Beruflich Dokumente

Kultur Dokumente

TR 05 07e 120402 PDF

Hochgeladen von

Flores JesusOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TR 05 07e 120402 PDF

Hochgeladen von

Flores JesusCopyright:

Verfügbare Formate

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

2/13

Revisions

Notes Change note Date

1 (A) Change of template 09 / 07 / 2008

2 Change of template. Clause 7.8.2.7 and 7.9.1 revised.Clause 7.8.3

added.

02 / 04 / 2012

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

3/13

Contents

7.1 References ................................................................................................................. 5

7.2 Scope .......................................................................................................................... 5

7.3 Definition ................................................................................................................... 6

7.4 Description ................................................................................................................ 6

7.4.1 Joint .............................................................................................................. 6

7.5 Requirements ............................................................................................................ 6

7.5.1 General ......................................................................................................... 6

7.5.2 Material ........................................................................................................ 6

7.5.3 Design ........................................................................................................... 6

7.5.4 Marking ........................................................................................................ 6

7.5.5 Mechanical requirements ............................................................................ 7

7.5.6 Electrical requirements ............................................................................... 7

7.5.6.1 Resistance ...................................................................................... 7

7.5.6.2 Corona ............................................................................................ 7

7.5.6.3 Fault current .................................................................................. 7

7.6 Type test ..................................................................................................................... 7

7.6.1 General ......................................................................................................... 7

7.6.2 Dimensions ................................................................................................... 7

7.6.3 Thickness of zinc coating ............................................................................. 7

7.6.4 Mechanical strength ................................................................................... 8

7.6.5 Resistance .................................................................................................... 8

7.6.6 Corona ......................................................................................................... 8

7.7 Sample test ............................................................................................................... 8

7.7.1 General ........................................................................................................ 8

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

4/13

7.7.2 Dimensions ................................................................................................... 9

7.7.3 Thickness of zinc coating ............................................................................. 9

7.8 Delivery ...................................................................................................................... 9

7.8.1 General ......................................................................................................... 9

7.8.2 Documentation ............................................................................................. 9

7.8.2.1 Assembly drawing ........................................................................ 9

7.8.2.2 List of material ............................................................................ 10

7.8.2.3 Manufacturing process ............................................................... 10

7.8.2.4 Quality system ............................................................................. 10

7.8.2.5 Installation instruction ............................................................... 10

7.8.2.6 Fault current ................................................................................ 10

7.8.2.7 Reports ......................................................................................... 10

7.8.3 Transport and storing ............................................................................... 10

7.9 Installation............................................................................................................... 10

7.9.1 General ....................................................................................................... 10

7.9.2 Measurement of resistance ....................................................................... 11

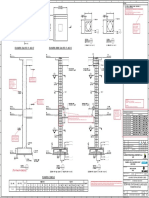

7.10 Figures ..................................................................................................................... 11

Figure 1 Measurement of resistance, Type test ....................................... 11

Figure 2 Measurement of resistance, Installation records ..................... 13

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

5/13

7.1 References

Note that standards, regulations etc. which are referred to in these guidelines are

subject to continuous change and can be withdrawn, revised or replaced. It is the

obligation that the contractor immediately will inform the client of such changes.

SS 424 12 41 Overhead line material Mid-span joints

SS-EN 50341 Overhead electrical lines exceeding AC 45 kV

SS-EN 50326 Conductors for overhead lines - Characteristics of

greases

SS-EN 61284 Overhead lines Requirements and test for fittings

SS-EN ISO 9001 Quality management systems - Requirements

SS-ISO 2178 Non-magnetic coatings on magnetic substrates -

Measurement of coating thickness - Magnetic method

SS-ISO 5455 Technical drawings - Scales

SvK TR 05-04E Technical guidelines Conductors

SvK TR 08E Technical guidelines - Documentation

EBR Maintenance overhead lines 0,4 420 kV

7.2 Scope

These guidelines are applicable to joints for steel reinforced aluminium and

aluminium alloy conductors according to SvK TR 05-04E for overhead lines and

comprise design, testing and installation.

The intention of the specification is to guarantee satisfactory performance of joints

during the lifetime of the overhead line.

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

6/13

7.3 Definition

Technical terms and definitions used in these regulations:

Corona extinction voltage

The voltage where no corona is visible when the voltage is reduced from a level with

visible corona.

7.4 Description

7.4.1 Joint

Device, comprising one or several parts, for joining two lengths of conductor to

provide mechanical and electrical continuity. In joints, contrary to clamps, the

conductor lengths have a common line of symmetry.

7.5 Requirements

7.5.1 General

Joints shall be able to withstand the mechanical stresses which can occur during

transport, handling and installation at temperatures as low as 40 C, in addition to

the mechanical stresses which can occur during the technical lifetime of the overhead

line at temperatures from -50 C to +100 C.

7.5.2 Material

Joints shall be made of material in accordance with SS 424 12 41.

7.5.3 Design

Joints shall have additional corrosion protection and be designed in accordance with

SS 424 12 41.

Extended joint, for replacement of existing joint with increased resistance, shall be

equipped with a filler rod or with the possibility to fill up the cavity with grease in

order to minimize the risk of frost burst.

Grease shall conform to the requirements of SS-EN 50326.

7.5.4 Marking

The joints shall be marked with raised or indented/stamped characters with a

minimum height of 3 mm as follows:

Manufacturers trademark

Type or catalogue number

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

7/13

Conductor diameter

Year of manufacture

7.5.5 Mechanical requirements

The mechanical strength of joints shall conform to the requirements of SS 424 12 41

and SS-EN 50341.

7.5.6 Electrical requirements

7.5.6.1 Resistance

The resistance (R0, R4) for joints for phase conductors and shield wires shall be at

maximum of 3,5 % of the resistance of a conductor with a length of one (1) metre. The

resistance shall be measured from a point on the conductor immediately outside the

joint, to a point immediately inside the end of the joint. See Figure 1.

The resistance (R1) for joints for phase conductors and shield wires shall be a

maximum of 55 % of the resistance of a conductor with the equivalent length. The

resistance shall be measured from the conductor immediately outside one end of the

joint to the conductor immediately outside the opposite end of the joint. See Figure 1.

7.5.6.2 Corona

The level of the corona extinction voltage for joints for phase conductors shall be equal

to that for the conductor.

7.5.6.3 Fault current

Joints shall withstand the fault current given in SvK TR 05-04E. The peak value of the

fault current shall be 2,3 times its effective value.

7.6 Type test

7.6.1 General

Unless otherwise agreed the type test shall be performed in accordance with clauses

7.6.2-7.6.6 on three test samples. The tests shall be performed in such a way that the

method and equipment do not affect the result.

7.6.2 Dimensions

This test intends to check that the joints fulfil the requirements in accordance with

clause 7.5.3-7.5.4 and also are in accordance with the manufacturer drawings

regarding measurements.

7.6.3 Thickness of zinc coating

This test shall be performed in accordance with SS-ISO 2178. Each sample shall be

subject to, depending on size, 3 to 10 measurements. The points of measurement shall

be evenly and randomly distributed over the entire sample surface.

The minimum and average layer thickness requirements in accordance with 7.5.2 shall

be fulfilled.

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

8/13

7.6.4 Mechanical strength

This test intends to verify that the joints comply with the requirements of clause 7.5.5.

The test shall be performed in accordance with clause 5.3 of SS 424 12 41

7.6.5 Resistance

This test intends to verify that the joints comply with the requirements of clause 7.5.6.1

and to give reference values for tests after installation.

The joints shall be installed on the conductor in accordance with the installation

instructions. The direct current resistances R0, R1, R2, R3, and R4 according to Figure 1,

shall be measured. The conductor tension shall be limited to a maximum of 40

N/mm

2

during the measurement of all resistances.

7.6.6 Corona

This test intends to establish the corona extinction voltage and shall be performed in a

fully darkened room.

The joint and the conductor shall be installed such that a clearance of 3 metres from

live to earth is obtained. The joint shall be exposed to 50 Hz of alternating current.

The corona extinction voltage shall be recorded by colour photographs, one with

visible corona and another at the corona extinction voltage level. The voltage levels

should be indicated on the photos.

The test shall be performed in accordance with SS-EN 61284 where applicable.

7.7 Sample test

7.7.1 General

Sample tests shall be carried out by the manufacturer on joints and clamps selected at

random from the lot to be supplied.

Test samples shall be supplied by the manufacturer free of charge to the client and

shall not be included in the lot to be supplied.

The size of the test samples are indicated in table below.

Lot size Sample size

N 300 Subject to agreement

300 < N 2000 4

2000 < N 5000 8

5000 < N 10000 12

The samples shall be subject to testing in accordance with clauses 7.7.2-7.7.3.

The manufacturer shall inform the client when sample tests shall be performed.

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

9/13

Records from the sample tests shall be filed by the manufacturer and be shown to the

client on request. In the case where any component does not comply with the

requirements, re-testing shall be performed as below.

If only one joint or part thereof, fails to comply with the sample test requirement, a

new sample equal to twice the quantity originally submitted for that test shall be

subject to re-testing. The re-testing shall comprise the test or tests in which failure

occurred.

If two or more joints, or parts thereof, fail to comply with any of the sample tests, or if

any failure occurs during re-testing, the complete lot shall be considered not to comply

with the requirements.

Provided that the cause of the failure can be clearly identified, the manufacturer may

sort the lot to eliminate all the joints with this defect. The sorted lot shall then be

resubmitted for sample testing. The number then selected shall be three times the first

quantity chosen for the test. The re-testing shall comprise the test or tests in which

failure occurred in the original test.

If any joint, or part thereof of the sorted lot, fails during this re-testing, the complete

lot shall be considered as not complying with the requirements.

7.7.2 Dimensions

The test shall be performed in accordance with clause 7.6.2.

7.7.3 Thickness of zinc coating

The test shall be performed in accordance with clause 7.6.3.

7.8 Delivery

7.8.1 General

The client shall, according to these guidelines, approve the joint before delivery. For

approval the manufacturer shall show that the joint conforms to the guidelines.

The manufacturer shall provide documentation in accordance with clauses 7.8.2.1-

7.8.2.7 inclusive for approval.

The approval of drawings by the client does not release the manufacturer from his

obligations regarding the joint/clamp complying with the guidelines.

All documentation shall be written in Swedish or English.

7.8.2 Documentation

General requirements for documentation see SvK TR 08E.

7.8.2.1 Assembly drawing

The assembly drawing shall have a minimum of two views at an appropriate scale in

accordance with SS-ISO 5455. On the drawing shall be given:

Type and/or catalogue number

Principal dimensions

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

10/13

The dimensions after installation

All marking.

Weight.

List of materials.

Required compression tools

7.8.2.2 List of material

Description of material in included parts.

7.8.2.3 Manufacturing process

Description of the manufacturing process.

7.8.2.4 Quality system

Quality system in accordance with SS-EN ISO 9001.

7.8.2.5 Installation instruction

Installation instructions in Swedish or English with the required figures.

7.8.2.6 Fault current

Test report verifying the compliance of the joint regarding the short circuit current

requirement as given in clause 7.5.5.3.

7.8.2.7 Reports

Reports in accordance with clause 7.6 and 7.7.

7.8.3 Transport and storing

The joints shall be packed up in that way that they will not be damaged or fouled at

transport, construction and storing.

7.9 Installation

7.9.1 General

At construction of new lines and reconstruction of old lines, shall joints not be

installed in the crossings or spans adjacent to the crossing spans with roads and

railways.

Installation on the conductor shall be performed in accordance with the

manufacturers installation instructions.

The conductors ends shall be free from dirt and not be damaged when the joint is

installed. Conductor adjacent to the joint shall not have protruding strands.

The jointing installation location shall be so arranged that the joint and the conductor

will not be in contact with the ground during preparation and jointing.

The distance from joints, after conductor sagging, to adjacent fittings shall be a

minimum of:

Other joints 50 metres.

Tension clamps 50 metres.

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

11/13

Suspension clamps 20 metres.

Spacers 2 metres.

7.9.2 Measurement of resistance

The resistance of the joint shall be measured after installation. Resistances R1, R2 and

R3 in accordance with Figure 2 shall be measured. Resistance R1 shall be equivalent to

the entire length of the joint and the measurement shall be performed from the

conductor immediately outside one end of the joint to the conductor immediately

outside the opposite end of the joint. Resistances R2 and R3 shall be equivalent to the

lengths of each joint half and the measurements shall be performed from the

conductor immediately outside each end of the joint to the middle of the joint.

Recommended procedures for measurements can be found in the handbook of EBR

Maintenance of transmission lines 0,4 420 kV Chapter 303K, measuring of joints.

Measured resistances, final span number and in which conductor each joint is located

shall be documented in records in accordance with Figure 2 and on computer diskette.

If the measured joint resistance exceeds 10 % of the resistance of the type test, the joint

in question shall be discarded and be replaced by a new joint.

7.10 Figures

Figure 1 Measurement of resistance, Type test

R0

R2

R1

R3

R4

Figure 1a Joint for ACSR conductor

R0

R2

R1

R3

R4

Figure 1b Joint for AAAC conductor

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

12/13

R0

R2

R1

R3

R4

Figure 1c Extended joint

TEKNISK RIKTLINJE 2012-04-02 TR 05-07E utg 2

13/13

Figure 2 Measurement of resistance, Installation records

1 2 3

a b

Conductor numbering

Phase

Triplex

Duplex

Towards greater structure number

a b

c

a b

c

a b

c

a b a b

R2

R1

R3

OH line name: . . . . . . . . . . . . . . . . . . . . . Line designation:. . . . . . . . . . . .

Joint, Catalogue number: . . . . . . . . . . . . . . . . Conductor:. . . . . . . . . . . . . . .

Span Con-

ductor

Measured resistance Installation

No. No. R1 R2 R3 Date Signature Remarks

Das könnte Ihnen auch gefallen

- Underground Cable Thermal Backfill: Proceedings of the Symposium on Underground Cable Thermal Backfill, Held in Toronto, Canada, September 17 and 18, 1981Von EverandUnderground Cable Thermal Backfill: Proceedings of the Symposium on Underground Cable Thermal Backfill, Held in Toronto, Canada, September 17 and 18, 1981S.A. BoggsBewertung: 3.5 von 5 Sternen3.5/5 (2)

- BS en 50368 Cable CleatDokument27 SeitenBS en 50368 Cable CleatNima dawa SherpaNoch keine Bewertungen

- Minimum Electrical Clearance. Electrical Notes & ArticalsDokument8 SeitenMinimum Electrical Clearance. Electrical Notes & ArticalsJoenathan EbenezerNoch keine Bewertungen

- Cyclic Current RatingsDokument5 SeitenCyclic Current RatingsJeremy Mcfadden100% (1)

- Total Standard For CablesDokument14 SeitenTotal Standard For CablesjamilNoch keine Bewertungen

- EHVHV Underground Cable Sheath Earthing Part 12Dokument5 SeitenEHVHV Underground Cable Sheath Earthing Part 12rajfab100% (1)

- Heatshrink Joints PDFDokument24 SeitenHeatshrink Joints PDFMonish KrishnaNoch keine Bewertungen

- En 50182Dokument1 SeiteEn 50182pankajnbi100% (2)

- Reconductoring Using HTLS Conductors. Case Study For A 220 KV Double Circuit Transmission LINE in RomaniaDokument7 SeitenReconductoring Using HTLS Conductors. Case Study For A 220 KV Double Circuit Transmission LINE in RomaniaJose ValdiviesoNoch keine Bewertungen

- SSE 2227 Archivo Ingecon Sun Catalogue 2016 v2 EnglishDokument160 SeitenSSE 2227 Archivo Ingecon Sun Catalogue 2016 v2 EnglishVitor Olivetti0% (1)

- IEEE Synchrophasor Measurement Test Suite Specification - Product Sheet PDFDokument2 SeitenIEEE Synchrophasor Measurement Test Suite Specification - Product Sheet PDFPartha Sarathi MannaNoch keine Bewertungen

- (BS EN 61439-2) - Low-Voltage Switchgear and Controlgear Assemblies. Part 2. Power Switchgear and Controlgear Assemblies PDFDokument26 Seiten(BS EN 61439-2) - Low-Voltage Switchgear and Controlgear Assemblies. Part 2. Power Switchgear and Controlgear Assemblies PDFjit dhara0% (1)

- BS7870-4.10 33kv Single Core Un ArmouredDokument3 SeitenBS7870-4.10 33kv Single Core Un Armouredrudypl100% (1)

- Safety ClearanceDokument19 SeitenSafety ClearanceAnand AgrawalNoch keine Bewertungen

- Description: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhDokument4 SeitenDescription: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhTarek FawzyNoch keine Bewertungen

- 011 - 2008 - Medium Voltage (36 Ka) Surge ArrestersDokument10 Seiten011 - 2008 - Medium Voltage (36 Ka) Surge Arresterse09341Noch keine Bewertungen

- Bu1 PDFDokument31 SeitenBu1 PDFGilberto MejíaNoch keine Bewertungen

- Seccionador de LíneaDokument1 SeiteSeccionador de LíneaGeorge O.Noch keine Bewertungen

- 05 - Att. #2.1 IEC60949 - 1988Dokument5 Seiten05 - Att. #2.1 IEC60949 - 1988Rahul SrivastavaNoch keine Bewertungen

- NESC Guidelines For GroundingDokument2 SeitenNESC Guidelines For GroundingsulemankhalidNoch keine Bewertungen

- Force Calc BusbarsDokument7 SeitenForce Calc BusbarsVimal Puthusseri100% (1)

- Iec60865 1Dokument8 SeitenIec60865 1Amritesh PandeyNoch keine Bewertungen

- HK 2014 EN - T12 Current Ratings Basic Table PDFDokument7 SeitenHK 2014 EN - T12 Current Ratings Basic Table PDFZoran FabekovicNoch keine Bewertungen

- Electrical Test After Site Installation 62067 IEC-2011Dokument5 SeitenElectrical Test After Site Installation 62067 IEC-2011waqas_a_shaikh4348Noch keine Bewertungen

- Info Iec62271-111 (Ed1.0) enDokument11 SeitenInfo Iec62271-111 (Ed1.0) enrlaureanoNoch keine Bewertungen

- Prysmian LV CatalogueDokument56 SeitenPrysmian LV CatalogueThinzarNoch keine Bewertungen

- FRP Rods For Brittle Fracture ResistantDokument9 SeitenFRP Rods For Brittle Fracture Resistantdmsoares1989Noch keine Bewertungen

- As NZS 5000.1 Standard For Earthing CableDokument20 SeitenAs NZS 5000.1 Standard For Earthing CableKamlesh VaishnavNoch keine Bewertungen

- HB 101-1997 (CJC 5) Coordination of Power and Telecommunications - Low Frequency Induction (LFI) - Code of PraDokument8 SeitenHB 101-1997 (CJC 5) Coordination of Power and Telecommunications - Low Frequency Induction (LFI) - Code of PraSAI Global - APACNoch keine Bewertungen

- As 60269.3.0-2005 Low-Voltage Fuses - Supplementary Requirements For Fuses For Use by Unskilled Persons (FuseDokument8 SeitenAs 60269.3.0-2005 Low-Voltage Fuses - Supplementary Requirements For Fuses For Use by Unskilled Persons (FuseSAI Global - APAC0% (2)

- IEC 60502 3 6 6kv ArmouredDokument2 SeitenIEC 60502 3 6 6kv ArmouredBajjaliNoch keine Bewertungen

- Technical Specification: IEC/TS 60815-1Dokument7 SeitenTechnical Specification: IEC/TS 60815-1Anonymous ep7LE5ZdP5Noch keine Bewertungen

- High Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YDokument3 SeitenHigh Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YNeven Ahmed HassanNoch keine Bewertungen

- Standards For PV Cable CompoundsDokument31 SeitenStandards For PV Cable CompoundsAHMED YOUSEFNoch keine Bewertungen

- Fire Resistant Fiber CablesDokument43 SeitenFire Resistant Fiber Cablesrose chenNoch keine Bewertungen

- Trefoil FormationDokument1 SeiteTrefoil FormationCisco KiNoch keine Bewertungen

- Gost 839-1980 PDFDokument1 SeiteGost 839-1980 PDFDejanNoch keine Bewertungen

- AFL Substation Bus DampersDokument12 SeitenAFL Substation Bus Dampersabhi120783Noch keine Bewertungen

- Single-Conductor Cables in Parallel - Wu, Alex Y.Dokument19 SeitenSingle-Conductor Cables in Parallel - Wu, Alex Y.eero.ylistalo100% (1)

- Iec 60038Dokument8 SeitenIec 60038Richard Campos0% (2)

- Principles and Testing Methods of Earth Ground ResistanceDokument20 SeitenPrinciples and Testing Methods of Earth Ground ResistanceYasir JamilNoch keine Bewertungen

- Associations and Reference StandardsDokument13 SeitenAssociations and Reference StandardsgaburrNoch keine Bewertungen

- Gas Insulated Substation Grounding System Design Using TheDokument6 SeitenGas Insulated Substation Grounding System Design Using Theraghavendran raghuNoch keine Bewertungen

- Brugg Cables User GuideDokument27 SeitenBrugg Cables User GuideMehdi_Mashayekhi_172Noch keine Bewertungen

- REF615 Modbuspoint 756581 ENcDokument48 SeitenREF615 Modbuspoint 756581 ENcharrisvasNoch keine Bewertungen

- IEEE 837-1989 Testing by Powertech PDFDokument23 SeitenIEEE 837-1989 Testing by Powertech PDFnicklionsNoch keine Bewertungen

- Ampacity Calculations For Deeply InstallDokument10 SeitenAmpacity Calculations For Deeply InstallsajuaanalsaNoch keine Bewertungen

- Different Types of BusDokument2 SeitenDifferent Types of Busrodolfoordiguez_70Noch keine Bewertungen

- HB 102-1997 (CJC 6) Coordination of Power and Telecommunications - Low Frequency Induction (LFI) - ApplicationDokument8 SeitenHB 102-1997 (CJC 6) Coordination of Power and Telecommunications - Low Frequency Induction (LFI) - ApplicationSAI Global - APACNoch keine Bewertungen

- 9Dokument25 Seiten9pcelisNoch keine Bewertungen

- Technical Data SheetDokument10 SeitenTechnical Data SheetaqazamNoch keine Bewertungen

- 15 TMSS 02 R0Dokument0 Seiten15 TMSS 02 R0renjithas2005Noch keine Bewertungen

- Insulator TieDokument14 SeitenInsulator TieMosa Elnaid Elnaid100% (2)

- WeldingDokument21 SeitenWeldingprabhatkumar_6657012Noch keine Bewertungen

- Ead 230005-00-0106Dokument14 SeitenEad 230005-00-0106Ana Luísa EvaristoNoch keine Bewertungen

- 5 Clamps Connectors 220 400kv SsDokument12 Seiten5 Clamps Connectors 220 400kv SsJaswanth SaiNoch keine Bewertungen

- Part 1: Two-And Three-Sheet Joints With Coated and Uncoated Steel SheetsDokument45 SeitenPart 1: Two-And Three-Sheet Joints With Coated and Uncoated Steel SheetsReginaldo Santos100% (1)

- 15 TMSS 04 R0Dokument0 Seiten15 TMSS 04 R0renjithas2005Noch keine Bewertungen

- 12 TMSS 10 R0Dokument0 Seiten12 TMSS 10 R0renjithas2005Noch keine Bewertungen

- Trunnion Support ClampDokument10 SeitenTrunnion Support ClampMosa Elnaid ElnaidNoch keine Bewertungen

- EE35T - Example of An Insulation Coordination: HereDokument1 SeiteEE35T - Example of An Insulation Coordination: HereFlores JesusNoch keine Bewertungen

- Modelling and Analysis of Transformer Winding at High FrequenciesDokument7 SeitenModelling and Analysis of Transformer Winding at High FrequenciesFlores JesusNoch keine Bewertungen

- Esquema Usb PDFDokument2 SeitenEsquema Usb PDFFlores JesusNoch keine Bewertungen

- Design of Overhead Transmission Line FoundationDokument8 SeitenDesign of Overhead Transmission Line FoundationFlores JesusNoch keine Bewertungen

- TR 05 04E 120402 English PDFDokument0 SeitenTR 05 04E 120402 English PDFFlores JesusNoch keine Bewertungen

- TYPE APPROVAL GUIDELINES PUBLIC CONSULTATION Ver3 PDFDokument47 SeitenTYPE APPROVAL GUIDELINES PUBLIC CONSULTATION Ver3 PDFFlores JesusNoch keine Bewertungen

- 004 - 058 - Tower - Reliability - Full Paper PDFDokument10 Seiten004 - 058 - Tower - Reliability - Full Paper PDFFlores JesusNoch keine Bewertungen

- Cable-Tech PFT PDFDokument13 SeitenCable-Tech PFT PDFFlores JesusNoch keine Bewertungen

- Surfing Through Breakers: Code CornerDokument2 SeitenSurfing Through Breakers: Code CornerFlores JesusNoch keine Bewertungen

- 20022-55, - 58 PDFDokument16 Seiten20022-55, - 58 PDFFlores JesusNoch keine Bewertungen

- 25kV KonNx CouplerDokument36 Seiten25kV KonNx CouplerFlores JesusNoch keine Bewertungen

- Comparison On Wind Load Prediction of Transmission Line Between Chinese New Code and Other StandardsDokument8 SeitenComparison On Wind Load Prediction of Transmission Line Between Chinese New Code and Other StandardsFlores JesusNoch keine Bewertungen

- CIGRE (International Council On Large Electric Systems) TutorialsDokument3 SeitenCIGRE (International Council On Large Electric Systems) TutorialsFlores JesusNoch keine Bewertungen

- The Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFDokument4 SeitenThe Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFLog LouNoch keine Bewertungen

- Technical Catalogue eSV-SpecialVersion 50-60HzDokument264 SeitenTechnical Catalogue eSV-SpecialVersion 50-60HzRichard Marco Antonio Obando LopezNoch keine Bewertungen

- Little Book of RubyDokument104 SeitenLittle Book of RubynoboNoch keine Bewertungen

- PreponlineDokument8 SeitenPreponlineGeeth SagarNoch keine Bewertungen

- DLP Sample Detailed Lesson PlanDokument4 SeitenDLP Sample Detailed Lesson PlanJaydie PalNoch keine Bewertungen

- 327101-BJ81-C-RCC-0007 Rev.00 - Client MarkupDokument1 Seite327101-BJ81-C-RCC-0007 Rev.00 - Client MarkupGokulprabhuNoch keine Bewertungen

- Basic NetworkingDokument21 SeitenBasic NetworkingMina Ilagan RazonNoch keine Bewertungen

- EXCEL To Tally LeggerImport-ok - 2Dokument7 SeitenEXCEL To Tally LeggerImport-ok - 2Mukesh MakadiaNoch keine Bewertungen

- Sony Walkman GuideDokument39 SeitenSony Walkman Guideapi-3797085Noch keine Bewertungen

- Mahila Pay and ParkDokument113 SeitenMahila Pay and ParkSaurabh PednekarNoch keine Bewertungen

- Design Report For Proposed 3storied ResidentialbuildingDokument35 SeitenDesign Report For Proposed 3storied ResidentialbuildingMohamed RinosNoch keine Bewertungen

- Transfer FunctionDokument19 SeitenTransfer FunctionVinay Kumar SmartyNoch keine Bewertungen

- LAPORAN PRAKTIK KERJA LAPANGAN - Id.enDokument25 SeitenLAPORAN PRAKTIK KERJA LAPANGAN - Id.enAhmad JupriNoch keine Bewertungen

- Voice Recognition Using MatlabDokument10 SeitenVoice Recognition Using MatlabSneha Muralidharan100% (1)

- Jce 70 2018 10 3 2437 enDokument7 SeitenJce 70 2018 10 3 2437 enaaNoch keine Bewertungen

- Tetrathiafulvalene - The Advent of Organic MetalsDokument3 SeitenTetrathiafulvalene - The Advent of Organic MetalsEduardo SilvaNoch keine Bewertungen

- AcetophenoneDokument1 SeiteAcetophenoneDinda Melissa ArdiNoch keine Bewertungen

- Garrita National High SchoolDokument5 SeitenGarrita National High SchoolAxle Rose CastroNoch keine Bewertungen

- Crystal StructuresDokument54 SeitenCrystal StructuresyashvantNoch keine Bewertungen

- Fluid Mechanics 2 Momentum Equ. 2Dokument3 SeitenFluid Mechanics 2 Momentum Equ. 2Mohamed Al AminNoch keine Bewertungen

- Omfb MTC 11.12.23Dokument2 SeitenOmfb MTC 11.12.23obviousplatinum2Noch keine Bewertungen

- 1L11545A E 3 ManipulatorDokument130 Seiten1L11545A E 3 ManipulatorFerenc BalazsNoch keine Bewertungen

- Acura RSX Linked Edition 02 06 Shop ManualDokument20 SeitenAcura RSX Linked Edition 02 06 Shop Manualoctavia100% (52)

- HSD Area Security GuardDokument2 SeitenHSD Area Security GuardSavita matNoch keine Bewertungen

- KNS2163 Week1Dokument32 SeitenKNS2163 Week1Nurul QurratuNoch keine Bewertungen

- Lect-6 - Economics of Chemical PlantsDokument36 SeitenLect-6 - Economics of Chemical Plantsmaged1998Noch keine Bewertungen

- 02 04 16 BPZ Transclinic 16i 4 Sprachen PRINTDokument144 Seiten02 04 16 BPZ Transclinic 16i 4 Sprachen PRINTjuanNoch keine Bewertungen

- IEEE Recommended Practice For Exc. Sys Models 2Dokument4 SeitenIEEE Recommended Practice For Exc. Sys Models 2Emmanuel ZamoranoNoch keine Bewertungen

- Print PDFDokument11 SeitenPrint PDFFe CasarolliNoch keine Bewertungen

- Minimal Requirements: Solaris InstallationDokument74 SeitenMinimal Requirements: Solaris InstallationsrinivasNoch keine Bewertungen