Beruflich Dokumente

Kultur Dokumente

Inside Electric Car

Hochgeladen von

shivisingh17Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Inside Electric Car

Hochgeladen von

shivisingh17Copyright:

Verfügbare Formate

Research & Development Centre, Automotive Division,

INSIDE ELECTRIC CAR

Chetan Bhavsar ( R&D Proto Development)

Research & Development Centre, Automotive Division,

Inside Electric Car

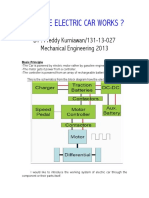

The heart of an electric car is the combination of: The electric motor The motor's controller The batteries

A SIMPLE DC CONTROLLER CONNECTED TO THE BATTERIES AND THE DC MOTOR. IF THE DRIVER FLOORS THE ACCELERATOR PEDAL, THE CONTROLLER DELIVERS THE FULL 96 VOLTS FROM THE BATTERIES TO THE MOTOR. IF THE DRIVER TAKES HIS/HER FOOT OFF THE ACCELERATOR, THE CONTROLLER DELIVERS ZERO VOLTS TO THE MOTOR. FOR ANY SETTING IN BETWEEN, THE CONTROLLER "CHOPS" THE 96 VOLTS THOUSANDS OF TIMES PER SECOND TO CREATE AN AVERAGE VOLTAGE SOMEWHERE BETWEEN 0 AND 96 VOLTS. The controller takes power from the batteries and delivers it to the motor. The accelerator pedal hooks to a pair of potentiometers (variable resistors), and these potentiometers provide the signal that tells the controller how much power it is supposed to deliver. The controller can deliver zero power (when the car is stopped), full power (when the driver floors the accelerator pedal), or any power level in between.

Research & Development Centre, Automotive Division,

The controller normally dominates the scene when you open the hood, as you can see here:

THE 300-VOLT, 50-KILOWATT CONTROLLER FOR THIS ELECTRIC CAR IS THE BOX MARKED "U.S. ELECTRICAR."

In this car, the controller takes in 300 volts DC from the battery pack. It converts it into a maximum of 240 volts AC, three-phase, to send to the motor. It does this using very large transistors that rapidly turn the batteries' voltage on and off to create a sine wave.

Research & Development Centre, Automotive Division,

When you push on the gas pedal, a cable from the pedal connects to these two potentiometers:

POTENTIOMETER

CABLE

THE POTENTIOMETERS HOOK TO THE GAS PEDAL AND SEND A SIGNAL TO THE CONTROLLER.

The signal from the potentiometers tells the controller how much power to deliver to the electric car's motor. There are two potentiometers for safety's sake. The controller reads both potentiometers and makes sure that their signals are equal. If they are not, then the controller does not operate. This

Research & Development Centre, Automotive Division,

arrangement guards against a situation where a potentiometer fails in the fullon position.

HEAVY CABLES (ON THE LEFT) CONNECT THE BATTERY PACK TO THE CONTROLLER. IN THE MIDDLE IS A VERY LARGE ON/OFF SWITCH. THE BUNDLE OF SMALL WIRES ON THE RIGHT CARRIES SIGNALS FROM THERMOMETERS LOCATED BETWEEN THE BATTERIES, AS WELL AS POWER FOR FANS THAT KEEP THE BATTERIES COOL AND VENTILATED.

THE HEAVY WIRES ENTERING AND LEAVING THE CONTROLLER

Research & Development Centre, Automotive Division,

The controller's job in a DC electric car is easy to understand. Let's assume that the battery pack contains 12 12-volt batteries, wired in series to create 144 volts. The controller takes in 144 volts DC, and delivers it to the motor in a controlled way. The very simplest DC controller would be a big on/off switch wired to the accelerator pedal. When you push the pedal, it would turn the switch on, and when you take your foot off the pedal, it would turn it off. As the driver, you would have to push and release the accelerator to pulse the motor on and off to maintain a given speed. Obviously, that sort of on/off approach would work but it would be a pain to drive, so the controller does the pulsing for you. The controller reads the setting of the accelerator pedal from the potentiometers and regulates the power accordingly. Let's say that you have the accelerator pushed halfway down. The controller reads that setting from the potentiometer and rapidly switches the power to the motor on and off so that it is on half the time and off half the time. If you have the accelerator pedal 25 percent of the way down, the controller pulses the power so it is on 25 percent of the time and off 75 percent of the time. Most controllers pulse the power more than 15,000 times per second, in order to keep the pulsation outside the range of human hearing. The pulsed current causes the motor housing to vibrate at that frequency, so by pulsing at more than 15,000 cycles per second, the controller and motor are silent to human ears.

Research & Development Centre, Automotive Division,

AN AC CONTROLLER HOOKS TO AN AC MOTOR. USING SIX SETS OF POWER

TRANSISTORS , THE CONTROLLER TAKES IN

300 VOLTS DC AND PRODUCES 240 VOLTS AC,

3-PHASE. SEE HOW THE POWER GRID W ORKS FOR A DISCUSSION OF 3-PHASE POWER . T HE

CONTROLLER ADDITIONALLY PROVIDES A CHARGING SYSTEM FOR THE BATTERIES , AND A TO-DC CONVERTER TO RECHARGE THE

DC-

12-VOLT ACCESSORY BATTERY.

In an AC controller, the job is a little more complicated, but it is the same idea. The controller creates three pseudo-sine waves. It does this by taking the DC voltage from the batteries and pulsing it on and off. In an AC controller, there is the additional need to reverse the polarity of the voltage 60 times a second. Therefore, you actually need six sets of transistors in an AC controller, while you need only one set in a DC controller. In the AC controller, for each phase you need one set of transistors to pulse the voltage and another set to reverse the polarity. You replicate that three times for the three phases -- six total sets of transistors.

Research & Development Centre, Automotive Division,

Most DC controllers used in electric cars come from the electric forklift industry. The Hughes AC controller seen in the photo above is the same sort of AC controller used in the GM/Saturn EV-1 electric vehicle. It can deliver a maximum of 50,000 watts to the motor.

Electric-car Motors and Batteries

Electric cars can use AC or DC motors:

If the motor is a DC motor, then it may run on anything from 96 to 192 volts. Many of the DC motors used in electric cars come from the electric forklift industry. If it is an AC motor, then it probably is a three-phase AC motor running at 240 volts AC with a 300 volt battery pack.

DC installations tend to be simpler and less expensive. A typical motor will be in the 20KW to 30KW range. A typical controller will be in the 40 KW to 60 KW range (for example, a 96-volt controller will deliver a maximum of 400 or 600 amps). DC motors have the nice feature that you can overdrive them (up to a factor of 10-to-1) for short periods of time. That is, a 20 KW motor will accept 100 KW for a short period of time and deliver 5 times its rated horsepower. This is great for short bursts of acceleration. The only limitation is heat build-up in the motor. Too much overdriving and the motor heats up to the point where it self-destructs

Research & Development Centre, Automotive Division,

AC installations allow the use of almost any industrial three-phase AC motor, and that can make finding a motor with a specific size, shape or power rating easier. AC motors and controllers often have a regen feature. During braking, the motor turns into a generator and delivers power back to the batteries.

The weak link in any electric car is the batteries. There are at least six significant problems with current lead-acid battery technology: They are heavy (a typical lead-acid battery pack weighs 450Kg or more). They are bulky (the car we are examining here has 50 lead-acid batteries, each measuring roughly 6" x 8" by 6"). They have a limited capacity (a typical lead-acid battery pack might hold 12 to 15 kilowatt-hours of electricity, range of only 80 Km or so). They are slow to charge (typical recharge times for a lead-acid pack range between four to 10 hours for full charge, depending on the battery technology and the charger). They have a short life (three to four years, perhaps 200 full charge/discharge cycles). They are expensive (perhaps 80,000 Rs. for the battery pack shown in the sample car). giving a car a

Research & Development Centre, Automotive Division,

Battery Problems

You can replace lead-acid batteries with NiMH batteries. The range of the car will double and the batteries will last 10 years (thousands of charge/discharge cycles), but the cost of the batteries today is 10 to 15 times greater than lead-acid. In other words, an NiMH battery pack will cost Rs. 12,00,000 to 13,00,000 (today) instead of Rs.80,000. Prices for advanced batteries fall as they become mainstream, so over the next several years it is likely that NiMH and lithium-ion battery packs will become competitive with lead-acid battery prices. Electric cars will have significantly better range at that point. Just about any electric car has one other battery on board. This is the normal 12-volt lead-acid battery that every car has. The 12-volt battery provides power for accessories -- things like headlights, radios, fans,

computers, air bags, wipers, power windows and instruments inside the

car. Since all of these devices are readily available and standardized at 12 volts, it makes sense from an economic standpoint for an electric car to use them. Therefore, an electric car has a normal 12-volt lead-acid battery to power all of the accessories. To keep the battery charged, an electric car needs a DC-to-DC converter. This converter takes in the DC power from the main battery array (at, for example, 300 volts DC) and converts it down to 12 volts to recharge the accessory battery. When the car is on, the accessories get their power from the DC-to-DC converter. When the car is off, they get their power from the 12-volt battery as in any gasoline-powered vehicle.

Research & Development Centre, Automotive Division,

The DC-to-DC converter is normally a separate box under the hood, but sometimes this box is built into the controller.

Charging an Electric Car

Any electric car that uses batteries needs a charging system to recharge the batteries. The charging system has two goals: To pump electricity into the batteries as quickly as the batteries will allow To monitor the batteries and avoid damaging them during the charging process

The most sophisticated charging systems monitor battery voltage, current flow and battery temperature to minimize charging time. The charger sends as much current as it can without raising battery temperature too much. Less sophisticated chargers might monitor voltage or amperage only and make certain assumptions about average battery characteristics. A charger like this might apply maximum current to the batteries up through 80 percent of their capacity, and then cut the current back to some preset level for the final 20 percent to avoid overheating the batteries.

Using a 240-volt circuit, The car might be able to receive 240 volts at 30 amps, or 6.6 kilowatt-hours per hour. This arrangement allows significantly faster charging, and can fully recharge the battery pack in four to five hours.

Research & Development Centre, Automotive Division,

PLUG THE CAR IN ANYWHERE TO RECHARGE .

In this car, the charger is built into the controller. In most home-brew cars, the charger is a separate box located under the hood, or could even be a freestanding unit that is separate from the car.

Research & Development Centre, Automotive Division,

The Magna-Charge System

The Magna-Charge system consists of two parts:

A CHARGING STATION MOUNTED TO THE WALL OF THE HOUSE

Research & Development Centre, Automotive Division,

A CHARGING SYSTEM IN THE TRUNK OF THE CAR

The charging station is hard-wired to a 240-volt 40-amp circuit through the house's circuit panel.

THE CHARGING SYSTEM SENDS ELECTRICITY TO THE CAR USING THIS INDUCTIVE PADDLE .

Research & Development Centre, Automotive Division,

THE PADDLE FITS INTO A SLOT HIDDEN BEHIND THE LICENSE PLATE OF THE CAR.

The paddle acts as one half of a transformer. The other half is inside the car, positioned around the slot behind the license plate. When you insert the paddle, it forms a complete transformer with the slot, and power transfers to the car. One advantage of the inductive system is that there are no exposed electrical contacts. You can touch the paddle or drop the paddle into a puddle of water and there is no hazard. The other advantage is the ability to pump a significant amount of current into the car very quickly because the charging station is hard-wired to a dedicated 240-volt circuit. The competing high-power charge connector is generally referred to as the "Avcon plug" and it is used by Ford and others. It features copper-tocopper contacts instead of the inductive paddle, and has an elaborate mechanical interconnect that keeps the contacts covered until the connector is mated with the receptacle on the vehicle. Pairing this connector with GFCI protection makes it safe in any kind of weather.

Research & Development Centre, Automotive Division,

Equalization charge

An important feature of the charging process is "equalization." An EV has a string of batteries (somewhere between 10 and 25 modules, each containing three to six cells). The batteries are closely matched, but they are not identical. Therefore they have slight differences in capacity and internal resistance. All batteries in a string necessarily put out the same current (laws of electricity), but the weaker batteries have to "work harder" to produce the current, so they're at a slightly lower state of charge at the end of the drive. Therefore, the weaker batteries need more recharge to get back to full charge.

Since the batteries are in series, they also get exactly the same amount of recharge, leaving the weak battery even weaker (relatively) than it was before. Over time, this results in one battery going bad long before the rest of the pack. The weakest-link effect means that this battery determines the range of the vehicle, and the usability of the car drops off.

The common solution to the problem is "equalization charge." You gently overcharge the batteries to make sure that the weakest cells are brought up to full charge. The trick is to keep the batteries equalized without damaging the strongest batteries with overcharging. There are more complex solutions that scan the batteries, measure individual voltages, and send extra charging current through the weakest module.

Das könnte Ihnen auch gefallen

- Build Your Own Electric Car PDFDokument91 SeitenBuild Your Own Electric Car PDFcarlosqfar100% (4)

- Green - Economical.future: Mayank Batra ME - 1508311 NcceDokument19 SeitenGreen - Economical.future: Mayank Batra ME - 1508311 NcceVineet BhokarNoch keine Bewertungen

- Electric Motors For Electric VehiclesDokument15 SeitenElectric Motors For Electric VehiclesFlavius Lungu100% (1)

- Heavy-Duty Electric Vehicles: From Concept to RealityVon EverandHeavy-Duty Electric Vehicles: From Concept to RealityNoch keine Bewertungen

- Battery Technology For Electric CarsDokument9 SeitenBattery Technology For Electric CarsIQPC GmbHNoch keine Bewertungen

- E RaajaDokument18 SeitenE RaajasksinghkgnNoch keine Bewertungen

- New Generation Electric Vehicles I To 12Dokument384 SeitenNew Generation Electric Vehicles I To 12glassyglass100% (4)

- Electric Car: GE109 Lab ReportDokument15 SeitenElectric Car: GE109 Lab ReportSujal BansalNoch keine Bewertungen

- Trends in Vehicle and Fuel Technologies Review of Past TrendsDokument247 SeitenTrends in Vehicle and Fuel Technologies Review of Past TrendsAmit ShuklaNoch keine Bewertungen

- Ford Battery Electric VehicleDokument1 SeiteFord Battery Electric VehicleFord Motor Company67% (3)

- Electric VehicleDokument24 SeitenElectric VehicleSriramShraff75% (4)

- Electric & Hybrid Vehicle TechDokument211 SeitenElectric & Hybrid Vehicle TechMihai Simion100% (4)

- How The Electric Car WorksDokument6 SeitenHow The Electric Car WorksFreddy KurniawanNoch keine Bewertungen

- EV Siting and Design GuidelinesDokument34 SeitenEV Siting and Design GuidelinesRuslan Menezes100% (3)

- The Electric Car BatteryDokument34 SeitenThe Electric Car BatteryJordi Jaumà100% (1)

- Final Training Report Electric VehicleDokument32 SeitenFinal Training Report Electric Vehicleadarsh kashyapNoch keine Bewertungen

- OVE - Everything You Need To Know About Electric Car-11Dokument52 SeitenOVE - Everything You Need To Know About Electric Car-11Giaccone A.Noch keine Bewertungen

- The Electric Vehicle: Raising The StandardsDokument504 SeitenThe Electric Vehicle: Raising The StandardsVan Den Bossche PeterNoch keine Bewertungen

- Electric Vehicle Ddesign & Development ProcessDokument6 SeitenElectric Vehicle Ddesign & Development Processparth sarthyNoch keine Bewertungen

- Powertrain For Electric and Hybrid VehiclesDokument15 SeitenPowertrain For Electric and Hybrid VehiclesAsmit JoshiNoch keine Bewertungen

- Charging of Electric VehiclesDokument12 SeitenCharging of Electric VehiclesMohit OjhaNoch keine Bewertungen

- Sus 2020.08.25 Ev-E-Bike Strat FinalDokument46 SeitenSus 2020.08.25 Ev-E-Bike Strat FinalJames Peters CfjcNoch keine Bewertungen

- Automating Battery Pack Design AA V9 I2Dokument4 SeitenAutomating Battery Pack Design AA V9 I2Anonymous hWj4HKIDOFNoch keine Bewertungen

- Electric Vehicle ChargingDokument119 SeitenElectric Vehicle Charginggeogho67% (3)

- General Functioning of Various Parts of Electric CarsDokument10 SeitenGeneral Functioning of Various Parts of Electric CarsRahul PalNoch keine Bewertungen

- Electrical Vehicles-Challenges and OpportuntiesDokument28 SeitenElectrical Vehicles-Challenges and OpportuntiesPrinkaNoch keine Bewertungen

- Electric VehiclesDokument13 SeitenElectric VehiclesMario ManciaNoch keine Bewertungen

- Pletcher - Industrial ElectrochemistryDokument668 SeitenPletcher - Industrial ElectrochemistrysalmaliskaNoch keine Bewertungen

- NEIS Recommended Practice For Installing Energy Storage Systems NECA 416 16Dokument70 SeitenNEIS Recommended Practice For Installing Energy Storage Systems NECA 416 16Domingo RuizNoch keine Bewertungen

- Information About Electric VehiclesDokument56 SeitenInformation About Electric VehiclespasistNoch keine Bewertungen

- Presentation On Electric CarDokument20 SeitenPresentation On Electric Carnirmalkr100% (1)

- Electric Vehicles: By: Ali Tariq BBA-6Dokument27 SeitenElectric Vehicles: By: Ali Tariq BBA-6AliTariqNoch keine Bewertungen

- Electric Cars - The Green Answer' To The Energy Crisis: RE FeatureDokument4 SeitenElectric Cars - The Green Answer' To The Energy Crisis: RE FeatureRed GarNoch keine Bewertungen

- Electric Cars PresentationDokument23 SeitenElectric Cars PresentationAndrew David Bushner100% (1)

- Design of Electric VehicleDokument13 SeitenDesign of Electric VehicleIJAERS JOURNALNoch keine Bewertungen

- Seminar On Electric CarDokument11 SeitenSeminar On Electric CarRaviganjoo0% (1)

- Handbook For Gel-VRLA Batteries - Part 2 - EXIDE Technologies PDFDokument73 SeitenHandbook For Gel-VRLA Batteries - Part 2 - EXIDE Technologies PDFpevare100% (1)

- A Literature Review On Hybrid Electric Vehicles IJERTCONV6IS04002Dokument3 SeitenA Literature Review On Hybrid Electric Vehicles IJERTCONV6IS04002sachin krupashankarNoch keine Bewertungen

- Overview of Electric Charging StationDokument5 SeitenOverview of Electric Charging StationTHuy DvNoch keine Bewertungen

- Modeling and Simulation of Smart Grid Integrated With Hybrid Renewable Energy Systems PDFDokument91 SeitenModeling and Simulation of Smart Grid Integrated With Hybrid Renewable Energy Systems PDFILBERIPUCINoch keine Bewertungen

- Innovation Landscape brief: Electric-vehicle smart chargingVon EverandInnovation Landscape brief: Electric-vehicle smart chargingNoch keine Bewertungen

- Electric Vehicle Note MaterialsDokument27 SeitenElectric Vehicle Note MaterialsChico Hermanu BrillianNoch keine Bewertungen

- Technical Specifications of Off Grid Solar Power PlantDokument23 SeitenTechnical Specifications of Off Grid Solar Power PlantAnand PuntambekarNoch keine Bewertungen

- Lacture 10. ElectrochemistryDokument68 SeitenLacture 10. ElectrochemistryHarish Kutty HariNoch keine Bewertungen

- Vehicle To Grid PDFDokument14 SeitenVehicle To Grid PDFVictor SampaNoch keine Bewertungen

- BESS BCU Specification XNBMS-3260-V1.0Dokument11 SeitenBESS BCU Specification XNBMS-3260-V1.0Serg MarushkoNoch keine Bewertungen

- Electric Vehicles Charging Systems - Ewr Addendum No. 1 PDFDokument18 SeitenElectric Vehicles Charging Systems - Ewr Addendum No. 1 PDFSanjay LohodasanNoch keine Bewertungen

- History Why Electric Car? Different Parts Motor Controller Batteries Used in Electric Cars Obstacles Future ReferencesDokument18 SeitenHistory Why Electric Car? Different Parts Motor Controller Batteries Used in Electric Cars Obstacles Future ReferencesDeepak KargetiNoch keine Bewertungen

- The Ev (Electric Vehicle) Bible: What Is An Ev?Dokument12 SeitenThe Ev (Electric Vehicle) Bible: What Is An Ev?AlykNoch keine Bewertungen

- Electric Motor Car 111120010Dokument24 SeitenElectric Motor Car 111120010Aman0% (1)

- 2014 Tesla Model S 568 DatasheetDokument5 Seiten2014 Tesla Model S 568 DatasheetDavid BravoNoch keine Bewertungen

- Electric Vehicle MarketDokument17 SeitenElectric Vehicle Marketramaswamykama786Noch keine Bewertungen

- Vehicle To GridDokument7 SeitenVehicle To GridSurajRGuptaNoch keine Bewertungen

- Electricvehiclerunbybldcmotor PDFDokument57 SeitenElectricvehiclerunbybldcmotor PDFSanthoshNoch keine Bewertungen

- Modern Electric, Hybrid Electric & Fuel Cell Vehicles - Mehrdad EhsaniDokument8 SeitenModern Electric, Hybrid Electric & Fuel Cell Vehicles - Mehrdad EhsaniPunit100% (2)

- A Project Seminar On: Design and Fabrication of Hybrid Electric BikeDokument19 SeitenA Project Seminar On: Design and Fabrication of Hybrid Electric BikeNaziya TazeenNoch keine Bewertungen

- Electric Vehicle Charging Infrastructure: A Guide For Discom ReadinessDokument64 SeitenElectric Vehicle Charging Infrastructure: A Guide For Discom ReadinessPixiNoch keine Bewertungen

- Lecture 1 Introduction To MechatronicsDokument15 SeitenLecture 1 Introduction To MechatronicsIljuha9Noch keine Bewertungen

- Top 15 EV Startup in WorldDokument10 SeitenTop 15 EV Startup in WorldAkash PrajapatiNoch keine Bewertungen

- Hybrid Electric VehicleDokument13 SeitenHybrid Electric VehicleNandakumar BasavarajNoch keine Bewertungen

- History of AutomobilesDokument3 SeitenHistory of AutomobilesBDineshPrabhu100% (1)

- A Dynamic Simulation Tool For Hydrogen Fuel Cell VehiclesDokument14 SeitenA Dynamic Simulation Tool For Hydrogen Fuel Cell Vehiclesapi-3709675Noch keine Bewertungen

- Hybrid Electric VehicleDokument23 SeitenHybrid Electric VehicleBalu CoolNoch keine Bewertungen

- Electric Battery Powered CarsDokument21 SeitenElectric Battery Powered CarsDavid ZhangNoch keine Bewertungen

- Fully Autonomous Vehicles: Visions of the future or still reality?Von EverandFully Autonomous Vehicles: Visions of the future or still reality?Noch keine Bewertungen

- Vivek Paper Battery OkDokument21 SeitenVivek Paper Battery OkShi BiliNoch keine Bewertungen

- Hybrid Electric Vehicle - GradeabilityDokument27 SeitenHybrid Electric Vehicle - GradeabilityPreservativo BorrachinhasNoch keine Bewertungen

- KA1102 Manual, KaitoDokument19 SeitenKA1102 Manual, KaitoJeffNoch keine Bewertungen

- Topics Covered in Introduction To Batteries The Voltaic Cell Common Types of Primary Cells Lead-Acid Wet Cell Additional Types of Secondary CellsDokument32 SeitenTopics Covered in Introduction To Batteries The Voltaic Cell Common Types of Primary Cells Lead-Acid Wet Cell Additional Types of Secondary CellsArvind VNoch keine Bewertungen

- Panasonic NCR20700BDokument7 SeitenPanasonic NCR20700BWouter Andriesse (Uberghymkhana)Noch keine Bewertungen

- English M23 Battery Charger, Choke, Condencer, Diode and Transformer (SSEE6)Dokument16 SeitenEnglish M23 Battery Charger, Choke, Condencer, Diode and Transformer (SSEE6)john powerNoch keine Bewertungen

- BHT300B Users Manual EDokument182 SeitenBHT300B Users Manual Esan nguyễn vănNoch keine Bewertungen

- User Manual Alloy - TrimbleDokument124 SeitenUser Manual Alloy - TrimbleruddyrezzaNoch keine Bewertungen

- IND22x English ManualDokument27 SeitenIND22x English ManualOsvaldo CarpioNoch keine Bewertungen

- Cube M Operating ManualDokument48 SeitenCube M Operating ManualTed LinNoch keine Bewertungen

- 6120c RM-243/RM-310 / 6121c RM-308 / NM705i RM-309 Service Manual Level 1&2Dokument29 Seiten6120c RM-243/RM-310 / 6121c RM-308 / NM705i RM-309 Service Manual Level 1&2Writte SmithNoch keine Bewertungen

- Failures Analysis and Improvement Lifetime of Lead Acid Battery in Different ApplicationsDokument7 SeitenFailures Analysis and Improvement Lifetime of Lead Acid Battery in Different ApplicationsErikNoch keine Bewertungen

- Solar Energy Wiring Installation TrainerDokument54 SeitenSolar Energy Wiring Installation TrainerJhepoy Lumanglas AstillaNoch keine Bewertungen

- Instruction Manual All in One R49 - Pag1-12 - A24.AAA.006A49-MDokument14 SeitenInstruction Manual All in One R49 - Pag1-12 - A24.AAA.006A49-Mchars choirNoch keine Bewertungen

- Tehnic Ventis Mx4Dokument54 SeitenTehnic Ventis Mx4Forum PompieriiNoch keine Bewertungen

- Det 4 TD 2Dokument2 SeitenDet 4 TD 2Carlos RodasNoch keine Bewertungen

- Manual Casio G5500Dokument4 SeitenManual Casio G5500Nur Alam SamsieNoch keine Bewertungen

- Manuale Inglese Cobra Marine MR hh600 FLT Gps BTDokument45 SeitenManuale Inglese Cobra Marine MR hh600 FLT Gps BTvojkan73Noch keine Bewertungen

- Fluxgate Gradiometer FM256: Instruction ManualDokument128 SeitenFluxgate Gradiometer FM256: Instruction ManualEdin BujakNoch keine Bewertungen

- PosiTestHHD-InstructionManual-12 230615 083938Dokument77 SeitenPosiTestHHD-InstructionManual-12 230615 083938Athit DathorngNoch keine Bewertungen

- Height of Danger: 2-5 Players Ages 10 +Dokument8 SeitenHeight of Danger: 2-5 Players Ages 10 +febza.argnwnNoch keine Bewertungen

- Fire Bird V ATMEGA2560 Hardware Manual 2010-03-26Dokument131 SeitenFire Bird V ATMEGA2560 Hardware Manual 2010-03-26Bedadipta Bain100% (1)

- Accu Charge 193111-0552Dokument43 SeitenAccu Charge 193111-0552Juan Azabache100% (1)

- Bosch Ebike Brochure All You Need To KnowDokument13 SeitenBosch Ebike Brochure All You Need To KnowAla TrabelsiNoch keine Bewertungen