Beruflich Dokumente

Kultur Dokumente

Twisted Tape and Wire Coil Inserts

Hochgeladen von

Antoni Macierewicz0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

164 Ansichten6 SeitenIn the present study, the influences of twisted tapes and wire coil on pressure drop, friction factor (f) and thermal enhancement index (p) are experimentally determined. The experiments using the twisted tape and with wire coil performed under similar operation test conditions, for comparison. The results also show that the WCTT are more efficient than the TT for heat transfer enhancement.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenIn the present study, the influences of twisted tapes and wire coil on pressure drop, friction factor (f) and thermal enhancement index (p) are experimentally determined. The experiments using the twisted tape and with wire coil performed under similar operation test conditions, for comparison. The results also show that the WCTT are more efficient than the TT for heat transfer enhancement.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

164 Ansichten6 SeitenTwisted Tape and Wire Coil Inserts

Hochgeladen von

Antoni MacierewiczIn the present study, the influences of twisted tapes and wire coil on pressure drop, friction factor (f) and thermal enhancement index (p) are experimentally determined. The experiments using the twisted tape and with wire coil performed under similar operation test conditions, for comparison. The results also show that the WCTT are more efficient than the TT for heat transfer enhancement.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

1

EXPERIMENTAL STUDY ON HEAT TRANSFER ENHANCEMENT IN A TUBE WITH

TWISTED TAPE AND WIRE COIL INSERTS

Swapnil A. Dahake

1

, Dr. A. G. Matani

2

1

M.Tech. student, Thermal Engineering, Govt. College of Engineering, Amravati, (M.S.) India.

2

Asso. Professor, Mechanical Engineering Department, Govt. College of Engineering, Amravati, (M.S.)

India.

1

swap0809@gmail.com,

2

matani.ashok@gcoea.ac.in

ABSTRACT

In the present study, the influences of twisted

tapes and wire coil on pressure drop, friction factor

(f) and thermal enhancement index (p) are

experimentally determined. The twisted tapes (TT)

are used as swirl flow generators while wire coil

along with twisted tapes (WCTT) used as co-swirl

flow generators in a test section. The tests are

conducted using the TT with three different twist

ratios (y/w = 3.5, 2.66 and 2.25) and WCTT pitch

ratio of 1.17 for Reynolds numbers range between

5000 and 18,000 under uniform heat flux conditions.

The experiments using the twisted tape and with wire

coil performed under similar operation test

conditions, for comparison. The experimental results

indicate that the tube with the various inserts

provides considerable improvement of the heat

transfer rate over the plain tube. The experimental

results demonstrate that friction factor (f) and thermal

enhancement index (p) increase with decreasing twist

ratio (y/w). The results also show that the WCTT are

more efficient than the TT for heat transfer

enhancement.

1. Introduction

In the last decades, significant effort has been

made to develop heat transfer enhancement

techniques in order to improve the overall

performance of heat exchangers. The interest in these

techniques is closely tied to energy prices and, with

the present increase in energy cost, it is expected that

the heat transfer enhancement field will go through a

new growth phase. Although there is need to develop

novel technologies, experimental work on the older

ones is still necessary. The knowledge of its

performance shows a large degree of uncertainty

which makes their industrial implementation difficult

[6]. The efficiency of heat transfer equipment is

essential in energy conservation. Furthermore, a more

efficient heat exchanger can reduce the size of the

heat exchanger, thus reducing the costs associated

with both material and manufacturing of the heat

exchanger [2]. There have been numerous attempts to

reduce the size and cost of heat exchangers. Hence,

there have been continuous attempts to improve the

efficiency of heat exchangers by various methods.

One of the best methods to achieve this is the use of

augmented heat transfer surfaces. Improved heat

transfer can make heat exchangers smaller and more

energy efficient.

Tube side enhancement techniques can be

classified according to the following criteria: (1)

additional devices which are incorporated into a plain

round tube (twisted tapes, wire coils) and (2) non-

plain round tube techniques such as surface

modification of a plain tube (corrugated and dimpled

tubes) [5] or manufacturing of special tube

geometries (internally finned tubes) [6]. The

dominant literature study usually mentions five types:

wire coils, twisted tapes, extended surface devices,

mesh inserts and displaced elements [7]. The main

advantage of these types in respect to other

enhancement techniques such as the artificial

roughness by mechanical deformation or internal fin

types is that they allow an easy installation in an

existing smooth-tube heat exchanger. The various

single and double twisted tapes are also used to

generate swirl/co-swirl [9]. Due to its low cost, the

insert devices which are most frequently used in

engineering applications are wire coils and twisted

tapes.

Heat transfer enhancement techniques have been

extensively developed to improve the thermal

performance of heat exchanger systems with a view

to reducing the size and cost of the systems.

Swirl/vortex flow is the one of the enhancement

techniques widely applied to heating/cooling systems

in many engineering applications. The vortex flows

can be classified into two types: continuous swirl and

decaying swirl flows. The former represents the

swirling motion that persists over the entire length of

the duct for example helical/twisted tape and coiled

wires inserts while the latter means the swirl created

at the duct entrance and then decays along the flow

path such as the tangential injection, the rib/baffle

and the winglet vortex generators [10]. Swirl flow

has been used in a wide range of applications from

various engineering areas such as chemical and

2

mechanical mixing and separation devices,

combustion chambers, turbo machinery to pollution

control devices. It is commonly known that the swirl

flow enhances the heat transfer mainly due to the

increased velocity in the swirl tube and the

circulation of the fluid by forced convection [4].

The main aim of this paper is to study the heat

transfer enhancement of air flowing through a

horizontal circular tube with wire coil, strip tape

inserts.

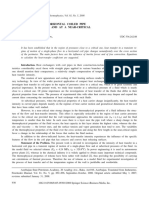

2. Twisted tapes & wire coil to generate swirl

The twisted tapes are made of aluminium and

have tape width (w) of 10 mm, 15 mm & 20mm.

Tape thickness (d) of 0.8 mm, and tape length (l) of

900 mm. Also a wire coil having pitch of 40 mm is

used to generate co-swirl. All tapes were prepared

with different twist ratios, y/w = 3.5, 2.66 and 2.25

respectively where twist ratio is defined as twist

length (l) to tape width (w). Schematic view of

twisted tape & wire coil is shown in Fig. 1. On the

other hand, to avoid an additional friction in the

system that might be caused the thicker tape. To

produce the twisted tape, one end of a straight tape

was clamped while another end was carefully twisted

to ensure a desired twist length. As shown in Fig. 1,

these twisted tapes are fixed one by one inside the

pipe having wire coil to generate co-swirl.

Figure 1: Details of twisted tapes and wire coil

3. Test section

The test section is surrounded by nichrome

heating wire, which is wrapped around the test

section with a pitch distance of 5 mm. This pitch is

good enough to provide a nearly uniform heating on

the outer surface of the test section tube. The heating

wire was powered by a variable AC power supply.

The overall electrical power added to the heating

section, Q, was calculated by measuring the voltage

(0200 V) and the electrical current (02 A). To

control the convection losses from the test section

and other components, foam insulation and glass

wool used. Four thermocouples are to be embedded

on the test section to measure surface temperature of

pipe and two thermocouples are placed in air stream

at entrance and exist of test section to measure air

temperature. To avoid floating voltage effects, the

thermocouple bead is insulated from the electrically

heated tube wall surface with a very thin sheet of

mica between the thermocouple and the tube surface

so as not to be effected from electricity. Fig. 2 shows

the schematic view of experimental set-up.

4. Data reduction

In the experiments, the heat transfer rate in the

tube is taken into account under a uniform heat flux

(UHF) condition by using air as the test fluid. The

heat transfer given by the hot surface to fluid (i.e. air)

at any Reynolds number is

Rate at which air is heated

Qa = mCp (To - Ti)

The convection heat transfer from the test section is

given as

Qc = hAs(Ts - Tm)

At steady state condition, the heat transfer is assumed

to be equal to the heat loss from the test section that

can be drawn as

Qa = Qc

The mean temperature of the fluid in the test tube is

given by

Tm = (To + Ti) / 2

Ts is the mean temperature of surface wall

temperature of the test tube. The average wall

temperature is calculated from 4 points of local wall

temperatures lined between the inlet and the exit of

the test tube. The average heat transfer coefficient (h)

and the mean Nusselt number (Nu) are estimated by

h = mCp (To - Ti) / hA(Ts - Tm)

Figure 3: Variation of pressure drop with mass flow rate

for swirl flow

Figure 4: Variation of pressure drop with mass flow rate

for co-swirl flow

2

4

6

8

10

12

14

16

18

20

0.003 0.008

P

r

e

s

s

u

r

e

d

r

o

p

(

m

m

o

f

H

w

)

Massflow rate (Kg/s)

10

15

20

25

30

35

40

45

50

0.003 0.008

P

r

e

s

s

u

r

e

d

r

o

p

(

m

m

o

f

H

w

)

Massflow rate (Kg/s)

3

Figure 2: Experimental set-up

ressure drop with mass flow rate

ressure drop with mass flow rate

The Nusselt number in terms of average heat transfer

coefficient is defined as

Nu = hD / k

The Reynolds number is written as

Re = UD /

The experiment pressure losses, p across the test

tube are arranged in non-dimensional form by using

the following equation

in which U is mean velocity in the test tube and L is

the test tube length. All of thermo

of the air are determined at the overall mean air

temperature (Tm).

Figure 5: Variation of friction factor with reynolds number

for swirl flow

smooth

tube

(y/w)=3.5

(y/w)=2.66

(y/w)=2.25

Massflow rate (Kg/s)

(p/d)=1.17

(p/d)=1.17,

(y/w)=3.5

(p/d)=1.17,

(y/w)=2.66

(p/d)=1.17,

(y/w)=2.25

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0.16

0.18

5000 15000

F

r

i

c

t

i

o

n

f

a

c

t

o

r

(

f

)

Re

number in terms of average heat transfer

The Reynolds number is written as

The experiment pressure losses, p across the test

dimensional form by using

in which U is mean velocity in the test tube and L is

the test tube length. All of thermo-physical properties

of the air are determined at the overall mean air

: Variation of friction factor with reynolds number

15000

smooth

tube

(y/w)=3.5

(y/w)=2.66

(y/w)=2.25

4

Figure 6: Variation of friction factor with reynolds number

for co-swirl flow

5. Experimental results and discussions

In this section, the pressure drop friction factor

characteristics and thermal enhancement index in a

tube fitted with twisted tapes and wire coil (co-swirl

tape) are presented.

The experiments are performed using twisted

tapes with three different twist ratios, y/w = 3.5, 2.66

and 2.25, in the range of Reynolds number between

5000 and 18,000. The results obtained for the tube

fitted with the single twisted tapes (ST) with three

different twist ratios and the empty tube are used as

the reference data for the performance evaluation of

the modified tubes.

5.1 Pressure drop results

Fig. 3 & Fig. 4 shows pressure drop curves for

four different heat transfer surface configurations.

Tubes with enhanced surfaces create more pressure

drop than the bare tube. Maximum pressure drop is

obtained in the (y/w) = 2.25, whereas minimum

pressure drop is obtained in the bare tube. The reason

of why enhanced surfaces have additional pressure

drop is that heat transfer with augmentation is

generally accompanied by an increase in pressure

drop.

5.2 friction factor results

The relationship between pressure loss in terms

of friction factor and Reynolds number for the tube

with twisted tape inserted which have given twist

ratios, and also for the plain tube is presented in Fig.

5 & Fig 6. It is found that using twisted tape gives

higher friction factor values than those from the plain

tube as expected. The friction factor decreases with

the increase of Reynolds number. The highest friction

factor (or pressure loss) is obtained in case (y/w) =

2.25.

5.3 Performance factor results

Siva Rama Krishna, Govardhan Pathipaka, P.

Sivashanmugam [3] proposed a performance

evaluation analysis for the same pumping power and

this method used for present study, the performance

ratio is defined as

p =

NuNup

(

]i

]p

)

0.291

Figure 7: Variation of performance factor with reynolds

number for swirl flow

Figure 8: Variation of performance factor with reynolds

number for co-swirl flow

The performance analysis was made by

above Eq. and the results are shown in Fig. 7 & Fig 8.

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

0.5

5000 15000

F

r

i

c

t

i

o

n

f

a

c

t

o

r

(

f

)

Re

(y/d)=1.17

(y/d)=1.17,

(y/w)=3.5

(y/d)=1.17,

(y/w)=2.66

(y/d)=1.17,

(y/w)=2.25

0.8

0.82

0.84

0.86

0.88

0.9

0.92

0.94

0.96

5000 10000 15000

P

e

r

f

o

r

m

a

n

c

e

f

a

c

t

o

r

Re

(y/w)=

3.5

(y/w)=

2.66

(y/w)=

2.25

0.6

0.62

0.64

0.66

0.68

0.7

0.72

0.74

0.76

5000 15000

P

e

r

f

o

r

m

a

n

c

e

f

a

c

t

o

r

Re

(y/d)=1.17

(y/d)=1.17,

(y/w)=3.5

(y/d)=1.17,

(y/w)=2.66

(y/d)=1.17,

(y/w)=2.25

5

It is observed from above Fig. that the thermal

enhancement index decreases with increasing

Reynolds number.

Fig. 7 & Fig 8 show the effect of various twisted

tapes at different twist ratios (y/w) on the thermal

enhancement index in Reynolds number range of

500018,000. The comparative data reveal that the

thermal enhancement index increases with decreasing

Reynolds number.

6. Conclusions

Thermal characteristics in a tube fitted with

twisted-tapes in co-swirl arrangement with wire coil

are presented in the present study. The work has been

conducted in the turbulent flow regime, Reynolds

number from 5000 to 18,000 using air as the test

fluid. The findings of the work can be drawn as

follows:

1. For the inserted tube, the pressure drop tends to

increase with the rise in mass flow rate while the

friction factor and performance factor give the

opposite trends.

2. The compound enhancement devices of the tube

and the co-swirl show a considerable improvement of

heat transfer rate and thermal performance relative to

the smooth tube acting alone, depending on twist

ratios.

3. The co-swirl tube yields higher friction factor and

performance factor than the smooth tube at low

Reynolds number.

Nomenclature

As Surface area of test tube, m

2

Cp Specific heat capacity of the fluid, J/kg k

D Test section pipe diameter, m

f Friction factor

h Llocal coefficient of heat transfer, W/m2 K

k Thermal conductivity of the fluid, W/m K

L Test section pipe length, m

m Air mass flow rate, kg/s

p Performance factor

Nu Nusselt number

Pr Prandtl number

Re Reynolds number

w Width of tape

y Twist length

(y/w) twist ratio

References

1. Shou-Shing Hsieh, Feng-Yu Wu, Huang-Hsiu

Tsai, Turbulent heat transfer and flow

characteristics in a horizontal circular tube with

Shou-Shing Hsieh, Feng-Yu Wu,Huang-Hsiu

strip-type inserts, International Journal of Heat

and Mass Transfer (2003),Vol. 46, pp. 823-835.

2. Leonard D. Tijing, Bock Choon Pak, Byung

Joon Baek, Dong Hwan Lee, A study on heat

transfer enhancement using straight and twisted

internal fin inserts, International

Communications in Heat and Mass Transfer

(2006), Vol. 33, pp. 719-726.

3. Siva Rama Krishna, Govardhan Pathipaka, P.

Sivashanmugam, Heat transfer and pressure

drop studies in a circular tube fitted with straight

full twist, Experimental Thermal and Fluid

Science (2009), Vol. 33, pp. 431438.

4. H. Gl a, D. Evinb, Heat transfer enhancement

in circular tubes using helical swirl generator

insert at the entrance, International Journal of

Thermal Sciences (2007), Vol. 46, pp. 1297-

1303.

5. Chinaruk Thianpong, Petpices Eiamsa-ard,

Khwanchit Wongcharee, Smith Eiamsa-ard,

Compound heat transfer enhancement of a

dimpled tube with a twisted tape swirl

generator, International Communications in

Heat and Mass Transfer (2009), Vol. 36, pp.

698704.

6. Alberto Garcia, Pedro G. Vicente, Antonio

Viedma, Experimental study of heat transfer

enhancement with wire coil inserts in laminar-

transition-turbulent regimes at different Prandtl

numbers Experimental study of heat transfer

enhancement with wire coil inserts in laminar-

transition-turbulent regimes at different Prandtl

numbers, International Journal of Heat and

Mass Transfer (2005), Vol. 48, pp. 4640-4651.

7. Alberto Garcia, Juan P. Solano, Pedro G.

Vicente, Antonio Viedma, Enhancement of

laminar and transitional flow heat transfer in

tubes by means of wire coil inserts,

International Journal of Heat and Mass Transfer

(2007), Vol. 50, pp. 3176-3189.

8. Kumbhar D.G., Dr. Sane N.K., Heat Transfer

Enhancement in a Circular Tube Twisted with

Swirl Generator: A Review, Proc. of the 3rd

6

International Conference on Advances in

Mechanical Engineering, SVNIT Surat, January

4-6, 2010.

9. Panida Seemawute, Smith Eiamsa-ard,

Thermohydraulics of turbulent flow through a

round tube by a peripherally-cut twisted tape

with an alternate axis, International

Communications in Heat and Mass Transfer

(2010), Vol. 37, pp. 652659.

10. Pongjet Promvonge, Somsak Pethkool, Monsak

Pimsarn, Chinaruk Thianpong, Heat transfer

augmentation in a helical-ribbed tube with

double twisted tape inserts, International

Communications in Heat and Mass Transfer

(2012), Vol. 39, pp. 953-959.

11. S. Eiamsa-ard, C. Thianpong, P. Eiamsa-ard,

Turbulent heat transfer enhancement by

counter/co-swirling flow in a tube fitted with

twin twisted tapes, Experimental Thermal and

Fluid Science (2010), Vol. 34, pp. 5362.

12. Halit Bas, Veysel Ozceyhan, Heat transfer

enhancement in a tube with twisted tape inserts

placed separately from the tube wall,

Experimental Thermal and Fluid Science (2012),

Vol. 41, pp. 5158.

13. S. Eiamsa-ard , P. Seemawute, Decaying swirl

flow in round tubes with short-length twisted

tapes, International Communications in Heat

and Mass Transfer (2012), Vol. 39, pp 649656.

Das könnte Ihnen auch gefallen

- Heat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysDokument6 SeitenHeat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysSwati KarNoch keine Bewertungen

- Enhancement of Heat Transfer Using Wire Coil Insert in TubesDokument10 SeitenEnhancement of Heat Transfer Using Wire Coil Insert in TubesIAEME PublicationNoch keine Bewertungen

- Effect of V-Shape Twisted Jaw Turbulators On Thermal Performance of Tube Heat Exchanger: An Experimental StudyDokument7 SeitenEffect of V-Shape Twisted Jaw Turbulators On Thermal Performance of Tube Heat Exchanger: An Experimental Studymustafa11dahamNoch keine Bewertungen

- Heat Transfer and Turbulent Flow Friction in A Circular Tube Fitted With Conical-Nozzle TurbulatorsDokument11 SeitenHeat Transfer and Turbulent Flow Friction in A Circular Tube Fitted With Conical-Nozzle TurbulatorsAnonymous 7BQxlt8cNoch keine Bewertungen

- Heat Transfer Enhancement in A Tube Using Rectangular-Cut Twisted Tape InsertDokument8 SeitenHeat Transfer Enhancement in A Tube Using Rectangular-Cut Twisted Tape InsertVenkat Rajesh AnapuNoch keine Bewertungen

- Heat Transfer Behaviors in A Tube With Combined Conical-Ring and Twisted-Tape InsertDokument11 SeitenHeat Transfer Behaviors in A Tube With Combined Conical-Ring and Twisted-Tape InsertAnonymous 7BQxlt8cNoch keine Bewertungen

- Forced ConvectionDokument9 SeitenForced ConvectionAmeer ShNoch keine Bewertungen

- J Enconman 2006 03 034Dokument16 SeitenJ Enconman 2006 03 034sergioteroNoch keine Bewertungen

- Sarc ConferenceDokument6 SeitenSarc ConferenceAJIT SHINDENoch keine Bewertungen

- Veeresh FuskeleDokument5 SeitenVeeresh FuskeleVeeresh FuskeleNoch keine Bewertungen

- Heat Transfer Augmentation in Round Tube With DiamDokument8 SeitenHeat Transfer Augmentation in Round Tube With DiamDarius PavriNoch keine Bewertungen

- The Effect of Channel Height On The Enhanced Heat Transfer Characteristics in A Corrugated Heat Exchanger ChannelDokument9 SeitenThe Effect of Channel Height On The Enhanced Heat Transfer Characteristics in A Corrugated Heat Exchanger ChannelFzico GtmanNoch keine Bewertungen

- Case Studies Thermal Engineering 1Dokument13 SeitenCase Studies Thermal Engineering 1stefano guercilenaNoch keine Bewertungen

- Overview of Heat Transfer Enhancement in Circular Pipe Using Serrated Plate Inserts NcimeDokument6 SeitenOverview of Heat Transfer Enhancement in Circular Pipe Using Serrated Plate Inserts NcimeAJIT SHINDENoch keine Bewertungen

- Optimization of Shell and Tube Heat ExchangerDokument29 SeitenOptimization of Shell and Tube Heat ExchangerAna QuintanaNoch keine Bewertungen

- Experimental Thermal and Fluid Science: Halit Bas, Veysel OzceyhanDokument8 SeitenExperimental Thermal and Fluid Science: Halit Bas, Veysel OzceyhanErPriyeRanjanNoch keine Bewertungen

- Ajit IRAJ JournalDokument6 SeitenAjit IRAJ JournalAJIT SHINDENoch keine Bewertungen

- Ijtra 140718Dokument4 SeitenIjtra 140718Akshay Kumar PandeyNoch keine Bewertungen

- Effect of Baffles Geometry On Heat Transfer Enhancement Inside Corrugated DuctDokument12 SeitenEffect of Baffles Geometry On Heat Transfer Enhancement Inside Corrugated Ductmustafa11dahamNoch keine Bewertungen

- Heat Transfer Enhancement by Using Dimpled Surface: Hemant C. Pisal, Avinash A. RanawareDokument9 SeitenHeat Transfer Enhancement by Using Dimpled Surface: Hemant C. Pisal, Avinash A. Ranawareashoku2Noch keine Bewertungen

- Heat Transfer Enhancement in A Circular Tube Twisted With Swirl Generator: A ReviewDokument5 SeitenHeat Transfer Enhancement in A Circular Tube Twisted With Swirl Generator: A ReviewAvinash RoshanNoch keine Bewertungen

- CFD Investigation of Heat Transfer and Flow Patterns in Tube Side Laminar Flow and The Potential For EnhancementDokument6 SeitenCFD Investigation of Heat Transfer and Flow Patterns in Tube Side Laminar Flow and The Potential For EnhancementRipmi KamandanuNoch keine Bewertungen

- 2018 - Kumar - Efek InsertDokument12 Seiten2018 - Kumar - Efek InsertAhmad Imam Rifa'iNoch keine Bewertungen

- Ijmet: ©iaemeDokument13 SeitenIjmet: ©iaemeIAEME PublicationNoch keine Bewertungen

- P PaperDokument5 SeitenP PaperUDAY KUMAR MARRAPUNoch keine Bewertungen

- Researchpaper Review On Twisted Tapes Heat Transfer EnhancementDokument9 SeitenResearchpaper Review On Twisted Tapes Heat Transfer EnhancementShreyas RathoreNoch keine Bewertungen

- 2009 Iraq TransysDokument17 Seiten2009 Iraq TransysAicha Chorak Franky TissoukiNoch keine Bewertungen

- Simulation and Study of Shell and Tube Type Heat EDokument9 SeitenSimulation and Study of Shell and Tube Type Heat EILEENVIRUSNoch keine Bewertungen

- G J E S R: Lobal Ournal of Ngineering Cience and EsearchesDokument7 SeitenG J E S R: Lobal Ournal of Ngineering Cience and EsearchesUNITED CADDNoch keine Bewertungen

- Energies: Enhanced Heat Transfer of A Heat Exchanger Tube Installed With V-Shaped Delta-Wing Baffle TurbulatorsDokument23 SeitenEnergies: Enhanced Heat Transfer of A Heat Exchanger Tube Installed With V-Shaped Delta-Wing Baffle Turbulatorsmustafa11dahamNoch keine Bewertungen

- Twisted Tube Heat Exchanger TechnologyDokument8 SeitenTwisted Tube Heat Exchanger TechnologyhuangjlNoch keine Bewertungen

- Heat Transfer Augmentation in A Circular Tube Using V-Nozzle Turbulator Inserts and Snail EntryDokument9 SeitenHeat Transfer Augmentation in A Circular Tube Using V-Nozzle Turbulator Inserts and Snail EntryAnonymous 7BQxlt8cNoch keine Bewertungen

- 1 s2.0 S135943111630031X MainDokument10 Seiten1 s2.0 S135943111630031X MainRahul PandeyNoch keine Bewertungen

- Presentation Heat ExchhangerDokument25 SeitenPresentation Heat ExchhangernagrajNoch keine Bewertungen

- Heat Transfer Analysis of Integral-Fin TubesDokument12 SeitenHeat Transfer Analysis of Integral-Fin Tubeshermez19Noch keine Bewertungen

- Experimental and Numerical Studies On Heat Transfer and Fluid Flow in A Duct Fitted With Inclined BafflesDokument37 SeitenExperimental and Numerical Studies On Heat Transfer and Fluid Flow in A Duct Fitted With Inclined BafflesHawraa ImadNoch keine Bewertungen

- 2017-ICHMT-Effect of Apex Angle Variation On Thermal and Hydraulic Performance ofDokument6 Seiten2017-ICHMT-Effect of Apex Angle Variation On Thermal and Hydraulic Performance ofmatheshwaran.mNoch keine Bewertungen

- IJERT CFD Analysis of Double Pipe Counte (Lab 11)Dokument13 SeitenIJERT CFD Analysis of Double Pipe Counte (Lab 11)bjuanlunabNoch keine Bewertungen

- Heat Transfer Enhancement by Using Twisted Tape in Horizontal and An Inclined TubeDokument19 SeitenHeat Transfer Enhancement by Using Twisted Tape in Horizontal and An Inclined TubeAdarsh ShindeNoch keine Bewertungen

- 1 s2.0 S2214157X22007869 MainDokument9 Seiten1 s2.0 S2214157X22007869 MainFarjallah Al-AssãadNoch keine Bewertungen

- 15 IJAERS-MAY-2017-35-Heat Transfer Enhancement For Tube in TubeDokument5 Seiten15 IJAERS-MAY-2017-35-Heat Transfer Enhancement For Tube in TubePNoch keine Bewertungen

- Heat Transfer in A Horizontal Coiled Pipe in A Transient Regime and at A Near-Critical Pressure of A FluidDokument5 SeitenHeat Transfer in A Horizontal Coiled Pipe in A Transient Regime and at A Near-Critical Pressure of A FluidM. SukarmanNoch keine Bewertungen

- Paper Conical Ring InsertsDokument8 SeitenPaper Conical Ring InsertssergioteroNoch keine Bewertungen

- 6 PDFDokument5 Seiten6 PDFmukesh poundekarNoch keine Bewertungen

- Chemical Engineering and Processing: Process Intensi FicationDokument13 SeitenChemical Engineering and Processing: Process Intensi FicationPrateek TanwarNoch keine Bewertungen

- Construction and Trial Experiment of A Small Size Thermo-Acoustic Refrigeration SystemDokument6 SeitenConstruction and Trial Experiment of A Small Size Thermo-Acoustic Refrigeration SystemijeteeditorNoch keine Bewertungen

- 3-D Numerical Simulation of Swirling Flow and ConvectiveDokument24 Seiten3-D Numerical Simulation of Swirling Flow and ConvectiveVenkat Rajesh AnapuNoch keine Bewertungen

- SSRN Id4147313Dokument29 SeitenSSRN Id4147313Rajeev PandeyNoch keine Bewertungen

- Numerical Investigation of Convective UDokument6 SeitenNumerical Investigation of Convective UGanesh BodakheNoch keine Bewertungen

- Heat Transfer Enhancement in A Tube Using Elliptical-Cut Twisted Tape InsertsDokument7 SeitenHeat Transfer Enhancement in A Tube Using Elliptical-Cut Twisted Tape InsertsPNoch keine Bewertungen

- The Heat Transfer and Pressure Drop Characteristics of The Finned Tube Banks in Forced Convection (Effects of Fin Height On Heat Transfer Characteristics)Dokument15 SeitenThe Heat Transfer and Pressure Drop Characteristics of The Finned Tube Banks in Forced Convection (Effects of Fin Height On Heat Transfer Characteristics)nadir adelNoch keine Bewertungen

- Steady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodDokument5 SeitenSteady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodAnonymous sAmJfcVNoch keine Bewertungen

- Heat Transfer Analysis of Pin Fin Array: March 2014Dokument6 SeitenHeat Transfer Analysis of Pin Fin Array: March 2014Dinu ChoudharyNoch keine Bewertungen

- 2011 IJAMELaminarDokument15 Seiten2011 IJAMELaminarVikash SinghNoch keine Bewertungen

- International Communications in Heat and Mass TransferDokument9 SeitenInternational Communications in Heat and Mass TransferTejal BanmareNoch keine Bewertungen

- Water-To-Water Heat Transfer in Tube-Tube Heat Exchanger: Experimental and Analytical StudyDokument15 SeitenWater-To-Water Heat Transfer in Tube-Tube Heat Exchanger: Experimental and Analytical StudyAhmad Arif SaktiNoch keine Bewertungen

- Tzeng 2006Dokument11 SeitenTzeng 2006yazenanesNoch keine Bewertungen

- SAFE RC Design ForDokument425 SeitenSAFE RC Design ForMarlon Braggian Burgos FloresNoch keine Bewertungen

- Cambridge IGCSE: CHEMISTRY 0620/42Dokument12 SeitenCambridge IGCSE: CHEMISTRY 0620/42Khairun nissaNoch keine Bewertungen

- 2023 Teacher Email ListDokument5 Seiten2023 Teacher Email ListmunazamfbsNoch keine Bewertungen

- Sanskrit Subhashit CollectionDokument110 SeitenSanskrit Subhashit Collectionavinash312590% (72)

- 21 Tara Mantra-Wps OfficeDokument25 Seiten21 Tara Mantra-Wps OfficeAlteo FallaNoch keine Bewertungen

- Just in Time and TQMDokument8 SeitenJust in Time and TQMBhramadhathNoch keine Bewertungen

- 32 Hyderabad HITEC City BisleriDokument23 Seiten32 Hyderabad HITEC City BisleriSridhar ViswanathanNoch keine Bewertungen

- Sheltered 2 Item Recycle ListDokument5 SeitenSheltered 2 Item Recycle ListRachel GNoch keine Bewertungen

- A Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyDokument11 SeitenA Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyNova Ariston100% (2)

- Notice: Premerger Notification Waiting Periods Early TerminationsDokument5 SeitenNotice: Premerger Notification Waiting Periods Early TerminationsJustia.comNoch keine Bewertungen

- ET4254 Communications and Networking 1 - Tutorial Sheet 3 Short QuestionsDokument5 SeitenET4254 Communications and Networking 1 - Tutorial Sheet 3 Short QuestionsMichael LeungNoch keine Bewertungen

- Amritsar Police StationDokument5 SeitenAmritsar Police StationRashmi KbNoch keine Bewertungen

- Jpedal ManualDokument20 SeitenJpedal ManualDamián DávilaNoch keine Bewertungen

- Truss-Design 18mDokument6 SeitenTruss-Design 18mARSENoch keine Bewertungen

- Introduction To HDLDokument28 SeitenIntroduction To HDLBack UpNoch keine Bewertungen

- Drager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementDokument24 SeitenDrager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementAmirNoch keine Bewertungen

- Veritas™ High Availability Agent For WebSphere MQ Installation and Configuration Guide / WebSphere MQ InstallationDokument64 SeitenVeritas™ High Availability Agent For WebSphere MQ Installation and Configuration Guide / WebSphere MQ InstallationkarthickmsitNoch keine Bewertungen

- ST3 ManualDokument48 SeitenST3 ManualRon FosterNoch keine Bewertungen

- Analytics Designer - Comment Deletion - SAP CommunityDokument6 SeitenAnalytics Designer - Comment Deletion - SAP CommunityARPITA BISWASNoch keine Bewertungen

- ETNOBotanica NombresDokument188 SeitenETNOBotanica Nombresjalepa_esNoch keine Bewertungen

- Clint Freeman ResumeDokument2 SeitenClint Freeman ResumeClint Tiberius FreemanNoch keine Bewertungen

- UFO Yukon Spring 2010Dokument8 SeitenUFO Yukon Spring 2010Joy SimsNoch keine Bewertungen

- Liquitex Soft Body BookletDokument12 SeitenLiquitex Soft Body Booklethello belloNoch keine Bewertungen

- Republic of The Philippines Division of Bohol Department of Education Region VII, Central VisayasDokument6 SeitenRepublic of The Philippines Division of Bohol Department of Education Region VII, Central VisayasJOHN MC RAE RACINESNoch keine Bewertungen

- Omnitron CatalogDokument180 SeitenOmnitron Catalogjamal AlawsuNoch keine Bewertungen

- William Hallett - BiographyDokument2 SeitenWilliam Hallett - Biographyapi-215611511Noch keine Bewertungen

- Aero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFDokument6 SeitenAero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFGana tp100% (1)

- Maha Vedha DikshaDokument1 SeiteMaha Vedha DikshaBallakrishnen SubramaniamNoch keine Bewertungen

- Arts 6 Week 6Dokument9 SeitenArts 6 Week 6JENNEFER ESCALANoch keine Bewertungen

- Stonehell Dungeon 1 Down Night Haunted Halls (LL)Dokument138 SeitenStonehell Dungeon 1 Down Night Haunted Halls (LL)some dude100% (9)