Beruflich Dokumente

Kultur Dokumente

Write-Up On Gear Pump and Associated Systems

Hochgeladen von

Anirudh SrikantOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Write-Up On Gear Pump and Associated Systems

Hochgeladen von

Anirudh SrikantCopyright:

Verfügbare Formate

FMEA of Extruder Gear Pump

I. GEAR PUMP:

PR 25-6 The gear pump installed in the HDPE-1 plant is model no. PR 25-6, manufactured ! "##$ P%"P &'&TE"& #$ (H-)*2+ ,%R-(H and integrated ! .erner / Pfleiderer $m H 0ith the rest of the e1truder s!stem. The num er 25 in the model signifies that the gear thic2ness is 25 1 1* 3 25* mm and the num er 6 indicates that it has a timing gear 0here ! oth shafts are dri4en independentl!. The shaft centerline distance et0een the 2 gears is +6* mm. -t 0as installed on 12th 5e ruar! 2***. -ts e6uipment tag num er is $PE1-7515. The e1truder s!stem can e run 0ithout the gear pump, 0ith the t0in scre0 e1truder producing the re6uired pressure to force the pol!mer melt through the die plate. Ho0e4er, operation 0ith the gear pump installed is highl! eneficial due to the reasons listed elo08

#s seen in the pressure profile to the left, the ma1imum attaina le pressure is limited to around 25* ar at the end of the arrel 9at the throttle 4al4e:. Due to the pressure drop in the s!stem, the pol!mer melt drops to a pressure of around 15* ar ! the time it reaches the %$ under0ater pelleti;er. Ho0e4er, upon adding a gear pump ahead of the di4erter 4al4e, the ma1 pressure generated increases to +** ar. The pressure drops to around 2** ar ! the time the melt reaches the under0ater pelleti;er. This ma2es it much more efficient at o4ercoming the resistance to pol!mer flo0 offered ! the screen pac2 and the die plate. The gear pump highl! reduces the load on the e1truder motor, gear o1 and clutch coupling. This helps to ensure a longer life and reduced 0ear of these components. "oreo4er, the energ! efficienc! of the entire s!stem 0ith a gear pump is also much higher as the gear pump is added as a speciali;ed unit to de4elop pressure. The 4olumetric efficienc! of a gear pump is in the range of <*-<<= depending on the clearances 0hereas that of the e1truder scre0s is around >*->5=. .ithout the gear pump, a lot of the input energ! is con4erted to heat due to friction in the scre0s, 0hich raises the melt temperature in the arrel to appro1. 2?5 deg (. @! adding the gear pump, the ma1imum melt temperature is reduced to around 2>* deg (.

THEAR' A5 APER#T-A78 $ear pumps operate on the displacement principle. The! comprise of t0o intermeshing gear0heels of the same si;e, encased in a housing 0ith closel! defined clearance 9clearance et0een teeth and housing are in the order of *.1 mm and the clearance et0een front B ac2 of the gears and the housing is of the order of *.*25 mm:. $enerall! one of the t0o gear0heels is directl! dri4en ! a shaft protruding out of the housing through a shaft seal. The second gear0heel is dri4en ! the teeth of the first one. 5or some gear pump applications, ho0e4er, it ma! e etter for oth gear0heels to e dri4en. This reduces the friction et0een the gear teeth and distri utes forces e6uall! on oth gear0heels. 5or this purpose a special pump dri4e gear o1 is re6uired. #s the gear0heels rotate, the spaces et0een unmeshing teeth are filled 0ith the inflo0ing pumping medium. This is then transported along the inside 0alls of the housing from the suction side to the pressure side. Here the pumping medium is displaced ! the meshing teeth and eCected through the pump outlet. The gear teeth fulfill the follo0ing main functions8 Transport of pumping medium from suction to pressure side Displacement of pumping medium on the pressure side

&ealing et0een suction and pressure sides

The pol!re1 is installed as a ooster generating the necessar! pressure ehind the die plate, relie4ing the e1truder of this 0or2 and sa4ing energ!. -t is installed et0een the start up B throttle 4al4e and the screen changer unit. -t is a con4entional gear pump ha4ing t0o gear 0ith spur teeth, thus minimi;ing product degradation ensuring effecti4e self cleaning. The gears are enclosed in a steel casing 0ith heating Cac2et. The pump installed 0ith timing gear allo0s each shaft of the t0o gears to e dri4en separatel! 0ithout touching the teeth of each other. The gear o1 nominal po0er used for its operation is 6** D. allo0ing a ma1imum speed ! the gears of ++.+ rpm. The earings can e heated prior to start up and cooled 0ith 0ater during normal operation, thus pre4enting degradation of melt. -t is designed to operate 0ithin the follo0ing pressure limits8 &uction side, ma1imum pressure Discharge side, ma1imum pressure Differential pressure, ma1imum &pecific deli4er! rate 1** 2gBcm2g +5* 2gBcm2g +2* 2gBcm2g 2).> lBre4

The main parts of the pump are8

Housing The housing has an integral heating Cac2et for li6uid or gaseous heating media. The housing has an inlet opening on the suction side and an outlet opening on the discharge side. The suction side of the housing is ored 0ith t0o relief holes, one on the dri4e side and one on the non-dri4e side. The housing is ored to ta2e measuring pro e cartridges and temperature pro es for housing and earing temperatures.

Housing co4ers The t0o co4ers are made of steel and incorporate heating channels for li6uid or gaseous heating media. Each co4er has a Eee-shaped relief groo4e 9E-groo4e: on the inside pointing to0ard the suction side and matching o4er the relief hole in the housing. @oth co4ers ha4e a oring for a temperature pro e on top.

Dri4e shaft and short shaft These straight-toothed shafts are each mounted in t0o plain earings in the pump housing. The long end of the dri4e shaft is splined for mounting a hu or toothed coupling. The non-dri4e end of proCecting dri4e shafts has a oring for a shaft cooling pipe.

Plain earings The dri4e and non-dri4e sides of the housing are each fitted 0ith a top and a ottom earing facing each other. Each pair of earings is loc2ed ! a 2e! against rotation. The dri4e side top and non-dri4e side ottom earings are identical and thus interchangea le, li2e0ise the non-dri4e side top and dri4e side ottom earings. The h!drod!anmic plain earings are lu ricated ! the pumping medium. The earings are designated according to installation position8 Dri4e side earing, top @earing D&T

Dri4e side earing, ottom 7on-dri4e side earing, top 7on-dri4e side earing, ottom

@earing D&@ @earing 7D&T @earing 7D&@

The earings ha4e tapped orings for fitting steel shoulder rings and a temperature pro e oring on the outside diameter.

&haft seals Pol!mer melt lea2age is pre4ented ! 4iscoseal in the housing co4ers. The 4iscoseals are fitted 0ith cooling 0ater channels. The! are connected to the cooling 0ater piping. -n case of dou le shaft dri4e, depending on top and ottom shaft rotation, lefthand or right-hand 4iscoseals are incorporated in the dri4e and non-dri4e side housing co4ers. The dri4e side top seal and non-dri4e side ottom seal are interchangea le, li2e0ise the dri4e side ottom and non-dri4e side top seals.

APER#T-7$ "ADE&8 There are four different operating modes a4aila le for the Pol!re1 installed in an e1trusion plant 0ith t0in-scre0 2neader and the follo0ing upstream and do0nstream e6uipments8 1. &tart-up 4al4e flanged to suction side 2. Do0nstream e6uipment 0ith screen changer and die-plate, flanged on to pressure side +. &paghetti mode 9purging of die-plate:8 -mmediatel! after starting the Pol!re1, pol!mer melt is e1truded through the die-plate on to the floor. This operating mode is 2no0n as &paghetti mode.This is necessar! 0ith a ne0 or freshl! assem led Pol!re1 in order to clean out all the "ol!2ote dr! lu ricant film. #fter pauses in operation, &paghetti mode is necessar! in order to purge thermall! damaged pol!mer from the Pol!re1 and die-plate.

7ormall! it ta2es a out + to 5 minutes to flush out the "ol!2ote, ut purging should e continued until clear pol!mer emerges from the die-plate.#fter operation in &paghetti mode, then the normal operation can e resumed. >. &tart-up mode8 #fter start-up, follo0ing chec2s should e carried out8 (hec2 the pressure control s!stem "easure the Pol!re1 speed 0ith a hand tachometer, and compare 0ith the speed indicator reading on the process control s!stem. (hec2 all measuring, displa! and recording instruments. (hec2 operating data. (hec2 the 4iscoseal shaft seals for lea2age. (hec2 all heating medium suppl! connections for lea2age. (hec2 for an! lea2age of the cooling medium connections to the 4iscoseal shaft seals. -f shaft cooling is installed, chec2 the suppl! piping for an! lea2age. (hec2 all au1iliar! s!stems such as for shaft cooling and lu e oil s!stem.

7ormal mode The follo0ing operating limits should e maintained during normal operation8 7o. Pumping medium T!pe Design ation "5-21.62gB1<**( "a1. throughput "a1.speed Pol!re1 "a1.Tpumping medium FgrB1*GH F2gBhH Rpm *( 1 HDPE $" 6255 2 <*** 1> 2)* 2 HDPE $" 6255 2 15*** 2+ 2)* + HDPE $" <2>* 5.6 22*** +> 2?* > HDPE $" >?6* +2 2>*** >* 2>* 5 HDPE $" ?26* 2+ 2>*** >1 22* 6 HDPE $" <>5*5 2+*** +6 2?* ? HDPE $" 5*1* 2>*** +) 2?*

--.

GEARBOX8

The $ear o1 for the Pol!re1 is model no. &P%-+6 made ! "##$ $ears. -t is a +-stage reduction gear unit 0ith a final timing gear stage. The first reduction stage is a right angle e4el gear stage. The second reduction stage is a planetar! gear. The last stage is the timing gear. The 2 shafts of the timing gear s!nchroni;e and dri4e the 2 pump shafts. The! ensure contact free meshing of the pump rotors. The coupling used is to e pf "##$ toothed coupling ,5I-)' t!pe. TE(H7-(#J D#T#8 $ear o18 Distance et0een oth dri4en shafts8 +6* mm $ear 7ominal Po0er8 6** 2. "a1 Tor6ue8 1?2 27m 7ominal input rpm8 1*** rpm 7ominal output rpm8 ++.+ rpm Ju ricating Ail8 Ju e Ail Kualit!8 (JP lu e oils Eiscosit!8 -&A E$ +2* Ail flo0rate8 <* lBmin

---.

SHAFT TEMPERING SYSTEM 8

The shaft tempering s!stem regulates the temperature of the t0o shafts of the Pol!re1 gear pump. -n order to do this, it carries out the follo0ing tas2s8 -t heats the tempering medium up to operating temperature. -t cools the t0o shafts under certain operating conditions of the Pol!re1 gear pump.

"#-7 (A"PA7E7T&8 The shaft tempering s!stem comprises the follo0ing elements8 T0o shaft cooling pipes 0ith 1 rotar! Coint each Ane tempering unit for circulating 0ater 25 L 21* deg. ( 8 -ndirectl! heated ! electrical resistance heaterM indirectl! cooled ! 0ater 4ia heat e1changer to TE"# (, designed for pressure class P7>*. -t also consists of a centrifugal circulation pump of Dic2o0 Pumpen ma2e , 7(J t!pe. Ane pressuri;ing and ma2e up 0ater station8 5or generating asic s!stem pressure re6uired to achie4e the ma1imum circulation temperature ! means of a high pressure triple1 piston pump. The triple1 plunger pump is of t!pe P11B1+-1**, manufactured ! &pec2 Pumps. -t has a po0er consumption of +.< 2., producing a ma1 pressure of 15* ar N 1>2* rpm. The ma1. flo0rate is 12.? litBmin. Ane control unit8 5or automatic control of the heating B cooling s!stem. Temperature and pressure are controlled ! digital electronic controllers L -P 55, 2+* E B 5* H;

THEAR' A5 APER#T-A78 Tempering %nit8 The temperature control unit heats up the tempering medium to the correct temperature prior to operation and automaticall! regulates it during operation. The Pol!re1 shafts are either heated ! s0itching on the heating s!stem, or cooled ! s0itching on the cooling s!stem.

Heat is transferred ! feed 0ater, circulated ! a pump through the t0o shafts of the Pol!re1. Heating is done ! electrical resistance heating element. (ooling is done indirectl! ! heat e1changer.

(ontrol &!stem The plain earing temperature control s!stem maintains the Pol!re1 earing temperature 9controlled 4aria le: at the set-point 9reference 4aria le:. The tempering medium temperature 9manipulated 4aria le: is regulated ! the earing temperature control s!stem. -f the earing temperature changes, the tempering medium temperature is adCusted accordingl!. -f the earing temperature rises a o4e the set-point 4alue, the tempering medium is cooled accordingl!. -f the earing temperature falls elo0 the set-point 4alue, the tempering medium is heated accordingl!.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Infosys (A) Strategic HRM - Group1 - Section BDokument5 SeitenInfosys (A) Strategic HRM - Group1 - Section BAnirudh SrikantNoch keine Bewertungen

- Chapter 33. Light and IlluminationDokument12 SeitenChapter 33. Light and IlluminationAndrey Ugalde50% (2)

- Chicago-West Coast Pricing Decision: Major ChallengesDokument2 SeitenChicago-West Coast Pricing Decision: Major ChallengesAnirudh SrikantNoch keine Bewertungen

- WebinarDokument13 SeitenWebinarAnirudh SrikantNoch keine Bewertungen

- CalculationDokument2 SeitenCalculationAnirudh SrikantNoch keine Bewertungen

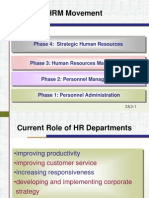

- HRM Movement: Phase 4: Strategic Human ResourcesDokument6 SeitenHRM Movement: Phase 4: Strategic Human ResourcesAnirudh SrikantNoch keine Bewertungen

- Analysis of Mechanical SystemDokument16 SeitenAnalysis of Mechanical SystembigbangNoch keine Bewertungen

- 2013 04Dokument110 Seiten2013 04Jose Emmanuel Martinez CordovaNoch keine Bewertungen

- En D6T CatalogDokument20 SeitenEn D6T CatalogHeddy ErizalNoch keine Bewertungen

- MIM WinGD X52DF-S2-0Dokument259 SeitenMIM WinGD X52DF-S2-0Κώστας ΧατζηδάκηςNoch keine Bewertungen

- 7PA22/23/26/27/30 Auxiliary Relays For Various Applications: Technical DataDokument7 Seiten7PA22/23/26/27/30 Auxiliary Relays For Various Applications: Technical DatasoltaniNoch keine Bewertungen

- EAF QuantumDokument2 SeitenEAF QuantumJosé Miguel RuanoNoch keine Bewertungen

- CS59201 DDokument4 SeitenCS59201 DJose M PeresNoch keine Bewertungen

- Title - Study and Analysis of The Effects of Waves and Wind On Offshore Structures and Marine VesselsDokument5 SeitenTitle - Study and Analysis of The Effects of Waves and Wind On Offshore Structures and Marine VesselsIszysax MediaNoch keine Bewertungen

- Dd311 Specification Sheet EnglishDokument4 SeitenDd311 Specification Sheet EnglishJose Antonio Sanchez SegoviaNoch keine Bewertungen

- GU-611 - PDO Engineering Standands PDFDokument1 SeiteGU-611 - PDO Engineering Standands PDFSheik Ali (QA/QC Manager Coastal)Noch keine Bewertungen

- Trouble Shooting EngineDokument188 SeitenTrouble Shooting EngineDedy setiawanNoch keine Bewertungen

- Lab 3 - SeepageTankDokument6 SeitenLab 3 - SeepageTankPrantik MaityNoch keine Bewertungen

- Forces On Large Steam Turbine Blades: RWE NpowerDokument5 SeitenForces On Large Steam Turbine Blades: RWE NpoweradawNoch keine Bewertungen

- Dextra Precast Pipe Racks Brochure 2020 ENDokument5 SeitenDextra Precast Pipe Racks Brochure 2020 ENCivix VarixNoch keine Bewertungen

- The New Amarok. Not Just Tough, Smart.: Subject To Change Without Notice 01 October 2010 WWW - Amarok.co - ZaDokument20 SeitenThe New Amarok. Not Just Tough, Smart.: Subject To Change Without Notice 01 October 2010 WWW - Amarok.co - ZaNaza MhamadNoch keine Bewertungen

- As 1038.14.2-2003 Coal and Coke - Analysis and Testing Higher Rank Coal Ash and Coke Ash - Major and Minor ElDokument7 SeitenAs 1038.14.2-2003 Coal and Coke - Analysis and Testing Higher Rank Coal Ash and Coke Ash - Major and Minor ElSAI Global - APAC100% (1)

- Sources of Energy Class 10Dokument17 SeitenSources of Energy Class 10Maan NmNoch keine Bewertungen

- ISO-50001-JK-WhiteDokument24 SeitenISO-50001-JK-WhiteAgustinusDwiSusantoNoch keine Bewertungen

- Egev ProhsDokument2 SeitenEgev ProhsOscar Campos TarazonaNoch keine Bewertungen

- Increasing Operational Stability in Low No GT Combustor by A Pilot FlameDokument10 SeitenIncreasing Operational Stability in Low No GT Combustor by A Pilot FlameGilles CabotNoch keine Bewertungen

- Bagi 'LKPD 2 Teks News ItemDokument8 SeitenBagi 'LKPD 2 Teks News ItemMuhammad IhsanNoch keine Bewertungen

- June 2017 (v1) QP - Paper 4 CIE Chemistry A-LevelDokument16 SeitenJune 2017 (v1) QP - Paper 4 CIE Chemistry A-LevelMustafa ShaukatNoch keine Bewertungen

- Leroy Somer D510C AVRDokument54 SeitenLeroy Somer D510C AVRabuzer1981Noch keine Bewertungen

- Prosper & Sucker RodDokument20 SeitenProsper & Sucker RodOmar AbdoNoch keine Bewertungen

- Notes:: Colombo Port City Development ProjectDokument1 SeiteNotes:: Colombo Port City Development Projectnadim7862Noch keine Bewertungen

- 1 Introduction and Mathematical ConceptsDokument13 Seiten1 Introduction and Mathematical ConceptsKim CastilloNoch keine Bewertungen

- Energy, Work and Power: PHY111: Mechanics and Thermo Properties of MatterDokument71 SeitenEnergy, Work and Power: PHY111: Mechanics and Thermo Properties of MatterStudent 365Noch keine Bewertungen