Beruflich Dokumente

Kultur Dokumente

norochcholai power plant overview

Hochgeladen von

ansudasinghaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

norochcholai power plant overview

Hochgeladen von

ansudasinghaCopyright:

Verfügbare Formate

norochcholai power plant

Ceylon electricity board is governing the main body responsible for electricity generation, transmission and distribution. Therefore Total electricity supply of the country depends on this single entity. It is dedicated to be a utility providing high quality service to its customers maintaining Reliability, affordability and sustainability of the power sector. To address the remaining power crisis in sri lanka CE started its first coal power plant construction in !""# in norochcholai following a lot of feasibility studies..$ain contractor for the pro%ect is China &ational $acinery and Equipment import and E'port Corporation.(ro%ect was funded by E)I$ ank of China with the total pro%ect cost of *+ , -.. million/for stage one only0.1akvi%aya power plant pro%ect consists of three stages/2 ' 2""$30. Total area for three stages is 4!ha.5irst stage of the pro%ect covers the v 2""$3 coal fired power plant. v +ite infrastructure and au'illary systems including the %etty of .""m. v 667 km long ,!!"k8 double circuit transmission line from 8eyangoda to &orochcholai. Steam turbine

2"" $w 2""" rpm turbine is used here. The turbine is mainly divided in to 2 parts such as high pressure turbine, intermediate pressure turbine and low pressure turbine. The high pressure turbine and intermediate pressure turbine are connected in same shaft but low pressure turbine is connected in separately. Coal handling process

ituminous coal type is designed to use as main fuel in the plant which is mainly imported from Indonesia. Coal requirement for 1akvi%aya power plant is 77",""" tons per year /average0.

I studied coal handling process from %etty to bunker bay which is used to store coal before enter to the furnace. +tudying this process would be very hard because I had to go by foot more than 2 km but with the help of engineers and other workers I did it without any trouble. Coal handling process is very important process because it directly affects the power generation in the plant. This process can be e'plained as follow. The coal is imported from Indonesia or 9ustralia using cargo ships and then coal is transferred from ships to %etty using barges. There are 2 barges belonging to the CE and each one has capacity of .""" tons. 9fter that convey belt system is used to transfer coal from %etty to bunker bay. The coal is unloaded into the convey belt number " from barges using coal unloaders which looks like as a crane. There are two coal unloaders and each one has capacity of ."" tons per hour. The technician who controls the coal unloaders taught me how to unload coal using coal unloaders. It was not easy %ob but it was a good e'perience in my training period. Convey number " goes to the %unction tower and where coal path is divided into ! paths which are called emergency path and normal path /convey belt number #0.The emergency path is used when there is a problem occurred in the normal path, this is very important because any delay in the unloading process CE has to pay millions of money to the cargo ship company. In the %unction tower coal sample is taken in every one hour for quality checking purpose. The normal path goes through the stockpile and here there is equipment called bucket wheel stacker reclaimer.

ucket wheel stacker reclaimer is used to stack the coal in to the stock pile or reclaim coal in to the convey belt. This equipment has stacking capacity of 6."" tons per hour and reclaiming capacity of #"" tons per hour. The convey belt # ends in the transfer tower !.In here there is an equipment called iron separator which is used to remove iron from coal. If bucket wheel stacker reclaimer is out of service they have another option. Two underground reclaim hoppers laid in the coal yard and using convey belt . coal can be transferred to the transfer tower 2 and then using convey belt number - coal can be transferred to the transfer tower ! then. Then coal is transferred to crusher house using convey belt number 2. In the crusher house coal is crushed and then coal particle si:e is reduced to 2 cm. 9fter that coal is transferred to the transfer tower 6 using convey belt number ! and then these coals are fed to . bunkers. Every bunker is connected with pulveri:er which is used to crush the coal particles in to the !" ;m. Then coal is send to the furnace using primary air. Coal burning process Primary air and secondary air (rimary air is get from atmosphere by using ! primary air supply fans which each one has capacity of 6.! $w. This primary air is used to send coal particles into the furnace in the boiler. The portion of primary air is sent through the air pre heater to increase temperature of air and

then this hot primary air and cold primary air are mi'ed to get required temperature because it will increase efficiency of burning process. Two forced draft fans are used to supply secondary air to the furnace. The main purpose of secondary air is to supply <! for coal burning process. This secondary air also is heated using air pre heater. Air pre heater

I observed air pre heater in several time and then I understood the working principle of air pre heater and importance of air pre heater but it was difficult to reach that place due to high heat. The e'haust flu gas has high amount of heat there for this heat is used to increase temperature of primary air and secondary air because it increases the efficiency of coal burning process. Therefore air pre heater is used to e'change heat from flue gas to the primary and secondary air. There is a 66 kw motor to rotate the air pre heater to 6 rpm. The inlet temperature of flu gas in the air pre heater is appro'imately 2.2 =C and outlet temperature is 6!6 =C. The inlet temperature of primary and secondary air is appro'imately 26 =C and outlet temperature of rimary is appro'imately 222 =C and outlet temperature of secondary is appro'imately 22> =C

Boiler This is the most important part of the power plant and there are several methods are used to increase the boiler efficiency and reduced air pollution. 5irst I visited boiler with an engineer and he e'plained basic information relating to the boiler. Then I studied boiler related notes which were given to me and got clear idea about the boiler. Then visited boiler number of times and learnt a lot of things with regard to the boiler. This boiler is the largest boiler in the +ri 1anka. The name of the boiler is inverted u type natural circulation balance draft subcritical boiler. I also studied the inside boiler arrangement. This boiler consists with burners, super heaters, re heaters, economi:er and air pre heater. Two induced draft fans are used to maintain negative pressure inside boiler and it helps to flue gas to go out inside the boiler easily. 9nother booster fan is also used to support this process. Furnace of the boiler Firing system of the furnace The firing system in the furnace is called circular firing system. Temperature of the furnace is always maintained below the 6!"" =C because it reduces &<' formation. I studied the main features of this firing system. There are ? +table ignition and combustion

? ?

1ow &<' emission *niform heat absorption

Bottom ash (Wet ash) handling 9fter the coal combustion the remaining residual in the furnace is called bottom ash and this is !"@ of the total ash production in the combustion. 3hen power plant runs in full load /2"" $w0 total bottom ash production is appro'imately !.. tonsAh. This value may be changed according to the quality of coal. +ubmerged scraper conveyor belt system is used to collect bottom ash from the furnace. I studied the how this belt system works and got clear idea with the help of a mechanical engineer in the plant. This bottom ash is used as land fill. Fly ash handling 5ly ashes are fine particles which are generated in the coal combustion and they rise with flue gas. The total fly ash production of the plant is 6-.4 tonsAh when plant runs in full load /2"" $w0. If these fly ash mi' with atmosphere then it will create a lot of environmental problems. 3hen establishing this 1akvi%aya power plant this point is highly concerned because numbers of environmental protection organi:ations opposed to establishing this kind of plant. Therefore especial mechanism is used in the plant to grab fly ash from the flue gas. This is called electrostatic precipitator. Collecting (lates

Collecting plates Every plate contains electrodes which are positively charged. 3hen the particulate gas enters the electrostatic precipitator and is struck with a negative charge electrode. The positively charged plates act as a magnet and pull the particulate gas to them. The plates are placed parallel to the incoming particulate gas. Bischarge Electrodes Bischarging electrodes are a high voltage unit that negatively charges the particulate gas as it enters. The discharge electrode is mounted to a frame in between the collecting plates

Sea water recovery system

9fter the absorption process the sea water consists with sulfite ions and hydrogen ions and then sea water flows to aeration basin by gravity. In the aeration basin, bicarbonate ions /CC<2D0 from the seawater react with hydrogen ions to form carbon dio'ide and thereby neutrali:e the acidity and raise the (C value. 9 mass of air aerate into the water through aeration pipe and seawater is further o'ygenated to complete the o'idation reaction and to bring the dissolved o'ygen to an environmentally acceptable level before discharge to sea. +<! is o'idi:ed to sulfate and sulfate is a natural ingredient in seawater, and there is only a slight increase in the sulfate in the seawater returned to the sea.

Das könnte Ihnen auch gefallen

- Mechanical Engg.: Report On Industrial TrainingDokument44 SeitenMechanical Engg.: Report On Industrial TrainingSakshi SanghiNoch keine Bewertungen

- Fire Fighting Robot by Using ArduinoDokument12 SeitenFire Fighting Robot by Using ArduinoVijay KumarNoch keine Bewertungen

- Effects of Norochcholai Coal Power Plant ProjectDokument11 SeitenEffects of Norochcholai Coal Power Plant Projectjanitha100% (2)

- Synopsis of Fire Fighting RobotDokument5 SeitenSynopsis of Fire Fighting RobotDivyangna0% (2)

- A Survey On Fire Fighting RobotDokument5 SeitenA Survey On Fire Fighting Robotsathish100% (1)

- Sri Lanka's Largest Coal Power PlantDokument6 SeitenSri Lanka's Largest Coal Power PlantIsuru Kodikara100% (1)

- ME8595-Thermal Engineering-II Valliammai PDFDokument19 SeitenME8595-Thermal Engineering-II Valliammai PDFSiva SubramaniamNoch keine Bewertungen

- EME Micro-ProjectDokument11 SeitenEME Micro-ProjectGanesh GoreNoch keine Bewertungen

- Boiler Report ProjectDokument22 SeitenBoiler Report ProjectAsad AyoubNoch keine Bewertungen

- MWM Microproject ReportDokument5 SeitenMWM Microproject Reportpratha100% (1)

- Hybrid Metal Additive ManufacturingDokument75 SeitenHybrid Metal Additive ManufacturingNursultan JyeniskhanNoch keine Bewertungen

- Adigrat University: Pedal Operated Water Pump (Concrete Pedal Pump)Dokument50 SeitenAdigrat University: Pedal Operated Water Pump (Concrete Pedal Pump)Melese HaileNoch keine Bewertungen

- Fan Blade Out Analysis PDFDokument2 SeitenFan Blade Out Analysis PDFStaceyNoch keine Bewertungen

- Training Report at CGRDokument18 SeitenTraining Report at CGRMohamed Ihsan75% (4)

- Ravi Intern ReportDokument66 SeitenRavi Intern ReportRavi KoiralaNoch keine Bewertungen

- Diesel EngineDokument14 SeitenDiesel EngineAyşenur ÇetinNoch keine Bewertungen

- FUELS AND SUPPLYDokument102 SeitenFUELS AND SUPPLYRushabh PatelNoch keine Bewertungen

- Wi-Fi Home Automation System ReportDokument44 SeitenWi-Fi Home Automation System Reportravi kumarNoch keine Bewertungen

- Overview of NTPC PDFDokument40 SeitenOverview of NTPC PDFRahul KediaNoch keine Bewertungen

- A Review On Revolution of Flat Plate Collector For Solar Water HeaterDokument17 SeitenA Review On Revolution of Flat Plate Collector For Solar Water HeaterIJRASETPublications100% (1)

- Optimised switched reluctance motors for hybrid electric vehiclesDokument6 SeitenOptimised switched reluctance motors for hybrid electric vehiclesgeerhardusvosNoch keine Bewertungen

- Sagar Kumar Seminar Report PDFDokument20 SeitenSagar Kumar Seminar Report PDFPRASHANTA BAL100% (1)

- Eme Lab Manual PDFDokument45 SeitenEme Lab Manual PDFpatidar montuNoch keine Bewertungen

- Hcci EngineDokument155 SeitenHcci Engineriyaz ahmedNoch keine Bewertungen

- Pneumatic Bike: A Step To Future: V. Lohit A. Imran MohideenDokument3 SeitenPneumatic Bike: A Step To Future: V. Lohit A. Imran MohideenTanviNoch keine Bewertungen

- Portable Mini Wooden Lathe ProjectDokument3 SeitenPortable Mini Wooden Lathe ProjectArsalan Ahmed100% (1)

- Pneumatic Hack SawmachineDokument93 SeitenPneumatic Hack Sawmachinesanthosh saravananNoch keine Bewertungen

- Automobile Air Conditioning Through Engine Exhaust GasesDokument18 SeitenAutomobile Air Conditioning Through Engine Exhaust Gasesagarwalsarthak121Noch keine Bewertungen

- Types of scavenging in IC enginesDokument18 SeitenTypes of scavenging in IC enginesSajjad Hossain ShuvoNoch keine Bewertungen

- Solar Water Heater Lab Guide FinalDokument14 SeitenSolar Water Heater Lab Guide Finalerduobing100% (1)

- MEP Internship Training Report Main PageDokument40 SeitenMEP Internship Training Report Main PageHhNoch keine Bewertungen

- Industrial Visit ReportDokument3 SeitenIndustrial Visit ReportBarzeen Mehr AfareenNoch keine Bewertungen

- Electron Beam MachiningDokument9 SeitenElectron Beam MachiningYunitha RatnadillaNoch keine Bewertungen

- Repoart On Automatic Braking Sysytem 1Dokument29 SeitenRepoart On Automatic Braking Sysytem 1VISHAL SEHRANoch keine Bewertungen

- Industrial Training Report-LoadstarDokument11 SeitenIndustrial Training Report-LoadstarNuwan Bandara100% (2)

- 08 CH-6, Fluid Motion Within Combustion ChamberDokument24 Seiten08 CH-6, Fluid Motion Within Combustion ChamberAhsan AliNoch keine Bewertungen

- Mohd Fadhil Musbah FYP Interim Report UTPDokument16 SeitenMohd Fadhil Musbah FYP Interim Report UTPMohd Fadhil Musbah0% (1)

- Surface Condenser Report SummaryDokument12 SeitenSurface Condenser Report Summaryshubham kesarkarNoch keine Bewertungen

- Fabrication of Pneumatic Auto Feed Drilling MachineDokument37 SeitenFabrication of Pneumatic Auto Feed Drilling Machinegnana muruganNoch keine Bewertungen

- CHAPTER 7 Combustion in SI and CI EnginesDokument47 SeitenCHAPTER 7 Combustion in SI and CI EnginesRushabh PatelNoch keine Bewertungen

- "Study of Convergent-Divergent Nozzle": A Minor Project ReportDokument67 Seiten"Study of Convergent-Divergent Nozzle": A Minor Project Reportchinna570% (1)

- Lab ReportDokument4 SeitenLab ReportNinton NawiwaNoch keine Bewertungen

- Virtual Manufacturing: ColloquiumDokument37 SeitenVirtual Manufacturing: ColloquiumSum Sumne SumanthNoch keine Bewertungen

- Engineering Ethics Activity SolutionsDokument4 SeitenEngineering Ethics Activity SolutionsJayvee Coliao100% (1)

- Vishwakarma Institute of TechnologyDokument36 SeitenVishwakarma Institute of TechnologyGaurav AthavaleNoch keine Bewertungen

- Energy Engineering (18ME81) : Pradeep N B Asst. Professor Mechanical Dept., JNNCEDokument50 SeitenEnergy Engineering (18ME81) : Pradeep N B Asst. Professor Mechanical Dept., JNNCEPradeep N BNoch keine Bewertungen

- MM323 Assignment 2 Report Format - NewDokument21 SeitenMM323 Assignment 2 Report Format - NewKelemedi DreuNoch keine Bewertungen

- Gogte Institute of Technology: Dr.V.N.SatwikDokument16 SeitenGogte Institute of Technology: Dr.V.N.Satwikaditya thakkarNoch keine Bewertungen

- Manufacturing Process Lab Manual1Dokument1 SeiteManufacturing Process Lab Manual1AliNoch keine Bewertungen

- Module 2 Notes 18ME81Dokument28 SeitenModule 2 Notes 18ME81Gaviroy PrasadNoch keine Bewertungen

- ME8792 PPE by WWW - Learnengineering.inDokument136 SeitenME8792 PPE by WWW - Learnengineering.inKarthi BENoch keine Bewertungen

- Mini ProjectDokument44 SeitenMini ProjectVenkata Sai M60% (5)

- Robots Handle Nuclear DangersDokument23 SeitenRobots Handle Nuclear DangersEjaz KNoch keine Bewertungen

- Vibration Analysis of Conventional Ceiling Fan BladeDokument3 SeitenVibration Analysis of Conventional Ceiling Fan Bladekrishhnagaikwad100% (1)

- Automatic Transmission Fluid Flywheel and Torque ConverterDokument14 SeitenAutomatic Transmission Fluid Flywheel and Torque ConverterERISON FARINoch keine Bewertungen

- Short ReportDokument2 SeitenShort ReportRaj MandloiNoch keine Bewertungen

- 3 Axis Pnumatic TrailerDokument50 Seiten3 Axis Pnumatic TrailerKritisundar Garnayak50% (2)

- Root Cause Identification and Elimination of Problems in Soot Blowers of Chemical Recovery BoilersDokument7 SeitenRoot Cause Identification and Elimination of Problems in Soot Blowers of Chemical Recovery BoilersDodi SuhendraNoch keine Bewertungen

- Summer Training Experience at NTPC Dadri Power PlantDokument33 SeitenSummer Training Experience at NTPC Dadri Power PlantSubodh DuhanNoch keine Bewertungen

- Drive Systems On ConveyorsDokument7 SeitenDrive Systems On Conveyorsrudolfhose100% (1)

- Chapter 1 of Materials Handling Handbook 2nd EditionDokument92 SeitenChapter 1 of Materials Handling Handbook 2nd EditionansudasinghaNoch keine Bewertungen

- Vibration Analysis Training Manual: Mobius InstituteDokument16 SeitenVibration Analysis Training Manual: Mobius InstituteansudasinghaNoch keine Bewertungen

- Cci Hp Bypass 6630-二期Dokument1 SeiteCci Hp Bypass 6630-二期ansudasinghaNoch keine Bewertungen

- Engineering Design Decision Matrix WorksheetDokument1 SeiteEngineering Design Decision Matrix WorksheetansudasinghaNoch keine Bewertungen

- ME349 Engineering Design Projects: Introduction To Materials SelectionDokument6 SeitenME349 Engineering Design Projects: Introduction To Materials SelectionMehul KaklotarNoch keine Bewertungen

- Engineering Design Ch8Dokument8 SeitenEngineering Design Ch8ansudasinghaNoch keine Bewertungen

- Boiler PreservationDokument3 SeitenBoiler PreservationansudasinghaNoch keine Bewertungen

- Coal Power Unit StartDokument8 SeitenCoal Power Unit StartansudasinghaNoch keine Bewertungen

- ESP Operation Manual-Trouble ShootingDokument5 SeitenESP Operation Manual-Trouble ShootingansudasinghaNoch keine Bewertungen

- Optimum Solution Matrix - 2Dokument1 SeiteOptimum Solution Matrix - 2ansudasinghaNoch keine Bewertungen

- DCS-of A Rankine Cycle of 300MWDokument1 SeiteDCS-of A Rankine Cycle of 300MWansudasinghaNoch keine Bewertungen

- Vaastu Shilpayai Obe NiwasaiDokument5 SeitenVaastu Shilpayai Obe NiwasaiansudasinghaNoch keine Bewertungen

- ME5004 Assignment 1 on Transfer ProcessesDokument1 SeiteME5004 Assignment 1 on Transfer ProcessesansudasinghaNoch keine Bewertungen

- AsanikDokument1 SeiteAsanikansudasinghaNoch keine Bewertungen

- Plant ArrangementDokument5 SeitenPlant ArrangementansudasinghaNoch keine Bewertungen

- Application Guide: Earth Leakage Circuit BreakersDokument0 SeitenApplication Guide: Earth Leakage Circuit BreakersansudasinghaNoch keine Bewertungen

- Condenser Tube Life-Cycle EconomicsDokument5 SeitenCondenser Tube Life-Cycle EconomicsansudasinghaNoch keine Bewertungen

- Springs U3 Sept13thDokument18 SeitenSprings U3 Sept13thansudasinghaNoch keine Bewertungen

- Welding Heat Treatment Standard for Power PlantsDokument31 SeitenWelding Heat Treatment Standard for Power PlantsansudasinghaNoch keine Bewertungen

- Chiller Types by Capacity Range and SizeDokument4 SeitenChiller Types by Capacity Range and SizeansudasinghaNoch keine Bewertungen

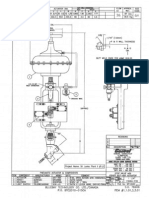

- Drain Control ValveDokument3 SeitenDrain Control ValveansudasinghaNoch keine Bewertungen

- Standing Orders BOCDokument1 SeiteStanding Orders BOCansudasinghaNoch keine Bewertungen

- Design and Selection Criteria For Check ValvesDokument26 SeitenDesign and Selection Criteria For Check Valvesmhopgood100% (3)

- Nipolac PrecoatDokument2 SeitenNipolac Precoatansudasingha100% (1)

- Application Guide: Earth Leakage Circuit BreakersDokument0 SeitenApplication Guide: Earth Leakage Circuit BreakersansudasinghaNoch keine Bewertungen

- Aux Steamblow DataDokument11 SeitenAux Steamblow DataansudasinghaNoch keine Bewertungen

- Aux Steamblow DataDokument11 SeitenAux Steamblow DataansudasinghaNoch keine Bewertungen

- norochcholai power plant overviewDokument5 Seitennorochcholai power plant overviewansudasinghaNoch keine Bewertungen

- Basic Inorganic ChemistryDokument20 SeitenBasic Inorganic ChemistryOMED gardiNoch keine Bewertungen

- UPSEE Full-Paper 2006Dokument40 SeitenUPSEE Full-Paper 2006AditiBhatnagar1100% (1)

- Project Content ChemistryDokument6 SeitenProject Content ChemistryPrathmesh MoreNoch keine Bewertungen

- Indoor Environmental Quality Factors for Comfort and HealthDokument42 SeitenIndoor Environmental Quality Factors for Comfort and HealthSyed Imtiaz Ali ShahNoch keine Bewertungen

- 01Dokument97 Seiten01cheery1Noch keine Bewertungen

- Experiment No. 4: Standardization of Sodium Thiosulphate Solution With A Standard Potassium Dichromate SolutionDokument20 SeitenExperiment No. 4: Standardization of Sodium Thiosulphate Solution With A Standard Potassium Dichromate Solutionshiam50% (2)

- Presentation On Forged Mill Balls Production in South AfricaDokument23 SeitenPresentation On Forged Mill Balls Production in South AfricaRamoutar (Ken) SeecharranNoch keine Bewertungen

- Extraction and Application of Lycopene From PapayaDokument5 SeitenExtraction and Application of Lycopene From PapayaDevita AmeliaNoch keine Bewertungen

- Review of Literature on Aloe Vera and Hand SanitizersDokument4 SeitenReview of Literature on Aloe Vera and Hand SanitizersRamNoch keine Bewertungen

- Ductulator May 2010Dokument8 SeitenDuctulator May 2010haroub_nasNoch keine Bewertungen

- Guidelines For BCS Based Biowaiver SFDA (8!4!2013)Dokument12 SeitenGuidelines For BCS Based Biowaiver SFDA (8!4!2013)Ali EnaNoch keine Bewertungen

- Magnetic Susceptibility ReportDokument13 SeitenMagnetic Susceptibility Reportsackeynat100% (1)

- Wear Plate SpecsDokument4 SeitenWear Plate SpecsJuan Carlos EspinozaNoch keine Bewertungen

- Corrosion PDFDokument51 SeitenCorrosion PDFSuryansh SinghNoch keine Bewertungen

- Ophthalmic InsertsDokument28 SeitenOphthalmic InsertsShendi SuryanaNoch keine Bewertungen

- Group II Cation AnalysisDokument4 SeitenGroup II Cation AnalysisClare CaspeNoch keine Bewertungen

- Rilco Aerogel ProductsDokument1 SeiteRilco Aerogel Productsnhr71Noch keine Bewertungen

- Dow Carbowax PEGs PDFDokument12 SeitenDow Carbowax PEGs PDFMattNoch keine Bewertungen

- My first experience student teaching chemistry at Manila Science High SchoolDokument2 SeitenMy first experience student teaching chemistry at Manila Science High SchoolIta Adri SupriatiNoch keine Bewertungen

- Martin Flexible Couplings CatalogDokument37 SeitenMartin Flexible Couplings CatalogJean CarlosNoch keine Bewertungen

- Material Safety Data Sheet Konkreton XSDokument9 SeitenMaterial Safety Data Sheet Konkreton XSDaniel DaiaNoch keine Bewertungen

- CODEX STANDARD FOR FERMENTED MILKSDokument11 SeitenCODEX STANDARD FOR FERMENTED MILKSvabimhah100% (2)

- Thermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesDokument2 SeitenThermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesAnonymous sAmJfcVNoch keine Bewertungen

- Acrolon 890 EN 20130206Dokument2 SeitenAcrolon 890 EN 20130206hainguyenbkvhv0% (1)

- 8-5 Destruction of Old ExplosivesDokument7 Seiten8-5 Destruction of Old ExplosivesOlubi FemiNoch keine Bewertungen

- VTP & VPC: Vertical Turbine Wet Pit and Double Casing Pumps Maintenance ChecklistDokument2 SeitenVTP & VPC: Vertical Turbine Wet Pit and Double Casing Pumps Maintenance Checklistsathiyam2kNoch keine Bewertungen

- Tai RaporDokument39 SeitenTai RaporerdemersoyNoch keine Bewertungen

- Catalog Copeland KCLDokument40 SeitenCatalog Copeland KCLIsidro MendozaNoch keine Bewertungen

- Bio Monitoring of AtmosphericDokument174 SeitenBio Monitoring of AtmosphericOluflourish EmmanuelNoch keine Bewertungen

- Kerosene: Prepared by Supervisor:-Mr. Shwan Ammar Askandar Waleed AdnanDokument9 SeitenKerosene: Prepared by Supervisor:-Mr. Shwan Ammar Askandar Waleed AdnanWalid Adnan100% (1)