Beruflich Dokumente

Kultur Dokumente

CPFR Value by Yossi

Hochgeladen von

Saurabh JainCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CPFR Value by Yossi

Hochgeladen von

Saurabh JainCopyright:

Verfügbare Formate

The value of CPFR

Yossi Sheffi Professor, Engineering Systems Division Professor, Civil and Environmental Engineering Department Director, Center for Transportation and Logistics MIT USA

RIRL Conference Proceedings Lisbon. Portugal, October 13 -16, 2002

(Submitted: Jan 2002; in revised form: March 2002, in revised form: May 2002)

Abstract The last several year has witnessed an explosion of interest in business collaboration. This paper looks at the latest form: collaborative planning forecasting and replenishment (CPFR). It looks at the possible benefits of business collaboration based on several pilot projects and pro-forma analysis and describes in some detail a case study, focusing on the mechanics of the CPFR process and its benefits.

The value of CPFR

Yossi Sheffi

1. Introduction One can classify inventory into two types: process time inventory and decoupling inventory. Process time inventory is carried during the time that the inventory undergoes another process, such as manufacturing (work-in-process inventory) or transportation (in-transit inventory). This inventory can be reduced only if the underlying process is sped up. The amount of time that material and goods spends in process inventory is typically dwarfed, however, by the time it is spending in decoupling inventory, in-between processes. That inventory is the subject of most of the work in logistics and supply chain management. Decoupling inventory ensures that the process that feeds it and the process that it feeds work at their peak efficiency. It is also the inventory that is stationary and it adds no value to the enterprise, aside from its enabling role regarding the processes around it. Decoupling inventory results from consideration of lot sizing, anticipation, and safety stock. The focus of this paper is on decoupling inventory and in particular on safety stock. The main problem facing retailers is out-of-stock (OOS) situation, which could, of course be remedied by extra safety stock, but the carrying cost of such inventories is prohibitive. Another possible remedy for OOS is better forecasting. Statistical forecasting, however, is fundamentally limited in predicting the future in an environment where the underlying buying behavior may change due to promotions, competitive product introductions, market entry and exit of retail chain, etc.

It has been long recognized that one of the most efficient methods for improving forecast accuracy and increasing service, while reducing costs, is better collaboration between trading partners. To this end, many supply chain partners have devised interenterprise collaboration processes to move the information to where it can add value and better coordinate supply chains. The paper is organized as follows: the next section (No. 2) reviews some of these efforts to introduce collaboration processes and evaluates them. Section 3 then looks at the current collaborative Planning Forecasting and Replenishment (CPFR) process. Section 4 reports on the results of several CPFR demonstration projects and looks at the expected results from implementing CPFR across the consumer packaged goods industry and at a model manufacturer. Section 5 looks at a more detailed case study and Section 6 concludes the paper. 2. 1990-s Collaboration Efforts The 1990-s saw an explosion of collaboration attempts. Dixon and Porter (1994) describe JIT II, a process initiated by BOSE, the audio system manufacturer. Under JIT II, BOSE brought key suppliers in-house and gave them authority to function as an integral part of the BOSE material and purchasing systems. The process replaced traditional buyers, planners, and salespeople with in-plant supplier personnel, thereby freeing up buyers' time to conduct value added activities. At the same time it gave the in-plant supplier representatives a better understanding of their customers changing needs. Many leading companies adopted the process on a small scale but it never caught on across whole industries, since many companies were not ready to make the long-term commitment to their suppliers and engage in the openness required for the JIT II process to work. The Efficient Consumer Response (ECR) movement began by the grocery industry in the US in 1993 and continued in Europe, where, as Bhulhi (1997) reports in his overview of ECR, the ECR Board (1995) defined the mission of the process as "working

together to fulfill consumer wishes better, faster and at less cost." As described by King and Phumpier (1996), ECR focused on category management (enhancing the effectiveness of the demand creation and satisfaction process through better promotions, new product introductions and store assortment); product replenishment with high consumer service and low inventories; and the development of enabling technologies. Continuous Replenishment Programs (CRP) have been frequently cited as key processes in the quest toward ECR implementation. Yet CRP implementation, rife with challenges, requires the management of new and more abundant sources of information and an understanding of the unique rules of engagement associated with each new relationship established among trading partners. In fact, Brown and Bukovinski (2001) claim (albeit tentatively) that most ECR adopters did not exhibit the positive results suggested by ECR proponents. In response to strong offshore competition, the American apparel industry in the early 1990-s started to formulate the set of initiatives known as Quick Response (QR). The QR leadership committee (1994) commissioned by the apparel industry defined the QR process goal to continually meet changing requirements of a competitive market place which promotes responsiveness to consumer demand, encourages business partnerships, makes effective use of resources and shortens the business cycle throughout the chain from raw materials to consumer. Both of the ECR and QR initiatives were slowly adopted across the respective industries that spawned them. They did help change attitudes and create the realization that companies must look beyond their own boundaries to achieve high level of customer service and low costs. The collaborative aspect of these processes, however, were never implemented as originally envisioned on a large scale, mainly due to the cultural difficulties associated with collaborative management and the lack of scaleable software.

Another approach for mitigating the communications problems between retailers and their suppliers is to let the vendor manage the retailers inventory1. In its purest form, vendors get information on sales and inventory levels and are committed to keep a certain level of service. This allows manufacturers to control the entire cycle of sales and order forecasts, order placement and replenishment. It also allows them to pull the forecasting risk across all their customers (see, for example, Bernstein, 1997). Retailers, naturally, enjoy lower inventory carrying costs since the suppliers carry the product until it is sold. In reality most VMI programs cover only the retailers distribution centers and not the stores. Many VMI programs have been discontinued since retailers were not satisfied with the lack of collaboration with their suppliers as well as with the forecasting ability of the suppliers, which led to low level of service. Thus, many of them turned into Co-Managed Inventory (CMI) or Joint-Managed Inventory (JMI) processes. These include a more detailed business process, which is mapped out front, and an explicit involvement of both sides in the sales and order forecasting and in the process of generating the replenishment orders.2 3. Collaborative Planning Forecasting and Replenishment All the initiatives mentioned in the last section are aimed at coupling supply chain more tightly by allowing for better forecasting and planning through information sharing, leading to synchronized channels. In other words, if suppliers have better visibility into the retailers sales forecast they can plan their operation better and if they have better visibility into the retailers order forecast they can plan their replenishment better. By the same token, retailers can lower the frequency of their OOS conditions and mitigate their consequences by getting continuous information about the replenishment status.

This is referred to as VMI Vendor-Managed-Inventory. In 1998 1999 Kmart went from 300 VMI relationships to less than 50 CMI relationships. While requiring more intensive effort, these relationships provided the collaborative benefits which Kmart sought.

2

While some of these initiatives were adopted more widely than others, clearly they all contributed to the recognition, by leading retail and manufacturing participants, of the need for cooperative information exchange. Many of the expected benefits of these ideas failed to materialize since trading partners could not work with enough partners for the collaboration to scale, and thus none of these initiatives developed a critical mass of participants. Consequently no partner could experience better forecasting of either sales or orders on a scale that would impact the bottom line. A significant part of the problem had to do with the EDI technology, which was the cornerstone of all the collaboration initiatives mentioned above. Verity (1996) reported in Business Week that Wal-Mart and Warner Lambert attained significant improvements of in-stock positions while reducing inventory through collaborative planning, forecasting, and replenishment (CFAR, now called CPFR). The VICS (Voluntary Inter-industry Commerce Standards) committee3 then followed with the development and publication, in January 1998 of the draft CPFR guidelines. Under CPFR, both trading partners develop a joint business plan, which includes a promotion calendar. The retailer and manufacturer agree on a joint sales forecast and a joint order forecast.4 The joint sales forecast can drive production scheduling, distribution planning, and store activity planning. Any changes from any of the forecasts, beyond an agreed-upon threshold are defined as exceptions, which generate collaborative actions by both parties to re-align the planning for the channel. Order forecasts are also checked for exceptions and then realigned to generate the actual replenishment orders. All the steps mentioned above, starting with a business plan and ending with replenishment, were codified by the VICS (2001) committee is a nine-step process.

Creators of bar code and EDI standards in general merchandise Order forecasts account for retailer-generated adjustments due to changes in assortments, store availability, competitive products, etc.

4

One of the main differences between CPFR and other collaborative arrangements is that under CPFR, both parties are informed of exceptions, which generate the collaborative activities aimed at resolving these exceptions. A second difference is the reliance on the exception engine to be able to point out discrepancies, when operating at scale in other words with a large number of stores and many stock keeping units. Figure 1 portrays an example of a graphical depiction of an exception.

Figure 1. Graphical Depiction of Exception (from Syncra) )Systems)

Modern exception algorithms used by advanced CPFR software can compare any two data streams and generate exceptions. Furthermore, these exceptions can be for data aggregates (like a sales forecast for a family of SKU-s or a group of stores), thus increasing substantially the value of the process and the software. 4. Value of CPFR There have been many reports on the benefits of CPFR. The CPFR documents available on the VICS Committee site5 describe the results of several pilot projects6.

5

www.cpfr.org

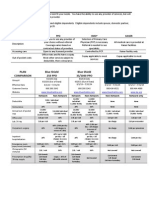

These projects achieved 30% - 40% improvements in forecast accuracy, significant increases in customer service, sales increase between 15% and 60%, and reductions in days of supply of 15% - 20%. (See also Ireland and Bruce, 2000.) AMR Research (2001) reported on the range of results actually achieved by many early adopters of CPFR. Their report is summarized in Table 1. Retailer Benefits Better Store Shelf Stock Rates Lower Inventory Levels Higher Sales Lower Logistics Costs Manufacturer Benefits Lower Inventory Levels Faster Replenishment Cycles Higher Sales Better Customer Service Table 1. Typical CPFR Benefits A study of a leading consulting firm with a leading consumer goods manufacturer catalogued every relevant process that the manufacturer was involved in to see how it would benefit from the adoption of CPFR. The manufacturer has approximately $10B in revenue, $3.6B in COGS and $4.1B in SG&A. Assuming 40% retailer adoption in the third year of the implementation, affecting 30% of single category initiatives and 50% of multi category initiatives, the study concluded that the effects would be as shown in Table 2. Typical Improvement 2% to 8% 10% to 40% 5% to 20% 3% to 4% Typical Improvement 10% to 40% 12% to 30% 2% to 10% 5% to 10%

The pilot projects include Wegmans and Nabisco; Kmart and Kimberly-Clark; Wal-Mart and Sara Lee; and Procter and gamble with five retailers (Target, Tesco, Meijer, Sainsburys and Wal-Mart).

Area 1 2 3 4 5 6 7 8 9 O/B Transportation Unauthorized deductions Slotting fees WIP Inventory Finished goods inventory Obsolescence & Write-offs Out of Stock conditions Effective trade promotions Smarter assortment of goods

Area SG&A SG&A SG&A W. Cap. W. Cap. COGS Revenue Revenue Revenue

Now

Potential

4.0% 0.50% - 2.50% 1.0% 0.00% - 0.50% 1.0% 0.00% - 0.15% 2.1% 0.11% - 0.13% 8.8% 0.44% - 0.66% 0.5% 0.10% - 0.25% 5.0% 1.25% - 2.50% 0.25% - 1.00% 0.25% - 1.00%

10 Speed to maturity of new products Revenue 10.00% 2.50% - 5.00% 11 Raw material & overtime COGS 36.40% 1.82% - 3.64%

Table 2. Financial Impact of CPFR on a $10B Manufacturer Thus, this manufacturer may see a cost reduction of 3% - 7.8% and revenue increases of 1.75% - 4.5%, not accounting for speeding the introduction and ramping up the volume of new products.

5. Superdrug Case Study On December 2001 Superdrug reported in a web seminar on their CPFR pilot with Johnson and Johnson (J&J), powered by Syncra Systems exception engine. Superdrug operates more than 700 stores throughout the United Kingdom, offering its customers an average of more than 6,000 product lines. It came to CPFR with the goal of to trimming inventory so that it would more closely match sales. In addition, Superdrug wanted to improve forecast accuracy and looked forward to an improved relationship with their trading partnerin this pilots case, J&J. Superdrug chose J&J

not only due to compatibility of systems, people and strategy, but most importantly, due to the similar culture of the two companies. Before launching the pilot, Superdrug developed a clear blueprint of the trading partners roles and responsibilities to make sure that their own strategy and structure were aligned with the CPFR process. They also developed a detailed plan to capture both the benefits and the costs of the pilot. Superdrug began the pilot process in April 2000 and by May 2000 the front-end agreement and joint business plan were agreed to and signed between the two companies. In August 2000 Superdrug and J&J started collaborating. Superdrug compared their sales forecast to J&Js order forecast. They also collaborated on the order forecast against the actual order that was received. The collaboration process developed its own rhythm week by week. The first steps during the week was for the IT department to capture all the information at either Superdrug or J&J, compose the file, validate the data and send it through to Syncra typically on a Sunday evening. Syncras processing engine crunched through the data and returned the exceptions. Personnel in the replenishment and supply chain departments at both Superdrug and J&J reviewed the information and prepared for a Wednesday conference call. During this call, decisions were reached as to which partner would adjust their forecast number and by how muchall with the ultimate goal of achieving one sales forecast. On Friday the CPFR pilot project manager at Superdrug would review the forecast and see that the necessary changes were made in Superdrugs forecasting systems. By the weekend, the IT department could update all the new information and the process would begin again.

10

The results can be divided into soft, subjective benefits and hard numbers. The subjective benefits included: Many problems were avoided since Superdrug was able to highlight future issues and resolve them with their trading partner. CPFR also gave Superdrug access for the first time to a range of previously unavailable data such as suppliers sales and order forecasts. Superdrug also found that communications were improved with their supplier through the weekly conference call, which resulted in J&Js profile within Superdrug being raised, and conversely, Superdrugs profile was raised within J&J. The measurable results are as follows:

13 percent average reduction in Stock, at Superdrugs distribution centers, for the lines that were collaborated on. Warehouse availability increased by 1.6 percent. Superdrugs forecast accuracy, which they thought was good before the trial began, saw an improvement of 21 percent. Superdrug also saw RDC cover (Present Stock On Hand/Last Weeks Sales) reduced by 23 percent for those J&Js product lines that were subject to CPFR. Moreover, RDC cover during the pilot period increased by 11.8% for those product lines not subject to CPFR.

Superdrug judged the pilot to be a success. It is now adding all of J&Js SKUs to the CPFR program and adding at two additional suppliers. They are also planning to start collaboration in other areas, particularly new product introductions and post-promotion analysis. The critical success factors for them were: Careful selection of trading partner Having a joint front-end agreement to refer back to when the project got off track

11

Selecting the right people within both organizations to work on the project making sure they all believe in the project and want to see the results.

5. Conclusions CPFR is the latest in an array of collaborative schemes aimed at better coordinating supply chain, thereby squeezing out decoupling inventory from the system. The roots of CPFR can be traced to the ECR and VMI/CMI initiatives. Unlike these initiatives, however, CPFR was designed as a balanced collaborative approach where all forecasts and exception are communicated to both retailers and manufacturers and the collaborative process of solving these exceptions is carefully laid out. It is also supported by much more robust software in particularly, strong exception engines that can deal with a very large number of retail selling points, vendors, and SKU-s, as well as various aggregations of these data. As one contemplates the future of collaboration, several trends are emerging: Companies are accelerating their collaborative relationships whether CPFR, Just-in-Time, ECR, CMI, or many other initiatives companies are getting on board CPFR is gathering momentum. Ireland and Bruce (2000) report that The Sport Authority is rolling CPFR with all its suppliers and many more companies have announced CPFR pilots. Companies are finding new and innovative ways to collaborate. For example, Procter and Gamble has implemented CPFR not only with some of its retail customers, but also with its suppliers, and even inside the company, between functions and divisions. While this paper focuses on the promise of CPFR, one has to remember that as one of the latest trends in supply chain management, consultants and software vendors are touting CPFR as the next silver bullet. This paper shows that CPFR is a continuation of many collaborative business trends. As such, it will be only as successful as the

12

underlying desire to actually collaborate and the incentive system that drives behavior in the collaborating partners. While CPFR may be supported by more robust software than earlier collaborative movements, it still requires a significant dedication of effort on the part of the collaborating partners, and while companies may be able to have more CPFR relationships than CMI, such relationships will still be reserved for their top vendors and customers. There are many parts of the supply chain and related enterprise activities, which are not covered by CPFR. These include the following: Demand management including collaborative merchandising, category management, promotional planning and even collaborative space management (in the stores and the distributing centers). On the manufacturer side, collaborative product design and new product introductions are already taking place in leading companies. As Ireland and Bruce (2000) comment, such complete collaborative merchandising plans can lead to even better forecasts since it looks at causal factors beyond random demand fluctuations. Fulfillment CPFR does not extend to many of the other parties involved in the fulfillment process. For example, transportation carriers, forwarders, public warehouse operators, are not yet part of any standard collaborative process. Interestingly, the VICS committee is developing guidelines for Collaborative Transportation Management (CTM) to start and address this deficiency. Joint optimization collaborative relationships allow enterprises to start optimizing operations outside the walls of the enterprise and across entire supply chains. Todays collaborative efforts are laying the foundation of trust and joint business processes that will enable future supply chain optimization. Real time collaboration most of the processes in use, in testing, and in development focus on planning activities. Many of the problems, however, arise in real time while the product is moving and the unexpected happens. Clearly, better planning and forecasting will yield a smaller number of real time discrepancies -- but processes for collaborative problem solving in real time,

13

based on data from visibility tools, can help retailers avoid stock-outs and manufacturers avoid plant stoppages. 6. Bibliography AMR Research (2001) Beyond CPFR: Collaboration Comes of Age, The Report on Retail E-Business, April 2001 Bernstein, R (1997) Vendor managed Inventory: What Works, Retail Information Systems news, March 1997. Available from: http://www.risnews.com/archive/march97_p.10.html Bhulhi, S. (1997) Efficient Consumer Response, BWI Paper, vrije Universiteit Amsterdam, Faculty of Sciences, Dep. of Mathematics and Computer Science. Available from: http://www.cs.vu.nl/~sbhulai/ecr/index.html Brown, T. A., and Bukovinski, D. M. (2001) ECR and Grocery Retailing: An Exploratory Financial Statement Analysis, Journal of Business Logistics, Vol. 22 No 2 pp. 77 90 Dixon, L. and Porter M. A. (1994), JIT: Revolution in Buying and Selling, 1st Edition, Cahners publishing Company, 234p. ECR Board (1995), ECR Europe Executive Board Vision Statement. Ireland, R and Bruce, R. (2000), CPFR: Only the Beginning of Collaboration, Supply Chain management review, September-October 2000. Also available: http://www.surgency.com/news/news/publications.htm

14

King, R. P. and Phumpier, P. F. (1996) Reengineering the Food Supply Chain: The ECR Initiative in the Grocery Industry, American Journal of Agricultural Economics, Vol. 78, pp. 1181 1186 Quick Response Leadership Committee (1995), Quick Response handout, American Apparel Manufacturers Association Committee Report. Available from: http://www.dama.tc2.com/qrlc/qrhand.htm Verity, J. (1996), Clearing the Cobwebs From the Stockroom, Business Week, October 21st, 1996 VICS (2001) Collaborative Planning Forecasting and Replenishment (CPFR). Available from: http://www.cpfr.org/

15

Das könnte Ihnen auch gefallen

- Bahan SCM Inventory 1Dokument27 SeitenBahan SCM Inventory 1Rurid Dwi AnggraenyNoch keine Bewertungen

- Collaboration Strategy ContinuumDokument33 SeitenCollaboration Strategy ContinuumNurtegin RysbaevNoch keine Bewertungen

- Supply Chain Collaboration: Making Sense of The Strategy ContinuumDokument12 SeitenSupply Chain Collaboration: Making Sense of The Strategy ContinuumMyself NoorNoch keine Bewertungen

- Collaboration Strategy ContinuumDokument33 SeitenCollaboration Strategy ContinuumDavid SantoNoch keine Bewertungen

- Vendor Managed Inventory Processes for Unified Supply Chain ViewDokument13 SeitenVendor Managed Inventory Processes for Unified Supply Chain ViewAnnisa RakhmawatiNoch keine Bewertungen

- Sai SIP PDFDokument51 SeitenSai SIP PDFsairaj patilNoch keine Bewertungen

- 2A VMI Kellogg ReportDokument12 Seiten2A VMI Kellogg ReportPrafull MalviyaNoch keine Bewertungen

- Estimating Benefi Ts of Demand Sensing For Consumer Goods OrganisationsDokument17 SeitenEstimating Benefi Ts of Demand Sensing For Consumer Goods OrganisationsIsmael SotoNoch keine Bewertungen

- Supply Chain MnagementDokument5 SeitenSupply Chain MnagementDanish AhsanNoch keine Bewertungen

- 18.SCM - Business Process IntegrationDokument2 Seiten18.SCM - Business Process IntegrationWah KhaingNoch keine Bewertungen

- Competitive Advantage with Vendor Managed InventoryDokument20 SeitenCompetitive Advantage with Vendor Managed InventoryVINITHANoch keine Bewertungen

- Vendor Managed Inventory (Vmi)Dokument10 SeitenVendor Managed Inventory (Vmi)France ParodiNoch keine Bewertungen

- CPFR Whitepaper Spring 2008-VICSDokument25 SeitenCPFR Whitepaper Spring 2008-VICSakashkrsnaNoch keine Bewertungen

- Balancing Marketing and Supply Chain CostsDokument11 SeitenBalancing Marketing and Supply Chain Costslucia zegarraNoch keine Bewertungen

- 020-0485 Feasibility of Vendor Inventory ManagementDokument13 Seiten020-0485 Feasibility of Vendor Inventory ManagementShanju AmathNoch keine Bewertungen

- Wal-Mart's Supply Chain Strategies Drive SuccessDokument10 SeitenWal-Mart's Supply Chain Strategies Drive SuccessCairis CairisNoch keine Bewertungen

- Gaining Competitive Advantages Through Supply Chain Management: Success StoriesDokument8 SeitenGaining Competitive Advantages Through Supply Chain Management: Success StoriesLijo M LoyidNoch keine Bewertungen

- Bahir Dar University College of Business and Economics Department of ManagementDokument23 SeitenBahir Dar University College of Business and Economics Department of ManagementSamuel AbebawNoch keine Bewertungen

- Benefits of CPFR and VMI SimulationDokument12 SeitenBenefits of CPFR and VMI SimulationSandeep SasidharanNoch keine Bewertungen

- Vendor Managed InventoryDokument3 SeitenVendor Managed InventoryHarshal BadheNoch keine Bewertungen

- Manufacturing Letters: Emanuele Frontoni, Roberto Rosetti, Marina Paolanti, A.C. AlvesDokument4 SeitenManufacturing Letters: Emanuele Frontoni, Roberto Rosetti, Marina Paolanti, A.C. AlvesKaren Stephanie Carranza VergaraNoch keine Bewertungen

- Bhutta ECR SWDSI 05formatted (T3D1)Dokument9 SeitenBhutta ECR SWDSI 05formatted (T3D1)sourabh_bhattacherjeeNoch keine Bewertungen

- Article Summary Ainul PDFDokument4 SeitenArticle Summary Ainul PDFAinul mardziahNoch keine Bewertungen

- A Reinforcement Learning Approach For Inventory ReplenishmentDokument11 SeitenA Reinforcement Learning Approach For Inventory ReplenishmentSyauqi Hidayat BaihaqiNoch keine Bewertungen

- AHP Supplier Selection Model for Textile IndustryDokument10 SeitenAHP Supplier Selection Model for Textile Industryimroz_ali90Noch keine Bewertungen

- CPFR Initiatives: A State of Art ReviewDokument22 SeitenCPFR Initiatives: A State of Art ReviewKing SolomonNoch keine Bewertungen

- Emj PDFDokument10 SeitenEmj PDFJuan David Carvajal HernandezNoch keine Bewertungen

- Exploration of The Gap Problem Between Planning and Execution in The Supply Chain - A Case of Taiwan IC IndustryDokument14 SeitenExploration of The Gap Problem Between Planning and Execution in The Supply Chain - A Case of Taiwan IC IndustryVanNguyenNoch keine Bewertungen

- DAMA Final ReportDokument8 SeitenDAMA Final ReportJJ KapsNoch keine Bewertungen

- Lead Time Reduction Thru ICT in FootwearDokument15 SeitenLead Time Reduction Thru ICT in FootwearHeena ZubairNoch keine Bewertungen

- Supply Chain Synchronization: White PaperDokument4 SeitenSupply Chain Synchronization: White PaperBrooke TillmanNoch keine Bewertungen

- Estimating Benefi Ts of Demand Sensing For Consumer Goods OrganisationsDokument17 SeitenEstimating Benefi Ts of Demand Sensing For Consumer Goods OrganisationsYashank JainNoch keine Bewertungen

- Supply Chain Integration Benefits in Vendor-Managed InventoryDokument12 SeitenSupply Chain Integration Benefits in Vendor-Managed InventoryLUIS GONZALEZ PEREZNoch keine Bewertungen

- Research Paper On Supply Chain ManagementDokument6 SeitenResearch Paper On Supply Chain Managementp0zikiwyfyb2100% (1)

- On The Benefits of CPFR and VMI A Comparative PDFDokument12 SeitenOn The Benefits of CPFR and VMI A Comparative PDFJose LaraNoch keine Bewertungen

- The 7 Principles of Supply Chain ManagementDokument10 SeitenThe 7 Principles of Supply Chain Managementmela917Noch keine Bewertungen

- 3c.supplier Relationship Management (SRM)Dokument10 Seiten3c.supplier Relationship Management (SRM)Jawad IginlaNoch keine Bewertungen

- Link between Supply Chain Fit and Financial PerformanceDokument2 SeitenLink between Supply Chain Fit and Financial PerformanceUmer RajaNoch keine Bewertungen

- Business-Process Integration: Supply-Chain Management 2.0 (SCM 2.0)Dokument8 SeitenBusiness-Process Integration: Supply-Chain Management 2.0 (SCM 2.0)nidayousafzaiNoch keine Bewertungen

- Spend AnalysisDokument6 SeitenSpend AnalysisChetanNoch keine Bewertungen

- PACSB Summit 2023Dokument53 SeitenPACSB Summit 2023rhallNoch keine Bewertungen

- Applying TOC to Reduce Bullwhip EffectDokument12 SeitenApplying TOC to Reduce Bullwhip EffectRitabrata MukherjeeNoch keine Bewertungen

- Supply Chain Logistics Management 4th Edition Bowersox Solutions ManualDokument3 SeitenSupply Chain Logistics Management 4th Edition Bowersox Solutions Manuala37113077575% (4)

- Final Edited Copy - 2-07-2019Dokument52 SeitenFinal Edited Copy - 2-07-2019roselyn degamoNoch keine Bewertungen

- JITDokument6 SeitenJITash1toshNoch keine Bewertungen

- Collaboration Forms and Differencies ArticleDokument21 SeitenCollaboration Forms and Differencies ArticleiacikgozNoch keine Bewertungen

- C-Commerce ImplementationDokument12 SeitenC-Commerce Implementationsivaranjani. kumarNoch keine Bewertungen

- 02 Liang-TuChen NDokument8 Seiten02 Liang-TuChen NAsthrid Lucia Paz HerreraNoch keine Bewertungen

- SCM Module 5 NotesDokument14 SeitenSCM Module 5 NotesNaik SamNoch keine Bewertungen

- How COVID-19 impacted foreign exchange market efficiencyDokument3 SeitenHow COVID-19 impacted foreign exchange market efficiencyDaii KdirectionNoch keine Bewertungen

- Quick Response Logistics - Sreenivas - Mba - PTDokument13 SeitenQuick Response Logistics - Sreenivas - Mba - PTJob ThomasNoch keine Bewertungen

- Supply Chain ManagementDokument29 SeitenSupply Chain ManagementShamNoch keine Bewertungen

- Sai Aswathy. SCM 2 03Dokument8 SeitenSai Aswathy. SCM 2 03sudeepptrNoch keine Bewertungen

- Department of Commerce: MCM - Ls 711: Capstone Project - IDokument19 SeitenDepartment of Commerce: MCM - Ls 711: Capstone Project - IKeerthana GanapathyNoch keine Bewertungen

- Customer FocusDokument20 SeitenCustomer FocusmahendranNoch keine Bewertungen

- Collaborative Planning, Forecasting, and Replenishment: CPFR OriginsDokument14 SeitenCollaborative Planning, Forecasting, and Replenishment: CPFR Originsshubhra_jais6888100% (1)

- Capital Equipment Purchasing: Optimizing the Total Cost of CapEx SourcingVon EverandCapital Equipment Purchasing: Optimizing the Total Cost of CapEx SourcingNoch keine Bewertungen

- Supply Chain Finance Solutions: Relevance - Propositions - Market ValueVon EverandSupply Chain Finance Solutions: Relevance - Propositions - Market ValueNoch keine Bewertungen

- Michael Porter's Value Chain: Unlock your company's competitive advantageVon EverandMichael Porter's Value Chain: Unlock your company's competitive advantageBewertung: 4 von 5 Sternen4/5 (1)

- Yahoo Mail - ACCEPTANCE OF PAPER FOR PUBLICATION - IJIRMFDokument2 SeitenYahoo Mail - ACCEPTANCE OF PAPER FOR PUBLICATION - IJIRMFWawan Flattron StraerNoch keine Bewertungen

- Final Report On NBFCDokument57 SeitenFinal Report On NBFCPravash Poddar0% (1)

- HDFC Credit Card Reward PointsDokument55 SeitenHDFC Credit Card Reward PointsamitkrayNoch keine Bewertungen

- 8F SC Wall Mount Fiber Terminal BoxDokument1 Seite8F SC Wall Mount Fiber Terminal BoxĐoàn LinhNoch keine Bewertungen

- LicenseDokument4 SeitenLicenseThant ZinNoch keine Bewertungen

- Cattle Insurance Policy UIN NUMBER - IRDAN190RP0152V01100001Dokument3 SeitenCattle Insurance Policy UIN NUMBER - IRDAN190RP0152V01100001sandeepNoch keine Bewertungen

- V13 Manual 1.0Dokument336 SeitenV13 Manual 1.0lp456Noch keine Bewertungen

- CH 04Dokument55 SeitenCH 04cris lu salemNoch keine Bewertungen

- Flujograma Grupo 6Dokument1 SeiteFlujograma Grupo 6ALESSANDRA MARIA ASMAT CENTENONoch keine Bewertungen

- Session 4 - Internal Control Procedures in AccountingDokument15 SeitenSession 4 - Internal Control Procedures in AccountingRej PanganibanNoch keine Bewertungen

- Screenshot 2022-08-04 at 12.53.07 PDFDokument1 SeiteScreenshot 2022-08-04 at 12.53.07 PDFSimi NaomiNoch keine Bewertungen

- Pag-IBIG Refund ApplicationDokument1 SeitePag-IBIG Refund ApplicationKristoffer John AmbueguiaNoch keine Bewertungen

- IT exam questions on telecom technologiesDokument5 SeitenIT exam questions on telecom technologiesemuye bawokeNoch keine Bewertungen

- Universal PTC GuideDokument28 SeitenUniversal PTC Guideapi-242474098Noch keine Bewertungen

- Bfi Reviewer 2CDokument22 SeitenBfi Reviewer 2Cjessa suazoNoch keine Bewertungen

- Horngrens Accounting Volume 1 Canadian 10Th Edition Nobles Solutions Manual Full Chapter PDFDokument67 SeitenHorngrens Accounting Volume 1 Canadian 10Th Edition Nobles Solutions Manual Full Chapter PDFgiaocleopatra192y100% (7)

- Medical RealDokument1 SeiteMedical Realapi-252555369Noch keine Bewertungen

- Networking XII Computer Science Question Answer CBSEDokument48 SeitenNetworking XII Computer Science Question Answer CBSEBipin SinghNoch keine Bewertungen

- Maximize Your Japan Rail Pass With These 5 TipsDokument2 SeitenMaximize Your Japan Rail Pass With These 5 TipsGretchen VenturaNoch keine Bewertungen

- T1 IP Static Routing, Troubleshoot Static and Default RoutesDokument6 SeitenT1 IP Static Routing, Troubleshoot Static and Default RoutesLAI XIAO CHERKNoch keine Bewertungen

- SAP Bank Accounting Configuration Steps - SAP TutorialDokument6 SeitenSAP Bank Accounting Configuration Steps - SAP TutorialKapadia MritulNoch keine Bewertungen

- Principles of LawDokument72 SeitenPrinciples of LawMakaha Rutendo100% (1)

- MCB Internship Report: Analysis of Operations at Muslim Commercial Bank Township Campus LahoreDokument68 SeitenMCB Internship Report: Analysis of Operations at Muslim Commercial Bank Township Campus LahoreAbdullah Afzal100% (1)

- Synpulse - Banking - Robo AdvisoryDokument4 SeitenSynpulse - Banking - Robo AdvisoryNygmazNoch keine Bewertungen

- E-Commerce and Social Media ImpactDokument11 SeitenE-Commerce and Social Media ImpactShane MastroNoch keine Bewertungen

- Özel Tekstil Commercial Invoice GermanyDokument1 SeiteÖzel Tekstil Commercial Invoice Germanyozel tekstilNoch keine Bewertungen

- Generic Life Insurance Needs Analysis Worksheet 2014-10Dokument3 SeitenGeneric Life Insurance Needs Analysis Worksheet 2014-10Christophe BernardNoch keine Bewertungen

- Logistics MCQDokument9 SeitenLogistics MCQDILIP JAIN90% (21)

- Bharti Airtel Limited's Response To TRAI Pre-Consultation Paper On "Net Neutrality"Dokument22 SeitenBharti Airtel Limited's Response To TRAI Pre-Consultation Paper On "Net Neutrality"ArtvickNoch keine Bewertungen

- DepreciationDokument19 SeitenDepreciationamit palNoch keine Bewertungen