SharmaNoch keine Bewertungen

- Uploads241324130184worksheet 9.1 Impulse and Momentum PDFDokument4 SeitenUploads241324130184worksheet 9.1 Impulse and Momentum PDFM DavisNoch keine Bewertungen

- Earth's Curvature and Atmospheric RefractionDokument11 SeitenEarth's Curvature and Atmospheric RefractionCharles Carpo67% (3)

- Dose Reduction Techniques1Dokument4 SeitenDose Reduction Techniques1eltonNoch keine Bewertungen

- Mechanics of Solids II Lab: Nice SceeDokument9 SeitenMechanics of Solids II Lab: Nice SceeSalmanNoch keine Bewertungen