Beruflich Dokumente

Kultur Dokumente

DY-1-5 Plastic Pyrolysis Plant of Doing Group

Hochgeladen von

pyrolysisoilOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DY-1-5 Plastic Pyrolysis Plant of Doing Group

Hochgeladen von

pyrolysisoilCopyright:

Verfügbare Formate

Henan DOING Mechanical Equipment Co.

,ltd Building 18, Area A, Yingxie Garden, Yingxie Road, Jinshui District, Zhengzhou, Henan Province, China TEL: +86-371-56771821 +86-371-56771823 FAX: +86-371-86129922

DY-1-5 plastic pyrolysis plant of Doing Group

DY-1-5 plastic pyrolysis plant Place of Origin Brand Name Model Number type land require weight length colour modal diameter one batch time welder Price: Henan, China (Mainland) DOING DY-1-5 plastic pyrolysis plant 200 sqm 25 tons 5500mm according to customers request 5 tons 2200mm 16 hours aoto-welding FOB USD 35000.00~70000.00 / Set

Website: http://www.doinggroup.com/

1

E-mail: market@doinggroup.com

Henan DOING Mechanical Equipment Co.,ltd Building 18, Area A, Yingxie Garden, Yingxie Road, Jinshui District, Zhengzhou, Henan Province, China TEL: +86-371-56771821 +86-371-56771823 FAX: +86-371-86129922

Minimum Order Quantity: 1 Set/Sets Port: Packaging Details: Delivery Time: Payment Terms: Supply Ability: Qingdao/Tianjin according to customers request 20 days after deposit T/T, Western Union 10 Set/Sets per Month

1. Overview of DY-1-5 plastic pyrolysis plant DY-1-5 plastic pyrolysis plant is composed by 13 parts, which are reactor, trans mission device, catalytic chamber, cooling tube, heavy oil tank, oil-water separa tor, condenser, light oil tank, safety device, vacuum system, dedusting system, dr aft fan, chimney. The two keys of DY-1-5 plastic pyrolysis plant are reactor and cooling system. Reactor directly decides the machines safety and service life. It is made by wel ded steel plate. So the quality of welding will have a direct impact on safety and servi ce life. Therefore, we use automatic welding machine, X rays detection and heating tr eatment which will not only guarantee the quality of welding but also greatly improv e working efficiency. For cooling systems, there are two steps. Cooling pipe is the first step. The second is c ondenser. We have three condensers. And there are 57 pipes in one condenser. Diamet er is 48mm for one small pipe. The heat exchanging area is about 13square meters fo r one condenser. So the total cooling area is about 40 square meters, which will guara ntee you a high oil yield. 2.Main features of DY-1-5 plastic pyrolysis plant: Safety: A With an auto welding machine for the reactor, it can not only greatly improv e working efficiency but also guarantee the quality of welding seam, thus avoid ex plosion caused by gas leak.

E-mail: market@doinggroup.com Website: http://www.doinggroup.com/

2

Henan DOING Mechanical Equipment Co.,ltd Building 18, Area A, Yingxie Garden, Yingxie Road, Jinshui District, Zhengzhou, Henan Province, China TEL: +86-371-56771821 +86-371-56771823 FAX: +86-371-86129922

B Professional heating treatment and x-ray detection chamber are especially fo r welding. C Vacuum system will prevent oil gas from going back to reactor and causing ac cident. D. Professional thermometer, pressure gauge and safety valve. E It is dangerous to burn exhaust gas (C1 to C4) without any safety measures. I n our process, it is transferred first through the safety device and a safety burnin g air muzzle. Before burning, we should ensure the safety of production. Environment friendly: A Well water dedusting system can avoid black smoke. B The exhaust gas will be recycled for heating reactor, no gas pollution. C Every junction of the reactor is in good sealing situation with professional seal ing material. Long service life: A Material: Q245R special steel plate, thickness 14mm. B Welding: Automatic welding machine with heating treatment and x-ray detecti on will prolong the service life of reactor to the max. C The service life of the reactor will be 8 -10 years Energy saving: A. Well sealing for heating system, no gas leak and saving fuel. B The exhaust gas will be recycled for reactor heating.

E-mail: market@doinggroup.com

Website: http://www.doinggroup.com/

Das könnte Ihnen auch gefallen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- EGR Cooler Removal and InstallationDokument46 SeitenEGR Cooler Removal and InstallationKevin VargasNoch keine Bewertungen

- Machines, Tools and Methods of Automobile ManufactureVon EverandMachines, Tools and Methods of Automobile ManufactureBewertung: 4 von 5 Sternen4/5 (1)

- Anhydrous Ammonia Safety 2006Dokument16 SeitenAnhydrous Ammonia Safety 2006AMIT KUMAR100% (1)

- Attachment PDFDokument362 SeitenAttachment PDFRudy Bukew Hernawan100% (2)

- Waste Oil Distillation MachineDokument12 SeitenWaste Oil Distillation Machinenazif100% (1)

- 3D & 5D Pipe Bend For PipelineDokument6 Seiten3D & 5D Pipe Bend For PipelinemohammadazraiNoch keine Bewertungen

- Sellick SD-80 Operators Manual Nov 1998Dokument100 SeitenSellick SD-80 Operators Manual Nov 1998Louis-Simon Chiasson100% (1)

- SHD Series Field Butt Fusion Welding Machine Technical ParametersDokument19 SeitenSHD Series Field Butt Fusion Welding Machine Technical ParametersPipa Hdpe Indonesia100% (1)

- Chicken Cage Welding Machine QuotationDokument10 SeitenChicken Cage Welding Machine QuotationRobert AdrianNoch keine Bewertungen

- PPR-C Pipe SpecificationDokument25 SeitenPPR-C Pipe SpecificationAlex Dulay85% (13)

- PWPS 013 PRDokument2 SeitenPWPS 013 PRRenjith Gopan100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- BEIER MACHINERY 110MM PIPE PRODUCTIONDokument9 SeitenBEIER MACHINERY 110MM PIPE PRODUCTIONAdoniyas Abayneh Negash100% (1)

- The Flow Chart of Tires Pyrolysis Equipment For 6TDokument3 SeitenThe Flow Chart of Tires Pyrolysis Equipment For 6TpyrolysisoilNoch keine Bewertungen

- Tyre Recycling Pyrolysis PlantDokument2 SeitenTyre Recycling Pyrolysis PlantpyrolysisoilNoch keine Bewertungen

- 6LTAADokument7 Seiten6LTAAAbi Fatih100% (2)

- Hatflex ChinaDokument31 SeitenHatflex ChinaedgarmerchanNoch keine Bewertungen

- Part II Chapter 1 API RP 572Dokument9 SeitenPart II Chapter 1 API RP 572Amr Mohamed SolimanNoch keine Bewertungen

- Clock Spring ApplicationDokument7 SeitenClock Spring Applicationsibi_s_rajNoch keine Bewertungen

- HongFeng Plastic Metalizin MachineDokument12 SeitenHongFeng Plastic Metalizin MachineSungam CorbenNoch keine Bewertungen

- Waste Plastic Pyrolysis Oil Plant DY-1-10Dokument4 SeitenWaste Plastic Pyrolysis Oil Plant DY-1-10pyrolysisoilNoch keine Bewertungen

- Doing Waste Tire Recycling Equipment DY-1-8Dokument5 SeitenDoing Waste Tire Recycling Equipment DY-1-8pyrolysisoilNoch keine Bewertungen

- The 4th Generation Waste Plastic Rubber Tire Recycling Pyrolysis PlantDokument3 SeitenThe 4th Generation Waste Plastic Rubber Tire Recycling Pyrolysis PlantpyrolysisoilNoch keine Bewertungen

- The Flow Chart of Tires Pyrolysis EquipmentDokument4 SeitenThe Flow Chart of Tires Pyrolysis EquipmentpyrolysisoilNoch keine Bewertungen

- The Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8TDokument3 SeitenThe Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8Tpyrolysisoil100% (1)

- Doing Waste Tire Pyrolysis PlantDokument4 SeitenDoing Waste Tire Pyrolysis PlantpyrolysisoilNoch keine Bewertungen

- Waste Tire Recycling Pyrolysis Equipment of Doing GroupDokument2 SeitenWaste Tire Recycling Pyrolysis Equipment of Doing GrouppyrolysisoilNoch keine Bewertungen

- VIP Business Service Proposal: The Most Prestigious 3d Panel Machine Line Research & Manufacturing Base in ChinaDokument27 SeitenVIP Business Service Proposal: The Most Prestigious 3d Panel Machine Line Research & Manufacturing Base in ChinaRafael Augusto Morgado SosaNoch keine Bewertungen

- Krishna ElectronicsDokument10 SeitenKrishna Electronicsrishi070881100% (1)

- Henan Xinghuo Bioenergy Co., LTD - Plant InformationDokument12 SeitenHenan Xinghuo Bioenergy Co., LTD - Plant InformationStefan EnacheNoch keine Bewertungen

- Dosing & Metering Gear Pumps: Nitrided Cast Iron (G25) Nitrided Cast Iron (G25)Dokument8 SeitenDosing & Metering Gear Pumps: Nitrided Cast Iron (G25) Nitrided Cast Iron (G25)2009tamerNoch keine Bewertungen

- Professional Vacuum Evaporation MachineDokument7 SeitenProfessional Vacuum Evaporation MachineMario QuiroaNoch keine Bewertungen

- Sai Guru 10KLDokument11 SeitenSai Guru 10KLRishi KathirNoch keine Bewertungen

- 90 MM PVC Compounding DanaDokument2 Seiten90 MM PVC Compounding DanaAbdur RahimNoch keine Bewertungen

- Complete Pellet LineDokument15 SeitenComplete Pellet LineHendi HendriansyahNoch keine Bewertungen

- DY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GroupDokument3 SeitenDY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GrouppyrolysisoilNoch keine Bewertungen

- T-2800-250 Type 1 Cylinder Group Second Quotation 3Dokument6 SeitenT-2800-250 Type 1 Cylinder Group Second Quotation 3Iwan SiswandiNoch keine Bewertungen

- Dk-1618 PVD Multi Arc Ion Coating Machine en 2021.05.06Dokument14 SeitenDk-1618 PVD Multi Arc Ion Coating Machine en 2021.05.06Ronaldo SilverioNoch keine Bewertungen

- CGD NetworkDokument30 SeitenCGD NetworkAnimesh ChoudharyNoch keine Bewertungen

- JC-41200 4 Color Flexographic Printing Machine SpecsDokument4 SeitenJC-41200 4 Color Flexographic Printing Machine SpecsFathi MustafaNoch keine Bewertungen

- 36CBM SK RBDokument13 Seiten36CBM SK RBJayadev KarthaNoch keine Bewertungen

- Technical Parameter of Doing Waste Tyre Recycling Pyrolysis Oil MachineDokument4 SeitenTechnical Parameter of Doing Waste Tyre Recycling Pyrolysis Oil MachinepyrolysisoilNoch keine Bewertungen

- NCC Nangsing HaisiDokument10 SeitenNCC Nangsing HaisiLam NgoNoch keine Bewertungen

- CNC router machine quotationDokument2 SeitenCNC router machine quotationSanrasniNoch keine Bewertungen

- SY-A500 Polyurethane Foam MachineDokument6 SeitenSY-A500 Polyurethane Foam MachineAlina RoscaNoch keine Bewertungen

- GEBERIT Building Drainage WEB HDPE Application TechniqueDokument43 SeitenGEBERIT Building Drainage WEB HDPE Application TechniqueVirgiliuParvuNoch keine Bewertungen

- Melt Flow Index Deluxe: Presto Stantest Private LimitedDokument1 SeiteMelt Flow Index Deluxe: Presto Stantest Private LimitedAkhilesh KumarNoch keine Bewertungen

- Information - Roofing SheetDokument5 SeitenInformation - Roofing SheetRajeev RanjanNoch keine Bewertungen

- Technical Specification Wet LabDokument5 SeitenTechnical Specification Wet Labmarfan75Noch keine Bewertungen

- Bechem Berutox M 21 KN 9007601 (GB)Dokument1 SeiteBechem Berutox M 21 KN 9007601 (GB)Luciano de Carvalho100% (2)

- Ti e Protegol 32-55 RRM Nov 07Dokument4 SeitenTi e Protegol 32-55 RRM Nov 07A MahmoodNoch keine Bewertungen

- Waste Tyre Pyrolysis Plant of Doing GroupDokument2 SeitenWaste Tyre Pyrolysis Plant of Doing GrouppyrolysisoilNoch keine Bewertungen

- PV PIPE - CONNECTING OIL AND GASDokument2 SeitenPV PIPE - CONNECTING OIL AND GASKyNoch keine Bewertungen

- Advantage of DOING Oil Distillation Machine2014.2.22Dokument3 SeitenAdvantage of DOING Oil Distillation Machine2014.2.22Kelly EdwardsNoch keine Bewertungen

- 2014 - 01 Eco Panel South Africa Offer Steel Beds, Rubi, Sicoma 300m2 2015.02Dokument7 Seiten2014 - 01 Eco Panel South Africa Offer Steel Beds, Rubi, Sicoma 300m2 2015.02Nay LinNoch keine Bewertungen

- Plastic Recycling Pyrolysis PlantDokument2 SeitenPlastic Recycling Pyrolysis PlantpyrolysisoilNoch keine Bewertungen

- C.I.engineering ThailandDokument18 SeitenC.I.engineering ThailandShin GamingNoch keine Bewertungen

- Keshav 10tn QuotationDokument3 SeitenKeshav 10tn QuotationSaurabh GuptaNoch keine Bewertungen

- Lotos CT520D ManualDokument12 SeitenLotos CT520D Manualgsmith21100% (1)

- Quotation Sheet (Pentagon Knit Company LTD & Gas) 210224Dokument8 SeitenQuotation Sheet (Pentagon Knit Company LTD & Gas) 210224Md MasumNoch keine Bewertungen

- Autoclave Presentation GP1Dokument30 SeitenAutoclave Presentation GP1Ogungbenro Adetola ChadashNoch keine Bewertungen

- Ti e Protegol 32-55 R Nov 07Dokument4 SeitenTi e Protegol 32-55 R Nov 07A MahmoodNoch keine Bewertungen

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeVon EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNoch keine Bewertungen

- What's The Application of Palm Oil and Palm Kernel OilDokument3 SeitenWhat's The Application of Palm Oil and Palm Kernel OilpyrolysisoilNoch keine Bewertungen

- What Is PP and PEDokument1 SeiteWhat Is PP and PEpyrolysisoilNoch keine Bewertungen

- How To Make BiodieselDokument1 SeiteHow To Make BiodieselpyrolysisoilNoch keine Bewertungen

- Rubber Recycling Pyrolysis MachineDokument2 SeitenRubber Recycling Pyrolysis MachinepyrolysisoilNoch keine Bewertungen

- What Is Pyrolysis TechnologyDokument1 SeiteWhat Is Pyrolysis TechnologypyrolysisoilNoch keine Bewertungen

- Used Tire Recycling Pyrolysis MachineDokument2 SeitenUsed Tire Recycling Pyrolysis MachinepyrolysisoilNoch keine Bewertungen

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDokument2 SeitenWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNoch keine Bewertungen

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDokument2 SeitenWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNoch keine Bewertungen

- Plastic Recycling Pyrolysis PlantDokument2 SeitenPlastic Recycling Pyrolysis PlantpyrolysisoilNoch keine Bewertungen

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDokument2 SeitenWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNoch keine Bewertungen

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDokument2 SeitenWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNoch keine Bewertungen

- Waste Plastic Recycling Machine DY-1-8Dokument3 SeitenWaste Plastic Recycling Machine DY-1-8pyrolysisoilNoch keine Bewertungen

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDokument2 SeitenWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNoch keine Bewertungen

- Doing Waste Tire Pyrolysis PlantDokument4 SeitenDoing Waste Tire Pyrolysis PlantpyrolysisoilNoch keine Bewertungen

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDokument2 SeitenWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNoch keine Bewertungen

- Doing Used Tire Recycling Machine DY-1-10Dokument4 SeitenDoing Used Tire Recycling Machine DY-1-10pyrolysisoilNoch keine Bewertungen

- DY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GroupDokument3 SeitenDY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GrouppyrolysisoilNoch keine Bewertungen

- Doing Tire Recycling Plant DY-1-6Dokument4 SeitenDoing Tire Recycling Plant DY-1-6pyrolysisoilNoch keine Bewertungen

- Condenser of Waste Tires Recycling Pyrolysis Oil Machine of Doing GroupDokument3 SeitenCondenser of Waste Tires Recycling Pyrolysis Oil Machine of Doing GrouppyrolysisoilNoch keine Bewertungen

- Technical Parameter of Doing Waste Tyre Recycling Pyrolysis Oil MachineDokument4 SeitenTechnical Parameter of Doing Waste Tyre Recycling Pyrolysis Oil MachinepyrolysisoilNoch keine Bewertungen

- DY-1-5 Plastic Pyrolysis Plant of Doing GroupDokument3 SeitenDY-1-5 Plastic Pyrolysis Plant of Doing GrouppyrolysisoilNoch keine Bewertungen

- Tire Recycling Machine of Doing GroupDokument2 SeitenTire Recycling Machine of Doing GrouppyrolysisoilNoch keine Bewertungen

- Waste Tyre Pyrolysis Plant of Doing GroupDokument2 SeitenWaste Tyre Pyrolysis Plant of Doing GrouppyrolysisoilNoch keine Bewertungen

- 8T Waste Tyre Recycling Pyrolysis Oil Machine of Doing GroupDokument2 Seiten8T Waste Tyre Recycling Pyrolysis Oil Machine of Doing GrouppyrolysisoilNoch keine Bewertungen

- Oil-Water Separator of Waste Tyre Recycling Pyrolysis Oil Machine of Doing GroupDokument1 SeiteOil-Water Separator of Waste Tyre Recycling Pyrolysis Oil Machine of Doing GrouppyrolysisoilNoch keine Bewertungen

- LPRC EoiDokument12 SeitenLPRC EoiwulwynNoch keine Bewertungen

- Valves PresentationDokument36 SeitenValves PresentationZikireya79100% (1)

- Performance of Centrifugal Pump Mechanic PDFDokument6 SeitenPerformance of Centrifugal Pump Mechanic PDF최승원Noch keine Bewertungen

- IntJHydrogenEnergy v41 P13308to13314Dokument7 SeitenIntJHydrogenEnergy v41 P13308to13314SapphireNoch keine Bewertungen

- Field Operator JobDokument2 SeitenField Operator JobismailchoughuleNoch keine Bewertungen

- Sclairpipe MS r12072011Dokument10 SeitenSclairpipe MS r12072011Daniel Cisterna BilbaoNoch keine Bewertungen

- 49 CFR 180.209 - Requirements For Requalification of Specification CylindersDokument8 Seiten49 CFR 180.209 - Requirements For Requalification of Specification CylindersviktorNoch keine Bewertungen

- Meshing 2Dokument26 SeitenMeshing 2sb aliNoch keine Bewertungen

- SPE84966 StrategyDokument12 SeitenSPE84966 StrategyS Hisham AlkatibNoch keine Bewertungen

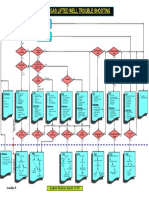

- Attachment-1: Gas Lifted Well Trouble ShootingDokument1 SeiteAttachment-1: Gas Lifted Well Trouble ShootingDaurenNoch keine Bewertungen

- Calibration of Helium Leak Detectors by Use of Secondary StandardsDokument7 SeitenCalibration of Helium Leak Detectors by Use of Secondary StandardsROHITNoch keine Bewertungen

- Condensate & CoolingDokument111 SeitenCondensate & CoolingSantosh KumarNoch keine Bewertungen

- Process Ball Valve Vent Options: E X Ternal and Internal Ball VentsDokument4 SeitenProcess Ball Valve Vent Options: E X Ternal and Internal Ball VentsvelusankarNoch keine Bewertungen

- 19 Troubleshooting: Error MessagesDokument10 Seiten19 Troubleshooting: Error MessagesJedidiah MillerNoch keine Bewertungen

- OTC 15133 Application of Decision Analysis To A Deepwater Well Integrity AssessmentDokument7 SeitenOTC 15133 Application of Decision Analysis To A Deepwater Well Integrity AssessmentMohammedNoch keine Bewertungen

- RMXS-DVM SMDokument479 SeitenRMXS-DVM SMttkohNoch keine Bewertungen

- AABC HVAC Testing SpecsDokument11 SeitenAABC HVAC Testing SpecssreejeshkeralamNoch keine Bewertungen

- Bellows Design GuideDokument8 SeitenBellows Design GuidemehdiNoch keine Bewertungen

- Model 5600SE Downflow Installation InstructionsDokument32 SeitenModel 5600SE Downflow Installation InstructionsWattsNoch keine Bewertungen

- Omniseal Expanding Plug Valve Brochure PDFDokument28 SeitenOmniseal Expanding Plug Valve Brochure PDFMohamadIbnuHassanNoch keine Bewertungen

- GRACO PumpDokument28 SeitenGRACO PumpPrakash SekarNoch keine Bewertungen

- TM 90 21 PDFDokument22 SeitenTM 90 21 PDFJuan MateNoch keine Bewertungen

- Manual PresurizadorDokument12 SeitenManual PresurizadorjulioNoch keine Bewertungen

- 6525 OtcDokument68 Seiten6525 OtcluisNoch keine Bewertungen

- Rev17 Volume2 PDFDokument384 SeitenRev17 Volume2 PDFhjduarteNoch keine Bewertungen