Beruflich Dokumente

Kultur Dokumente

Enhanced Ionic Conductivity in Polymer Electrolytes: Pan-Pegme-Liclo - PC Composite

Hochgeladen von

Deva RajOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Enhanced Ionic Conductivity in Polymer Electrolytes: Pan-Pegme-Liclo - PC Composite

Hochgeladen von

Deva RajCopyright:

Verfügbare Formate

Int. J. Electrochem. Sci.

, 8 (2013) 3834 - 3850

International Journal of

ELECTROCHEMICAL

SCIENCE

www.electrochemsci.org

Enhanced Ionic Conductivity in PANPEGME-LiClO

4

-PC

Composite Polymer Electrolytes

Chung-Wen Kuo

1

, Chao-Wen Huang

1

, Bor-Kuan Chen

2

, Wen-Bin Li

1

, Pin-Rong Chen

3

,

Tsung-Han Ho

1

, Ching-Guey Tseng

1

, Tzi-Yi Wu

3,*

1

Department of Chemical and Materials Engineering, National Kaohsiung University of Applied

Sciences, Kaohsiung 80778, Taiwan

2

Department of Materials Engineering, Kun Shan University, Tainan 71003, Taiwan

3

Department of Chemical and Materials Engineering, National Yunlin University of Science and

Technology, Yunlin 64002, Taiwan, ROC

*

E-mail: wuty@yuntech.edu.tw

Received: 22 January 2013 / Accepted: 11 February 2013 / Published: 1 March 2013

Poly(acrylonitrile) (PAN) and polyethyl glycol methyl ether (PEGME) blended with lithium

perchlorate (LiClO

4

) as dopant salt and propylene carbonate (PC) as plasticizer are prepared in the

form of thin film. Fourier transform infrared studies show the evidence of the complexation between

PAN, PEGME, and LiClO

4

. The maximum conductivity of polymer electrolyte is up to 4.16 mS cm

-1

at 90

o

C by optimizing the composition of the polymers, salts, and plasticizer, and the temperature

dependence of the conductivity of solid polymer electrolyte obeys the VogelTammanFulcher (VTF)

relationship. X-ray diffraction studies are carried out to reveal that the PAN phase changes from

crystalline to amorphous when PEGME concentration increases.

Keywords: Conductivity, polymer electrolytes, Fourier transform infrared spectroscopy, polyethyl

glycol methyl ether

1. INTRODUCTION

Research on polymer electrolytes has been growing since 1973 when Fenton et al. developed

complexes of alkali metal ions with poly (ethylene oxide) (PEO) [1]. The interest in the study of

polymer electrolyte system is due to the potential application of these materials in a great variety of

electrochemical devices such as high energy density batteries, fuel cells, sensors, and electrochromic

devices [2-12]. Generally, there are three types of polymer electrolytes: solid polymer electrolytes

(SPEs), gel polymer electrolytes (GPEs), and composite polymer electrolytes (CPEs) [13-20].

Int. J. Electrochem. Sci., Vol. 8, 2013

3835

In GPEs, polymer matrixes are required for the immobilization of electrolytes. Among the

polymer matrixes that are promising for the application in GPE, polyacrylonitrile (PAN) [21,22],

poly(vinylidene fluoride) (PVDF) [23,24], poly(methyl methacrylate) (PMMA) [25], and

poly(ethylene oxide) (PEO) [26-29] based polymers have been most extensively studied. The use of

poly (acrylonitrile) (PAN) as a host polymer was first reported by Reich and Michaeli [30] and then by

many others [31]. Slane and Salomon [32] studied a composite polymer electrolyte that consisted of

zeolite powders dispersed in PAN-based gels with LiAsF

6

. PAN-based electrolytes showed interesting

characteristics such as high ionic conductivity, high thermal stability, desirable morphology for

electrolyte uptake and compatibility with the lithium electrodes [33]. Moreover, it has been revealed

that CN group in PAN could interact with Li

+

ions and PAN might provide rigidity to the polymer

electrolytes with high lithium ion conduction [34].

The blending of polymers may lead to the increase in stability due to one polymer portraying

itself as a mechanical stiffener and the other as a gelled matrix supported by the other. Monofunctional

polyethylene glycols (methoxypolyethylene glycols, PEGME) can serve as lubricants, foam regulators,

defoaming agents, emulsifiers, thickeners, superabsorbent polymers, stabilizers in emulsion and

suspension polymerization, concrete superplasticizers, and textile auxiliaries [35]. Compared with

poly(ethylene glycol) (PEG), PEGME only has a single free hydroxyl group, and some derivatives

contain a polymerizable group that may allow incorporation of the MPEG group into PAN. Moreover,

the lithium salts (LiAsF

6

, LiClO

4

, LiCF

3

SO

3

, LiBF

4

, and LiN(SO

2

CF

3

)

2

) are added so as to increase

the amorphicity and the introduction of conducting moieties into the matrix. In the present work,

hybrid solid polymer electrolyte films that consist of PAN, MPEG, LiClO

4

, and propylene carbonate

(PC) are examined to overcome the problem inherent to gel electrolytes. The choice of LiClO

4

salt is

due to its smaller dissociation energy, and PANLiClO

4

-based electrolytes have higher

electrochemical stability than any of the other PAN Li

+

salt-based electrolytes [36]. The effect of PAN/

PEGME blend ratio on the ionic conductivity and mechanical stability has been investigated to

optimize the appropriate concentration of plasticizer at which the electrolyte provides both maximum

conductivity and good mechanical stability. The prepared polymer electrolyte films are characterized

by XRD, FTIR, ac impedance, and Instron universal tester for the structural, complexation,

conductivity, and mechanical properties, respectively.

2. EXPERIMENTAL

2.1. Materials

The starting materials polyethyl glycol methyl ether (PEGME) and poly(acrylonitrile) (PAN)

with an average molecular weight of 2,000 and 150,000 obtained from Aldrich were dried at 373K

under vacuum for 10 h. LiClO

4

(Aldrich) was dried at 343K under vacuum for 24 h. Plasticizer

propylene carbonate (PC) (Alfa Aesar) was used without further purification.

Int. J. Electrochem. Sci., Vol. 8, 2013

3836

2.2. Preparation of thin films

Appropriate weight percentage of PEGME, PAN, PC, and LiClO

4

were dissolved in DMF. The

solution was stirred for 24 h at room temperature to obtain a homogenous mixture. The solution was

then poured into a Petri dish and allowed to evaporate slowly inside a hood. This procedure yields

mechanically stable and free standing thin films. The films were dried in a vacuum oven at 333K under

a pressure of 10

3

Torr for 24 h. The resulting films were visually examined for their dryness and free-

standing nature.

2.3. Measurements

FTIR studies were carried by using Perkin-Elmer FTIR Spectrophotometer Spectrum RX1. It

was recorded in the range of 4,000 and 400 cm

1

, with resolution 4 cm

1

. X-ray diffractograms (XRD)

were obtained at room temperature on a Rigaku RINT 2000 instrument, using Ni-filtered Cu Ko

radiation (40 kV, 100 mA). An Instron universal tester model 3369 was used to study the mechanical

properties. The load cell used was 5 kg and the crosshead rate was 5 mm/min. Measurements were

performed with film specimens (1.35 cm wide, 6 cm long, and 50 ~ 60 mm thick). The ionic

conductivity (A) of the gel polymer electrolytes was determined by AC impedance spectroscopy (CHI

627D). The membrane was sandwiched between two parallel stainless steel discs (d = 1 cm). The

frequency ranged from 100 kHz to 10 Hz at a perturbation voltage of 10 mV. The ionic conductivity

was calculated from the electrolyte resistance (R

b

) (obtained from the intercept of the Nyquist plot with

the real axis), the membrane thickness (l), and the electrode area (A) according to the equation:

b

l

R

A

A = (1)

3. RESULTS AND DISCUSSION

3.1. FTIR studies

Infrared spectral (IR) analysis is a powerful tool for identifying the nature of bonding and

different functional groups present in a sample by monitoring the vibrational energy levels of the

molecules, which are essentially the fingerprint of different molecules [37]. Fig. 1 shows the FTIR

spectra of PAN/PEGME/PC (wt. %: 96/4/100) polymer matrix and Fig. 2 shows the FTIR spectra of

polymer electrolytes prepared by blending various concentrations of LiClO

4

with PAN/PEGME/PC

(wt. %: 96/4/100), among them, the most characteristic peaks of the interaction between polymer

electrolytes and lithium salt are contributed to the C=O group of PC, CN group of PAN, and

CH

2

OCH

2

group of PEGME. Fig. 3 shows the FT-IR spectra of C=O group in polymer

electrolytes prepared by blending 0, 150, 200, 250, 300, and 400 mg LiClO

4

with 1 g

PAN/PEGME/PC (wt. %: 96/4/100), the characteristic frequency at 1790 cm

1

is assigned to the

carbonyl stretching of PC in PAN/PEGME/PC electrolyte (wt. %: 96/4/100), the C=O characteristic

Int. J. Electrochem. Sci., Vol. 8, 2013

3837

frequency of the propylene carbonate shifts to 1780 cm

1

gradually after the addition of LiClO

4

,

indicating the interaction of the plasticizer with LiClO

4

on complexation.

4000 3500 3000 2500 2000 1500 1000 500

A

b

s

o

r

b

a

n

c

e

Wavenumber (cm

-1

)

CN

CO

CH

2

OCH

2

Figure 1. The FT-IR spectrum of PAN/PEGME/PC (wt. %: 96/4/100).

4000 3500 3000 2500 2000 1500 1000 500

T

r

a

n

s

i

m

t

t

a

n

c

e

Wavenumber (cm

-1

)

(a)

(b)

(c)

(d)

(e)

(f)

Figure 2. The FT-IR spectra of polymer electrolytes prepared by blending (a) 0, (b) 150, (c) 200, (d)

250, (e) 300, and (f) 400 mg LiClO

4

with 1 g PAN/PEGME/PC (wt. %: 96/4/100).

The CN group stretching spectra of SPEs based on PAN is presented in Fig. 4, the group

frequency at 2242 cm

1

is assigned to CN stretching frequency of neat PAN. After the addition of

LiClO

4

gradually, a new component (at 2270 cm

1

in Li-based PAN) split from the CN stretching

band of free CN at 2242 cm

1

was observed, demonstrating the Li

+

ion coordination with the CN

group of PAN [38]. The relative peak intensity at 2270 cm

1

increases with salt concentration due to an

increase in the number of carrier ion. The characteristic frequency at 2270 cm

1

is not clear in low

Int. J. Electrochem. Sci., Vol. 8, 2013

3838

LiClO

4

concentration, but its obvious in high LiClO

4

concentration, this can be attributed to the

following two factors: (1) the bonding energy of CN group is stronger than C=O group,

accordingly, the CN characteristic peak is not clear, (2) as shown in Fig. 5, several factors influence

the interaction between polymer matrix and lithium salt, such as the interaction between lithium ion

and plasticizer may decrease the bonding opportunity between lithium ion and the CN group of

PAN.

1900 1880 1860 1840 1820 1800 1780 1760 1740 1720 1700

A

b

s

o

r

b

a

n

c

e

Wavenumber (cm

-1

)

(a)

(b)

(c)

(d)

(e)

(f)

Figure 3. The FT-IR spectra of C=O group in polymer electrolytes prepared by blending (a) 0, (b)

150, (c) 200, (d) 250, (e) 300, and (f) 400 mg LiClO

4

with 1 g PAN/PEGME/PC (wt. %:

96/4/100).

2320 2300 2280 2260 2240 2220 2200

A

b

s

o

r

b

a

n

c

e

Wavenumber (cm

-1

)

(f)

(e)

(d)

(c)

(b)

(a)

Figure 4. The FT-IR spectra of CN group in polymer electrolytes prepared by blending (a) 0, (b)

150, (c) 200, (d) 250, (e) 300, and (f) 400 mg LiClO

4

with 1 g PAN/PEGME/PC (wt. %:

96/4/100).

Int. J. Electrochem. Sci., Vol. 8, 2013

3839

Fig. 6 shows the FTIR spectra of PEGME CH

2

OCH

2

group in solid polymer electrolytes

prepared by blending 0, 150, 200, 250, 300, and 400 mg LiClO

4

with 1 g PAN/PEGME/PC (wt. %:

96/4/100). The characteristic frequency of CH

2

OCH

2

group at 1035~1185 cm

-1

increases with the

increasing LiClO

4

concentration, this change is expected because of the well known coordination of

lithium ions to the un-bonded electrons of the ether oxygen [39].

Figure 5. The interaction mechanism of lithium ion, plasticizer, and polymer matrix.

1300 1250 1200 1150 1100 1050 1000 950

A

b

s

o

r

b

a

n

c

e

Wavenumber (cm

-1

)

(a)

(b)

(c)

(d)

(e)

(f)

Figure 6. The FT-IR spectra of CH

2

OCH

2

group in polymer electrolytes prepared by blending (a)

0, (b) 150, (c) 200, (d) 250, (e) 300, and (f) 400 mg LiClO

4

with 1 g PAN/PEGME/PC (wt. %:

96/4/100).

Int. J. Electrochem. Sci., Vol. 8, 2013

3840

The dissociation of lithium salt is an important parameter that determines the ionic conductivity

of the electrolyte, the absorption peak of LiClO

4

can be de-convoluted into two components centered

at 624 and 640 cm

1

, respectively. Among them, the 624 cm

1

band can be attributed to the free ClO

4

and the 640 cm

1

mode is assigned to the ion-pair formation or the contact of ClO

4

with lithium ion

[40]. Fig. 7 shows the FT-IR spectra of ClO

4

in polymer electrolytes prepared by blending 400 mg

LiClO

4

with 1 g PAN/PEGME/PC. Weight percentage of PAN/PEGME/PC is 96/4/100, 90/10/100,

and 80/20/100. The ratio of peak areas (624 cm

1

/640 cm

1

) can be used as an index of the degree of

ionization of the lithium salt in the polymer electrolytes. The dissociation of LiClO

4

increased with the

PEGME content in Fig. 7, indicating that the PEGME segment promoted the dissociation of lithium

salt in electrolytes.

660 650 640 630 620 610 600 590

A

b

s

o

r

b

a

n

c

e

Wavenumber (cm

-1

)

area ratio: 3.26

area ratio: 3.61

area ratio: 4.09

(a)

(b)

(c)

area ratio=(624 cm

-1

)/(640 cm

-1

)

Figure 7. The FT-IR spectra of the ClO

4

in polymer electrolytes prepared by blending 400 mg LiClO

4

with 1 g PAN/PEGME/PC. (a) wt. % of PAN/PEGME/PC is 96/4/100, (b) wt. % of

PAN/PEGME/PC is 90/10/100, and (c) wt. % of PAN/PEGME/PC is 80/20/100.

3.2. Conductivity studies

The ionic conductivity of a polymer electrolyte depends on the concentration of carriers and on

their mobility. Generally, the ionic conductivity of polymer solid electrolytes increase with

temperature due to the higher segmental motion of polymer chain in the amorphous phase. The

investigation of conductivity contain two topics in this study, one studies the conductivity of SPEs by

blending various LiClO

4

concentrations with PAN/PEGME/PC (wt %: 96/4/100), the other one studies

the conductivity of SPEs by blending various polymer concentrations (PAN/PEGME/PC wt %:

96/4/100, 90/10/100, and 80/20/100) with the same LiClO

4

concentration.

The temperature dependence of the ionic conductivity of the polymer electrolytes is generally

following by either an Arrhenius Eq. (2) [41,42] or a VogelTammanFulcher (VTF) Eq. (3) equation

[43-52],

Int. J. Electrochem. Sci., Vol. 8, 2013

3841

a

B

-

[ ]

E

A

k T

o =

(2)

B 0

- '

exp[ ]

( - )

A B

k T T

T

o =

(3)

where A is a constant that is proportional to the number of carrier ions, B is the pseudo-

activation energy for the redistribution of the free volume, k

B

is the Boltzmann constant (1.38 10

-23

J

K

-1

), E

a

is the activation energy, and T

o

is a reference temperature, normally associated with the ideal

T

g

at which the free volume is zero or with the temperature at which the configuration entropy

becomes zero [53].

300 310 320 330 340 350 360 370

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

o

(

m

S

c

m

-

1

)

Temperature (K)

Figure 8. o vs. T plot of polymer electrolytes prepared by blending 150 (), 200 (), 250 (), 300

(), and 400 mg () LiClO

4

with 1 g PAN/PEGME/PC (wt. %: 96/4/100).

Eq. 4 is Eyring equation, a linear relationship is obtained from the plot of

B

ln( )

h

k T

o

vs. 1/T, the

slope is H, and the intercept is S. Accordingly, the Arrhenius active energy (E

a

), entropy (S), and

enthalpy (H) can be estimated from Arrhenius equation and Eyring equation [54-58]:

B

-

ln( )

h H

R S

k T T

o A

= + A

(4)

where h is Planck's constant (6.63 x 10

-34

J s), H is the enthalpy of electrolyte, S is the

entropy of electrolyte.

Int. J. Electrochem. Sci., Vol. 8, 2013

3842

3.2.1 Conductivity of SPEs prepared by blending various LiClO

4

concentrations

with PAN/PEGME/PC (wt %: 96/4/100)

Fig. 8 shows the conductivity vs. temperature plot of polymer electrolytes prepared by blending

150, 200, 250, 300, and 400 mg LiClO

4

with 1 g PAN/PEGME/PC, weight ratio of PAN/PEGME/PC

is 96/4/100, and the conductivity of SPEs is summarized in Table 1. When 1 g PAN/PEGME/PC

blends with 400 mg LiClO

4

, the conductivity of SPEs is up to 3.69 10

-3

S cm

-1

at 90

o

C. Fig. 9 shows

the VTF plot of SPEs ionic conductivity at various temperatures, the observed temperature

dependences of conductivity are well fitted by VogelTammannFulcher (VTF) equation, the VTF

fitting parameters of the ionic conductivity for these SPEs are summarized in Table 2.

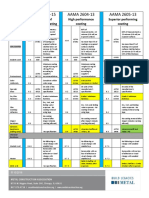

Table 1. Conductivity of polymer electrolytes prepared by blending various LiClO

4

concentrations

with 1 g PAN/PEGME/PC.

T / K

Concentration of LiClO

4

(mg LiClO

4

/ g PAN/PEGME/PC)

150

a

200 250 300 400

303 6.9210

-2

b

1.5510

-1

2.4510

-1

5.9610

-1

1.31

313 1.1510

-1

2.6710

-1

3.8610

-1

8.2310

-1

1.62

323 1.6810

-1

3.9010

-1

4.9210

-1

1.08 1.89

333 2.6310

-1

5.1810

-1

6.6410

-1

1.33 2.36

343 3.4410

-1

6.1910

-1

8.2310

-1

1.45 2.84

353 4.2210

-1

7.3110

-1

9.6410

-1

1.81 3.20

363 4.7810

-1

7.4710

-1

1.02 2.09 3.69

a

The polymer electrolytes is prepared by blending 150 mg LiClO

4

with 1 g

PAN/PEGME/PC, the weight ratio of PAN:PEGME:PC is 96:4:100.

b

The unit of conductivity is mS cm

-1

.

Table 2. VTF parameters of polymer electrolytes prepared by blending various LiClO

4

concentrations

with 1 g PAN/PEGME/PC.

Concentration of LiClO

4

(mg LiClO

4

/ g polymer)

150

a

200 250 300 400

o

/ mS cm

-1

11.21 2.32 4.13 9.06 28.15

T

o

/ K 212.82 264.5 247.23 229.16 181.95

B / KJ mole

-1

458.95 103.83 157.35 200.87 374.21

R

2 b

0.998 0.999 0.998 0.998 0.998

a

The polymer electrolytes is prepared by blending 150 mg LiClO

4

with 1 g

PAN/PEGME/PC, the weight ratio of PAN:PEGME:PC is 96:4:100.

b

Correlation coefficient.

Fig. 10 shows the Arrhenius plot of polymer electrolytes prepared by blending 150, 200, 250,

300, and 400 mg LiClO

4

with 1 g PAN/PEGME/PC (wt%: 96/4/100), the Arrhenius active energy (E

a

),

entropy (S), and enthalpy (H) can be estimated from Arrhenius equation and Eyring equation, and

Int. J. Electrochem. Sci., Vol. 8, 2013

3843

are summarized in Table 3. E

a

, S, and H decreases with increasing concentration of LiClO

4

,

depicting lower E

a

facilitates the lithium ion hopping in polymer backbone.

Table 3. The E

a

, S, and H of polymer electrolytes prepared by blending various LiClO

4

concentrations with 1 g PAN/PEGME/PC.

Concentration of LiClO

4

(mg LiClO

4

/ g polymer)

150

a

200 250 300 400

H / kJ mole

-1

27.33 21.11 19.11 15.77 13.36

S / J mole

-1

K

-1

-176.05 -189.17 -192.58 -196.67 -198.71

E

a

/ kJ mole

-1

30.09 23.86 21.87 18.53 16.12

a

The polymer electrolytes is prepared by blending 150 mg LiClO

4

with 1 g

PAN/PEGME/PC, the weight ratio of PAN:PEGME:PC is 96:4:100.

5 10 15 20 25

-7.0

-6.5

-6.0

-5.5

-5.0

-4.5

-4.0

-3.5

-3.0

-2.5

l

n

(

o

T

1

/

2

)

(

S

c

m

-

1

K

1

/

2

)

1000/T-T

0

(K

-1

)

Figure 9. VTF plot of ionic conductivity for 1 g PAN/PEGME/PC (wt %: 96/4/100) doped with ()

150, () 200, () 250, () 300, and () 400 mg LiClO

4

.

3.2.2 The conductivity of SPEs prepared by blending various polymer concentrations

(PAN/PEGME/PC wt %: 96/4/100, 90/10/100, and 80/20/100) with the same LiClO

4

concentration

Fig. 11 shows the o vs. T plot of polymer electrolytes prepared by blending 400 mg LiClO

4

with 1 g PAN/PEGME/PC, weight ratio of PAN/PEGME/PC is 96/4/100, 90/10/100, and 80/20/100,

and the conductivity of SPEs is summarized in Table 4. SPEs prepared by PAN/PEGME/PC (wt %:

80/20/100) show conductivity of 1.5 10

-3

S cm

-1

at 30

o

C, and 4.16 10

-3

S cm

-1

at 90

o

C, the

conductivity increases with the increasing weight ratio of PEGME, implying the incorporation of

CH

2

OCH

2

group in PEGME facilitates ionic transport of electrolyte. The observed temperature

dependences of conductivity are well fitted by VogelTammannFulcher (VTF) equation, and the VTF

fitting parameters of the ionic conductivity for these SPEs are summarized in Table 5. Fig. 12 shows

Int. J. Electrochem. Sci., Vol. 8, 2013

3844

the Arrhenius plot of polymer electrolytes prepared by blending 400 mg LiClO

4

with 1 g

PAN/PEGME/PC, weight ratio of PAN/PEGME/PC is 96/4/100, 90/10/100, and 80/20/100, the

Arrhenius active energy (E

a

), entropy (S), and enthalpy (H) can be estimated from Arrhenius

equation and Eyring equation, and are summarized in Table 6. E

a

decreases with increasing weight

ratio of PEGME, demonstrating the CH

2

OCH

2

group in PEGME facilitates the lithium ion

hopping in polymer electrolytes.

2.7 2.8 2.9 3.0 3.1 3.2 3.3

-9.5

-9.0

-8.5

-8.0

-7.5

-7.0

-6.5

-6.0

-5.5

l

n

o

(

S

/

c

m

)

1000/T (K

-1

)

Figure 10. Arrhenius plot of ionic conductivity vs. T for polymer electrolytes prepared by blending

() 150, () 200, () 250, () 300, and () 400 mg LiClO

4

with 1 g PAN/PEGME/PC (wt.

%: 96/4/100).

Table 4. Conductivity of polymer electrolytes prepared by blending 400 mg LiClO

4

with 1 g

PAN/PEGME/PC.

T / K

PAN/PEGME (wt. %)

96/4

a

90/10 80/20

303 1.30

b

1.41 1.50

313 1.60 1.74 1.85

323 1.89 2.10 2.20

333 2.36 2.54 2.73

343 2.84 2.91 3.19

353 3.20 3.37 3.75

363 3.69 3.72 4.16

a

The polymer electrolytes is prepared by blending 400 mg LiClO

4

with 1 g

PAN/PEGME/PC, the weight ratio of PAN:PEGME:PC is 96:4:100.

b

The unit of conductivity is mS cm

-1

.

Int. J. Electrochem. Sci., Vol. 8, 2013

3845

Table 5. VTF parameters of polymer electrolytes prepared by blending 400 mg LiClO

4

with 1 g

PAN/PEGME/PC.

T / K

PAN/PEGME (wt. %)

96/4

a

90/10 80/20

o

/ mS cm

-1

28.15 43.14 39.14

T

o

/ K 181.95 154.43 170.11

B / kJ mol

-1

374.21 508.05 434.81

R

2 b

0.998 0.999 0.998

a

The polymer electrolytes is prepared by blending 400 mg LiClO

4

with 1 g

PAN/PEGME/PC, the weight ratio of PAN:PEGME:PC is 96:4:100.

b

Correlation coefficient.

Table 6. The E

a

, S, and H of polymer electrolytes prepared by blending 400 mg LiClO

4

with 1 g

PAN/PEGME/PC.

T / K

PAN/PEGME (wt. %)

96/4

a

90/10 80/20

H / kJ mole

-1

13.36 13.11 12.17

S / J mole

-1

K

-1

-198.71 -198.35 -201.81

E

a

/ kJ mole

-1

16.62 15.85 14.92

a

The polymer electrolytes is prepared by blending 400 mg LiClO

4

with 1 g

PAN/PEGME/PC, the weight ratio of PAN:PEGME:PC is 96:4:100.

300 310 320 330 340 350 360 370

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

o

m

S

/

c

m

)

Temperature (K)

Figure 11. o vs. T plot of polymer electrolytes prepared by blending 400 mg LiClO

4

with 1 g

PAN/PEGME/PC. (a) wt. % of PAN/PEGME/PC is 96/4/100 (), (b) wt. % of

PAN/PEGME/PC is 90/10/100 (), (c) wt. % of PAN/PEGME/PC is 80/20/100 ().

Int. J. Electrochem. Sci., Vol. 8, 2013

3846

2.7 2.8 2.9 3.0 3.1 3.2 3.3

-6.8

-6.6

-6.4

-6.2

-6.0

-5.8

-5.6

-5.4

l

n

o

(

S

/

c

m

)

1000/T (K)

Figure 12. Arrhenius plot of ln o vs. T for polymer electrolytes prepared by blending 400 mg LiClO

4

with 1 g PAN/PEGME/PC. (a) wt. % of PAN/PEGME/PC is 96/4/100 (), (b) wt. % of

PAN/PEGME/PC is 90/10/100 (), (c) wt. % of PAN/PEGME/PC is 80/20/100 ().

3.3. Mechanical properties of PAN/PEGME/PC electrolytes

It is known that the mechanical properties of the SPEs are as important as the ionic

conductivity at room temperature for their practical applications. The stressstrain properties of three

PAN/PEGME/PC electrolytes are summarized in Table 7, which may be used to evaluate the

mechanical properties of corresponding SPEs. The Youngs Modulus of the SPEs follow the order: (wt

% of PAN/PEGME/PC is 96/4/100) > (wt % of PAN/PEGME/PC is 90/10/100) > (wt % of

PAN/PEGME/PC is 80/20/100), SPEs possess higher PAN weight ratio shows higher Youngs

Modulus, whereas SPEs possess higher PEGME weight ratio shows lower Youngs Modulus, this can

be attributed to PEGME is soft matter, incorporate PEGME into PAN decreases the mechanical

properties of SPEs.

Table 7. The mechanical properties of PAN/PEGME/PC electrolytes.

PAN/PEGME/PC

Max of tensile stress

/ MPa

Tensile strain

/ %

Youngs modulus

/ GPa

96/4/100

a

67.15 3.04 3.11

90/10/100 46.82 3.42 2.82

80/20/100 23.19 4.96 1.98

a

The weight ratio of PAN:PEGME:PC is 96:4:100.

Int. J. Electrochem. Sci., Vol. 8, 2013

3847

10 20 30 40 50 60

2u (degree)

(a)

I

n

t

e

n

s

i

t

y

(

a

r

b

.

u

n

i

t

s

)

(b)

(c)

(d)

(e)

Figure 13. XRD pattern of (a) neat PAN, (b) PAN/PEGME (wt %: 96/4), (c) PAN/PEGME (wt %:

90/10), (d) PAN/PEGME (wt %: 80/20), and (e) neat LiClO

4

.

10 20 30 40 50 60

2u (degree)

I

n

t

e

n

s

i

t

y

(

a

r

b

.

u

n

i

t

s

)

(b)

(c)

(a)

Figure 14. XRD pattern of polymer electrolytes prepared by blending 400 mg LiClO

4

with 1 g

PAN/PEGME/PC. (a) wt. % of PAN/PEGME/PC is 96/4/100, (b) wt. % of PAN/PEGME/PC is

90/10/100, (c) wt. % of PAN/PEGME/PC is 80/20/100.

3.4. X-ray diffraction studies

Fig. 13 shows the XRD patterns of SPEs (PAN/PEGME/PC) with various PAN/PEGME

weight ratio compared with neat PAN and LiClO

4

. The XRD pattern of neat PAN (Fig. 13a) shows a

crystalline peak at 2 = 17

o

and it corresponds to orthorhombic PAN (1 1 0) reflection [59-61]. The

XRD pattern of LiClO

4

(Fig. 13e) shows intense peaks at angles 2 = 23.2, 32.99, and 36.58

o

, which

represent the crystalline nature of the salt. As shown in Fig. 13b, 13c, and 13d, the XRD pattern of

SPEs (PAN/PEGME/PC) with various PAN/PEGME weight ratio show the incorporation of PEGME

Int. J. Electrochem. Sci., Vol. 8, 2013

3848

into PAN decrease the crystallinity of PAN electrolyte. Fig. 14 shows the XRD patterns of Li-based

PAN/PEGME/PC, most of the peaks pertaining to LiClO

4

disappeared in the Li-based SPEs

complexes, this indicates the complete dissolution of the LiClO

4

in the polymeric matrix. It is evident

from Fig. 14b and 14c that the amorphous nature is predominant in the Li-based SPEs complexed

system.

4. CONCLUSIONS

PANPEGMELiClO

4

PC blended polymer electrolytes have been prepared by a solvent

casting technique. FTIR and XRD studies revealed the occurrence of complexation between PAN,

PEGME, and LiClO

4

in the composite matrix polymer. Ionic conductivity studies reveal that polymer

electrolyte prepared using 1 g PAN/PEGME/PC (wt. % of PAN/PEGME is 96/4) blends with 400 mg

LiClO

4

has the highest ionic conductivity of 3.69 mS cm

-1

at 90

o

C, whereas polymer electrolyte

prepared using 1 g PAN/PEGME/PC (wt. % of PAN/PEGME is 80/20) blends with 400 mg LiClO

4

has the highest ionic conductivity of 4.16 mS cm

-1

at 90

o

C. The temperature dependence conductivity

of the PANPEGMELiClO

4

PC blended polymer electrolytes obeys the VTF relationship, and the

active energy (E

a

), entropy (S), and enthalpy (H) of polymer electrolytes are estimated. SPEs

possess higher PAN weight ratio shows higher Youngs Modulus, indicating PEGME is soft matter.

ACKNOWLEDGEMENTS

The financial support of this work by the National Science Council of Taiwan under NSC 101-2221-E-

151-058, NSC 99-2218-E-151-003, and NSC101-2218-E-224-002 is gratefully acknowledged.

References

1. D.E. Fenton, J.M. Parker, P.V. Wright, Polymer, 14 (1973) 589.

2. J. Gao, J. Liu, W. Liu, B. Li, Y. Xin, Y. Yin, Z. Zou, Int. J. Electrochem. Sci., 6 (2011) 6115.

3. L.C. Xuan, Y.X. An, W. Fang, L.X. Liao, Y.L. Ma, Z.Y. Ren, G.P. Yin, Int. J. Electrochem. Sci., 6

(2011) 6590.

4. M.S.M. Eldin, M.A. Abu-Saied, A.A. Elzatahry, K.M. El-Khatib, E.A. Hassan, K.M. El-Sabbah,

Int. J. Electrochem. Sci., 6 (2011) 5417.

5. J.H. Kim, S.K. Kim, Y.Z. You, D.I. Kim, S.T. Hong, H.C. Suh, K.S. Weil, Int. J. Electrochem.

Sci., 6 (2011) 4365.

6. A. Anis, S.M. Al-Zahrani, A.K. Banthia, S. Bandyopadhyay, Int. J. Electrochem. Sci., 6 (2011)

2461.

7. A. Anis, S.M. Al-Zahrani, A.K. Banthia, S. Bandyopadhyay, Int. J. Electrochem. Sci., 6 (2011)

2652.

8. W.H. Chen, T.H. Ko, J.H. Lin, C.H. Liu, C.W. Shen, C.H. Wang, Int. J. Electrochem. Sci., 6

(2011) 2192.

9. C.H. Wan, J.M. Wei, M.T. Lin, C.H. Lin, Int. J. Electrochem. Sci., 6 (2011) 889.

10. B.C. Ng, H.Y. Wong, K.W. Chew, Z. Osman, Int. J. Electrochem. Sci., 6 (2011) 4355.

Int. J. Electrochem. Sci., Vol. 8, 2013

3849

11. P.C. Barbosa, M. Fernandes, S.M.F. Vilela, A. Goncalves, M.C. Oliveira, E. Fortunato, M.M.

Silva, M.J. Smith, R. Rego, V.D. Bermudez, Int. J. Electrochem. Sci., 6 (2011) 3355.

12. T.Y. Wu, H.C. Wang, S.G. Su, S.T. Gung, M.W. Lin, C.B. Lin, J. Chin. Chem. Soc., 57 (2010) 44.

13. A.M. Stephan, K.S. Nahm, Polymer, 47 (2006) 5952.

14. J.C. Cruz, V. Baglio, S. Siracusano, V. Antonucci, A.S. Arico, R. Ornelas, L. Ortiz-Frade, G.

Osorio-Monreal, S.M. Duron-Torres, L.G. Arriaga, Int. J. Electrochem. Sci., 6 (2011) 6607.

15. T.Y. Wu, B.K. Chen, L. Hao, Y.C. Lin, H.P. Wang, C.W. Kuo, I.W. Sun, Int. J. Mol. Sci., 12

(2011) 8750.

16. M.R. Johan, L.M. Ting, Int. J. Electrochem. Sci., 6 (2011) 4737.

17. R.C. Agrawal, Y.K. Mahipal, Int. J. Electrochem. Sci., 6 (2011) 867.

18. N.A. Aini, M.Z.A. Yahya, A. Lepit, N.K. Jaafar, M.K. Harun, A.M.M. Ali, Int. J. Electrochem.

Sci., 7 (2012) 8226.

19. H.N. Su, B.J. Bladergroen, S. Pasupathi, V. Linkov, S. Ji, Int. J. Electrochem. Sci., 7 (2012) 4223.

20. S. Siracusano, V. Baglio, M.A. Navarra, S. Panero, V. Antonucci, A.S. Arico, Int. J. Electrochem.

Sci., 7 (2012) 1532.

21. S. Rajendran, R.S. Babu, P. Sivakumar, Ionics, 14 (2008) 149.

22. X.H. Flora, M. Ulaganathan, S. Rajendran, Int. J. Electrochem. Sci., 7 (2012) 7451.

23. M.S. Mohy Eldin, M.A. Abu-Saied, A.A. Elzatahry, K.M. El-Khatib, E.A. Hassan, M.M. El-

Sabbah, Int. J. Electrochem. Sci., 6 (2011) 5417.

24. N. Ataollahi, A. Ahmad, H. Hamzah, M.Y.A. Rahman, N.S. Mohamed, Int. J. Electrochem. Sci., 7

(2012) 6693.

25. K.W. Chew, K.W. Tan, Int. J. Electrochem. Sci., 6 (2011) 5792.

26. S. Ibrahim, M.R. Johan, Int. J. Electrochem. Sci., 6 (2011) 5565.

27. E.M. Fahmi, A. Ahmad, N.N.M. Nazeri, H. Hamzah, H. Razali, M.Y.A. Rahman, Int. J.

Electrochem. Sci., 7 (2012) 5798.

28. S. Ibrahim, M.R. Johan, Int. J. Electrochem. Sci., 7 (2012) 2596.

29. M.R. Johan, S.M.M. Yasin, S. Ibrahim, Int. J. Electrochem. Sci., 7 (2012) 222.

30. S. Reich, I. Michaeli, J. Polym. Sci. Phys. Ed., 13 (1975) 9.

31. C.R. Yang, J.T. Perng, Y.Y. Wang, C.C. Wan, J. Power Sources, 62 (1996) 89.

32. S. Slane, M. Salomon, J. Power Sources, 55 (1975) 7.

33. M.M. Rao, J.S. Liu, W.S. Li, Y. Liang, Y.H. Liao, L.Z. Zhao, J. Power Sources, 189 (2009) 711.

34. A.I. Gopalan, P. Santhosh, K.M. Manesh, J.H. Nho, S.H. Kim, C.G. Hwang, K.P. Lee, J. Memb.

Sci., 325 (2008) 683.

35. K.S. Kazanskii, G. Lapienis, V.I. Kuznetsova, L.K. Pakhomova, V.V. Evreinov, S. Penczek,

Polym. Sci. Ser. A, 42 (2000) 585.

36. H.S. Kim, B.W. Cho, K.S. Yun, H.S. Chun, KIChE, 1 (1995) 49.

37. T. Nagamoto, C. Ichikawa, O. Omoto, J. Electrochem. Soc., 134 (1987) 305.

38. U.-S. Park, Y.-J. Hong, S.M. Oh, Electrochem. Acta, 41 (1996) 849.

39. W.H. Hou, C.Y. Chen, C.C. Wang, Y.H. Huang, Electrochim. Acta, 48 (2003) 679.

40. H.L. Wang, H.M. Kao, M. Digar, T.C. Wen, Macromolecules, 34 (2001) 529.

41. T.Y. Wu, H.C. Wang, S.G. Su, S.T. Gung, M.W. Lin, C.B. Lin, J. Taiwan Inst. Chem. Eng., 41

(2010) 315.

42. T.Y. Wu, S.G. Su, S.T. Gung, M.W. Lin, Y.C. Lin, C.A. Lai, I.W. Sun, Electrochim. Acta, 55

(2010) 4475.

43. T.Y. Wu, B.K. Chen, L. Hao, K.F. Lin, I.W. Sun, J. Taiwan Inst. Chem. Eng., 42 (2011) 914.

44. T.Y. Wu, B.K. Chen, L. Hao, C.W. Kuo, I.W. Sun, J. Taiwan Inst. Chem. Eng., 43 (2012) 313.

45. T.Y. Wu, S.G. Su, S.T. Gung, M.W. Lin, Y.C. Lin, W.C. Ou-Yang, I.W. Sun, C.A. Lai, J. Iran.

Chem. Soc., 8 (2011) 149.

46. T.Y. Wu, I.W. Sun, S.T. Gung, B.K. Chen, H.P. Wang, S.G. Su, J. Taiwan Inst. Chem. Eng., 42

(2011) 874.

Int. J. Electrochem. Sci., Vol. 8, 2013

3850

47. T.Y. Wu, S.G. Su, H.P. Wang, I.W. Sun, Electrochem. Commun., 13 (2011) 237.

48. T.Y. Wu, L. Hao, C.W. Kuo, Y.C. Lin, S.G. Su, P.L. Kuo, I.W. Sun, Int. J. Electrochem. Sci., 7

(2012) 2047.

49. T.Y. Wu, S.G. Su, Y.C. Lin, H.P. Wang, M.W. Lin, S.T. Gung, I.W. Sun, Electrochim. Acta, 56

(2010) 853.

50. T.Y. Wu, B.K. Chen, L. Hao, Y.C. Peng, I.W. Sun, Int. J. Mol. Sci., 12 (2011) 2598.

51. T.Y. Wu, I.W. Sun, S.T. Gung, M.W. Lin, B.K. Chen, H.P. Wang, S.G. Su, J. Taiwan Inst. Chem.

Eng., 42 (2011) 513.

52. T.Y. Wu, I.W. Sun, M.W. Lin, B.K. Chen, C.W. Kuo, H.P. Wang, Y.Y. Chen, S.G. Su, J. Taiwan

Inst. Chem. Eng., 43 (2012) 58.

53. M. Salomon, M. Xu, E.M. Eyring, S. Petrucci, J. Phys. Chem., 98 (1994) 8234.

54. I.W. Sun, Y.C. Lin, B.K. Chen, C.W. Kuo, C.C. Chen, S.G. Su, P.R. Chen, T.Y. Wu, Int. J.

Electrochem. Sci., 7 (2012) 7206.

55. T.Y. Wu, S.G. Su, H.P. Wang, Y.C. Lin, S.T. Gung, M.W. Lin, I.W. Sun, Electrochim. Acta, 56

(2011) 3209.

56. I.W. Sun, H.P. Wang, H. Teng, S.G. Su, Y.C. Lin, C.W. Kuo, P.R. Chen, T.Y. Wu, Int. J.

Electrochem. Sci., 7 (2012) 9748.

57. T.Y. Wu, S.G. Su, K.F. Lin, Y.C. Lin, H.P. Wang, M.W. Lin, S.T. Gung, I.W. Sun, Electrochim.

Acta, 56 (2011) 7278.

58. T.Y. Wu, L. Hao, P.R. Chen, J.W. Liao, Int. J. Electrochem. Sci., 8 (2013) 2606.

59. D. Sawai, M. Miyamoto, T. Kanamoto, M. Ito, J. Polym. Sci. B Polym. Phys., 38 (2000) 2571.

60. Z. Zhang, L. Zhang, S. Wang, W. Chen, Y. Lei, Polymer, 42 (2001) 8315.

61. S. Rajendran, R. Kannan, O. Mahendran, Mater. Lett., 48 (2001) 331.

2013 by ESG (www.electrochemsci.org)

Das könnte Ihnen auch gefallen

- Handbook of Oligo- and PolythiophenesVon EverandHandbook of Oligo- and PolythiophenesDenis FichouNoch keine Bewertungen

- The Feasibility Study of Composite Electrolytes Comprising Thermoplastic Polyurethane and Poly (Ethylene Oxide)Dokument8 SeitenThe Feasibility Study of Composite Electrolytes Comprising Thermoplastic Polyurethane and Poly (Ethylene Oxide)rash4344Noch keine Bewertungen

- Conductive PolymersDokument8 SeitenConductive Polymersliga21Noch keine Bewertungen

- Mechanical Properties and Ionic Conductivity of Gel Polymer Electrolyte Based On Poly (Vinylidene-Fluoride-Co - Hexafluoropropylene)Dokument9 SeitenMechanical Properties and Ionic Conductivity of Gel Polymer Electrolyte Based On Poly (Vinylidene-Fluoride-Co - Hexafluoropropylene)poniceNoch keine Bewertungen

- Role of Preparation Methods On The Structural and DielectricDokument12 SeitenRole of Preparation Methods On The Structural and DielectricAneeka KamalNoch keine Bewertungen

- Polymer Electrolytes ResearchDokument13 SeitenPolymer Electrolytes ResearchclaudjiuNoch keine Bewertungen

- 1 s2.0 S1010603008003717 Main PDFDokument12 Seiten1 s2.0 S1010603008003717 Main PDFMuhammad Faisal AminNoch keine Bewertungen

- 2008 Synthesis, Characterization, and Photovoltaic Properties of Novel Semiconducting Polymers WithDokument8 Seiten2008 Synthesis, Characterization, and Photovoltaic Properties of Novel Semiconducting Polymers WithDoktor transmisionesNoch keine Bewertungen

- Role of Polymer Matrix in Gel ElectrolyteDokument7 SeitenRole of Polymer Matrix in Gel Electrolytehanayuki007Noch keine Bewertungen

- CHOUGULE Et Al (2011) - Synthesis and Characterization of Polypyrrole (Ppy) Thin FilmsDokument5 SeitenCHOUGULE Et Al (2011) - Synthesis and Characterization of Polypyrrole (Ppy) Thin FilmsAdriano SilvaNoch keine Bewertungen

- FTIR Studies of PVC/PMMA Blend Based Polymer Electrolytes: S. Ramesh, Koay Hang Leen, K. Kumutha, A.K. ArofDokument6 SeitenFTIR Studies of PVC/PMMA Blend Based Polymer Electrolytes: S. Ramesh, Koay Hang Leen, K. Kumutha, A.K. Arofhabiba jamilNoch keine Bewertungen

- CPs and Their applications-SCsDokument18 SeitenCPs and Their applications-SCsanamurboyNoch keine Bewertungen

- ELSEVIER 1998 PPy CompositeDokument13 SeitenELSEVIER 1998 PPy CompositeWilliam VianaNoch keine Bewertungen

- J Mat Sci 2011, 46, 6508 Efecto de La Organoarcilla Con Diferentes Modificadores Organicos en Las Propiedades TermoplasticasDokument10 SeitenJ Mat Sci 2011, 46, 6508 Efecto de La Organoarcilla Con Diferentes Modificadores Organicos en Las Propiedades TermoplasticasDavid ContrerasNoch keine Bewertungen

- Photooxidative Degradation of Poly (Alkyl Methacrylate) SDokument11 SeitenPhotooxidative Degradation of Poly (Alkyl Methacrylate) SAli AhmedNoch keine Bewertungen

- A 0230106Dokument6 SeitenA 0230106AJER JOURNALNoch keine Bewertungen

- Effect of Oxide Nanoparticles On Thermal and Mechanical Properties Ofelectrospun Separators For Lithium-Ion BatteriesDokument10 SeitenEffect of Oxide Nanoparticles On Thermal and Mechanical Properties Ofelectrospun Separators For Lithium-Ion BatteriesTamam AbymNoch keine Bewertungen

- High T, Ambipolar, and Near-Infrared Electrochromic Anthraquinone-Based Aramids With Intervalence Charge-Transfer BehaviorDokument9 SeitenHigh T, Ambipolar, and Near-Infrared Electrochromic Anthraquinone-Based Aramids With Intervalence Charge-Transfer BehaviorManthan JainNoch keine Bewertungen

- Topal Et Al. - 2021 - Synthesis and Characterization of 3 - (4-Fluorophenyl) Thieno3,2-Bthiophene and 3,3' - (4 - Fluorophenyl) Dithieno3,2-B2'Dokument12 SeitenTopal Et Al. - 2021 - Synthesis and Characterization of 3 - (4-Fluorophenyl) Thieno3,2-Bthiophene and 3,3' - (4 - Fluorophenyl) Dithieno3,2-B2'Pelin UlukanNoch keine Bewertungen

- Studies On Magnesium Ion Conducting Polymer ElectrolytesDokument9 SeitenStudies On Magnesium Ion Conducting Polymer ElectrolytesRakeshconclaveNoch keine Bewertungen

- Electrospinning of PMMADokument7 SeitenElectrospinning of PMMAvetrixNoch keine Bewertungen

- Tpu PC PDFDokument15 SeitenTpu PC PDFmohammad norooziNoch keine Bewertungen

- 1 s2.0 S0378775310016411 Main PDFDokument7 Seiten1 s2.0 S0378775310016411 Main PDFMuhammad Faisal AminNoch keine Bewertungen

- Blending Thermoplastic Polyurethanes and Poly (Ethylene Oxide) For Composite Electrolytes Via A Mixture Design ApproachDokument13 SeitenBlending Thermoplastic Polyurethanes and Poly (Ethylene Oxide) For Composite Electrolytes Via A Mixture Design ApproachDavid Andres FernandezNoch keine Bewertungen

- Thin Solid Films: Nina Zeilmann, Benedikt Rösner, Andreas Späth, Ute Schmidt, Rainer H. FinkDokument7 SeitenThin Solid Films: Nina Zeilmann, Benedikt Rösner, Andreas Späth, Ute Schmidt, Rainer H. FinkBhabani Sankar SwainNoch keine Bewertungen

- Studies On The Conducting Polymer of 8 - Hydroxy QuinolineDokument12 SeitenStudies On The Conducting Polymer of 8 - Hydroxy QuinolineTJPRC PublicationsNoch keine Bewertungen

- Catalysis Communications: Guangyong Xie, Gongyi Liu, Long Li, Tingcheng Li, Aiqing Zhang, Jiwen FengDokument4 SeitenCatalysis Communications: Guangyong Xie, Gongyi Liu, Long Li, Tingcheng Li, Aiqing Zhang, Jiwen FengyukathejiNoch keine Bewertungen

- Polarographic and Voltammetric Determination of Meso-Tetrakis (4-Sulfonatophenyl) Porphyrin Tetrasodium Salt at Mercury ElectrodesDokument13 SeitenPolarographic and Voltammetric Determination of Meso-Tetrakis (4-Sulfonatophenyl) Porphyrin Tetrasodium Salt at Mercury ElectrodeslorenzoseijoNoch keine Bewertungen

- Alternative Composite Polymer Electrolyte For SSBDokument10 SeitenAlternative Composite Polymer Electrolyte For SSB1DS19CH002 Akash SamantaNoch keine Bewertungen

- Engineering Journal Anticorrosion Behavior of Deposited Nanostructured Polythiophene On Stainless Steel, Carbon Steel, and Aluminum in Sea WaterDokument7 SeitenEngineering Journal Anticorrosion Behavior of Deposited Nanostructured Polythiophene On Stainless Steel, Carbon Steel, and Aluminum in Sea WaterEngineering JournalNoch keine Bewertungen

- 28606-Article Text-113078-1-10-20220823Dokument11 Seiten28606-Article Text-113078-1-10-20220823Amina AshrafNoch keine Bewertungen

- Zou 2021Dokument7 SeitenZou 202112334sohakamNoch keine Bewertungen

- Sun 2006Dokument6 SeitenSun 2006Giacomo AccomandoNoch keine Bewertungen

- International Refereed Journal of Engineering and Science (IRJES)Dokument8 SeitenInternational Refereed Journal of Engineering and Science (IRJES)www.irjes.comNoch keine Bewertungen

- Temperature Dependent Interaction Parameters of Poly (Methyl Methacrylate) Poly (2 Vinyl Pyridine) and Poly (Methyl Methacrylate) Poly (4 Vinyl Pyridine) Pairs 2009 Reactive and Functional PolymersDokument5 SeitenTemperature Dependent Interaction Parameters of Poly (Methyl Methacrylate) Poly (2 Vinyl Pyridine) and Poly (Methyl Methacrylate) Poly (4 Vinyl Pyridine) Pairs 2009 Reactive and Functional PolymersAtul ChaudhariNoch keine Bewertungen

- Derivatization of Bichromic Cyclometalated Ru (II) Complexes With Hydrophobic SubstituentsDokument7 SeitenDerivatization of Bichromic Cyclometalated Ru (II) Complexes With Hydrophobic SubstituentsJorge Sebastian Alegre LeytonNoch keine Bewertungen

- Poly Pyrole - DDokument2 SeitenPoly Pyrole - DHamedNahavandiNoch keine Bewertungen

- 10 1002@pola 21485Dokument10 Seiten10 1002@pola 21485tigharaNoch keine Bewertungen

- Author's Accepted Manuscript: Journal of Solid State ChemistryDokument23 SeitenAuthor's Accepted Manuscript: Journal of Solid State ChemistryCamilaBurgosNoch keine Bewertungen

- UNIT 4 PolymersDokument54 SeitenUNIT 4 PolymersSarita SharmaNoch keine Bewertungen

- 805836Dokument7 Seiten805836Deva RajNoch keine Bewertungen

- Novel Soluble and Thermally-Stable Fullerene Dyad Containing Perylene (Dokument5 SeitenNovel Soluble and Thermally-Stable Fullerene Dyad Containing Perylene (Lodrick WangatiaNoch keine Bewertungen

- Peo/Pvdf-Based Gel Polymer Electrolyte by Incorporating Nano-Tio For Electrochromic GlassDokument9 SeitenPeo/Pvdf-Based Gel Polymer Electrolyte by Incorporating Nano-Tio For Electrochromic Glassvinay krNoch keine Bewertungen

- 1 FTPDokument14 Seiten1 FTPvsiNoch keine Bewertungen

- Study The Mechanical and Thermal Properties of Biodegradable Polylactic Acid/poly Ethylene Glycol NanocompositesDokument6 SeitenStudy The Mechanical and Thermal Properties of Biodegradable Polylactic Acid/poly Ethylene Glycol NanocompositesInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Inspired by Placoid Scale To Fabricate MXene Derivative BiomimeticDokument13 SeitenInspired by Placoid Scale To Fabricate MXene Derivative BiomimeticHiran ChathurangaNoch keine Bewertungen

- 04 Chapter 1.unlockedDokument58 Seiten04 Chapter 1.unlockedideepujNoch keine Bewertungen

- Effect of Lithium Salt On The Structural and Thermal Behavior of PMMAPEOPVAc Blended CompositesDokument5 SeitenEffect of Lithium Salt On The Structural and Thermal Behavior of PMMAPEOPVAc Blended CompositesGul FamNoch keine Bewertungen

- Photolysis Study by FtirDokument8 SeitenPhotolysis Study by FtirrakibhossainNoch keine Bewertungen

- Mechanical and Swelling Properties of HydrogelDokument77 SeitenMechanical and Swelling Properties of HydrogelThinh Nguyen TienNoch keine Bewertungen

- Conformational Energy From The Oxidation Kinetics of Poly (3,4-Ethylenedioxythiophene) FilmsDokument8 SeitenConformational Energy From The Oxidation Kinetics of Poly (3,4-Ethylenedioxythiophene) FilmsaneicouboiNoch keine Bewertungen

- Essay 01Dokument10 SeitenEssay 01maedeh.216.froNoch keine Bewertungen

- Pani Pmma NanoDokument4 SeitenPani Pmma NanoRanjana SinghNoch keine Bewertungen

- Electrochimica Acta 52 (2006) 1398-1408 (Verificar A Referncia) PDFDokument11 SeitenElectrochimica Acta 52 (2006) 1398-1408 (Verificar A Referncia) PDFElisangelaCordeiroNoch keine Bewertungen

- InTech-Preparation and Characterization of PVDF Pmma Graphene Polymer Blend Nanocomposites by Using Atr Ftir TechniqueDokument21 SeitenInTech-Preparation and Characterization of PVDF Pmma Graphene Polymer Blend Nanocomposites by Using Atr Ftir TechniqueSreenu Vasan RajaNoch keine Bewertungen

- Analytical Applications of Conducting PolymersDokument17 SeitenAnalytical Applications of Conducting PolymersNikola Obradovic100% (1)

- Polythiophene: From Fundamental Perspectives To ApplicationsDokument36 SeitenPolythiophene: From Fundamental Perspectives To ApplicationsMarius MurgociNoch keine Bewertungen

- A Thermoplastic Gel Electrolyte For Stable Quasi-Solid-StateDye-Sensitized Solar CellsDokument8 SeitenA Thermoplastic Gel Electrolyte For Stable Quasi-Solid-StateDye-Sensitized Solar CellsKazmirNoch keine Bewertungen

- 1 s2.0 S0969806X21005181 MainDokument9 Seiten1 s2.0 S0969806X21005181 MainJessica GattiNoch keine Bewertungen

- Oxygen Permeation Studies On Alternative PDFDokument15 SeitenOxygen Permeation Studies On Alternative PDFIrina PetreanuNoch keine Bewertungen

- Chapter-16 Chemistry in Everyday LifeDokument9 SeitenChapter-16 Chemistry in Everyday LifeDeva RajNoch keine Bewertungen

- 34 ch15 PDFDokument8 Seiten34 ch15 PDFDeva RajNoch keine Bewertungen

- 6TH SEM MechsyllDokument38 Seiten6TH SEM MechsyllAnonymous SLKWYHBoNoch keine Bewertungen

- Between Aldehyde and Ketones Which One Is Confirmed Using Fehling's Solution.. 1Dokument7 SeitenBetween Aldehyde and Ketones Which One Is Confirmed Using Fehling's Solution.. 1Deva RajNoch keine Bewertungen

- Unit 13-Nitrogen Containing Organic CompoundsDokument5 SeitenUnit 13-Nitrogen Containing Organic CompoundsDeva RajNoch keine Bewertungen

- UNIT 9 Topic: Coordination CompoundsDokument9 SeitenUNIT 9 Topic: Coordination CompoundsDeva RajNoch keine Bewertungen

- Unit 11. Alcohols, Phenols and Ethers One Mark Questions: Ans: EthanolDokument10 SeitenUnit 11. Alcohols, Phenols and Ethers One Mark Questions: Ans: EthanolDeva RajNoch keine Bewertungen

- Induction Sintering of %3 Cu Contented Iron Based Powder Metal PartsDokument8 SeitenInduction Sintering of %3 Cu Contented Iron Based Powder Metal PartsDeva RajNoch keine Bewertungen

- Unit 8 The D-And F - Block Elements I. Answer The Following Questions. Each Question Carries One MarkDokument9 SeitenUnit 8 The D-And F - Block Elements I. Answer The Following Questions. Each Question Carries One MarkDeva RajNoch keine Bewertungen

- 34 ch10 PDFDokument13 Seiten34 ch10 PDFDeva Raj100% (1)

- Jobber XLDokument4 SeitenJobber XLDeva RajNoch keine Bewertungen

- Jobber JRDokument2 SeitenJobber JRDeva RajNoch keine Bewertungen

- Me 266 Solid Mechanics Laboratory Virtual Tensile Test Tutorial 1 Problem DescriptionDokument9 SeitenMe 266 Solid Mechanics Laboratory Virtual Tensile Test Tutorial 1 Problem DescriptionDeva RajNoch keine Bewertungen

- Prediction of Elastic Properties For Polymer-Particle Nanocomposites Exhibiting An InterphaseDokument8 SeitenPrediction of Elastic Properties For Polymer-Particle Nanocomposites Exhibiting An InterphaseDeva RajNoch keine Bewertungen

- 805836Dokument7 Seiten805836Deva RajNoch keine Bewertungen

- Preparation of Biodegradable Crosslinking Agents and Application in PVP HydrogelDokument0 SeitenPreparation of Biodegradable Crosslinking Agents and Application in PVP HydrogelDeva RajNoch keine Bewertungen

- Formation of Zno Within Flexible Polymer FibersDokument4 SeitenFormation of Zno Within Flexible Polymer FibersDeva RajNoch keine Bewertungen

- ME 266 Solid Mechanics Laboratory Virtual Hardness Test TutorialDokument6 SeitenME 266 Solid Mechanics Laboratory Virtual Hardness Test TutorialDeva RajNoch keine Bewertungen

- Ac 2008-1447: Undergraduate Materials Research: Tensile Impact Toughness of PolymersDokument10 SeitenAc 2008-1447: Undergraduate Materials Research: Tensile Impact Toughness of PolymersDeva RajNoch keine Bewertungen

- 4 Vector Slide PDFDokument27 Seiten4 Vector Slide PDFNasibhaNoch keine Bewertungen

- Duncan-Chang Hyperbolic ModelDokument5 SeitenDuncan-Chang Hyperbolic ModelAntariksa Prianggara100% (2)

- Comet Mystery Boxes: Educator GuideDokument4 SeitenComet Mystery Boxes: Educator GuideABD00LNoch keine Bewertungen

- Measurements of Dynamic Friction Between Rock andDokument54 SeitenMeasurements of Dynamic Friction Between Rock andLuiz Francisco MacedoNoch keine Bewertungen

- CP 2Dokument1 SeiteCP 2shameer bashaNoch keine Bewertungen

- Composite Lecture 2Dokument28 SeitenComposite Lecture 2Nuelcy LubbockNoch keine Bewertungen

- Computer Vision Three-Dimensional Data From ImagesDokument12 SeitenComputer Vision Three-Dimensional Data From ImagesminhtrieudoddtNoch keine Bewertungen

- Cathedrals of Science - The Personalities and Rivalries That Made Modern ChemistryDokument400 SeitenCathedrals of Science - The Personalities and Rivalries That Made Modern ChemistryPushkar Pandit100% (1)

- 14.4D ExerciseDokument18 Seiten14.4D ExerciseKnyazev DanilNoch keine Bewertungen

- Stability of Tapered and Stepped Steel Columns With Initial ImperfectionsDokument10 SeitenStability of Tapered and Stepped Steel Columns With Initial ImperfectionskarpagajothimuruganNoch keine Bewertungen

- By Dr. Gamal Helmy, PH.D., P.EDokument43 SeitenBy Dr. Gamal Helmy, PH.D., P.EAhmed ArafaNoch keine Bewertungen

- Part I: Multiple Choice: Physisc 82 - 1 Semester AY '16 - 17Dokument4 SeitenPart I: Multiple Choice: Physisc 82 - 1 Semester AY '16 - 17deusleanNoch keine Bewertungen

- Tos Grade 10Dokument1 SeiteTos Grade 10Zechnas Ma Ria LouNoch keine Bewertungen

- Guia Procedimiento Inspeccion MFL PDFDokument6 SeitenGuia Procedimiento Inspeccion MFL PDFleonciomavarezNoch keine Bewertungen

- Handwheel To Road Wheel 730039V001Dokument79 SeitenHandwheel To Road Wheel 730039V001Dinesh Maheshwari100% (1)

- Resistance Vs Temperature Experiment Lab ReportDokument7 SeitenResistance Vs Temperature Experiment Lab ReportEmily Gatlin67% (3)

- Mathcad FormulasDokument2 SeitenMathcad FormulasRicardo O. Casimiro Jr.Noch keine Bewertungen

- The Mechanism of The Leuckart Reaction PDFDokument12 SeitenThe Mechanism of The Leuckart Reaction PDFatomoscoNoch keine Bewertungen

- 0625 m18 Ms 62Dokument7 Seiten0625 m18 Ms 62Syed AshabNoch keine Bewertungen

- Shigley Mechanical Engineering Design SODokument182 SeitenShigley Mechanical Engineering Design SOAtidech Tepputorn100% (1)

- Hdpe Pipe Design PDFDokument27 SeitenHdpe Pipe Design PDFAshley Dillon TothNoch keine Bewertungen

- Interpolation and The Lagrange PolynomialDokument9 SeitenInterpolation and The Lagrange PolynomialEmmanuel Jerome TagaroNoch keine Bewertungen

- Chemistry MSCDokument17 SeitenChemistry MSCRajesh ShahiNoch keine Bewertungen

- Using BRDF For Radiance and Luminance CalculationDokument8 SeitenUsing BRDF For Radiance and Luminance CalculationChiara FerrariNoch keine Bewertungen

- GRP Specification BY CKDokument44 SeitenGRP Specification BY CKchandana kumar100% (2)

- CHM510 - SpeDokument7 SeitenCHM510 - SpeafifiNoch keine Bewertungen

- Class 12 - PhysicsDokument222 SeitenClass 12 - PhysicsviddusagarNoch keine Bewertungen

- U0/U U Is The Power Frequency Voltage Between Phase and Earth (V RMS)Dokument3 SeitenU0/U U Is The Power Frequency Voltage Between Phase and Earth (V RMS)ShashidharNoch keine Bewertungen

- Torsion of Reinforced Concrete MembersDokument34 SeitenTorsion of Reinforced Concrete Membersprabhu8150% (2)