Beruflich Dokumente

Kultur Dokumente

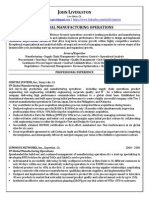

Director Engineering Manager in Atlanta GA Resume Gary Sobus

Hochgeladen von

GarySobusCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Director Engineering Manager in Atlanta GA Resume Gary Sobus

Hochgeladen von

GarySobusCopyright:

Verfügbare Formate

Cumming, GA 30041 Phone (678) 468-6301

E-mail Gesobus@aol.com

Gary Sobus

Summary of Over 25 years of successful, goal oriented strategic managerial experience in Engineering, Quality

qualifications Management, Quality Assurance, Compliance, Validation, Operations and R&D Management with

specific experience in manufacturing engineering and operations for medical devices and

combination products.

Energetic, output oriented, Engineering Director with progressive experience in diversified

manufacturing environment with a unique combination of project management and leadership

experience.

Technical skills include; injection molding and extrusion of plastics, metal stamping, metal forming,

Die casting, welding and machining of metal and plastic components.

Experienced with manufacturing both disposable and durable products including packaging and

sterilization efforts.

Proven ability to deliver innovative solutions that fully supports corporate growth objectives.

Multiple experiences in start-up of new operations, Design Control Management, Verification and

Validation, fiscal planning and management, work simplification, lean manufacturing, DMAIC Six

Sigma, workplace automation and process improvement.

Strong knowledge of quality control, quality assurance, design controls, 510(k) submissions,

Internal and External quality auditing, corrective and preventative action process, change control

practices, Change Control Management and DOE.

Work May 2010 to Present CHART Industries, Ball Ground, GA

experience Director, Innovation and Sustaining Engineering

Led initiative to strengthen and grow the Biomedical Research and Development, Innovation,

Sustaining and Manufacturing Engineering teams and to provide leadership, strategic direction,

and management for the engineering functions within the Biomedical Division.

Responsible for seeking out new potential business to grow the respiratory and cryogenic

storage business within the Biomedical Division.

Team leader for new product development projects requiring oversight to ensure products under

development follow full design controls and the Global Product Commercialization Process.

Product launches include; Strategic resourcing of critical components to address quality and

performance issues, 510(k) submissions, new design and release of a cryogenic freezers, new

freezer controller, Stationary oxygen concentrator and cryogenic specimen storage Dewar.

Provided team direction and leadership for creating and implementing a new quality

management and design controls process.

Provided team direction and leadership to bring the current product lines in compliance to the

rd

new 60601 3 edition requirements.

Provide team direction and responsibility for overseeing timely patent filing protection,

confidentiality and design agreements.

Provide technical leadership to the engineering team for complying with the RoHS2 initiatives.

Responsible for directing the manufacturing engineering functions including manufacturing

methods, engineering standards, product validations including IQ/OQ/PQ activities, plant

engineering efforts such as FMEA and PFMEA, Design Controls, equipment selection and design,

Lean practices and process validation efforts.

June 2008 to May 2010 KCI, San Antonio, Texas

Director, Research and Development 2008-2010 TSS R&D

Led initiative to strengthen and grow the Therapeutic Support Research and Development team

and to provide strategic direction and management for a group consisting of 8 associates, 3

consultants and 3 key strategic business partners.

Team leader for new product development projects requiring oversight to ensure products under

development follow full design controls and the Stage Gate Approach to Project Management

Responsibility for product five product launches with new surfaces and beds.

Provide technical engineering management and leadership within the Therapeutic Support

Systems, sustaining engineering group to provide dedicated leadership in support of growing the

TSS business.

Responsible for directing the manufacturing engineering functions including manufacturing

methods, engineering standards, product validations including IQ/OQ/PQ activities, plant

engineering efforts such as FMEA and PFMEA, Design Controls, equipment selection and design,

Lean practices and process validation efforts.

Established team to address internal audit findings and outstanding CAPA actions.

Direct Franchise Readiness Assessments for domestic US and Canada products requiring UL

60601 update due to UL withdrawal of the UL544 standard.

1997 to June 2008 Covidien, formerly Tyco Healthcare

Engineering Manager 2004-2008 Puritan Bennett Plainfield, Indiana

Transferred to Puritan Bennett to provide technical engineering management and leadership within

the oxygen therapy group undergoing a management transformation from groups to a more

traditional staff.

Responsible for directing the Plainfield Plant manufacturing engineering functions including

manufacturing methods, engineering standards, product validations including IQ/OQ/PQ activities,

plant engineering efforts such as FMEA and PFMEA, equipment selection and design and process

validation efforts.

Lead the efforts as the sites project manager for a facility expansion project costing in excess of

$3M.

Oversaw the machine center manufacturing operations for six months as part of a cross training

self-development initiative. Reduced the machine center cost from over $55/hr. to under $48/hr.

Responsible for overseeing the efforts to incorporate cost saving projects that increase the bottom

line by $1.3 million in 2005, $500k in 2006 and $1.4 million in 2007.

Lead the manufacturing engineering efforts to bring four new products to market.

Managed the validation engineering functions to assure compliance with corporate programs and

FDA/ISO, DOT, TPED, Canadian, Japanese and Swiss requirements.

Provide oversight to the plant engineering operation (facilities), which includes supervision of all

environmental and regulatory issues such as wastewater discharges, air permits and rainwater

runoff.

Engineering Manager 2002-2004 Kendall Healthcare Argyle, New York

Transferred to Kendall Argyle to provide technical engineering management and leadership at two

manufacturing sites supporting the Dialysis-Vascular and Critical Care business units.

Supervise and review the establishment of all engineering production standards for labor, scrap,

set-up and bills of materials.

Responsible for the cost savings and cost avoidance initiatives for both Tyco Healthcare plants in

Argyle, New York.

Optimized automated equipment through redesign of mechanical stations and reprogramming of

the PLC logic, which improved productivity from 43% to 97% efficiency.

Implemented a scrap tracking procedure to aid the engineering and production groups with

identifying cost savings/cost avoidance opportunities that has yielded a monthly savings of $15,000

material variance.

Completed a make versus buy project including a material change that involved biocompatibility

study and testing yielding an annual savings of $265,000.

Provide oversight to the plant engineering operation (facilities), which includes supervision of all

environmental and regulatory issues.

Engineering Manager 2000-2002 U. S. Surgical Fort Worth, Texas

Responsibilities include designing, qualifying and implementing design modifications to improve the

overall performance of the products.

Redesigned and Qualified “Tacker Hernia Repair Fastener” from multi-part design to single

component design generating an annual cost savings of $1M.

Redesigned “Blunt Tip Trocar” to reduce scrap, generated during testing, from 45% to less than 4%

without negatively affecting use or effectiveness of product.

Experience with wire drawing, progressive die stamping, MIM, and 3-axis machining centers for

manufacture of “Skin Staplers” and staples.

Evaluated manufacturing lines/cells which improved productivity, improved quality and reduced

scrap/rework by 25%

Generated cost saving projects that produced an annual savings of $909,000.

Instrumental with automating several areas of the manufacturing process to improve the

manufacturing efficiency and cost savings through the use of LEAN practices.

Senior Divisional Engineer 1999-2000 U. S. Surgical North Haven, Ct.

Engineering responsibility for overseeing all engineering functions of transferring products acquired

through mergers to the US Surgical Fort Worth facility.

Senior Manufacturing Engineer 1997-1999 U. S. Surgical North Haven, Ct.

Instrumental with process changes that resulted in increasing the efficiency of an automated

assembly process from 69% to 90% daily average.

Continuous improvement focused on scrap reduction and equipment utilization

Senior Systems Engineer, General Dynamics 1996-1997

Cognizant Engineer for the design of and development of system for the new attack submarine

program.

Senior Shift Test Engineer, General Dynamics 1988-1997

Acted as Electric Boat’s on-the scene representative to ensure the proper conduct of testing

nuclear reactors and related systems onboard new construction and commissioned ships.

Education/ Bachelor of Science Technology in Mechanical Engineering:

Training Rochester Institute of Technology, Rochester, NY

ISO 13485

ISO 9000

Pro Engineering (Pro E), AutoCAD and Solid Works

Kepner Tregoe Project Management

Validation Training

Lessons in Leadership Program and Diversity Training

Advanced Excel for Window

Geometric Dimensioning and Tolerancing

Blood borne Pathogens Training

Supervisory Skills Training

Naval Nuclear Propulsion Radiological Controls Training

NAVSEA 08 Naval Nuclear Propulsion Training/Certification

Guiding Conflict Resolution and Positive Human Resource Practices

Failure Investigation

DMAIC Six Sigma Green Belt (trained)

OSHA 10-hour safety training

UL/IEC/EN 60601 training

RoHS and RoHS2

Das könnte Ihnen auch gefallen

- Director Manufacturing in Greater Denver CO Resume Erik Van HornDokument2 SeitenDirector Manufacturing in Greater Denver CO Resume Erik Van HornErik Van HornNoch keine Bewertungen

- P.O. Box 12672 Albany, NY 12212-2672: Professional Strengths IncludeDokument2 SeitenP.O. Box 12672 Albany, NY 12212-2672: Professional Strengths IncludesdvikkiNoch keine Bewertungen

- Director Business Development Strategic Alliances in San Diego CA Resume David BerryDokument2 SeitenDirector Business Development Strategic Alliances in San Diego CA Resume David BerryDavidBerry2Noch keine Bewertungen

- Process Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDokument2 SeitenProcess Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDouglasWilkinsNoch keine Bewertungen

- Vice President Engineering in San Antonio TX Resume David LingreyDokument4 SeitenVice President Engineering in San Antonio TX Resume David LingreyDavidLingreyNoch keine Bewertungen

- Naukri SharathA (7y 0m)Dokument2 SeitenNaukri SharathA (7y 0m)RaghuNoch keine Bewertungen

- Director Quality Assurance Operations in Tampa ST Petersburg FL Resume Gary SteinerDokument5 SeitenDirector Quality Assurance Operations in Tampa ST Petersburg FL Resume Gary SteinerGarySteinerNoch keine Bewertungen

- MD Shahnewaz Sabit Faisal: Phone: Home: EmailDokument4 SeitenMD Shahnewaz Sabit Faisal: Phone: Home: Emailkiran2710Noch keine Bewertungen

- Quality Technical Leader in Marietta GA Resume Wayne BoldenDokument2 SeitenQuality Technical Leader in Marietta GA Resume Wayne BoldenWayneBoldenNoch keine Bewertungen

- Name Mobile Phone Email Address Linkedin: EngineeringDokument2 SeitenName Mobile Phone Email Address Linkedin: EngineeringdannyNoch keine Bewertungen

- CV Kevin Moriarty 20170828Dokument7 SeitenCV Kevin Moriarty 20170828api-372585023Noch keine Bewertungen

- Program Manager Plastics Engineering in Chicago IL Resume Dennis TortorellaDokument2 SeitenProgram Manager Plastics Engineering in Chicago IL Resume Dennis TortorellaDennisTortorellaNoch keine Bewertungen

- Quality Manager or Quality EngineerDokument3 SeitenQuality Manager or Quality Engineerapi-77217896Noch keine Bewertungen

- Yril Ossa: Pharmaceutical Biotech Medical DeviceDokument3 SeitenYril Ossa: Pharmaceutical Biotech Medical DeviceCyril PossaNoch keine Bewertungen

- Quality Manager Senior Engineer in Los Angeles CA Resume Joannes HsueanDokument4 SeitenQuality Manager Senior Engineer in Los Angeles CA Resume Joannes HsueanJoannesHuseanNoch keine Bewertungen

- Professional Opportunities in Eni For Chemical EngineersDokument4 SeitenProfessional Opportunities in Eni For Chemical Engineersanon_552162647Noch keine Bewertungen

- VP Director Operations Manufacturing in Chicago IL Resume Erik PetersonDokument2 SeitenVP Director Operations Manufacturing in Chicago IL Resume Erik PetersonErikPeterson1Noch keine Bewertungen

- Manufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczDokument2 SeitenManufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczJosephMarkowiczNoch keine Bewertungen

- VP General Manager in United States Resume Art ChristiansonDokument2 SeitenVP General Manager in United States Resume Art ChristiansonArtChristiansonNoch keine Bewertungen

- VP Director Operations Semiconductor in San Francisco Bay CA Resume Joel CamardaDokument3 SeitenVP Director Operations Semiconductor in San Francisco Bay CA Resume Joel CamardaJoelCamardaNoch keine Bewertungen

- Plant HeadDokument25 SeitenPlant Headpankajmpawar1986Noch keine Bewertungen

- Shubailat - Omar - Quality and MBA Leadership Resume (June 09)Dokument3 SeitenShubailat - Omar - Quality and MBA Leadership Resume (June 09)Omar ShubailatNoch keine Bewertungen

- QC Specialist Holly Springs, NC 12 Months: Minimum RequirementsDokument7 SeitenQC Specialist Holly Springs, NC 12 Months: Minimum Requirementschintan patelNoch keine Bewertungen

- Director Program Management in Auburn Hills MI Resume Greggory OrlandiDokument4 SeitenDirector Program Management in Auburn Hills MI Resume Greggory OrlandiGreggoryOrlandiNoch keine Bewertungen

- Frederick Ferguson: Operations ManagerDokument2 SeitenFrederick Ferguson: Operations ManagerZoe TanNoch keine Bewertungen

- VP Quality Operations Executive in Kansas City MO Resume Saul PachecoDokument3 SeitenVP Quality Operations Executive in Kansas City MO Resume Saul PachecoSaulPacheco100% (2)

- VP Director Engineering MBA in San Francisco Bay CA Resume Mark RosenDokument2 SeitenVP Director Engineering MBA in San Francisco Bay CA Resume Mark RosenMarkRosen1Noch keine Bewertungen

- Plant Operations Engineering Manager in Minneapolis ST Paul Resume Wade WoodsDokument3 SeitenPlant Operations Engineering Manager in Minneapolis ST Paul Resume Wade WoodsWadeWoodsNoch keine Bewertungen

- Chemical Process Engineer in Los Angeles Orange County CA Resume Tessa KelleyDokument2 SeitenChemical Process Engineer in Los Angeles Orange County CA Resume Tessa KelleyTessaKelleyNoch keine Bewertungen

- Jaime M. Ramirez: Engineering / Operations / Plant ManagerDokument4 SeitenJaime M. Ramirez: Engineering / Operations / Plant ManagerjaimejaimearturoNoch keine Bewertungen

- Engineering Project Manager Continuous Improvement in Richmond VA Resume Richard MestlerDokument2 SeitenEngineering Project Manager Continuous Improvement in Richmond VA Resume Richard MestlerRichardMestlerNoch keine Bewertungen

- Rufus Short ResumeDokument3 SeitenRufus Short ResumeStacy ElliottNoch keine Bewertungen

- Functional Area:: ManufacturingDokument4 SeitenFunctional Area:: ManufacturingHuman ResorceNoch keine Bewertungen

- Process Engineer in Houston TX Resume Douglas Chiau Funn MaDokument3 SeitenProcess Engineer in Houston TX Resume Douglas Chiau Funn MaDouglasChiauFunnMaNoch keine Bewertungen

- Director Engineering ResumeDokument3 SeitenDirector Engineering Resumeapi-72678201Noch keine Bewertungen

- VP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonDokument2 SeitenVP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonJohn Livingston2Noch keine Bewertungen

- Operations ManagementDokument12 SeitenOperations Managementshabeena ShahNoch keine Bewertungen

- Nabeel Ahmed Malik: ExperienceDokument3 SeitenNabeel Ahmed Malik: ExperiencenabeelNoch keine Bewertungen

- Quality Improvement Manager Engineer in Lincoln NE Resume Monte BainterDokument2 SeitenQuality Improvement Manager Engineer in Lincoln NE Resume Monte BainterMonteBainterNoch keine Bewertungen

- Samir S. Al Yasen - CVDokument3 SeitenSamir S. Al Yasen - CVMoh MohNoch keine Bewertungen

- Manufacturing Engineer Production Manager in New York City Resume Ivan DominguezDokument2 SeitenManufacturing Engineer Production Manager in New York City Resume Ivan DominguezIvanDominguezNoch keine Bewertungen

- Operations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsDokument2 SeitenOperations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsPaulRoberts2Noch keine Bewertungen

- Sample Resume Process Engineer Economic RecoveryDokument10 SeitenSample Resume Process Engineer Economic RecoveryVijay RajaindranNoch keine Bewertungen

- Director VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuDokument3 SeitenDirector VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuThomasZhu2Noch keine Bewertungen

- Articulo Tecnologia de TransferenciaDokument10 SeitenArticulo Tecnologia de Transferencia20172504Noch keine Bewertungen

- CV of Muhammad Adeel RajputDokument4 SeitenCV of Muhammad Adeel RajputFarhan SaghirNoch keine Bewertungen

- Sample Resume - GKN AerospaceDokument2 SeitenSample Resume - GKN AerospaceRolndoNoch keine Bewertungen

- Resume of BlouinrDokument3 SeitenResume of Blouinrapi-30207141Noch keine Bewertungen

- Director Lean Manufacturing Engineering Operations in Philadelphia PA Resume Frank FloresDokument2 SeitenDirector Lean Manufacturing Engineering Operations in Philadelphia PA Resume Frank FloresFrankFlores1Noch keine Bewertungen

- System Design: Dr. Mohammed Shamim Uddin Khan Professor and Chairman Department of Finance University of ChittagongDokument84 SeitenSystem Design: Dr. Mohammed Shamim Uddin Khan Professor and Chairman Department of Finance University of ChittagongShafayet JamilNoch keine Bewertungen

- Vice President Engineering in Seattle WA Resume Roger McGheeDokument2 SeitenVice President Engineering in Seattle WA Resume Roger McGheeRogerMcGheeNoch keine Bewertungen

- Richard Newman ResumeDokument2 SeitenRichard Newman ResumeRichNoch keine Bewertungen

- Lean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichDokument3 SeitenLean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichMichaelMakarewichNoch keine Bewertungen

- MD Shahnewaz: Manufacturing EngineerDokument4 SeitenMD Shahnewaz: Manufacturing Engineerkiran2710Noch keine Bewertungen

- SaivDokument5 SeitenSaivRohith korrapatiNoch keine Bewertungen

- Plant Manager Manufacturing or VP Operations Manufacturing or DiDokument3 SeitenPlant Manager Manufacturing or VP Operations Manufacturing or Diapi-121669822Noch keine Bewertungen

- Continuous Improvement Manager Manufacturing in Butler PA Resume Kevin HilliardDokument2 SeitenContinuous Improvement Manager Manufacturing in Butler PA Resume Kevin HilliardKevinHilliard2Noch keine Bewertungen

- Stephanie L Skipper: Career ObjectiveDokument6 SeitenStephanie L Skipper: Career Objectivesudar1477Noch keine Bewertungen

- Quality Management/ R D / Product Development Professional: Arun Kumar ShrivastavaDokument4 SeitenQuality Management/ R D / Product Development Professional: Arun Kumar ShrivastavaArunNoch keine Bewertungen

- TOPIC 2 Mio2Dokument46 SeitenTOPIC 2 Mio2Natti NonglekNoch keine Bewertungen

- SME and SE ParagraphDokument2 SeitenSME and SE ParagraphAimee CuteNoch keine Bewertungen

- Blue Diamond Pattern Background Writer ResumeDokument2 SeitenBlue Diamond Pattern Background Writer ResumerabiaNoch keine Bewertungen

- Principle of MarketingDokument16 SeitenPrinciple of MarketingahmedbariNoch keine Bewertungen

- Restriction On Transfer of SharesDokument20 SeitenRestriction On Transfer of SharesPrerna GuptaNoch keine Bewertungen

- Grievance Handling Policy LSMDokument4 SeitenGrievance Handling Policy LSMEngr Muhammad Zubair FarooqNoch keine Bewertungen

- The Effects of Market Orientation On Business Performance - Vodafone Ghana PDFDokument102 SeitenThe Effects of Market Orientation On Business Performance - Vodafone Ghana PDFhortalemos100% (1)

- Business Plan - Tour Company (JST)Dokument26 SeitenBusiness Plan - Tour Company (JST)Adrian Keys81% (68)

- El Nido Plaza - 2960, 2982, 2990 E. Colorado BLVD, Pasadena - For LeaseDokument3 SeitenEl Nido Plaza - 2960, 2982, 2990 E. Colorado BLVD, Pasadena - For LeaseJohn AlleNoch keine Bewertungen

- Marketing Report of Bharia TownDokument45 SeitenMarketing Report of Bharia Townabbas121100% (9)

- Real Estate Buyer GuideDokument18 SeitenReal Estate Buyer GuideJustin Huynh0% (1)

- Module 1 FINP7Dokument3 SeitenModule 1 FINP7gfdhgfhgfhgfhNoch keine Bewertungen

- Iso 9001 - 2015 Awarness TrainingDokument39 SeitenIso 9001 - 2015 Awarness TrainingSasi KssNoch keine Bewertungen

- Marginal Costing: Definition: (CIMA London)Dokument4 SeitenMarginal Costing: Definition: (CIMA London)Pankaj2cNoch keine Bewertungen

- Waterfall Project PlanningDokument19 SeitenWaterfall Project PlanningAhmed ShakilNoch keine Bewertungen

- Final Term Assignment 3 On Cost of Production Report - FIFO CostingDokument2 SeitenFinal Term Assignment 3 On Cost of Production Report - FIFO CostingUchiha GokuNoch keine Bewertungen

- PCM Book - Part IDokument72 SeitenPCM Book - Part Ithilina madhushanNoch keine Bewertungen

- Cycle Count ProcessDokument41 SeitenCycle Count ProcessRjNoch keine Bewertungen

- Black BookDokument50 SeitenBlack BookRaj PatelNoch keine Bewertungen

- ACN - Outsourcing Overview V02Dokument35 SeitenACN - Outsourcing Overview V02Dimpi DhimanNoch keine Bewertungen

- Lectures For Basic Seminar On Cooperative Development 1203395026675748 4Dokument37 SeitenLectures For Basic Seminar On Cooperative Development 1203395026675748 4Marlon CorpuzNoch keine Bewertungen

- The Essential Tax Guide - 2023 EditionDokument116 SeitenThe Essential Tax Guide - 2023 Editionธนวัฒน์ ปิยะวิสุทธิกุล100% (2)

- MFIN6012 Risk ManagementDokument6 SeitenMFIN6012 Risk ManagementjessieNoch keine Bewertungen

- Business Judgement Rule Dikaitkan Dengan Tindak Pidana Korupsi Yang Dilakukan Oleh Direksi Badan Usaha Milik Negara Terhadap Keputusan Bisnis Yang DiambilDokument12 SeitenBusiness Judgement Rule Dikaitkan Dengan Tindak Pidana Korupsi Yang Dilakukan Oleh Direksi Badan Usaha Milik Negara Terhadap Keputusan Bisnis Yang DiambilWied WidayatNoch keine Bewertungen

- Gete Ermias - ProposalDokument22 SeitenGete Ermias - ProposalTise TegyNoch keine Bewertungen

- Graduate CV TemplateDokument3 SeitenGraduate CV TemplateAlvaro Ahmadi AlvarezNoch keine Bewertungen

- Bengin New Dim03 Beta eDokument36 SeitenBengin New Dim03 Beta ePeter BretscherNoch keine Bewertungen

- Instructions For Registration and Bidding: KarachiDokument2 SeitenInstructions For Registration and Bidding: Karachifardasa123Noch keine Bewertungen

- Chandra Sekhar - CRM ConsultantDokument4 SeitenChandra Sekhar - CRM ConsultantDotNet developerNoch keine Bewertungen

- Term Sheet-36Inc-30042018-v2Dokument3 SeitenTerm Sheet-36Inc-30042018-v2harshdeep gumberNoch keine Bewertungen