Beruflich Dokumente

Kultur Dokumente

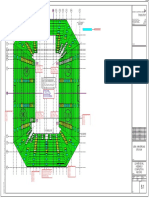

Heavy Density

Hochgeladen von

mohdnazirCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Heavy Density

Hochgeladen von

mohdnazirCopyright:

Verfügbare Formate

Affiliate of

Member of

Arabian Fiberglass Insulation Company Ltd. J.V. of Zamil Industrial & Owens Corning Corp.

Heavy Density Pipe Insulation

DESCRIPTION APPLICATION Heavy Density Pipe Insulation is intended for use in commercial, institutional, industrial and residential construction and in power and process plants as thermal and acoustic insulation for hot or cold, concealed or exposed steel, copper and plastic piping where temperatures are between -18C and +450C (0 to 850 F). STANDARD AVAILABLE SIZES Heavy Density Pipe Insulation is made in standard 1m and 1.2m lengths and is available in nominal iron pipe sizes from 12.7 mm ( in) through 650 mm (26 in) and in nominal copper tube sizes from 15 mm (5/ 8 in) through 156 mm (6 1/ 8 in). Nominal wall thickness ranges from 13 mm ( in) to 100 mm (4 in), with 13 mm ( in), 25 mm (1 in), 38 mm (1 in), 50 mm (2 in), 64 mm (2 in), 75 mm (3 in) and 100 mm (4 in) as standard. NOMINAL DENSITY 64 kg/m3 to 128 kg/m3 or 4 lbs/ft3 to 8 lbs/ft3

Technical Data Sheet Product Code: PI

Pipe Insulation is a heavy density, preformed insulation composed of ne, stable and uniformly textured inorganic glass bers bonded together by a non-water soluble and re-retardant thermosetting and heat resistant resin. It is free from coarse bers and shot due to its mineral composition, molded in one-piece sections and made with a single seam. Heavy Density Pipe Insulation are damage resistant, easy to handle and spread open to receive the pipe and snaps closed after placement. FACING Heavy Density Pipe Insulation is supplied plain or with a factory-applied jacket for applications requiring an integral vapor barrier. Standard jacketing materials include Aluminum Foil Glass Reinforced Kraft Paper Laminate (FRK), the White All Service Jacket (ASJ) and the Aluminum Foil Woven Fiber Glass Jacket (AWF). All jackets are provided with a nominal 50mm lap to facilitate closure and vapor sealing of the longitudinal joint. Outdoor or direct bury applications require additional protection from the elements.

NOMINAL THERMAL CONDUCTIVITY (BS 874)

K or value at mean temperatures

OHSAS

18 001

HEALT H & S A F E T Y STA N D A R D

Product Type PI

640* 800 960

Density

Kg/m3 64 80 96 Lb/ft3 4 5 6 0C 0.029 0.030 0.030 32F 0.21 0.21 0.21 10C 0.029 0.030 0.031 10F 0.20 0.21 0.21 24C 0.030 0.032 0.032

W/m.C Btu.in/ft2.hr. F (ASTM C 518)

75F 0.21 0.22 0.22 50C 0.032 0.033 0.035 122F 0.22 0.23 0.24 75C 0.036 0.037 0.036 167F 0.27 0.26 0.25 100C 0.040 0.039 0.038 212F 0.27 0.27 0.26 150C 0.050 0.047 0.044 302F 0.34 0.33 0.31 260C 0.079 0.065 0.057 500F 0.55 0.45 0.40

* Standard Products and Sizes

Heavy Density Pipe Insulation

Technical Data Sheet Product Code: PI

Performance & Physical Characteristics

Working Temperature Limitations (ASTM C 411) -18C to +450C (0 to 850F) At excessive temperatures, a limited migration of binder may occur in the insulation in contact with the hot surface. This in no way impairs the performance of the insulation. Corrosiveness (ASTM C 665) Chemically inert. Will not cause or accelerate corrosion of steel, stainless steel, copper or aluminum, due to its particular inorganic and mineral composition. Alkalinity pH 9 Mold Growth (ASTM D 2020, UL 181) Does not breed or sustain mold, fungus, bacteria or rodents. Moisture Absorption (ASTM D-07 B, ASTM C 553) In conditions of 95% relative humidity at 49C for 96 hours, moisture absorption is less than 0.2% by volume, when tested in accordance with ASTM C 533. berglass products do not absorb moisture from the ambient air nor water by capillary attraction, only water under pressure can enter the insulation products but that will quickly dry out owing to the materials open cell structure. Vapor Permeability (ASTM E 96A) FRK 0.02 PERM (U.S. Federal Specication HH-B-100 B TYPES I & II) ASJ 0.02 PERM AWF 0.018 PERM Puncture Resistance (ASTM D 781) FRK ASJ AWF 25 Units 50 Units 10 Units (270 PSi) Fire Properties B.S. 476 PART 4 Non-combustible B.S. 476 PART 5 Ignitability B.S. 476 PART 6 Fire propagation B.S. 476 PART 7 Surface spread of ame Class O re rating to the building regulations section E15 Specication Compliance Heavy Density Pipe Insulation complies with the property requirements of the following specications: US Federal Specification HH-1-558 B, Form D, TYPE III, Classes 12 and 13 ASTM 547, ASTM C 795 Class 1 and 2 Standard specication for mineral ber performed pipe insulation DCL ASTM - C 533 - C 547 - C 612 - C 665 CE-EN 13162 Thermal Resistance R Value (Excluding Facings) (ASTM C 167) It is a measure of the resistance to heat ow of a material of any given thickness, calculated as follows: L R = where L = equivalent thickness of the insulation K K = Thermal Conductivity L = r2 1n (r2/r1) Where r1 = inner radius of insulation r2 = outer radius of insulation 1n log to the base e (natural log)

ASJ Jacket for up to 16 NPS (400 mm DN), in (mm)

Ambient Temperature

F 110 C (43) 50%-70% 80% 90% 100 (38) 50%-70% 80% 90% 90 (32) 50%-70% 80% 90% 80 (27) 50%-80% 90% 70 (21) 50%-80% 90%

Thickness to Prevent Surface Condensation

Relative Humidity

35F 1 1 3 1 1 3 1 1 3 1 2 1 1

System Operating Temperatures

(2C) (25) (38) (89) (25) (38) (89) (25) (38) (76) (25) (64) (25) (38) 45F 1 1 3 1 1 3 1 1 2 1 2 1 1 (7C) (25) (38) (76) (25) (38) (76) (25) (38) (64) (25) (51) (25) (38) 55F 1 1 2 1 1 2 1 1 2 1 1 1 1 (13C) (25) (25) (64) (25) (25) (64) (25) (38) (51) (25) (38) (25) (25)

Surface Burning Characteristics (UL 723, ASTM E 84, ASTM E 136) Base glass ber is non-combustible when tested to ASTM E84.

Facing

UNFACED FRK ASJ AFW

Flame Spread

10 0 5 10

Smoke Developed

0 0 5 0

Fuel Contributed

0 0 0 0

Linear Shrinkage (ASTM C 356) Will not crack or shrink while permitting expansion and contraction of the pipe.

Data generated using NAIMA 3E Plus computer program available at www.naima.org. For NPS (DN) greater than 16* (400 mm), please contact your local AFICO representatives. / If humidity exceeds 90%,some condensation is to be expected; therefore, a coating of mastic or PVC Jacket overwrap is recommendedas repeated or continual wetting of the ASJ jacket will degrade its vapor retarder performance.

Arabian Fiberglass Insulation Company Ltd. J.V. of Zamil Industrial & Owens Corning Corp.

Performance & Physical Characteristics

Economic Thickness

Guide Specications

Pipe Sizes (mm) Piping System Types

Heating Systems Steam and Hot Water High Pressure/ Temperature Medium Pressure/ Temperature Low Pressure/ Temperature Low Temperature Steam Condensate for feed water Cooling systems Chilled water Refrigerant, or Brine 4.5 - 13 Below 4.5 13 25 13 25 25 40 25 40 25 40 25 40 152 - 238 40 64 64 75 89 89 Fluid Temperature Range o C

Runouts Up to 50

25 & Under

3250

64100

125150

200 and Over

Minimum Insulation (mm) for Pipes sizes

Fiberglass pipe For Exposed Pipe section faced with Aluminum Woven Glass (AWF) Facing will provide: A substitute for conventional thermal insulation products that requires a costly & labour intensive work at site e.g. protection of pipe insulation by additional weather proong. An ideal substitute for conventional thermal insulation practices. AWF facing provides factory applied thermal sealing system. Rigid Pipe Coverings is faced with factory applied AWF facing. AWF is aluminum foil laminated with glass fabric. It has extremely high Bursting strength of 270 psi i.e. 3-4 times higher than that of conventional facings. It has extremely high Tensile strength of 14.5 KN/m i.e. 3-4 times higher than that of conventional facings. AWF is having high mechanical strength, durability and dimensional stability. AWF will achieve water vapor permeance of 0.018 perm better than the conventional facings. AWF can withstand temperature up to 500 deg C while other conventional facing are suitable to 100 deg C. Rigid Pipe Coverings faced with AWF can be used with no additional requirement of handling and weather protection such as application of canvas + vapor barrier. Rigid Pipe Coverings faced with AWF are not proof, resist the effects of moisture and will not decompose through continual exposure to the elements. Rigid Pipe Covering faced with AWF will maintain their thermal properties through the life time of the construction. Insulation contractors will be benefited as they can save on installation cost because of protection of pipe insulation by applying canvas + vapor barrier will not be needed.

122 151 94 - 121 49 93 Any

40 25 13 25

50 40 25 25

64 40 25 40

64 50 40 50

75 50 40 50

75 50 40 50

The Economic Thickness chart is taken directly from ASHRAE Standard 90A-80 and reects minimum Pipe Insulation thickness recommended for commercial or residential applications.

Installation Recommendation Heavy Density Pipe Insulation products are easily installed. The one piece sections are snapped in place on the pipe to be insulated. Longitudinal and butt joints are vapor sealed by application of ASJ or FRK pressure-sensitive tape, or the use of mastics (both supplied separately). Note: Outdoor applications require additional weather protection.

If two layers of pipe sections are to be installed on one another, the longitudinal cut should not be on the same line. For single layer applications, the longitudinal cut should be placed to the under side of the pipe section.

FRK TAPE FRK TAPE

VAPOR BARRIER JACKET

Installing single layer pipe sections Installing double layer pipe sections

HEAVY DENSITY PIPE INSULATION STAPLE @ 150 MM (6) O.C.

40 0 30

150

PIPE

ADHESIVE COATING

Heavy Density Pipe Insulation

Technical Data Sheet Product Code: PI

MAINTENANCE No maintenance is required. Heavy Density Pipe Insulation have a high resistance to accidental damage from knocks and handling during installation and maintenance. Dimensionally stable under varying conditions of temperature and humidity, rot-proof, odourless, non-hygroscopic and will not sustain vermin or fungus due to its inorganic and mineral compositions. The product will maintain its thermal properties throughout the lifetime of the construction and will not age. breglass is non toxic and not hazardous to health. STORAGE To avoid moisture in the building construction, insulation products stored outside must be kept dry. We recommend products to be always stored in covered and dry areas. is not liable for the damage resulting from inadequate utilization, loading and off loading and mishandling of its products. WARRANTY See manufacturers General Terms and Conditions of Sale. As and/or OC has no control over installation design, installation workmanship, accessory materials, or conditions of application, and/or OC does not warrant the performance or results of any installation containing their products. This warranty disclaimer includes all implied warranties, including the warranties or merchantability and tness for a particular purpose. Arabian Fiberglass Insulation Company reserves the right to alter product specications without prior notice, as part of its policy of continued development and improvement. The installation methods described in this leaet are not compulsory. The choice of materials and methods of xing are the decision of the specier, consultant or contractor. For further information or advice on specication of products, contact your local sales ofce. AVAILABILITY Manufactured by Arabian Fiberglass Insulation Company, Ltd. (AFICO), member of Zamil Industrial, with headquarters and production facilities located in Dammam, Saudi Arabia, under license from and utilizing the manufacturing specications and technology of Owens-Corning Corporation (OC), Toledo, Ohio, U.S.A. Marketed throughout Saudi Arabia, the G.C.C. countries, the Middle East and the Far East. products are available directly from as well as through a vast and reliable network of local distributors. Special products are manufactured on request.

PRODUCTS

PRODUCTS CODE ACP BKT HDB BD RI RD CWI MBI FDW DL DLB MBD PI PWI TIW AQL AWF PDB

Acoustical Ceiling Panels Blanket Insulation HD Series Blanket Insulation Board Insulation Roof Insulation Roof Deck Board Insulation Cavity Wall Insulation Pre-engineered Metal Building Insulation Faced Duct Wrap Duct Liner Duct Liner Board Mechanical Board Insulation Heavy Density Pipe Insulation Pipe Wrap Insulation Thermal Insulating Wool Quiet Liner Woven Facing Prefabricated Duct Board

For more information call the insulation professionals:

H.O. & Factory: Tel: Fax: E-mail: Riyadh Ofce: Tel: Fax: E-mail: Jeddah ofce: Tel: Fax: E-mail:

P.O. Box 1289, Dammam 31431, Saudi Arabia +966 3 847 2901 / 847 1519 +966 3 847 3605 wajdei@aco.com.sa P.O. Box 50281, Riyadh 11523, Saudi Arabia +966 1 472 5555 ext. 283 +966 1 291 0162 kathunaiyan@aco.com.sa P.O. Box 2140, Jeddah 21451, Saudi Arabia +966 2 670 0020 ext. 133 +966 2 287 2283

Gulf Regional Ofce: P.O. Box 44493, Deira, Dubai, U.A.E. Tel: +971 4 294 1211 Fax: +971 4 294 1168 E-mail: acogcc@emirates.net.ae Export Ofce: Tel: Fax: E-mail: P.O. Box 90-284, Jdeidet El Metn Beirut Lebanon +961 1 900962 +961 1 900963 AFICO@cyberia.net.lb www.aco.com.sa Authorized Distributor

info@aco.com.sa

Our GREEN promise the healthy solut on

ENERGY SAVING ENVIRONMENTALLY FRIENDLY RECYCLED MATERIALS SOLUTION FOR GLOBAL WARMING

AFICO is committed to a greener, cleaner environment. AFICO have responded to this call for conservation by increasing the amounts of recycled materials in our products.

Pub No. 05-TDS-CWI Printed November 2007

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- ColebrookDokument12 SeitenColebrookmohdnazirNoch keine Bewertungen

- Colebrook White EquationDokument1 SeiteColebrook White EquationRendi KurniawanNoch keine Bewertungen

- Sanitary Design and Technical Criteria Manual - March 2008Dokument75 SeitenSanitary Design and Technical Criteria Manual - March 2008mohdnazirNoch keine Bewertungen

- Sewage Lift StationDokument110 SeitenSewage Lift Stationmohdnazir100% (1)

- Preferred Option:: Install A Permanent Plumbing Fixture On Vehicle To Allow For Air GapDokument1 SeitePreferred Option:: Install A Permanent Plumbing Fixture On Vehicle To Allow For Air GapmohdnazirNoch keine Bewertungen

- Quick Calculation of Cooling Tower Blowdown and MakeupDokument3 SeitenQuick Calculation of Cooling Tower Blowdown and Makeupmohdnazir100% (1)

- ASPE Sump Pump SizingDokument60 SeitenASPE Sump Pump Sizingzaqhusanz100% (5)

- 500 GPM Electric W EnclDokument1 Seite500 GPM Electric W EnclmohdnazirNoch keine Bewertungen

- Minor Pipe Losses (Equivalent Lengths)Dokument4 SeitenMinor Pipe Losses (Equivalent Lengths)Hassan AbdulAzim FadilNoch keine Bewertungen

- Simplified Sizing Procedure For Solar Domestic Hot Water SystemsDokument0 SeitenSimplified Sizing Procedure For Solar Domestic Hot Water SystemsmohdnazirNoch keine Bewertungen

- One-And Two-Family Residential Building Fires (2008-2010) : T F R SDokument14 SeitenOne-And Two-Family Residential Building Fires (2008-2010) : T F R SmohdnazirNoch keine Bewertungen

- The Control of Air Pressure Within Tall Building Drainage-SoPHE - PPT (Compatibility Mode)Dokument24 SeitenThe Control of Air Pressure Within Tall Building Drainage-SoPHE - PPT (Compatibility Mode)mohdnazirNoch keine Bewertungen

- Compressed Air Piping-Economic PipingDokument5 SeitenCompressed Air Piping-Economic PipingMOHAMMAD ASIFNoch keine Bewertungen

- Optimal Design of Hybrid MSFRO Desalination PlantDokument185 SeitenOptimal Design of Hybrid MSFRO Desalination PlantmohdnazirNoch keine Bewertungen

- Hydrant and Hose Equipment Cabinet 01-2012Dokument2 SeitenHydrant and Hose Equipment Cabinet 01-2012mohdnazirNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Introduction To EthicsDokument18 SeitenIntroduction To EthicsMarielle Guerra04Noch keine Bewertungen

- Alchemy of The HeartDokument7 SeitenAlchemy of The HeartAbdul RahimNoch keine Bewertungen

- SDSSSSDDokument1 SeiteSDSSSSDmirfanjpcgmailcomNoch keine Bewertungen

- SilmaDokument12 SeitenSilmanobleconsultantsNoch keine Bewertungen

- Analysis of Rates (Nh-15 Barmer - Sanchor)Dokument118 SeitenAnalysis of Rates (Nh-15 Barmer - Sanchor)rahulchauhan7869Noch keine Bewertungen

- PDFDokument40 SeitenPDFAndi NursinarNoch keine Bewertungen

- Caterpillar Cat C7 Marine Engine Parts Catalogue ManualDokument21 SeitenCaterpillar Cat C7 Marine Engine Parts Catalogue ManualkfsmmeNoch keine Bewertungen

- 220245-MSBTE-22412-Java (Unit 1)Dokument40 Seiten220245-MSBTE-22412-Java (Unit 1)Nomaan ShaikhNoch keine Bewertungen

- Test Bank For Psychology 6th Edition Don HockenburyDokument18 SeitenTest Bank For Psychology 6th Edition Don HockenburyKaitlynMorganarwp100% (42)

- MH5-C Prospekt PDFDokument16 SeitenMH5-C Prospekt PDFvatasaNoch keine Bewertungen

- De Thi Hoc Ki 1 Lop 11 Mon Tieng Anh Co File Nghe Nam 2020Dokument11 SeitenDe Thi Hoc Ki 1 Lop 11 Mon Tieng Anh Co File Nghe Nam 2020HiềnNoch keine Bewertungen

- Been There, Done That, Wrote The Blog: The Choices and Challenges of Supporting Adolescents and Young Adults With CancerDokument8 SeitenBeen There, Done That, Wrote The Blog: The Choices and Challenges of Supporting Adolescents and Young Adults With CancerNanis DimmitrisNoch keine Bewertungen

- Contoh Exposition TextDokument1 SeiteContoh Exposition TextKristin SeranNoch keine Bewertungen

- State Space ModelsDokument19 SeitenState Space Modelswat2013rahulNoch keine Bewertungen

- Is 2 - 2000 Rules For Rounded Off For Numericals PDFDokument18 SeitenIs 2 - 2000 Rules For Rounded Off For Numericals PDFbala subramanyamNoch keine Bewertungen

- EMD Question Bank II 2Dokument4 SeitenEMD Question Bank II 2Soham MisalNoch keine Bewertungen

- 02 Object Modeling TechniqueDokument50 Seiten02 Object Modeling TechniqueMuhammad Romadhon Batukarang EsdNoch keine Bewertungen

- SP-Chapter 14 PresentationDokument83 SeitenSP-Chapter 14 PresentationLoiDa FloresNoch keine Bewertungen

- RCA LCD26V6SY Service Manual 1.0 PDFDokument33 SeitenRCA LCD26V6SY Service Manual 1.0 PDFPocho Pochito100% (1)

- Lacey Robertson Resume 3-6-20Dokument1 SeiteLacey Robertson Resume 3-6-20api-410771996Noch keine Bewertungen

- Noise and DB Calculations: Smart EDGE ECE Review SpecialistDokument2 SeitenNoise and DB Calculations: Smart EDGE ECE Review SpecialistLM BecinaNoch keine Bewertungen

- Mfin 7002 Investment Analysis and Portfolio ManagementDokument5 SeitenMfin 7002 Investment Analysis and Portfolio ManagementjessieNoch keine Bewertungen

- Words of Radiance: Book Two of The Stormlight Archive - Brandon SandersonDokument6 SeitenWords of Radiance: Book Two of The Stormlight Archive - Brandon Sandersonxyrytepa0% (3)

- IT Level 4 COCDokument2 SeitenIT Level 4 COCfikru tesefaye0% (1)

- Teaching Trigonometry Using Empirical Modelling: 2.1 Visual Over Verbal LearningDokument5 SeitenTeaching Trigonometry Using Empirical Modelling: 2.1 Visual Over Verbal LearningJeffrey Cariaga Reclamado IINoch keine Bewertungen

- Toh736 - 84000 The Dharani of Parnasavari PDFDokument24 SeitenToh736 - 84000 The Dharani of Parnasavari PDFJames LeeNoch keine Bewertungen

- Applying For A Job: Pre-ReadingDokument5 SeitenApplying For A Job: Pre-ReadingDianitta MaciasNoch keine Bewertungen

- NAV SOLVING PROBLEM 3 (1-20) .PpsDokument37 SeitenNAV SOLVING PROBLEM 3 (1-20) .Ppsmsk5in100% (1)

- Saiva Dharma ShastrasDokument379 SeitenSaiva Dharma ShastrasfunnybizNoch keine Bewertungen

- Quotation of Suny PDFDokument5 SeitenQuotation of Suny PDFHaider KingNoch keine Bewertungen