Beruflich Dokumente

Kultur Dokumente

Using Effective Supplier Appraisal Techniques To Improve The Supply Chain

Hochgeladen von

elmenoufiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Using Effective Supplier Appraisal Techniques To Improve The Supply Chain

Hochgeladen von

elmenoufiCopyright:

Verfügbare Formate

Using effective supplier appraisal .

techniques to improve the supply chain

Suppliers can have a significant bearing on the success of an organization and businesses can introduce a number of problems through inadvertently using poor or inappropriate suppliers. Issues can include poor quality goods, ineffective delivery schedules and poor service levels which can all impact the procuring company in varying degrees. For many organizations protecting the supply chain through effective sourcing is a key task. The management of this is usually achieved through the implementation of an approved supplier list coupled with an effective appraisal .system The reason behind an approved supplier list is simple enough, the list comprises the suppliers that are approved! to be used and have passed through some form of assessment. The approved suppliers list acts a control for the buying community to ensure that only suitable suppliers are used. "valuation therefore acts as the initial stage in identifying organizations with suitable controls and capacity that can supply .the desired products or services #hilst there is no standard evaluation method there are several areas that should be considered, as a result supplier appraisal often includes criteria to ensure the supplier $is Technically sound % &anagerially competent % 'dequately resourced % Financially stable % )(ompetitive )often in terms of price and availability % *eliable % +rovides goods of suitable quality % "nvironmentally,"thically sound % ."ach factor can be weighted according to their importance to the procuring company From time to time new organizations will need to be added to the approved supplier list and an appraisal is carried out. There are two typical methods of obtaining $evaluation information -uestionnaire % Supplier .isit % It should be remembered that obtaining accurate information can sometimes be tricky and due time and resource should be committed to the evaluation process. This should involve a range of personnel from the buying company who are stakeholders in the material being procured. This may typically involve the -' dept but should be e/tended to manufacturing and,or engineering teams. 'nother crucial aspect is that an effective process is required to capture new suppliers )prior to an order being raised0 .and to prevent use prior to appraisal #hile supplier evaluation should be seen as a critical process it is not without problems. "valuation can be resource intensive and can create a bottleneck between the supplier and buyer this is especially true where evaluation data is difficult to .obtain For most organizations appraisal is a continuing process and becomes part of an integrated supplier management process. Thus the appraisal process may be carried out intermittently, often on an annual basis to ensure that once a supplier is added to

the approved supplier list to ensure its performance against the appraisal criteria is .maintained 1 The advantages to running an evaluation program are various and include +oor supplier are weeded out prior to use .2 Identified weaknesses of suppliers that are approved can be targeted by .3 improvement programs "ach organization gains understanding over potential influencers of the relationship .4 (ompany spend can be leveraged on approved suppliers .5 (ustomer service levels are secured .6 Supplier appraisal is one activity which supply chain teams undertake that can have real bottom line fiscal impact. 7et it wrong or have none at all and the business can find itself aligned with improper suppliers, ineffective goods and impractical delivery schedules 1 get it right and the organization can be positioned with suppliers who are .focused and tuned alongside the needs of the business

Supply Chain KPIs Understanding Supply Chain Metrics and Choosing the ight KPIs to Measure

8y Sam &iller 7etting your supply chain management right can give your business competitive advantage by lowering costs, greater efficiency and improving customer satisfaction by getting goods to customers faster. The impact of technology with the use of *FI9 tags to track pallets and shipments electronically and merging this into the stock and order management system is making the S(& aspect of a business an area of .substantial opportunity for creating competitive advantage :ow that all sounds fantastic with the ability to track individual shipments through the supply chain and maintaining data on product, serial codes, description, quantity and so on. (ombining *FI9 data with barcode information creates even more .information that can be manipulated and collected In truth though, what we have is a ;+I nightmare with such a huge choice of metrics to choose from we are at serious risk of ;+I overload with metrics duplicating .information and business trends leading to information overload for management *emember that using ;+I<s effectively means that you first must select the right metrics to measure and ensure that managers fully understand what those metrics are actually telling them. The best metrics to use are those that combine in a ratio form and this means that we lose some of the underlying raw data trend that is available. (ombining delivery time with order value will give us an inde/ of how well we are at getting our order pipeline to our customer base but the smoothing effect of the ratio will hide long delivery times for low value products which may increase rather than decrease overall customer satisfaction leading to a knock on effect in customer care .and contact center ;+I<s #ith any ;+I scorecard system, choosing the right metrics is essential and less is also more. *emember +areto<s +rinciple, =>? of the benefit will be derived from 3>? of the activity 1 the same applies with your metrics. Scorecards carrying twenty or thirty

metrics are going to overload decision makers using the dashboard so keep it simple .and reduce the metrics being used to those that are essential 'llowing the metrics to be reduced means that managers can gain a far more intimate knowledge of what a metric is actually trying to tell them and this makes the difference between using the dashboard for a simple performance against target check and really unleashing the diagnostic and management power of a the ;+I metrics. #ith the massive influ/ of data that is being collected and collated by an S(& system, it is very tempting to rush headlong into trying to use all of this information. The fact is that in those ;+I systems where metric selection is rigorously kept to a minimum, managers tend to make more successful decisions that their counterparts .operating a complicated, metric overloaded dashboard The adage here is that less is more and following +areto<s +rinciple, 3>? of your metrics are going to give you =>? of the S(& information you really need to make .effective management decisions If you are interested in learning more about supply chain kpi, check Sam &iller new .web@site

Das könnte Ihnen auch gefallen

- l4 03 Measuring Purchasing PerformanceDokument150 Seitenl4 03 Measuring Purchasing PerformanceMahendra Kumar Soni100% (3)

- SIPOC: A Six Sigma Tool Helping On ISO 9000 Quality Management SystemsDokument10 SeitenSIPOC: A Six Sigma Tool Helping On ISO 9000 Quality Management SystemsYogesh ChavanNoch keine Bewertungen

- Strategic Supplier EvaluationDokument226 SeitenStrategic Supplier EvaluationarrjudNoch keine Bewertungen

- Best Practices in Supplier Quality ManagementDokument4 SeitenBest Practices in Supplier Quality ManagementAnonymous 3tOWlL6L0UNoch keine Bewertungen

- Supplier Performance ManagementDokument6 SeitenSupplier Performance ManagementYogesh Sharma100% (1)

- The Why, What and How of Supplier ManagementDokument8 SeitenThe Why, What and How of Supplier ManagementZycusInc100% (1)

- Measure Supplier PerformanceDokument6 SeitenMeasure Supplier PerformanceDharmesh MistryNoch keine Bewertungen

- Supplier Quality Management System A Complete Guide - 2020 EditionVon EverandSupplier Quality Management System A Complete Guide - 2020 EditionNoch keine Bewertungen

- Procurement & Materials Management - Supplier: Arvind Tiwari Guest Faculty IIFTDokument40 SeitenProcurement & Materials Management - Supplier: Arvind Tiwari Guest Faculty IIFTguru945Noch keine Bewertungen

- Best Practices - Supplier ScorecardDokument16 SeitenBest Practices - Supplier ScorecardSandeep Sharma100% (1)

- Supplier Quality Improvement - ChecklistDokument16 SeitenSupplier Quality Improvement - ChecklistmuneerppNoch keine Bewertungen

- Quality Metrics For Aerospace: Tim Robertson PQA Nasa/JplDokument20 SeitenQuality Metrics For Aerospace: Tim Robertson PQA Nasa/Jplnikhil jNoch keine Bewertungen

- TP11 Supplier Evaluation System MTUFNDokument8 SeitenTP11 Supplier Evaluation System MTUFNcastor2010Noch keine Bewertungen

- Supplier ManagementDokument15 SeitenSupplier Managementking100% (1)

- Value Stream MappingDokument14 SeitenValue Stream MappingMihir ZalawadiaNoch keine Bewertungen

- Vendor Rating 1Dokument9 SeitenVendor Rating 1wilsongouveiaNoch keine Bewertungen

- Supply ChainDokument12 SeitenSupply ChainManish SinghNoch keine Bewertungen

- Why and How To Conduct A Warehouse Assessment 7-31-12Dokument6 SeitenWhy and How To Conduct A Warehouse Assessment 7-31-12Partha Patim GiriNoch keine Bewertungen

- Supplier PerformanceDokument80 SeitenSupplier PerformancessNoch keine Bewertungen

- Шпаргалка от индусаDokument79 SeitenШпаргалка от индусаVyacheslavNoch keine Bewertungen

- Lean Deployment in Supply ChainDokument38 SeitenLean Deployment in Supply Chainss2mrattri100% (1)

- Supplier Management Self-Assessment Tool: Lean Aerospace InitiativeDokument56 SeitenSupplier Management Self-Assessment Tool: Lean Aerospace Initiativesudar1477Noch keine Bewertungen

- SCLM ChecklistDokument38 SeitenSCLM ChecklistMayur GaidhaneNoch keine Bewertungen

- QP 74001 Rev 13 Supplier Management ProcedureDokument15 SeitenQP 74001 Rev 13 Supplier Management ProcedureDKY EDPAPNoch keine Bewertungen

- supplier segmentation A Complete Guide - 2019 EditionVon Everandsupplier segmentation A Complete Guide - 2019 EditionNoch keine Bewertungen

- Balanced ScorecardDokument36 SeitenBalanced Scorecardwessam777Noch keine Bewertungen

- Supply Chain Management (SCM)Dokument47 SeitenSupply Chain Management (SCM)sean buenaventura100% (1)

- EPRI Supplier Performance Base AuditDokument84 SeitenEPRI Supplier Performance Base AuditixoteeNoch keine Bewertungen

- MC Ds Mastercontrol AuditDokument3 SeitenMC Ds Mastercontrol AuditManish PatelNoch keine Bewertungen

- Supplier Selection DefinitionDokument25 SeitenSupplier Selection Definitionkitmos1Noch keine Bewertungen

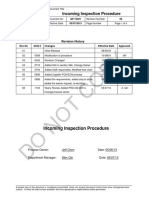

- QP 74301 Rev 08 Incoming Inspection ProcedureDokument9 SeitenQP 74301 Rev 08 Incoming Inspection ProcedureAngeline D'AlmaidaNoch keine Bewertungen

- Vendor Performance Measurement System User ManualDokument52 SeitenVendor Performance Measurement System User ManualMonching AdecerNoch keine Bewertungen

- Eaton Global Supplier Excellence ManualDokument30 SeitenEaton Global Supplier Excellence Manualfdsa01100% (1)

- Supplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLDokument38 SeitenSupplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLsrkadaliNoch keine Bewertungen

- Review Iso 9001 2015 PPMDokument27 SeitenReview Iso 9001 2015 PPMAFDHAL PASANoch keine Bewertungen

- Supply Chain IntegrationDokument8 SeitenSupply Chain IntegrationMan Singh0% (1)

- BuyerSupplier Relationship ValueDokument42 SeitenBuyerSupplier Relationship ValuelrNoch keine Bewertungen

- GSQM TRW PDFDokument48 SeitenGSQM TRW PDFJuan José Viñas Méndez50% (2)

- Quality Engineer or Supplier Quality or Failure Analysis EngineeDokument3 SeitenQuality Engineer or Supplier Quality or Failure Analysis Engineeapi-121417252Noch keine Bewertungen

- Supplier Guide DetailedDokument24 SeitenSupplier Guide Detailedsuresh6265Noch keine Bewertungen

- How Mature Is Your Supply ChainDokument10 SeitenHow Mature Is Your Supply ChainAlejandro OlaldeNoch keine Bewertungen

- Supplier Perfomance ProgramDokument24 SeitenSupplier Perfomance Programduytaybui94Noch keine Bewertungen

- Demand And Supply Management A Complete Guide - 2020 EditionVon EverandDemand And Supply Management A Complete Guide - 2020 EditionNoch keine Bewertungen

- Advanced Supply Chain Planning at Usg Planning at Usg2861Dokument20 SeitenAdvanced Supply Chain Planning at Usg Planning at Usg2861zeeshan78Noch keine Bewertungen

- Supplier Evaluation - SourcingDokument43 SeitenSupplier Evaluation - SourcingBalaji ShindeNoch keine Bewertungen

- FCA US LLC Customer Specific Requirements For IATF 16949 June 8 2018Dokument48 SeitenFCA US LLC Customer Specific Requirements For IATF 16949 June 8 2018lorenzordzrmzNoch keine Bewertungen

- Assignment 3 EPMDokument3 SeitenAssignment 3 EPMWajiha JawwadNoch keine Bewertungen

- How Is BOM Cost CalculatedDokument16 SeitenHow Is BOM Cost Calculatedjack100% (1)

- Supplier Selection and Business Process ImprovementDokument63 SeitenSupplier Selection and Business Process ImprovementGursharan Singh100% (1)

- System-Based, Customer-Centered Quality Plan For ManufacturersDokument9 SeitenSystem-Based, Customer-Centered Quality Plan For ManufacturersmsbarretosNoch keine Bewertungen

- Understand What Is A Benchmark and How It Is UsedDokument8 SeitenUnderstand What Is A Benchmark and How It Is UsedSharah Del Tabudlong TudeNoch keine Bewertungen

- Conformity AssessmentDokument15 SeitenConformity AssessmentMaruan MuhammadNoch keine Bewertungen

- Bosch - Supplier-Quality-RequirementsDokument55 SeitenBosch - Supplier-Quality-RequirementsumtNoch keine Bewertungen

- Borgwarner Supplier ManualDokument63 SeitenBorgwarner Supplier ManualBertha Uribe100% (1)

- Supplier Evaluation The First Step in Effective SoDokument4 SeitenSupplier Evaluation The First Step in Effective SoShatender kumar Kumar100% (1)

- Effectiveness of The QMSDokument33 SeitenEffectiveness of The QMSvavvavNoch keine Bewertungen

- SM Standard PresentationDokument64 SeitenSM Standard PresentationJuan CNoch keine Bewertungen

- Young Procurement Leadership Programme - Overview of Learning ModulesDokument12 SeitenYoung Procurement Leadership Programme - Overview of Learning ModulesStephen TanNoch keine Bewertungen

- Scor Model and The Balanced Scorecard, A Powerful Combination For Business Management AssetsDokument18 SeitenScor Model and The Balanced Scorecard, A Powerful Combination For Business Management Assetsokto8uNoch keine Bewertungen

- Can Lean Six Sigma Drive Sales & Lower Costs?: Kush Shah, ChairmanDokument30 SeitenCan Lean Six Sigma Drive Sales & Lower Costs?: Kush Shah, ChairmanMario Alejandro Charlin SteinNoch keine Bewertungen

- Supplier EvaluationDokument2 SeitenSupplier EvaluationIonut EduardNoch keine Bewertungen

- QUALITYDokument1 SeiteQUALITYelmenoufiNoch keine Bewertungen

- Six SigmaDokument1 SeiteSix SigmaelmenoufiNoch keine Bewertungen

- PET Bottles ProjectDokument1 SeitePET Bottles ProjectelmenoufiNoch keine Bewertungen

- PET Bottles ProjectDokument1 SeitePET Bottles ProjectelmenoufiNoch keine Bewertungen

- Plastic IndustryDokument80 SeitenPlastic IndustryelmenoufiNoch keine Bewertungen

- PAFDokument2 SeitenPAFHuda ImdadNoch keine Bewertungen

- Notre Dame University Bangladesh: Assignment On Total Quality ManagementDokument4 SeitenNotre Dame University Bangladesh: Assignment On Total Quality ManagementYeasin AzizNoch keine Bewertungen

- Spare Parts ProvisioningDokument76 SeitenSpare Parts ProvisioningMilion dugumaNoch keine Bewertungen

- Carter's 10 Cs of Supplier EvaluationDokument6 SeitenCarter's 10 Cs of Supplier EvaluationPHAM PHI HUNGNoch keine Bewertungen

- Purchasing and Vendor ManagementDokument53 SeitenPurchasing and Vendor Managementnarenmadhav100% (1)

- METHODOLOGY FOR Vendor Rating SystemDokument5 SeitenMETHODOLOGY FOR Vendor Rating SystemRangaNoch keine Bewertungen

- Supplier Evaluation MatrixDokument48 SeitenSupplier Evaluation MatrixJohn Moshiro71% (7)

- Purchasing Analytics For Supplier EvaluationDokument6 SeitenPurchasing Analytics For Supplier Evaluation33286762Noch keine Bewertungen

- NC Purchasing and Supply Management Revised FinalDokument160 SeitenNC Purchasing and Supply Management Revised Finalrumbidzayiruwizhi9Noch keine Bewertungen

- Chap 7 QuizDokument25 SeitenChap 7 QuizUyên DươngNoch keine Bewertungen

- Downloaded From WWW - Ktunotes.in: Only Mohan, Sngce, KadayiruppuDokument59 SeitenDownloaded From WWW - Ktunotes.in: Only Mohan, Sngce, KadayiruppuBibin K SNoch keine Bewertungen

- BRS FinalDokument104 SeitenBRS FinalrubaminNoch keine Bewertungen

- Procedure For Evaluation and SelectionDokument2 SeitenProcedure For Evaluation and SelectionSharif KhanNoch keine Bewertungen

- CAR - SOP.18-ASSESSMENT OF VENDORS (EXTERNAL PROVIDERS) Iss 1 Rev 01 Issue Date May 11 2018Dokument8 SeitenCAR - SOP.18-ASSESSMENT OF VENDORS (EXTERNAL PROVIDERS) Iss 1 Rev 01 Issue Date May 11 2018Nicholas MohammedNoch keine Bewertungen

- VALVEXPO Manufacturer CatalogDokument96 SeitenVALVEXPO Manufacturer CatalogAnnie De WildeNoch keine Bewertungen

- Supplier SelectionDokument12 SeitenSupplier SelectionSimon Chege100% (2)

- Vendor Rating: Reference For BusinessDokument10 SeitenVendor Rating: Reference For BusinessSaikumar SelaNoch keine Bewertungen

- Organization For Materials ManagementDokument60 SeitenOrganization For Materials ManagementNaushad PulikkandyNoch keine Bewertungen

- Sop 7 4 1 B Qualifying New and Existing VendorsDokument7 SeitenSop 7 4 1 B Qualifying New and Existing Vendorsיוליה רחמילובNoch keine Bewertungen

- HBC 2112 Principles of MarketingDokument91 SeitenHBC 2112 Principles of MarketingAntonyNoch keine Bewertungen

- Procedure For Supplires EvaluationDokument3 SeitenProcedure For Supplires EvaluationShiraz Khan100% (1)

- Proposal Supplier Selection 1Dokument19 SeitenProposal Supplier Selection 1Tafadzwa BhaselaNoch keine Bewertungen

- FIT QSP 06 Purchase ProcessDokument6 SeitenFIT QSP 06 Purchase Processsasi10000Noch keine Bewertungen

- POM Module 3Dokument16 SeitenPOM Module 3fifalegends0730Noch keine Bewertungen

- Supplier Evaluation: (Supplier) Evaluation ... Without Action Is Not Effective (Gordon, 2008)Dokument9 SeitenSupplier Evaluation: (Supplier) Evaluation ... Without Action Is Not Effective (Gordon, 2008)Nyeko FrancisNoch keine Bewertungen

- Procedure For Qualification of Vendors For Raw Material and Packaging Materials - Pharmaceutical GuidelinesDokument2 SeitenProcedure For Qualification of Vendors For Raw Material and Packaging Materials - Pharmaceutical Guidelineskavya nainitaNoch keine Bewertungen

- Study On Vendor Rating and Vendor Evaluation at Big BazaarDokument7 SeitenStudy On Vendor Rating and Vendor Evaluation at Big BazaarSreeja sathyanarayananNoch keine Bewertungen

- SCM Q BankDokument18 SeitenSCM Q BankNisha PradeepaNoch keine Bewertungen

- SDFDokument3 SeitenSDFKANWAL RAINoch keine Bewertungen