Beruflich Dokumente

Kultur Dokumente

1939 - 0834

Hochgeladen von

seafire47Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1939 - 0834

Hochgeladen von

seafire47Copyright:

Verfügbare Formate

296

FLIGHT.

M A R C H 23,

1939

THE ROTOL AIRSCREW

A Detailed Description of a Notable Design Now in Large-scale Production : Manufacturing Methods

(Illustrated with "Flight" Photographs and Drawings) The oil then passes along these ducts, which lead into the cylinder either in front of or behind the piston. In this way oil pressure applied through one pipe from the governor unit is transmitted through one set of ducts to a particular side of the piston, the oil on the other side of the piston returning through the other set of ducts back to the governing unit. As the oil pressure is applied to one side or the other of the piston so the cylinder is forced to slide forwards or backwards along the hub driving centre. Bolted to the outside circumference of the cylinder are three lugs, into each of which is fitted a sliding bush of Tufnol. I t is into this bush that the steel pin attached to each blade root housing is fitted. By this method the longitudinal motion of the cylinder is transformed into a partial rotary movement of the blades.

The visitor to the works of Rotol Airscrews Ltd., at Gloucester, is greeted by this striking frontage of offices. OR some time prior to 1936 the research departments of the Bristol Aeroplane Co., Ltd., and Rolls-Royce, Ltd., had been conducting experiments in connection with the developments of constant-speed and other types of controlled-pitch airscrews. In many respects the research work of the two companies was running in similar channels, therefore it was not surprising that in June, 1937, a decision was reached whereby the resources and knowledge of the two departments could be pooled. Rotol' Airscrews, Ltd., had come into being, linking both in name and fact the airscrew development departments of the two famous companies from Bristol and Derby. Within six months a large factory, with an arresting frontage of administrative offices, had been erected in the heart of the Cotswolds alongside the main CheltenhamGloucester road and opposite the municipal airport of those two towns. Serious production of Rotol constant-speed airscrews had started. At the helm, as general manager, wasand -isMr. R. Stammers, who was for many years a member of Mr. A. H. R. Fedden's staff at Bristol. To-day production is concentrated on constant-speed airscrews of different sizes. The Rotol airscrew which is being produced at this factory is of the three-bladed type, with the hydraulic actuating mechanism located in the hub, the blades being controlled by a combined pump and governor unit situated on the engine.

Fretting

Prevented

The blades are of forged magnesium alloy, prepared by High Duty Alloys, Ltd., of Slough. These blades are screwed into steel sockets and locked in position by dowel pins. To prevent the magnesium fretting against the steel at the upper end of the socket, a wedge-shaped section ring of Tufnol is fitted into the mouth of the socket and secured by a locking ring and set screw. Incidentally, the removal of this Tufnol ring in service would be a difficult proposition but for the presence of a wedge-sectioned groove round its circumference. The groove coincides with the position of the set screw of the locking ring. After first slacking off the locking ring, the set screw is replaced with a grease gun nipple, and, with the aid of a grease gun, pressure is

]

The Airscrew

Hub

Three short barrels in the hub accommodate the blades, which are carried in stacks of thrust-bearing races t h a t serve the dual purpose of retaining the blades against the action of centrifugal force and at the same time allow them to be rotated in the barrel of the hub for pitch-changing. The hub is mounted on the airscrew shaft by means of a splined sleeve. I t is so designed that it is able to counteract the centrifugal force acting on the blades, and at the same time is able to transmit direct to them the engine torque. The forward section of the h u b driving centre is of a reduced diameter, and on this neck a stationary piston is fixed. Around the piston is fitted a free cylinder, which is sealed at both ends and is free to slide under oil pressure introduced by the pump unit on one or other side of the piston. The oil is conducted from the combined pump and governor unit by two pipes which are connected to the airscrew by means of an oil transfer or muff housing at the rear end of the hub driving centre. This housing allows the oil to pass through annular grooves in its bore to ducts in the hub driving centre, which revolves in a floating bush.

A sectioned Rotol airscrew hub was shown at the rec: Paris Show to help visitors to understand the intricacies the operating mechanism-

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Senarai Upah Kerja Mengikut Pasaran Semasa - Bengkel Kereta Milik Sepenuhnya Bumiputera Islam Aunas EnterpriseDokument8 SeitenSenarai Upah Kerja Mengikut Pasaran Semasa - Bengkel Kereta Milik Sepenuhnya Bumiputera Islam Aunas EnterpriseAzrai Aziz71% (31)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Stranger Things Dnd5eDokument1 SeiteStranger Things Dnd5ejeff fejjNoch keine Bewertungen

- JodoDokument10 SeitenJodoJanne Fredrik100% (1)

- Magna vf750c PDFDokument306 SeitenMagna vf750c PDFAldair MartínezNoch keine Bewertungen

- The Ultimate FPS Strategy Guide BookDokument45 SeitenThe Ultimate FPS Strategy Guide BookAlesio Salvado100% (1)

- Wattbike Power Cycling Course ManualDokument47 SeitenWattbike Power Cycling Course ManualFrancesco MatteoliNoch keine Bewertungen

- Gtsac : Flight Engineering SectionDokument1 SeiteGtsac : Flight Engineering Sectionseafire47100% (1)

- Percival Q4,6 1937 - 3486Dokument1 SeitePercival Q4,6 1937 - 3486seafire47Noch keine Bewertungen

- PH - Carolina's Chorizo Carbonara With Garden SaladDokument2 SeitenPH - Carolina's Chorizo Carbonara With Garden Saladseafire47Noch keine Bewertungen

- PH - Almond & Garlic Crusted Chicken With Cherry Tomato SaladDokument2 SeitenPH - Almond & Garlic Crusted Chicken With Cherry Tomato Saladseafire47Noch keine Bewertungen

- 1937 - 3485Dokument1 Seite1937 - 3485seafire47Noch keine Bewertungen

- Second Parting: Short-Mayo Compo-Site Separated "In Public"Dokument1 SeiteSecond Parting: Short-Mayo Compo-Site Separated "In Public"seafire47Noch keine Bewertungen

- Shor BRQS.: of RochesterDokument1 SeiteShor BRQS.: of Rochesterseafire47Noch keine Bewertungen

- Short S.20 Mercury SDokument3 SeitenShort S.20 Mercury Sseafire47Noch keine Bewertungen

- 1938 - 2869Dokument1 Seite1938 - 2869seafire47Noch keine Bewertungen

- Commercial Aviation and Airlines Updates in 1935Dokument1 SeiteCommercial Aviation and Airlines Updates in 1935seafire47Noch keine Bewertungen

- Flight.: Final Gliding Contest ResultsDokument1 SeiteFlight.: Final Gliding Contest Resultsseafire47Noch keine Bewertungen

- 203 Sample ArticleDokument8 Seiten203 Sample Articleseafire47Noch keine Bewertungen

- East To West Record: 13% HOURSDokument1 SeiteEast To West Record: 13% HOURSseafire47Noch keine Bewertungen

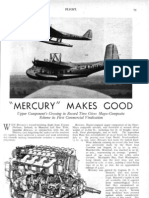

- "Mercury" Makes GoodDokument1 Seite"Mercury" Makes Goodseafire47Noch keine Bewertungen

- 74-A-23 Se5a F938Dokument4 Seiten74-A-23 Se5a F938seafire47Noch keine Bewertungen

- 598 Flight.: DECEMBER I 6, 1937Dokument1 Seite598 Flight.: DECEMBER I 6, 1937seafire47Noch keine Bewertungen

- 4 Worlds FairDokument5 Seiten4 Worlds Fairseafire47Noch keine Bewertungen

- 1937 - 3487Dokument1 Seite1937 - 3487seafire47Noch keine Bewertungen

- SB2U VindicatorDokument11 SeitenSB2U Vindicatorseafire47100% (1)

- Wright Flyer 1903 EngineDokument3 SeitenWright Flyer 1903 Engineseafire47Noch keine Bewertungen

- 8 Ross RS1 93Dokument4 Seiten8 Ross RS1 93seafire47Noch keine Bewertungen

- 95 Sample ArticleDokument5 Seiten95 Sample Articleseafire47Noch keine Bewertungen

- 7 Moundsville Lone Eagle 94Dokument9 Seiten7 Moundsville Lone Eagle 94seafire47Noch keine Bewertungen

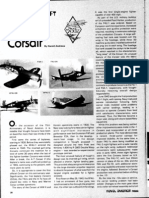

- Chance Vought F4u CorsairDokument6 SeitenChance Vought F4u Corsairseafire47100% (3)

- F4u 4Dokument8 SeitenF4u 4seafire47100% (1)

- VS-10001 GA 02 F4U-1 CorsairDokument0 SeitenVS-10001 GA 02 F4U-1 Corsairseafire47Noch keine Bewertungen

- Splash 1Dokument4 SeitenSplash 1seafire47100% (1)

- Designation OF USA AIRCRAFTDokument9 SeitenDesignation OF USA AIRCRAFTseafire47Noch keine Bewertungen

- Raid On Regensburg2Dokument8 SeitenRaid On Regensburg2seafire47100% (1)

- b47 v3Dokument4 Seitenb47 v3seafire47100% (1)

- By Guru Scott Mcquaid: Thursday, 28 February 2013 12:17Dokument4 SeitenBy Guru Scott Mcquaid: Thursday, 28 February 2013 12:17diamond68Noch keine Bewertungen

- Oasis Club MembershipDokument2 SeitenOasis Club Membershiprajasikander aliNoch keine Bewertungen

- Compressor Crankcase Breather: Service BulletinDokument2 SeitenCompressor Crankcase Breather: Service BulletinAlexander MugabeNoch keine Bewertungen

- Follow The Instructions For R.I.C.EDokument2 SeitenFollow The Instructions For R.I.C.Eayatolla ayatollaTMNoch keine Bewertungen

- Crossword Puzzle: Hidden OccupationsDokument2 SeitenCrossword Puzzle: Hidden OccupationsFabriciogerig LezcanoNoch keine Bewertungen

- Chanel IndihomeDokument4 SeitenChanel IndihomenatayaNoch keine Bewertungen

- Rhythmic ActivitiesDokument4 SeitenRhythmic ActivitiesErica Piga ButacNoch keine Bewertungen

- Advocate 13122022Dokument418 SeitenAdvocate 13122022samarNoch keine Bewertungen

- A MomentsDokument14 SeitenA MomentsMartha DE Gama100% (2)

- Staying Safe Indoors and OutDokument15 SeitenStaying Safe Indoors and OutAlyssum JJNoch keine Bewertungen

- Case Study On Bobby FischerDokument2 SeitenCase Study On Bobby FischerZain KhanNoch keine Bewertungen

- 875 Physical Education - Isc SpecimenDokument13 Seiten875 Physical Education - Isc SpecimenRyan BradleyNoch keine Bewertungen

- Video Zone Meet The Kids Racing Electric Cars WorksheetDokument2 SeitenVideo Zone Meet The Kids Racing Electric Cars WorksheetОльга ПокровскаяNoch keine Bewertungen

- 01fjmc2016 PDFDokument26 Seiten01fjmc2016 PDFSaad AtherNoch keine Bewertungen

- Artificial Sports Lighting Design Guide 2012 051112Dokument61 SeitenArtificial Sports Lighting Design Guide 2012 051112Mohamed FaragNoch keine Bewertungen

- 58-98HP C-MAX TRACTOR RANGE TECHNICAL SPECSDokument2 Seiten58-98HP C-MAX TRACTOR RANGE TECHNICAL SPECShuskerchampsNoch keine Bewertungen

- Sparco Catalogue 2020 ENG PRICES LWDokument151 SeitenSparco Catalogue 2020 ENG PRICES LWmarianNoch keine Bewertungen

- FIFA 2015 Womens World Cup Schedule and Scoresheet TemplateDokument35 SeitenFIFA 2015 Womens World Cup Schedule and Scoresheet TemplateGomv ConsNoch keine Bewertungen

- Lesson 5 - Respiratory SystemDokument29 SeitenLesson 5 - Respiratory Systemapi-307592530Noch keine Bewertungen

- Regulament Receptie ConstructiiDokument1 SeiteRegulament Receptie ConstructiiFlorian RapanuNoch keine Bewertungen

- New 1 - 000002Dokument262 SeitenNew 1 - 000002DJ&Music channelNoch keine Bewertungen

- 5 AS EnergyDokument3 Seiten5 AS EnergyfdadsfNoch keine Bewertungen

- 1 - QF - A Story About The Reels - With AnswersDokument41 Seiten1 - QF - A Story About The Reels - With AnswersMarcosMarcosLimaPeruNoch keine Bewertungen

- Jute Draw FrameDokument4 SeitenJute Draw FrameRobotrix100% (2)