Beruflich Dokumente

Kultur Dokumente

Gulf-O-Flex Insulation Tube & Coil: Dimensions of Box: 50x50x20 Cms

Hochgeladen von

Riyas UdheenOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gulf-O-Flex Insulation Tube & Coil: Dimensions of Box: 50x50x20 Cms

Hochgeladen von

Riyas UdheenCopyright:

Verfügbare Formate

Gulf-O-Flex Insulation Tube & Coil

FLAME AND SMOKE RATING.

Gulf-O-Flex Tube insulation has a ame spread rating of 25 or less and a smoke development rating of 50 or less as tested by the third party testing lab . (ASTM E 84 Method of testing surface burning characteristics of building materials complied.) Gulf-O-Flex is acceptable for use in duct/planning application.

OUT DOOR APPLICATIONS

Gulf-O-Flex Tube insulation is made from a UV resistant elastomeric blend, for moderate UV exposure applications, no additional protection is needed. However, for severe UV exposure applications (rooftop application) or where optimum performance is required, an approved UV protected coating or appropriate jacketing or cladding should be used. For best appearance two coats are recommended.

GULF-O-FLEX INSULATION TUBE

Flexible Closed Cell Elastomeric Pipe Insulation. The Product you can rely on .

UNDERGROUND

For buried line above the water table use a clean ll such as sand (3-5 layer) to protect Gulf-O-Flex before back lling. It is recommended that materials to be buried are properly sealed at all seams and butt joints with an approved contact adhesive. For optimum performance, the lines should be encased in a conduit to protect them from problems associated with ground water.

DESCRIPTION

Gulf-O-Flex Tube insulation is an environmentally friendly CFC free , exible elastomeric thermal insulation. With smooth shark skin and is available in unslit form in wall Thickness of 1/4 , 3/8 , 1/2 , 3/4 , 1 , 1-1/4 in sizes ranging from 1/4 ID to 4-3/8 Iron Pipe size. Gulf-O-Flex Tube is non porous and resists mildew growth.

RESISTANCE TO MOISTURE VAPOUR FLOW.

The closed-cell structure and unique formulation of Gulf-O-Flex effectively retards the ow of moisture vapour and is considered a low transmittance vapour retarded. For most applications, Gulf-O-Flex needs no additional protection. Additional vapour barrier protection may be necessary for Gulf-O-Flex when installed on low temperature surfaces that are exposed to continuous high humidity.

APPLICATION

Gulf-O-Flex is used to retard heat gain and prevent Condensation or frost formation on refrigerant lines. Cold water plumbing and chilled water systems. It Also retard heat loss for hot water plumbing, liquid Heating , dual temperature piping and many solar systems. Gulf-O-Flex is recommended for application Ranging from -40C to +120C. The expanded closed cell structure makes an efcient insulator and an Effective moisture vapour retarder. Gulf-O-Flex has a very tough Shark Skin which with Stand tearing rough handling and severe environmental conditions. And yet is quite exible for easy installation. Gulf-O-Flex has superior cold weather exibility. Gulf-O-Flex can be used with heat tracing/heat tapes . Cut tubular Sections and cover, anges, etc. from our Gulf-O-Flex Sheet.

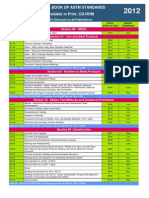

SPECIFICATION COMPLIANCE.

ASTM C 518 ASTM D 1056-00-2C1 CLASS 0 (Fire propagation test according to BS 476 part 6 & 7 complies with the requirements of UK.) CLASS 1 (Fire propagation test according to BS 476 part 6 & 7 complies with the requirements of UK.) ASTM E-84 ( 25 / 50 )

INSTALLATION

With a factory applied coating of talc on the smooth inner surface. Gulf-O-Flex slides easily over pipes or tubing for quick installation. When applied to existing lines, Tubing is slit lengthwise and snapped in to place. (Slitting can be done on the job with a sharp knife. All seams and butt joints should be sealed with an approved contact adhesive (Gulf-O-Flex Glue is available on request) making sure both surfaces to be joined are coated with adhesive. Fittings are fabricated from Miter.

Gulf-O-Flex Insulation Tube & Coil

Product Data

Physical Properties

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Cell Structure Density Gms / Cm Thermal Conductivity K Value at 40C mean Temperature Temperature limit C Thermal Stability % Shrinkage Water Absorption Water vapour Permeability perm/Max Resistance to Ozone Flammability Fire Rating Average time of Burning Average extend of Burning Flexibility Resistance to Weather & Ultra Violet Rays Resistance to Chemicals Odour Mildew resistance Copper Corrosion Closed 0.050 - 0.070 Gms / cm

BS 476 Part 6 & 7 ASTM D 3575- 91

0.0391 w/m - K -40 C to +120 C 2.54 (7 days at 95 C) 2.98 0.19 Perm - in Excellent Self Extinguishing Class 0, Class 1 25 / 50 Less then 4 Sec 15min Excellent Very Good Very Good Negligible No Fungal Growth Negligible

ASTM C518

ASTM D 3575-91 ASTM D 3575-91

BS 874 1986

ASTM E 96-95 ASTM D 1149 ASTM D 635-91

BS 476 Part 6 & 7

ASTM E 96-95

ASTM E-84 ASTM D 1149

ASTM D 1056-85

ASTM G 53-96 SAEJ 1351 ASTM G 21-80 ASTM C 665-94

Thickness Recommendations to control Condensation

THICKNESS RECOMMENDATIONS

PIPE SIZE USED LINE TEMP 50F NORMAL CONDITIONS ( Max 85 Deg.F,29Deg.C -70% RH ) 3/8" I.D.thru 1-3/8" IPS Over 1-3/8"thru 3"IPS Over 3"IPS thru 4"IPS Over 4" IPS MILD CONDITIONS ( Max 80 Deg.F, 26Deg.C -50%RH ) 3/8" I.D. thru 2-1/8" IPS Over2-1/8'thru 3"IPS Over 3"IPS thru 4"IPS Over 4" IPS SEVERE CONDITOINS ( Max.90 Deg.F, 32 Deg.C.-80%RH) 3/8" I.D. thru 1-1/4" IPS Over 1-1/4" ID thru 4" IPS Over 4" IPS 3/4" 3/4" 3/4" 3/4" 1" 1-1/4" 1-1/4" 1-1/2" 1-3/4" 1-1/4" 1-1/2" 2 3/8" 3/8" 1/2" 1/2" 3/8" 3/8" 1/2" 1/2" 1/2" 1/2" 3/4" 3/4" 1/2" 3/4" 3/4" 3/4" 3/8" 3/8" 1/2" 1/2" 1/2" 1/2" 1/2" 3/4" 3/4" 1" 1" 1" 1" 1" 1-1/4" 1-1/4" 10C LINE TEMP 35F 2C LINE TEMP 0F - 18C LINE TEMP - 20F - 29C

Gulf-O-Flex Insulation Tube & Coil

Pipe RValues per Square Foot

Pipe O.D or Normal Insulation I.D. R Value 3/8(10mm) Wall R Value 1/2 (13mm) Wall R Value 3/4(19mm) Wall R Value 1(25mm) Wall

3/8 5/8 7/8 1-1/8 1-3/8 1-5/8 1-1/2 IPS 2-1/8 2 IPS 2-1/2 IPS 2-5/8 3-1/8 3 IPS 3-5/8 3-1/2 IPS 4-1/8

9mm 13mm 16mm 19mm 22mm 29mm 35mm 41mm 48mm 54mm 60mm 64mm 67mm 79mm 89mm 92mm 102mm 105mm

2.5 2.4 2.4 2.3 2.2 2.1 1.6 2.2 2.3 2.2 2.2 2.2 2.2 2.2 2.2 2.1 2.1 2.1

3.0 3.1 3.1 3.1 3.1 3.1 3.1 3.1 2.9 3.0 3.0 3.0 3.0 2.9 2.9 2.9 2.9 2.9

5.1 5.1 5.2 5.1 5.1 5.3 5.1 4.9 4.7 4.7 4.6 4.5 4.5 4.4 4.4 4.4 4.3 4.3

- 6.7 6.5 6.5 6.8 6.7 6.4 6.9 6.3 6.2 6.0 6.0 5.9 5.8 5.8 5.7 5.7

Gulf-O-Flex Nominal Insulation Size ID mm inch

Copper Pipe Iron Pipe Nominal Size OD mm inch Nominal Size IPS mm inch Nominal 6 mm wall

Tubing Unit Length 1.8 Meters (Standard) Nominal 9 mm wall Nominal 13 mm wall

No.of Total Pcs Meters per Per Carton Carton

Nominal 19 mm wall

No.of Total Pcs Meters per Per Carton Carton

Nominal 25 mm wall

Nominal 32 mm wall

No. Total No.of Total of Meters Pcs Meters Per Per per Per Carton Carton Carton Carton

No.of Total No.of Total Pcs Meters Pcs Meters per Per per Per Carton Carton Carton Carton

6 9 13 16 19 22 25 28 32 35 38 42 48 51 54 60 67 73 76 79 89

1/4 3/8 1/2 5/8 3/4 7/8 1 1-1/8 1-1/4 1-3/8 1-1/2 1-5/8 1-7/8 2 2-1/8 2-3/8 2-5/8 2-7/8 3 3-1/8 3-1/2

6 9 13 16 19 22 25 32 35 38 42 48 51 54 60 67 73 76 79 89

1/4 3/8 1/2 5/8 3/4 7/8 1 1-1/8 1-1/4 1-3/8 1-1/2 1-5/8 1-7/8 2 2-1/8 2-3/8 2-5/8 2-7/8 3 3-1/8 3-1/2

6 10 13 19 25 32 38 51 75

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 3

180 170 150 120 100 90 80 70 60 -

324 306 270 216 180 162 144 126 108 -

168 130 115 90 76 70 55 55 40 36 30 25 25 20 -

302.4 234 207 162 136.8 126 99 99 72 64.8 54 45 45 36 -

90 80 65 60 45 40 40 36 30 30 24 25 20 20 20 18 15 15 12 12 10

162 144 117 108 81 72 72 64.8 54 54 43.2 45 36 36 36 32.4 27 27 21.6 21.6 18

50 40 40 35 30 30 25 25 20 20 17 17 15 15 15 12 10 10 10 10 8

90 72 72 63 54 54 45 45 36 36 30.60 30.60 27 27 27 21.6 18 18 18 18 14.4

35 25 25 25 20 20 20 18 15 15 12 12 10 9 9 9 8 6 6 6 6

63 45 45 45 36 36 36 32.4 27 27 21.6 21.6 18 16.2 16.2 16.2 14.4 10.8 10.8 10.8 10.8

30 25 20 20 15 15 15 15 15 12 12 10 10 9 9 6 6 4 4 4 4

54 45 36 36 27 27 27 27 27 21.6 21.6 18 18 16.2 16.2 10.8 10.8 7.2 7.2 7.2 7.2

Gulf-O-Flex Insulation Tube & Coil

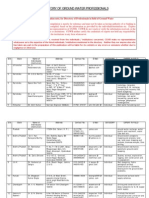

GULF-O-FLEX INSULATION TUBE COIL COIL LONGER, MORE EFFICIENT LESS WASTE DESCRIPTION

Gulf-O-Flex Insulation Tube Coil is a system designed for convenience and labor savings with superior toughness. It is provided in continuous-length coils, designed to minimize waste, reduce butt joints, and is packaged in easy-handle, easy-store cartons. The pipe insulation is tough but exible elastomeric thermal insulation, black in color, supplied as continuous length unslit tubing in nominal wall thicknesses of 3/8(9mm) and 1/2(13mm) in popular sizes up to 1-1/8 ID. Its closed cell structure makes it an efcient insulation with the proven performance of Gulf-O-Flex ECR. It is manufactured without the use of CFC's, HCFC's or HFC's. It is also formaldehyde free, dust free, ber free and resists mold and mildew.

USES

Gulf-O-Flex Insulation Tube Coil is engineered for air conditioning applications in which speed, ease of installation; convenient handling and on-site durability are of primary importance. It slides on the pipe easier, making the installation job faster and more protable for contractors.

INSTALLATION

Gulf-O-Flex Insulation Tube Coil uncoils easily from its convenient carton, so it can be cut to desired lengths for longer runs with fewer seams. It also slides on the pipe easier, making the installation job faster and more protable for contractors. The specially formulated lubricating powder effectively reduces friction, and relaxed I.D. tolerances accommodate elbows and ttings. Its thermal conductivity (0.27), WVT (0.80), ame spread and smoke developed index (25/50) and temperature use ranges (-70F to +220F) are the best. Installs with simple hand tools and Gulf-O-Glue (which is a low V.O.C. adhesive). Gulf-O-Glue is a contact adhesive, therefore, in all cases both surfaces to be joined are coated with adhesive.

Dimensions of box: 50x50x20 cms

Thickness 9 mm Thickness 13 mm

Gulf-O-Flex Insulation Tube & Coil

Das könnte Ihnen auch gefallen

- Ficha Tecnica PikotekDokument2 SeitenFicha Tecnica Pikoteking_arriagaNoch keine Bewertungen

- ARIFLEXDokument8 SeitenARIFLEXRiyas Udheen50% (2)

- KflexDokument8 SeitenKflexEddie BoyzNoch keine Bewertungen

- Afico Pipe Insulation PDFDokument4 SeitenAfico Pipe Insulation PDFHusni HayathNoch keine Bewertungen

- Technip Drilling BrochureDokument12 SeitenTechnip Drilling Brochurenedumaran.sNoch keine Bewertungen

- Winterizing Section CC Marine Catalogue Pages 1119 To 1138Dokument20 SeitenWinterizing Section CC Marine Catalogue Pages 1119 To 1138GregGGHNoch keine Bewertungen

- 3 LayerDokument4 Seiten3 LayerArya Raditya100% (1)

- 01 Rubber HoseDokument26 Seiten01 Rubber Hosewenny_tpdNoch keine Bewertungen

- Arc Insulations BrochureDokument5 SeitenArc Insulations BrochureacompositesNoch keine Bewertungen

- GPT 1-3 PGE Tech SpecificationsDokument4 SeitenGPT 1-3 PGE Tech SpecificationsEhtisham AndrAbiNoch keine Bewertungen

- Oilfield Hoses Fittings AccembliesDokument29 SeitenOilfield Hoses Fittings Accembliesthapa786mNoch keine Bewertungen

- LIL-Products-PUF-PIR Pipesection For Insulation Res17 PDFDokument2 SeitenLIL-Products-PUF-PIR Pipesection For Insulation Res17 PDFJoshua FernandezNoch keine Bewertungen

- Aerocel Epdm Tube Sheet 8 06 09Dokument2 SeitenAerocel Epdm Tube Sheet 8 06 09Nabil RamehNoch keine Bewertungen

- Garlock Expansion Joints Catalog ManualDokument29 SeitenGarlock Expansion Joints Catalog ManualCRISTIAN GUZMÁNNoch keine Bewertungen

- Afico Faceed InsulationDokument4 SeitenAfico Faceed Insulationhello1230Noch keine Bewertungen

- Recotec Rotafil enDokument16 SeitenRecotec Rotafil enJordan RileyNoch keine Bewertungen

- Technical DataDokument29 SeitenTechnical DataGregory StewartNoch keine Bewertungen

- Expansion JointsDokument8 SeitenExpansion Jointsterencejustine100% (1)

- Piping Equipment IsolationDokument14 SeitenPiping Equipment IsolationLữ Hành ShutoNoch keine Bewertungen

- Olex Nexan HandbookDokument112 SeitenOlex Nexan Handbook322399mk7086Noch keine Bewertungen

- NewAge Silicone Catalog PDFDokument8 SeitenNewAge Silicone Catalog PDFRahman FatahNoch keine Bewertungen

- SSI AFD270 9in DiscDiff FinalDokument2 SeitenSSI AFD270 9in DiscDiff FinalNicolas Solano CondeNoch keine Bewertungen

- 3M Pipeline Tape Coating System Data SheetDokument4 Seiten3M Pipeline Tape Coating System Data SheetWarlexNoch keine Bewertungen

- Ficha Tecnica DURFLEXDokument5 SeitenFicha Tecnica DURFLEXManuel MoranNoch keine Bewertungen

- Nesl Training ManualDokument91 SeitenNesl Training ManualSOUMYA DEEP CHATTERJEENoch keine Bewertungen

- Drawing 80H30Dokument3 SeitenDrawing 80H30kpranjal15Noch keine Bewertungen

- Cam LockDokument7 SeitenCam LockBrant AkkanNoch keine Bewertungen

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Dokument3 SeitenDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNoch keine Bewertungen

- Flexitallic FlexproDokument7 SeitenFlexitallic FlexproHeryanto SyamNoch keine Bewertungen

- English Trenton Wax Tape SystemsDokument16 SeitenEnglish Trenton Wax Tape SystemsTaylorNoch keine Bewertungen

- Astava CatalogDokument26 SeitenAstava CatalogPritesh PatelNoch keine Bewertungen

- AFICO Heavy Density Pipe Insulation - NewDokument4 SeitenAFICO Heavy Density Pipe Insulation - NewNickolas HeadNoch keine Bewertungen

- PPR-C Pipe SpecificationDokument25 SeitenPPR-C Pipe SpecificationAlex Dulay85% (13)

- FOAM GLASS UG Piping Insulation Underground BrochureDokument12 SeitenFOAM GLASS UG Piping Insulation Underground BrochureSethuraman SaravanakumarNoch keine Bewertungen

- PGE Tech GPT PDFDokument2 SeitenPGE Tech GPT PDFAnonymous 1ykzuaxWgYNoch keine Bewertungen

- Thermobreak Tube Installation InstructionsDokument8 SeitenThermobreak Tube Installation Instructionssurya325kiranNoch keine Bewertungen

- Armaflex Tube Insulation CatalogueDokument4 SeitenArmaflex Tube Insulation CatalogueRiyas UdheenNoch keine Bewertungen

- Sectional Pipe InsulationDokument2 SeitenSectional Pipe InsulationjackwpsoNoch keine Bewertungen

- PDS Na GTS80 PDFDokument2 SeitenPDS Na GTS80 PDFAnant RubadeNoch keine Bewertungen

- Superlon 16 Pages CatalogDokument16 SeitenSuperlon 16 Pages CatalogDevan SanmugamNoch keine Bewertungen

- Installation ManualDokument20 SeitenInstallation ManualHasan GüleryüzNoch keine Bewertungen

- Ameron PSXJFDokument4 SeitenAmeron PSXJFmohammadazraiNoch keine Bewertungen

- Insulation Engineered For: Cold SystemsDokument0 SeitenInsulation Engineered For: Cold SystemsjeewanaaNoch keine Bewertungen

- Marine Exhaust HoseDokument3 SeitenMarine Exhaust HoseDanilo ContrerasNoch keine Bewertungen

- PGE Product BrochureDokument4 SeitenPGE Product Brochureadventure11111Noch keine Bewertungen

- Polyken 1600 High TempDokument2 SeitenPolyken 1600 High TempKyaw Kyaw AungNoch keine Bewertungen

- HDPE Drainage ManualDokument48 SeitenHDPE Drainage ManualTransgulf2013Noch keine Bewertungen

- Duct Liner (AFICO)Dokument4 SeitenDuct Liner (AFICO)hshoooma65Noch keine Bewertungen

- Tubería de Resina Reforzada PSX L3 y JF.Dokument5 SeitenTubería de Resina Reforzada PSX L3 y JF.Sanna DiazNoch keine Bewertungen

- BWT&P 2ND YrDokument43 SeitenBWT&P 2ND YrDaniel MkandawireNoch keine Bewertungen

- Silicone Rubber Cold Shrink Connector Insulators 8440 SeriesDokument4 SeitenSilicone Rubber Cold Shrink Connector Insulators 8440 SerieshendrabudimanNoch keine Bewertungen

- Pikotek Vcs Tech SpecsDokument2 SeitenPikotek Vcs Tech SpecsBaskar KannaiahNoch keine Bewertungen

- EG Tech Bulletin ASTM C1695Dokument3 SeitenEG Tech Bulletin ASTM C1695AuburnMfgNoch keine Bewertungen

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168Von EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168Noch keine Bewertungen

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsVon EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsNoch keine Bewertungen

- Vvs PDFDokument1 SeiteVvs PDFRiyas UdheenNoch keine Bewertungen

- Toast-Qwik®: Models TQ-10, - 400, - 400BA, - 400H, - 800, - 800BA, - 800H, - 800HBA, - 1200, - 1800, - 1800BA, - 1800H, - 1800HBADokument2 SeitenToast-Qwik®: Models TQ-10, - 400, - 400BA, - 400H, - 800, - 800BA, - 800H, - 800HBA, - 1200, - 1800, - 1800BA, - 1800H, - 1800HBARiyas UdheenNoch keine Bewertungen

- Catalogo Ibaiondo Uk1Dokument46 SeitenCatalogo Ibaiondo Uk1Riyas UdheenNoch keine Bewertungen

- All The Features of A High-End Toaster With A Low-End PriceDokument2 SeitenAll The Features of A High-End Toaster With A Low-End PriceRiyas UdheenNoch keine Bewertungen

- Resistance Values of Structural and Finish Materials: Material R-Value Material R-ValueDokument1 SeiteResistance Values of Structural and Finish Materials: Material R-Value Material R-ValueRiyas UdheenNoch keine Bewertungen

- Armaflex Tube Insulation CatalogueDokument4 SeitenArmaflex Tube Insulation CatalogueRiyas UdheenNoch keine Bewertungen

- Econ Gate ValvesDokument22 SeitenEcon Gate ValvesRiyas Udheen100% (1)

- Air System Sizing Summary For PACU-Z2-FF WTING AREADokument1 SeiteAir System Sizing Summary For PACU-Z2-FF WTING AREARiyas UdheenNoch keine Bewertungen

- Astm2012 PDFDokument3 SeitenAstm2012 PDFRiyas UdheenNoch keine Bewertungen

- Master Hvac BoqDokument15 SeitenMaster Hvac BoqRiyas UdheenNoch keine Bewertungen

- Low Noise PVC PipesDokument44 SeitenLow Noise PVC PipesRiyas UdheenNoch keine Bewertungen

- Directory of GROUND WATER Professionals PDFDokument10 SeitenDirectory of GROUND WATER Professionals PDFSathenapalle Kiran BabuNoch keine Bewertungen

- What Is Presumptive Bearing Capacity of Soil and Its ValuesDokument5 SeitenWhat Is Presumptive Bearing Capacity of Soil and Its ValuesRona Alexis CardenasNoch keine Bewertungen

- Lubricating Oils Test MethodsDokument32 SeitenLubricating Oils Test MethodsnicholeonNoch keine Bewertungen

- Plate Heat ExchangerDokument7 SeitenPlate Heat ExchangerDilipNoch keine Bewertungen

- List of ABS Notations and SymbolsDokument270 SeitenList of ABS Notations and SymbolsLucian100% (1)

- Chapter 9Dokument2 SeitenChapter 9MarielVillalunaNoch keine Bewertungen

- DocxDokument35 SeitenDocxqweqwe67% (3)

- FINAL-THESIS EditedDokument46 SeitenFINAL-THESIS EditedRhea MambaNoch keine Bewertungen

- AQUAMANDokument2 SeitenAQUAMANJodi Marielet EufracioNoch keine Bewertungen

- Muh Irgi Bahqiawan 210109512012Dokument33 SeitenMuh Irgi Bahqiawan 210109512012Mhmd IrgiNoch keine Bewertungen

- Types of SlopesDokument21 SeitenTypes of SlopesJezel Mae Calderon100% (1)

- Bishop Scott Girls' School: Jaganpura, Brahmpura, By-Pass, Patna-27Dokument20 SeitenBishop Scott Girls' School: Jaganpura, Brahmpura, By-Pass, Patna-27Siddharth RoyNoch keine Bewertungen

- Nitoflor Lithurin TechnicalDokument2 SeitenNitoflor Lithurin Technicalmyke_0101Noch keine Bewertungen

- Barriers of Implementing Renewable Energy in The Philippines - Ilagan, Millena, Santos, ValerioDokument8 SeitenBarriers of Implementing Renewable Energy in The Philippines - Ilagan, Millena, Santos, Valeriootsipotsi100% (3)

- DLP in Science (Chemistry and Biology)Dokument8 SeitenDLP in Science (Chemistry and Biology)Ana Rose OcfemiaNoch keine Bewertungen

- Paryavaranam Suraksha - Dr. Ankit TodiDokument5 SeitenParyavaranam Suraksha - Dr. Ankit ToditodilawgroupNoch keine Bewertungen

- S-101 Shoring Layout & DetailsDokument1 SeiteS-101 Shoring Layout & Detailsjibeesh cmNoch keine Bewertungen

- Waste Water TreatmentDokument39 SeitenWaste Water TreatmentIr. feizzsal kent100% (4)

- 2.3.8.a ResidentialWaterSupplyDokument4 Seiten2.3.8.a ResidentialWaterSupplyRay NolascoNoch keine Bewertungen

- Determining The Hardness of WaterDokument3 SeitenDetermining The Hardness of Waterchrisbarnes051Noch keine Bewertungen

- Safe Practices Guide For Cryogenic Air Separation PlantsDokument71 SeitenSafe Practices Guide For Cryogenic Air Separation Plantsdaimon_p100% (1)

- Unit C Exam Questions 2019 PDFDokument30 SeitenUnit C Exam Questions 2019 PDFTI Henry Martins100% (1)

- Water Distribution System: by Mr. Ravi Kumar GARREDokument17 SeitenWater Distribution System: by Mr. Ravi Kumar GARREMrunmayee ManjariNoch keine Bewertungen

- Md. Sahabuddin: (Total Experience 7 Years +)Dokument3 SeitenMd. Sahabuddin: (Total Experience 7 Years +)Abdullah Al JubayerNoch keine Bewertungen

- PDD, MSDS, Battery, Leoch, 2015-01, Lead Acid Battery - Huse2015 - Aaen - Msds Battery - LeochDokument7 SeitenPDD, MSDS, Battery, Leoch, 2015-01, Lead Acid Battery - Huse2015 - Aaen - Msds Battery - LeochMarco Antonio Valdez RojasNoch keine Bewertungen

- IAS Baba Test 12 QDokument45 SeitenIAS Baba Test 12 QGopal KumharNoch keine Bewertungen

- Ch-1 Spillways-1Dokument6 SeitenCh-1 Spillways-1Fikir YoNoch keine Bewertungen

- BayerDokument2 SeitenBayerkarthick1792Noch keine Bewertungen

- Koteles Nandor 1Dokument6 SeitenKoteles Nandor 1Bia PopNoch keine Bewertungen

- 2011-03 Selection of Pumps PDFDokument47 Seiten2011-03 Selection of Pumps PDFKwabena OtchereNoch keine Bewertungen