Beruflich Dokumente

Kultur Dokumente

1957 - 1624

Hochgeladen von

johnblackburnCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1957 - 1624

Hochgeladen von

johnblackburnCopyright:

Verfügbare Formate

712

AIRLINERS OF THE WORLD

FLIGHT

FOKKER F.27 FRIENDSHIP Two Rolls-Royce Dart 511 of 1,740 e.p.h. each driving Rotol four-bladed. 12ft propellers* Dimensions: Span, 95ft 2in; length, 75ft 9in; height, 27ft 6in; wing area, 754 sq ft; aspect ratio, 12. Weights: Operating weight empty (32 seats), 22,0001b; max. payload, 10,200 Ib (32 passengers, catering and 4,792 Ib of baggage and cargo); max. zero fuel weight, 32,200 Ib; max. landing weight, 34,000 Ib: max. take-off weioht 34,250 Ib. " Performance (at 33,000 Ib in standard condition*): Take-off balanced field length, sea level, 3.600ft; rate of climb, sea level, 1, (80ft/min: 100ft/min ceiling, 34,000ft; cruising speed at 20,000ft, 13,600 r.p.m., 275 m.p.h.; landing field length, sea level, 2,90Cft. * A version with Dart 528s (1,960 e.h.p.) with improved performance, is offered also.

FRIENDSHIP

Royal Netherlands Aircraft Factories, Fokker, Amsterdam U.S. Licensees: Fairchild Engine and Airplane Corp., Hagerstown, Maryland N a world air transport building industry which is dominated by a few big firms, it is remarkable that a small country like Holland should have come up with a transport as best-selling as the Fokker F.27 Friendship. This aeroplane has been greatly sought by that most needy, if the poorest, category of air transport the branchline feeder routes of not very high traffic density which are still today largely flown by obsolete DC-3s and C-46s. The Dutch firm of Fokker does not enjoy a big home market for diis type of aircraft (K.L.M. operate a dozen DC-3s) but this fact, frequently bewailed by other European manufacturers, does not seem to have handicapped world-wide sales of the Friendship. It was a tremendous encouragement to Fokker when, last year, the Fairchild Engine and Airplane Corporation of America took up a licence to produce the Friendship for the U.S. local service airlines. The aircraft may now be considered as a joint marketing and production effort by the Dutch and American firms, with the British industry making a substantial contribution (amounting tc about 30 per cent of total aircraft value) in the form of the RollsRoyce powerplant, Rotol propellers, Dowty undercarriage and certain systems equipment. Fokker sum up the case for the Friendship as follows: "The many twin-engined commercial aircraft of pre-war design, often bought from war surplus dumps, though still faithfully serving short- and medium-range traffic, do not comply any more with the present-day requirements of single-engine performance, economy and speed. Take-off and landing performance are now dictated by stringent rules and regulations. Speed and economy are essentials for a profitable operation. All these factors have been taken into account in the conception and development of the Fokker F.27 Friendship. To cover the average demand, standard seating capacity has been fixed to 32 passengers and 4,800 lb of cargo with facilities for an increase to 36 or 40 passengers, without affecting the basic airframe. The combination of a payload of about four tons, a range variety of 300 to 1,000 miles, a high cruising speed and a lew operating cost, make this propeller-turbine airliner a revenue-earning proposition which can be called attractive." AIRFRAME The fuselage consists of a pressurized hull, designed for a differential pressure of 4.16 lb/sq in (8,000ft at 20,000ft). A large cargo door is included on the port forward side of die fuselage. Extensive use is made of Redux bonding in the attachment of stringers to skin. The high wing arrangement gives the advantage of low fuselage floor level for easy loading. The wing is of stressed skin construction comprising a centre section carrying the engine nacelles and detachable outer wing sections. The spars are of particular interest: the booms are bonded angle laminations, and the change in section is achieved by progressively reducing the number of laminations to combine strength with lightness and simplicity of construction. The outer wing is covered by a machine-tapered skin over two inboard sections, and integral fuel tanks are located between the front and rear spars. The construction of the tailplane and fin is conventional, as are all control surfaces. The main undercarriage is a Dowty unit with twin Dunlop wheels incorporating Maxaret brakes. Tyre pressure is 60 lb/sq in. SYSTEMS Flying Controls Duplicated cockpit controls are fitted, and the control surfaces are conventionally operated by cables and push-pull rods, each surface having a servo-trim tab. A gust-lock lever in the cockpit allows only one engine at a time to be run to take-off r.p.m. with the flying controls locked. The flaps extend from fuselage to ailerons, and are of single-slotted compound type designed by Fokker. They extend for almost three-quarters of the total wing span, and are about one-third of the wing chord in depth. Maximum lift co-efficient for take-off is 3.7. Cabin Air System The Friendship is pressurized to a maximum differential of 4.16 Ib/sq in (8,000ft at 20,000ft). Two Godfrey cabin blowers, one driven by each engine, are the source of supply. The pressurized air enters through apertures under the luggage racks and through a separate duct to the cockpit, and is discharged via relief valves from an outlet aft of the rear pressure bulkhead. Air conditioning equipment includes a turbine-expansion cold-air unit located behind the rear pressure bulkhead, and automatic temperature control to maintain the cabin at 70 deg F in the lowest outside air temperatures. Electrical System The electrical installation comprises two separate systems, (1) a 28V D.C. circuit, supplied by one enginedriven generator on each engine charging a 24 V battery, and,

(2) an A.C. system using 115 V, 400 c/s main and auxiliary inverters run off normal aircraft D.C. supply, and two engine-driven alternators giving 208 V, 400 c/s. Pneumatic System There are no hydraulics in the Friendship; pneumatic power was chosen to operate the undercarriage, brakes, and nosewheel steering. The system is powered by two Dunlop compressors, one driven by each engine, at 3,000 lb/sq in pressure. All actuators operate at 1,000 lb/sq in. The system is designed so that each half is independent in the event of failure. The undercarriage air supply is controlled by an electro-pneumatic valve which has a mechanical over-ride to guard against electrical failure; retraction time is 5 sec. Nosewheel steering is controlled by an infinitely variable valve coupled by lever and cable to the steering wheel on the left of the instrument panel (duplication for the first officer is optional). Power supply is cut off at a steering angle of 58 deg, and the self-centring device in the steering motor ensures that the whole assembly is centralized for retraction. The wheel-brakes are powered by the main storage system, with a small supplementary air bottle to maintain full pressure should the main air bottle pressure be low. The brakes are double-plate assemblies, and pneumatic Maxaret anti-skid units are fitted. Parking is achieved by depressing the toe-pedals and pulling a lock lever. An emergency pneumatic system provides power for lowering the undercarriage and applying the brakes should there be a failure in the duplicated main supply system.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

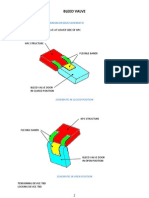

- Property Name: Die Casting Centrifugal Casting Investment CastingDokument11 SeitenProperty Name: Die Casting Centrifugal Casting Investment CastingjohnblackburnNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- AircraftDokument3 SeitenAircraftjohnblackburnNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Composite StructuresDokument6 SeitenComposite StructuresjohnblackburnNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Cargo DoorDokument1 SeiteCargo DoorjohnblackburnNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- F27Dokument1 SeiteF27johnblackburnNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 1 November 1957: /rawn at Anwterrfom May 195S, Reviierf October) 957Dokument1 Seite1 November 1957: /rawn at Anwterrfom May 195S, Reviierf October) 957johnblackburnNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- AircraftDokument3 SeitenAircraftjohnblackburnNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Bleed ValveDokument4 SeitenBleed ValvejohnblackburnNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The 1957 Aircraft Year BookDokument434 SeitenThe 1957 Aircraft Year Bookjjs100% (3)

- Fokker 27 Maintenance ManualDokument8 SeitenFokker 27 Maintenance Manualjorman0% (5)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Aircraft Performance Profiles DatabaseDokument76 SeitenAircraft Performance Profiles Databasedagger21100% (2)

- European Aviation Safety Agency: Easa Type-Certificate Data SheetDokument32 SeitenEuropean Aviation Safety Agency: Easa Type-Certificate Data SheetFaisNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Coalescers & Filters Specification & Application GuideDokument6 SeitenCoalescers & Filters Specification & Application GuideCarlos Alberto Rozo R.Noch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Tcds Easa A 036 Fokker f27 Iss 07 20180903 FinalDokument33 SeitenTcds Easa A 036 Fokker f27 Iss 07 20180903 Finalسید مسعود ابطحیNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Generic Aircraft Database Aircraft TypesDokument58 SeitenGeneric Aircraft Database Aircraft TypesGiangi MandiNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- A-817 Rev 22Dokument18 SeitenA-817 Rev 22api-542084058Noch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Spec Aircraft M50, M75, M100Dokument11 SeitenSpec Aircraft M50, M75, M100mutiara hitamNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Technical Engineering Support Services for Rolls Royce Dart EnginesDokument5 SeitenTechnical Engineering Support Services for Rolls Royce Dart EnginesBrayan RobertoNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)