Beruflich Dokumente

Kultur Dokumente

Swivel Joint 229-244

Hochgeladen von

Gregory StewartOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Swivel Joint 229-244

Hochgeladen von

Gregory StewartCopyright:

Verfügbare Formate

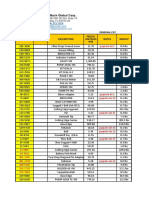

FLUID CONVEYING

PRODUCTS

Hose

Fittings

Adapters and

Tube Fittings

Pages

Section

15-67

68-180

181-228

Pages

Section

Pages

Swivel Joints

229-244

Quick Disconnect

Couplings

268-345

Flexmaster Joints

245-260

Access., Equipment &

Assembly Instructions

346-393

FLOCS

261-267

Technical Data

394-433

SWIVEL JOINTS

Description

Page

How to Order 230

Selection Criteria 231

Selection Chart 232

Fluid Compatibility Chart

for Seals 232

Swivel Joint Configurations

BD5500 Series 233

FS5500 Series 237

FS5900 Series 240

Seal Repair Kits 243

10-62017 243

10-62018 243

10-62019 243

10-62020 243

10-62021 243

10-62022 243

10-62023 243

Description

Page

BD5500 233

BD55000 234

BD55001 234

BD55004 234

BD55005 234

BD55009 235

BD55011 235

BD55012 235

BD55014 235

BD55015 235

BD55021 236

BD55029 236

BD55031 236

BD55058 236

Description

Page

FF028 243

FF974 243

FF975 243

FS5500 237

FS5900 240

FS55005 238

FS55009 238

FS55012 238

FS55014 238

FS55021 238

FS55029 239

FS55031 239

FS55058 239

FS55059 239

FS59000 241

FS59001 241

FS59002 241

FS59003 241

FS59004 242

FS59005 242

FS59006 242

FS59011 242

SWIVEL JOINTS

Section

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

RETURN TO CONTENTS PAGE

229

SWIVEL JOINTS

FLUID CONVEYING

PRODUCTS

How to Order

When ordering a swivel joint, follow the steps below:

Seal Material Options:

First, state the base part number, casing and sleeve port

size, as shown.

Second, add the suffix code which indicates the seal

required, as shown in the seal code chart at right. (See Fluid

Compatibility Chart on page 232).

Seal

Code

75

Material

Hytrel/Buna

Description

Standard U-Cup

Seal

74

Urethane/Buna

01*

Buna-N

04*

EPR

06*

Viton

Optional U-Cup

Seal

Standard T-Ring

Seal or O-Ring

Seal

Optional T-Ring

Seal or O-Ring

Seal

Optional T-Ring

Seal or O-Ring

Seal

BD55000

08 08

01

Swivel Joint Base Number

Casing Port Size

Sleeve Port Size

Seal Code

Application**

Petroleum-Base

Fluids, Phosphate

Esters, Solvents

Hydraulic Fluids

Hydraulic Oils,

Water Glycol

Brake Fluids,

Water, Phosphate

Ester, Alcohols

Chemicals,

Gasoline,

Aromatic Solvents

*Limited service life above 3000 psi in sizes above 08.

**See Fluid Compatibility Chart on page 232 for additional information.

Viton is a DuPont trademark.

Advantages of using Aeroquip Swivel Joints

1. Better System Plumbing:

2. Prevent Hose Twisting:

4. Absorb System Shock:

a) Because less hose is needed when

swivel joints are used, the system is

more space efficient (Figure 1).

b) Swivel joints can eliminate the need

for tubing configurations to accommodate 90 and other angles.

c) Swivel joints can be directly connected to hose lines frequently eliminating the need for adapters.

Because of the swivel action, swivel

joints prevent hose twisting and kinking

(Figure 2).

Swivel joints are not rigid and therefore

capable of absorbing some hose shortening when the system is pressurized.

3. Less Downtime:

5. Save Money:

With the problem of hose twisting and

kinking eliminated, hose line replacement becomes significantly less

frequent.

Less hose, fewer adapters and tubing

configurations and less downtime add

up to saving money when swivel joints

are used.

Figure 1

Figure 2

Figure 3

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

230

SELECTION CRITERIA

Many variables are involved in the application and selection

of industrial swivel joints in a fluid power system. Careful

consideration must be paid to each of the criteria listed below

to achieve optimum efficiency from a swivel joint.

1. Pressure:

This is a force or thrust applied on the surface of a fluid carrying vehicle. System operating pressure must not exceed

the rating of the swivel joint.

2. Temperature:

Both internal and ambient temperatures are important in

proper swivel joint functioning. Internally, the temperature

rating is determined by the seals. If the fluid is too hot, the

seals will deteriorate and the swivel joint will leak and resist

rotation. Externally, too high a temperature will damage the

casing and seals causing similar problems. When selecting

seals, always insure they meet the required temperature

ranges.

3. Fluid Compatibility:

6. Pressure Drop:

This is the resistance to the flow of the agent through the

swivel joint measured in pounds per square inch (psi). The

higher the resistance to flow, the greater is the loss of efficiency. Aeroquip swivel joints have been designed for minimal resistance to flow.

7. Torque:

Defined as the force that produces a rotation, torque is an

important consideration when specifying swivel joints.

Aeroquip swivel joints rotate freely with low torque even

under pressures up to 10,000 psi. This permits consistent,

trouble-free service.

8. Configurations:

The swivel joint configuration specified (straight or 90) is

determined by such factors as available space and system

routing. Make sure the swivel joint configuration and envelope dimensions allow freedom of movement while maintaining compatibility with the systems routing.

An important consideration in determining which joint and

seal material to use is their compatibility with the agent to be

conveyed in the system. Internal swivel joint components

that are not suitable for the fluid being carried in the system

will be severely damaged. Carefully check the fluid compatibility chart on Page 232.

9. Port Size:

4. Cost:

Make sure the environment in which the swivel joint works

and the fluid carried are free of corrosive elements which

could severely limit service life.

Cost, of course, is an important consideration. However, the

initial cost of a swivel joint can be more than offset by cost

reduction benefits such as an improved system routing with

less hose, fewer adapters and tube fittings and longer service life.

5. Side Loading:

Using the right port size and thread is a significant factor in

the proper selection of a swivel joint. The port size and

thread must match that of the end fitting on the connecting

hose line.

10. Corrosion Resistance:

SWIVEL JOINTS

Selection Criteria and Product Safety Considerations

11. Rotation:

Rotation must be easy and unrestricted for proper service of

the swivel joint. The joint and the connecting line must be

allowed to rotate freely for optimum performance.

Defined as the stress caused by angular deflection in a piping system, side loading causes excessive wear on the bearing surfaces and inhibits smooth swivel joint operation. Care

must be taken when plumbing a system with swivel joints to

avoid stress situations.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

231

SWIVEL JOINTS

COMPATIBILITY CHARTS

FOR SEALS

Selection Chart

BD5500

Selection Criteria

Rated Operating Pressure (psi)

Side Loading Capability**

Configurations Available

Pressure Drop

Brass/Steel

3,000

G

90

Moderate

Torque

Size Range

Corrosion Resistance**

Low

/2 and 1

E

Steel

3,000

G

90

Moderate

Low

/4 11/2

VG

FS5500

Steel

4,000*

VG

90

Moderate

FS5900

Steel

5,000

E

90 and Straight

Low

Low

/4 2

VG

Moderate

1

/4 1

VG

*In sizes 4 and 6.

**Rating Codes: E = Excellent

VG = Very Good

G = Good

Fluid Compatibility Chart

Fluids

Acetone

Acetylene

Air

Alcohol Ethyl, Methyl

Alcohol Amyl, Isobutyl, Isopropyl

Benzene

Carbon Tetrachloride

Cellulube - A60, 220, 300, 500

Ethylene Glycol

Gasoline Refined

Glycerin

Hydr. Oil Petr. Base (Incl. 5606)

JP-4, JP-5, Kerosene

Lindol, Hydr. Fluid

Lube Oils Petr. Base

Lube Oils Diester Base

Methyl Ethyl Ketone

Naphtha

Oronite 8200, 8515

Orthene

Oxygen Note: 2

Pydraul Series E

Pydraul Series C

Silicone Oils, Skydrol 500A

Trichloroethylene

Water Fresh Note: 3

Xylene

This chart is intended as a guide only and is not a guarantee. Many factors such

as concentration, fluid and ambient temperature, pressure, duration of exposure,

etc., have a bearing on the suitability of each seal for a specific application. For

further information on fluid compatibility, contact Eaton Aeroquip.

75 (Hytrel)

20F to +250F

74 (Urethane)

40F to +180F

Seals

06 (Viton)

20F to +300F

04 (EPR) Note: 1 01 (Buna-N)

60F to +300F 40F to +250F

NOTES: (1) EPR Compounds must not contact Petroleum Base Lubricants. Use Silicone Grease.

(2) The Aeroquip swivel joints are not recommended for oxygen use in breathing applications.

(3) Hytrel seals rated for 180F maximum in water and water base fluids.

Hytrel and Viton are DuPont trademarks.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

232

BD5500 STANDARD DUTY

BALANCED PRESSURE

Pressure Drop vs Flow

SWIVEL JOINTS

The Aeroquip BD5500 series industrial swivel joints pressure

balanced design distributes pressure evenly through the body

of the joint which eliminates axial loading of the sleeve. This

pressure balanced design allows the BD5500 series swivel

joint to turn with very low torque even under pressures up to

3000 psi.

Torque vs Pressure

This chart shows the low torque required to rotate the

BD5500 series swivel joint while under pressure. This data is

based on actual testing of production assemblies.

These test results for pressure drop at various flow rates

were made with MIL-H-5606A oil at temperatures (+70F to

+80F) on production assemblies.

Seal Options:

Suffix

Number

Material

Standard

01

Buna-N

04

EPR

06

Viton*

Optional

Pressure Rating for BD5500:

Size

Operating Pressure

All Sizes

25 in./Hg vacuum to

3000 psi

*Viton is a DuPont trademark.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

233

SWIVEL JOINTS

BD5500 STANDARD DUTY

BALANCED PRESSURE

Part Number

BD55000040401

BD55000060601

BD55000080801

BD55000121201

BD55000161601

BD55000202001

BD55000242401

Nom.

Casing

Size

Thread

1

1

/4

/4-18NPSM

3

3

/8

/8-18NPSM

1

1

/2

/2-14NPSM

3

3

/4

/4-14NPSM

1

1-111/2NPSM

11/4 11/4-111/2NPSM

11/2 11/2-111/2NPSM

Sleeve

Thread

1

/4-18NPTF

3

/8-NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

A

2.21

2.74

3.09

3.48

3.94

4.88

5.30

B

1.47

1.80

2.06

2.36

2.64

3.16

3.50

C

.91

1.12

1.16

1.46

1.70

2.00

2.25

.62

.94

1.00

1.25

1.50

1.75

2.12

1.00

1.25

1.38

1.75

2.12

2.50

3.00

/16-20UNF-2A

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

2.37

2.21

2.82

2.83

3.09

3.10

3.48

3.94

4.88

5.30

1.60

1.47

1.85

1.89

2.03

2.07

2.36

2.64

3.16

3.50

.91

.91

1.12

1.12

1.16

1.16

1.46

1.70

2.00

2.25

.62

.62

.94

.94

1.00

1.00

1.25

1.50

1.75

2.12

1.00

1.00

1.25

1.25

1.38

1.38

1.75

2.12

2.50

3.00

2.17

2.07

2.65

2.70

2.84

2.92

3.29

3.74

4.60

5.06

1.41

1.34

1.68

1.76

1.81

1.90

2.18

2.45

2.89

3.27

.91

.91

1.12

1.12

1.16

1.16

1.46

1.70

2.00

2.25

.62

.62

.94

.94

1.00

1.00

1.25

1.50

1.88

2.12

1.00

1.00

1.25

1.25

1.38

1.38

1.75

2.12

2.50

3.00

Female Pipe Swivel to Male Pipe

BD55001040401

BD55001040501

BD55001060601

BD55001060801

BD55001080801

BD55001081001

BD55001121201

BD55001161601

BD55001202001

BD55001242401

/4

/4

3

/8

3

/8

1

/2

1

/2

3

/4

1

11/4

11/2

1

/4-18NPSM

/4-18NPSM

3

/8-18NPSM

3

/8-18NPSM

1

/2-14NPSM

1

/2-14NPSM

3

/4-14NPSM

1-111/2NPSM

11/4-111/2NPSM

11/2-111/2NPSM

Female Pipe Swivel to Male SAE 37

BD55004040401

BD55004040501

BD55004060601

BD55004060801

BD55004080801

BD55004081001

BD55004121201

BD55004161601

BD55004202001

BD55004242401

/4

/4

3

/8

3

/8

1

/2

1

/2

3

/4

1

11/4

11/2

1

/4-18NPSM

/4-18NPSM

3

/8-18NPSM

3

/8-18NPSM

1

/2-14NPSM

1

/2-14NPSM

3

/4-14NPSM

1-111/2NPSM

11/4-111/2NPSM

11/2-111/2NPSM

/16-20UNF-2A

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

Female Pipe Swivel to Male SAE O-Ring

BD55005040401

BD55005050401

BD55005060601

BD55005080601

BD55005080801

BD55005100801

/4

/4

3

/8

3

/8

1

/2

1

/2

/16-20UNF-2A

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

/4-18NPTF

/4-18NPTF

3

/8-18NPTF

3

/8-18NPTF

1

/2-14NPTF

1

/2-14NPTF

2.21

2.21

2.74

2.74

3.09

3.09

1.47

1.47

1.80

1.80

2.06

2.06

1.06

1.06

1.19

1.28

1.39

1.47

.62

.62

.94

.94

1.00

1.00

1.00

1.00

1.25

1.25

1.38

1.38

BD55005121201

BD55005161601

BD55005202001

BD55005242401

11/16-12UN-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

3.48

3.94

4.88

5.30

2.36

2.64

3.16

3.50

1.74

1.97

2.20

2.57

1.25

1.50

1.75

2.12

1.75

2.12

2.50

3.00

/4

1

11/4

11/2

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

Male SAE 37 to Male Pipe

All dimensions in inches.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

234

BD5500 STANDARD DUTY

BALANCED PRESSURE

Male SAE 37

to Male

SAE 37

BD55009060601

BD55009080801

BD55009101001

BD55009121201

BD55009161601

BD55009202001

BD55009242401

BD55011040401

BD55011060601

BD55011080801

BD55011121201

BD55011161601

BD55011202001

BD55011242401

Nom.

Size

1

/4

1

/4

Casing

Thread

7

/16-20UNF-2A

1

/2-20UNF-2A

Sleeve

Thread

7

/16-20UNF-2A

1

/2-20UNF-2A

/8

/8

1

/2

3

/4

1

11/4

11/2

/16-18UNF-2A

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/1612UN-2A

15/812UN-2A

17/8-12UN-2A

1

/4

/4-18NPSM

3

/8

/8-18NPSM

1

1

/2

/2-14NPSM

3

3

/4

/4-14NPSM

1

1-111/2NPSM

11/4 11/4-111/2NPSM

11/2 11/2-111/2NPSM

3

A

2.37

2.21

B

1.60

1.47

C

1.06

1.06

.62

.62

1.00

1.00

2.82

2.83

3.10

3.48

3.94

4.88

5.30

1.85

1.89

2.07

2.36

2.64

3.16

3.50

1.19

1.28

1.47

1.74

1.97

2.20

2.57

.94

.94

1.00

1.25

1.50

1.75

2.12

1.25

1.25

1.38

1.75

2.12

2.50

3.00

2.14

2.54

2.97

3.12

3.68

4.50

4.62

1.40

1.60

1.94

2.00

2.38

2.78

2.82

.91

1.12

1.16

1.46

1.70

2.00

2.25

.75

.94

1.06

1.31

1.62

2.00

2.38

1.00

1.25

1.38

1.75

2.12

2.50

3.00

2.21

2.74

3.09

3.48

3.94

4.88

5.30

1.47

1.80

2.06

2.36

2.64

3.16

3.50

1.06

1.28

1.42

1.71

1.98

2.27

2.54

.62

.94

1.00

1.25

1.50

1.75

2.12

1.00

1.25

1.38

1.75

2.12

2.50

3.00

2.21

2.74

3.09

3.48

3.94

4.88

5.30

1.47

1.80

2.06

2.36

2.64

3.16

3.50

1.44

1.49

1.80

2.02

2.44

2.77

3.02

.62

.94

1.00

1.25

1.50

1.75

2.12

1.00

1.25

1.38

1.75

2.12

2.50

3.00

2.14

1.40

1.44

.75

1.00

2.54

2.97

3.12

3.68

4.50

4.62

1.60

1.94

2.00

2.38

2.78

2.82

1.49

1.80

2.02

2.44

2.77

3.02

.94

1.06

1.31

1.62

2.00

2.38

1.25

1.38

1.75

2.12

2.50

3.00

/16-18UNF-2A

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

1

/4-18NPTF

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

3

Female

Pipe Swivel

to Female Pipe

BD55012040401

BD55012060601

BD55012080801

BD55012121201

BD55012161601

BD55012202001

BD55012242401

/4

/8

1

/2

3

/4

1

11/4

11/2

3

/4-18NPTF

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

3

/4-18NPTF

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

3

SWIVEL JOINTS

Part Number

BD55009040401

BD55009050501

Male Pipe

to Male Pipe

BD55014040401

BD55014060601

BD55014080801

BD55014121201

BD55014161601

BD55014202001

BD55014242401

/4

/8

1

/2

3

/4

1

11/4

11/2

3

/4-18NPTF

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

3

/4-18NPTF

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

3

Female Pipe

Fixed to

Male Pipe

BD55015040401

BD55015060601

BD55015080801

BD55015121201

BD55015161601

BD55015202001

BD55015242401

/4

/8

1

/2

3

/4

1

11/4

11/2

3

/4-18NPTF

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

3

/4-18NPTF

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

Female Pipe

Fixed to

Female Pipe

All dimensions in inches.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

235

SWIVEL JOINTS

BD5500 STANDARD DUTY

BALANCED PRESSURE

Part Number

BD55021040401

BD55021050501

BD55021060601

BD55021080801

BD55021101001

BD55021121201

BD55021161601

BD55021202001

BD55021242401

Nom.

Casing

Size

Thread

1

7

/4

/16-20UNF-2A

1

1

/4

/2-20UNF-2A

3

9

/8

/16-18UNF-2A

3

3

/8

/4-16UNF-2A

1

7

/2

/8-14UNF-2A

3

/4

11/16-12UN-2A

1

15/16-12UN-2A

1

1 /4 15/8-12UN-2A

11/2 17/8-12UN-2A

Sleeve

Thread

7

/16-20UNF-2A

1

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UNF-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

A

2.17

2.07

2.65

2.70

2.92

3.29

3.74

4.60

5.06

B

1.41

1.34

1.68

1.76

1.90

2.18

2.45

2.89

3.27

C

1.06

1.06

1.19

1.28

1.47

1.74

1.97

2.20

2.57

.62

.62

.94

.94

1.00

1.25

1.50

1.88

2.12

1.00

1.00

1.25

1.25

1.38

1.75

2.12

2.50

3.00

/16-20UNF-2A

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

2.37

2.21

2.82

2.83

3.09

3.10

3.48

3.94

4.88

5.30

1.60

1.47

1.85

1.89

2.03

2.07

2.36

2.64

3.16

3.50

1.44

1.44

1.49

1.49

1.80

1.80

2.02

2.44

2.77

3.02

.62

.62

.94

.94

1.00

1.00

1.25

1.50

1.75

2.12

1.00

1.00

1.25

1.25

1.38

1.38

1.75

2.12

2.50

3.00

/16-20UNF-2A

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

2.17

2.07

2.65

2.70

2.84

2.92

3.29

3.74

4.60

5.06

1.41

1.34

1.68

1.76

1.81

1.90

2.18

2.45

2.89

3.27

1.44

1.44

1.49

1.49

1.80

1.80

2.02

2.44

2.77

3.02

.62

.62

.94

.94

1.00

1.00

1.25

1.50

1.88

2.12

1.00

1.00

1.25

1.25

1.38

1.38

1.75

2.12

2.50

3.00

15/1612UN-2B

3.56

2.26

1.97

1.50

2.12

Male SAE 37 to Male SAE O-Ring

BD55029040401

BD55029040501

BD55029060601

BD55029060801

BD55029080801

BD55029081001

BD55029121201

BD55029161601

BD55029202001

BD55029242401

/4

/4

3

/8

3

/8

1

/2

1

/2

3

/4

1

11/4

11/2

1

/4-18NPTF

/4-18NPTF

3

/8-18NPTF

3

/8-18NPTF

1

/2-14NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

Female Pipe Fixed to Male SAE 37

1

BD55031040401

BD55031040501

BD55031060601

BD55031060801

BD55031080801

BD55031081001

BD55031121201

BD55031161601

BD55031202001

BD55031242401

/4

/4

3

/8

3

/8

1

/2

1

/2

3

/4

1

11/4

11/2

/4-18NPTF

/4-18NPTF

3

/8-18NPTF

3

/8-18NPTF

1

/2-14NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

BD55058161601

15/16-12UN-2A

Female Pipe Fixed to Male SAE O-Ring

Male SAE 37 to

Female SAE 37 Swivel

All dimensions in inches.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

236

FS5500 HEAVY DUTY

BALANCED PRESSURE

Pressure Drop vs Flow

Torque vs Pressure

SWIVEL JOINTS

The Aeroquip FS5500 series swivel joint is a heavy duty version of the BD5500 series. The FS5500 series has a special

hardened casing and heavy duty U-Cup seals which permit a

pressure range from vacuum up to 4,000 psi. The balanced

pressure design allows the FS5500 series swivel joint to

rotate with low torque even when exposed to maximum pressures and side loads.

These test results for pressure drop at various flow

rates were made with MIL-H-5606A oil at temperatures

(+70F to +80F) on production assemblies.

This chart shows the low torque required to rotate the

FS5500 series swivel joint while under pressure. This data is

based on actual testing of production assemblies.

Seal Options:

Style

Suffix

No.

U-Cup

U-Cup

Material

Standard

75

Hytrel/

Buna-N

X(08 & up)

Pressure Rating for FS5500:

Size

Operating Pressure

04 & 06

25 in./Hg vacuum to 4,000 psi

08 & 12

25 in./Hg vacuum to 3,500 psi

16, 20 & 24

25 in./Hg vacuum to 3,000 psi

Optional

74

Urethane

T-Ring

01

Buna-N

T-Ring

04

EPR

T-Ring

06

Viton*

X(04 & 06)

X(08 & up)

Reduced service life in sizes 12 and larger when used above 3,000 psi operating pressure.

*Viton is a DuPont trademark.

U-Cup Seal

T-Ring Seal

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

237

SWIVEL JOINTS

FS5500 HEAVY DUTY

BALANCED PRESSURE

Part Number

FS55005040401

FS55005050401

FS55005060601

FS55005080601

FS55005080875

FS55005121275

FS55005161675

FS55005202075

FS55005242475

Nom.

Casing

Size

Thread

1

7

/4

/16-20UNF-2A

1

1

/4

/2-20UNF-2A

3

9

/8

/16-18UNF-2A

3

3

/8

/4-16UNF-2A

1

3

/2

/4-16UNF-2A

3

/4

11/16-12UN-2A

1

15/16-12UN-2A

1

1 /4 15/8-12UN-2A

11/2 17/8-12UN-2A

Sleeve

Thread

1

/4-18NPTF

1

/4-18NPTF

3

/8-18NPTF

3

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

A

2.21

2.21

2.74

2.74

3.09

3.48

3.94

4.88

5.30

B

1.47

1.47

1.80

1.80

2.06

2.36

2.64

3.16

3.50

C

1.06

1.06

1.19

1.28

1.39

1.74

1.97

2.20

2.57

.62

.62

.94

.94

1.00

1.25

1.50

1.75

2.12

1.00

1.00

1.25

1.25

1.38

1.75

2.12

2.50

3.00

2.37

2.21

2.82

2.83

3.10

3.48

3.94

4.88

5.30

1.60

1.47

1.85

1.89

2.07

2.36

2.64

3.16

3.50

1.06

1.06

1.19

1.28

1.47

1.74

1.97

2.20

2.57

.62

.62

.94

.94

1.00

1.25

1.50

1.75

2.12

1.00

1.00

1.25

1.25

1.38

1.75

2.12

2.50

3.00

2.21

2.74

3.09

3.48

3.94

4.88

5.30

1.47

1.80

2.06

2.36

2.64

3.16

3.50

1.06

1.28

1.42

1.71

1.98

2.27

2.54

.62

.94

1.00

1.25

1.50

1.75

2.12

1.00

1.25

1.38

1.75

2.12

2.50

3.00

2.21

2.74

3.09

3.48

3.94

4.88

5.30

1.47

1.80

2.06

2.36

2.64

3.16

3.50

1.44

1.49

1.80

2.02

2.44

2.77

3.02

.62

.94

1.00

1.25

1.50

1.75

2.12

1.00

1.25

1.38

1.75

2.12

2.50

3.00

2.17

2.07

2.65

2.70

2.92

3.29

3.74

4.60

5.06

1.41

1.34

1.68

1.76

1.90

2.18

2.45

2.89

3.27

1.06

1.06

1.19

1.28

1.47

1.74

1.97

2.20

2.57

.62

.62

.94

.94

1.00

1.25

1.50

1.88

2.12

1.00

1.00

1.25

1.25

1.38

1.75

2.12

2.50

3.00

Male SAE 37

to Male Pipe

Male SAE 37

to Male SAE 37

FS55009040401

FS55009050501

FS55009060601

FS55009080801

FS55009101075

FS55009121275

FS55009161675

FS55009202075

FS55009242475

/4

/4

3

/8

3

/8

1

/2

3

/4

1

11/4

11/2

1

FS55012040401

FS55012060601

FS55012080875

FS55012121275

FS55012161675

FS55012202075

FS55012242475

/4

/8

1

/2

3

/4

1

11/4

11/2

FS55014040401

FS55014060601

FS55014080875

FS55014121275

FS55014161675

FS55014202075

FS55014242475

/16-20UNF-2A

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/1612UN-2A

15/812UN-2A

17/8-12UN-2A

1

/4-18NPTF

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

3

/16-20UNF-2A

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

1

/4-18NPTF

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

3

Male Pipe

to Male Pipe

/4

/8

1

/2

3

/4

3

1

11/4

11/2

/4-18NPTF

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

3

/4-18NPTF

/8-18NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

3

Female Pipe Fixed to Male Pipe

FS55021040401

FS55021050501

FS55021060601

FS55021080801

FS55021101075

Male SAE 37

to Male SAE

O-Ring

FS55021121275

FS55021161675

FS55021202075

FS55021242475

/4

/4

3

/8

3

/8

1

/2

3

/4

1

11/4

11/2

/16-20UNF-2A

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

/16-20UNF-2A

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

All dimensions in inches.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

238

FS5500 HEAVY DUTY

BALANCED PRESSURE

Female Pipe Fixed to Male SAE O-Ring

Nom.

Casing

Size

Thread

1

1

/4

/4-18NPTF

1

1

/4

/4-18NPTF

3

3

/8

/8-18NPTF

3

3

/8

/8-18NPTF

1

1

/2

/2-14NPTF

1

1

/2

/2-14NPTF

3

3

/4

/4-14NPTF

1

1-111/2NPTF

11/4 11/4-111/2NPTF

11/2 11/2-111/2NPTF

1

FS55031040401

FS55031040501

FS55031060601

FS55031060801

FS55031080875

FS55031081075

FS55031121275

FS55031161675

FS55031202075

FS55031242475

/4

/4

3

/8

3

/8

1

/2

1

/2

3

/4

1

11/4

11/2

/4-18NPTF

/4-18NPTF

3

/8-18NPTF

3

/8-18NPTF

1

/2-14NPTF

1

/2-14NPTF

3

/4-14NPTF

1-111/2NPTF

11/4-111/2NPTF

11/2-111/2NPTF

FS55058161675

15/16-12UN-2A

Sleeve

Thread

7

/16-20UNF-2A

1

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

/16-20UNF-2A

/2-20UNF-2A

9

/16-18UNF-2A

3

/4-16UNF-2A

3

/4-16UNF-2A

7

/8-14UNF-2A

11/16-12UN-2A

15/16-12UN-2A

15/8-12UN-2A

17/8-12UN-2A

15/16-12UN-2B

A

2.37

2.21

2.82

2.83

3.09

3.10

3.48

3.94

4.88

5.30

B

1.60

1.47

1.85

1.89

2.03

2.07

2.36

2.64

3.16

3.50

C

1.44

1.44

1.49

1.49

1.80

1.80

2.02

2.44

2.77

3.02

.62

.62

.94

.94

1.00

1.00

1.25

1.50

1.75

2.12

1.00

1.00

1.25

1.25

1.38

1.38

1.75

2.12

2.50

3.00

2.17

2.07

2.65

2.70

2.84

2.92

3.29

3.74

4.60

5.06

1.41

1.34

1.68

1.76

1.81

1.90

2.18

2.45

2.89

3.27

1.44

1.44

1.49

1.49

1.80

1.80

2.02

2.44

2.77

3.02

.62

.62

.94

.94

1.00

1.00

1.25

1.50

1.88

2.12

1.00

1.00

1.25

1.25

1.38

1.38

1.75

2.12

2.50

3.00

3.56

2.26

1.97

1.50

2.12

3.29

2.18

1.54

1.25

1.75

SWIVEL JOINTS

Female Pipe Fixed to Male SAE 37

Part Number

FS55029040401

FS55029040501

FS55029060601

FS55029060801

FS55029080875

FS55029081075

FS55029121275

FS55029161675

FS55029202075

FS55029242475

Male SAE 37

to Female

SAE 37 Swivel

FS55059121275

/4

13/16-12UN-2A

11/16-12UN-2A

ORS Male to Male SAE O-Ring

All dimensions in inches.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

239

SWIVEL JOINTS

FS5900 HEAVY DUTY

FULL FLOW

The Aeroquip FS5900 series swivel joint is designed for 25

in./Hg vacuum to 5000 psi operating pressure service made

possible by advanced design needle bearings and seals. In

addition to high pressures the FS5900 series provides full

fluid flow with minimal pressure drop.

The excellent corrosion resistance of the FS5900 series is

made possible by the plated steel components.

Both field and laboratory testing have proven the FS5900

series swivel joints can withstand greater side loads than

conventional swivel joints. High pressure impulse life has

also been improved.

Pressure Drop vs Flow

Torque vs Pressure

Testing to determine the torque required to rotate an FS5900

series swivel joint was conducted on actual production

assemblies.

Testing for pressure drop at various flow rates was conducted with MIL-H-5606 hydraulic oil at temperatures (+70F to

+80F).

Seal Options:

O-Ring Seals (1/4 inch size only)

Suffix

Number

01

04

06

Temperature

Range

40F to 250F

60F to 300F

20F to 300F

Material

Buna-N

EPR

Viton*

Standard

X

Optional

X

X

U-Cup Seals (3/8" through 1" sizes)

Suffix

Number

75

74

Material

Hytrel/Buna

Urethane/Buna

Temperature

Range

20F to 250F

40F to 180F

Standard

X

Optional

X

*Viton is a DuPont trademark.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

240

FS5900 HEAVY DUTY

FULL FLOW

Nom.

Size

Thread

P1

Thread

P2

FS59000161601*

1-111/2 NPTF

1-111/2 NPTF

P1

1-11 /2 NPTF

P2

1-11 /2 NPTF

2.50

3.87

2.41

1.62

1.91

2.50

1.62

Female Pipe to Female Pipe

*1000 psi operating pressure

FS59001161675

4.31

(Straight)

Female Pipe to Female Pipe

Part Number

FS59002-0404-01

FS59002-0606-75

FS59002-0808-75

FS59002-1212-75

FS59002-1616-75

Nom.

Size

1

/4

/8

1

/2

3

/4

1

Thread

P1

Thread

P2

/4-18 NPTF

/8-18 NPTF

1

/2-14 NPTF

3

/4-14 NPTF

1-111/2 NPTF

/4-18 NPTF

/8-18 NPTF

1

/2-14 NPTF

3

/4-14 NPTF

1-111/2 NPTF

3.20

3.67

4.01

4.32

4.88

2.82

3.21

3.45

3.64

4.08

1.19

1.88

1.88

2.12

2.50

.56

.94

.94

1.19

1.44

P

/4-18 NPTF

3

/8-18 NPTF

1

/2-14 NPTF

3

/4-14 NPTF

1-111/2 NPTF

T

/2-20 UNF-2A

3

/4-16 UNF-2A

7

/8-14 UNF-2A

11/16-12 UN-2A

15/16-12 UN-2A

3.19

3.77

4.00

4.43

4.85

2.81

3.31

3.44

3.75

4.05

1.19

1.88

1.88

2.12

2.50

.56

.94

.94

1.19

1.44

1

3

1

3

SWIVEL JOINTS

Part Number

Female Pipe to Male Pipe

FS59003-0405-01

FS59003-0608-75

FS59003-0810-75

FS59003-1212-75

FS59003-1616-75

/4

3

/8

1

/2

3

/4

1

Female Pipe to Male SAE 37

All dimensions in inches.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

241

SWIVEL JOINTS

FS5900 HEAVY DUTY

FULL FLOW

Nom.

Size

Part Number

FS59004-0404-01

FS59004-0606-75

FS59004-0808-75

FS59004-1212-75

FS59004-1616-75

FS59005-0405-01

FS59005-0608-75

FS59005-0810-75

FS59005-1212-75

FS59005-1616-75

/4

/8

1

/2

3

/4

1

3

Thread

P1

Thread

P2

/4-18 NPTF

/8-18 NPTF

1

/2-14 NPTF

3

/4-14 NPTF

1-111/2 NPTF

/4-18 NPTF

/8-18 NPTF

1

/2-14 NPTF

3

/4-14 NPTF

1-111/2 NPTF

P

/4-18 NPTF

3

/8-18 NPTF

1

/2-14 NPTF

3

/4-14 NPTF

1-111/2 NPTF

T

/2-20 UNF-2A

3

/4-16 UNF-2A

7

/8-14 UNF-2A

11/16-12 UN-2A

15/16-12 UN-2A

1

3

1

3

3.23

3.62

3.97

4.04

4.57

1.19

1.88

1.88

2.12

2.50

.56

.94

.94

1.19

1.44

3.22

3.72

3.96

4.15

4.54

1.19

1.88

1.88

2.12

2.50

.56

.94

.94

1.19

1.44

Female Pipe to Male Pipe

/4

3

/8

1

/2

3

/4

1

Female Pipe to Male SAE 37

Part Number

FS59006050501

FS59006080875

FS59006101075

FS59006121275

FS59006161675

Nom.

Thread

Size

T1

1

/4 1/2-20 UNF-2A

3

/8 3/4-16 UNF-2A

1

/2 7/8-14 UNF-2A

3

/4 11/16-12 UN-2A

1 15/16-12 UN-2A

Thread

T2

1

/2-20 UNF-2B

3

/4-16 UNF-2B

/8-14 UNF-2B

11/16-12 UN-2B

15/16-12 UN-2B

3.74

3.88

4.03

T1

/2-20 UNF-2A

3

/4-16 UNF-2A

7

/8-14 UNF-2A

11/16-12 UN-2A

15/16-12 UN-2A

T2

/2-20 UNF-2B

3

/4-16 UNF-2B

7

/8-14 UNF-2B

11/16-12 UN-2B

15/16-12 UN-2B

2.69

3.08

3.46

3.58

3.91

A

2.98

3.48

1.19

1.88

.62

.94

1.88

2.12

2.50

1.00

1.25

1.50

1.19

1.88

1.88

2.12

2.50

.62

.94

1.00

1.25

1.50

Male SAE 37to Female SAE 37

FS59011050501

FS59011080875

FS59011101075

FS59011121275

FS59011161675

/4

3

/8

1

/2

3

/4

1

2.41

2.73

3.06

3.08

3.29

1.16

1.59

1.70

1.93

2.16

Male SAE 37to Female SAE 37

All dimensions in inches.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

242

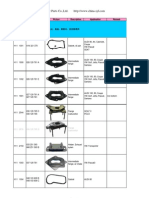

SEAL REPAIR KITS

Replacement seal kit consists of (2) TRI-RING SEALTM assemblies, (2) dust seals, (1) washer and (1) snap ring.

Seal Type

Nominal Size

Seal Kit Part Numbers

1

/4

/8

/2

/4

11/4

11/2

Buna-N (Code 01)

106201701

106201801

106201901

106202001

106202101

106202201

106202301

EPR (Code 04)

106201704

106201804

106201904

106202004

106202104

106202204

106202304

Viton* (Code 06)

106201706

106201806

106201906

106202006

106202106

106202206

106202306

SWIVEL JOINTS

BD5500 and FS5500 Swivel Joint Repair Kits

Note: 74 and 75 Seals are not field serviceable. Contact Eaton Aeroquip.

*Viton is a DuPont trademark.

FS5900 Swivel Joint Repair Kits

The FS5900 series swivel joints are easily field repaired. Two

different kits are available. The choice of which kit to use is

dependent upon the extent of repairs necessary.

FF974 Kits include: a replacement seal assembly, back-up

rings and a new dust seal.

FF975 Kits include: a replacement seal assembly, back-up

rings, a new dust seal and two sets of bearings and races.

For FS59000161601 order repair kit FF0281601

includes: a replacement seal assembly, back-up rings and a

new dust seal.

To order FF974 and FF975 Kits:

FF974 08 75

Kit Base Number

Joint Size

(Swivel Joint Nominal size 1/2)

Seal Material Code

(see Seal Material Options chart on page 230)

NOTE: Use swivel joint nominal size when ordering kits, not port size.

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

243

SWIVEL JOINTS

SWIVEL JOINTS

This page is part of a complete catalog which contains technical and safety data that must be reviewed when selecting a product.

244

RETURN TO CONTENTS PAGE

Das könnte Ihnen auch gefallen

- TF100-54A 1965-2055 Series Low Profile QDDokument8 SeitenTF100-54A 1965-2055 Series Low Profile QDrrrrNoch keine Bewertungen

- TF100-53B 3900 Series QD CouplingsDokument6 SeitenTF100-53B 3900 Series QD CouplingsrrrrNoch keine Bewertungen

- PCT 325616 PDFDokument6 SeitenPCT 325616 PDFAnonymous ZebRdjlN1Noch keine Bewertungen

- Aeroquip Military and Marine CatalogDokument206 SeitenAeroquip Military and Marine CatalogJenner Volnney Quispe ChataNoch keine Bewertungen

- TF100-7A - 1800 Series CouplingDokument8 SeitenTF100-7A - 1800 Series CouplingrrrrNoch keine Bewertungen

- Eaton-Aeroquip Adapters, Tube Fittings and ConnectorsDokument108 SeitenEaton-Aeroquip Adapters, Tube Fittings and ConnectorsPinaki GhoshNoch keine Bewertungen

- Aerospace Parts 2 Quick Disconnect CouplingsDokument104 SeitenAerospace Parts 2 Quick Disconnect CouplingsSohail100% (1)

- Ultra Mate BrochureDokument11 SeitenUltra Mate BrochureEagle1968Noch keine Bewertungen

- Swivel Joints: Section Pages Section Pages Section PagesDokument16 SeitenSwivel Joints: Section Pages Section Pages Section PagesMartinez Mauricio Martinez GomezNoch keine Bewertungen

- Eaton CarterDokument5 SeitenEaton Carterviktor_gligorovNoch keine Bewertungen

- Miele G2432 Dishwasher Operating Instructions ManualDokument60 SeitenMiele G2432 Dishwasher Operating Instructions ManualjeanNoch keine Bewertungen

- BAHCO 01.10.2012 CenovnikDokument432 SeitenBAHCO 01.10.2012 CenovnikAleksandar LekicNoch keine Bewertungen

- (Catalogue) Eaton - Hydraulics - Guide To Mobile Industrial HydraulicsDokument16 Seiten(Catalogue) Eaton - Hydraulics - Guide To Mobile Industrial HydraulicsTrần LêNoch keine Bewertungen

- Equiv. FiltrosDokument61 SeitenEquiv. FiltrosDaniel Ayala100% (1)

- Partmaster AmgDokument1.132 SeitenPartmaster Amgashish kumarNoch keine Bewertungen

- Ficatalog PDFDokument202 SeitenFicatalog PDFDijana Vukovic-AleksicNoch keine Bewertungen

- Copia de COTIZACION CAT - KOMATSUDokument12 SeitenCopia de COTIZACION CAT - KOMATSUautolineNoch keine Bewertungen

- YUKEN Size of O-RingDokument3 SeitenYUKEN Size of O-RingNal FivefivetwooneNoch keine Bewertungen

- Cross ReferenceDokument352 SeitenCross ReferenceEdilson SEminaraNoch keine Bewertungen

- NO Part Number Description QTY RemarkDokument3 SeitenNO Part Number Description QTY RemarkDeny Yusuf100% (1)

- MANN-FILTER - PU 10 005 X - NEW - AU - Eng - 2017-09-21Dokument3 SeitenMANN-FILTER - PU 10 005 X - NEW - AU - Eng - 2017-09-21jose manuel barroso pantojaNoch keine Bewertungen

- O-Ring Cross ReferenceDokument40 SeitenO-Ring Cross Referencecamohunter71Noch keine Bewertungen

- John Deere BeltsDokument2 SeitenJohn Deere BeltssenatNoch keine Bewertungen

- BearingsDokument299 SeitenBearingsktef_010417030Noch keine Bewertungen

- Air Starter CrossoverDokument14 SeitenAir Starter Crossoverwilson.demaria3037Noch keine Bewertungen

- Aust Cross RefDokument202 SeitenAust Cross RefPablo Gaspar D'Agostini AmengualNoch keine Bewertungen

- 2-26 Camshaft and Rocker Arm Assembly, Tmd-20 Diesel EngineDokument3 Seiten2-26 Camshaft and Rocker Arm Assembly, Tmd-20 Diesel EnginePaull SalasNoch keine Bewertungen

- Oferta de Pret Rulmenti GenOparts GermaniaDokument10 SeitenOferta de Pret Rulmenti GenOparts GermaniaPopa CatalinNoch keine Bewertungen

- The Unforeseen Series: Books 1 - 3 (Box Set): Unforeseen SeriesVon EverandThe Unforeseen Series: Books 1 - 3 (Box Set): Unforeseen SeriesNoch keine Bewertungen

- Filter Kits: JLG Original PartsDokument3 SeitenFilter Kits: JLG Original PartsashielanieNoch keine Bewertungen

- ZKL MRP Pricelist 2011Dokument55 SeitenZKL MRP Pricelist 2011Mahesh Daxini Thakker100% (4)

- Dana 30 InformationDokument14 SeitenDana 30 InformationBrianssrt4Noch keine Bewertungen

- Kaydon Catalog 300 RULMENTIDokument132 SeitenKaydon Catalog 300 RULMENTICostel SentesNoch keine Bewertungen

- Filter Alternative - Cross ReferenceDokument5 SeitenFilter Alternative - Cross ReferenceKhun khai100% (1)

- One Safe Source From DortmundDokument21 SeitenOne Safe Source From DortmundMiguel RodriguezNoch keine Bewertungen

- Cummins Heavy Duty Product Guide PDFDokument22 SeitenCummins Heavy Duty Product Guide PDFthailanNoch keine Bewertungen

- World Wide Fittings Catalog - BodyDokument230 SeitenWorld Wide Fittings Catalog - BodywarrentimeNoch keine Bewertungen

- Water Pump SetsDokument360 SeitenWater Pump Setsaharish_iitkNoch keine Bewertungen

- New Ferrule Selection Chart ALFAGOMMADokument5 SeitenNew Ferrule Selection Chart ALFAGOMMAArtari RNoch keine Bewertungen

- ArranqueDokument6 SeitenArranqueNeftali RosalesNoch keine Bewertungen

- Agri CulturaDokument111 SeitenAgri CulturaAlin PuscasuNoch keine Bewertungen

- Master Catalog-AeroquipDokument388 SeitenMaster Catalog-AeroquipCOM GRAVENoch keine Bewertungen

- 1829Dokument12 Seiten1829Pavlova AsiaNoch keine Bewertungen

- Book 2Dokument139 SeitenBook 2Safianu Abbas Abdul-RaheemNoch keine Bewertungen

- Viking EMEA Price List 2016 1 en EURDokument697 SeitenViking EMEA Price List 2016 1 en EURAnonymous 3oYaSKf0% (1)

- Aplic (1) - Bandas Aut.Dokument25 SeitenAplic (1) - Bandas Aut.Jorge Luis Amores Torres50% (2)

- Cummins y Otras Marcas - Correas y ManguerasDokument733 SeitenCummins y Otras Marcas - Correas y ManguerasWilliam Alvarado100% (1)

- Cross Reference of StandardsDokument30 SeitenCross Reference of StandardsParag VirojaNoch keine Bewertungen

- FAF 6100 PN 16 Resilient Seal Gate ValveDokument4 SeitenFAF 6100 PN 16 Resilient Seal Gate Valveاحمد حسين100% (1)

- MPS Engine Bearing CatalogueDokument66 SeitenMPS Engine Bearing CatalogueLuis Miguel MartínezNoch keine Bewertungen

- Catalogo o Rings KOIO 2 PDFDokument153 SeitenCatalogo o Rings KOIO 2 PDFMariana De Oliveira Bitencourt AugustoNoch keine Bewertungen

- Auto Rubber ProductsDokument198 SeitenAuto Rubber Productschinmoyd1Noch keine Bewertungen

- Bearings Code New Old 2017Dokument256 SeitenBearings Code New Old 2017Anonymous pm1hDaNoch keine Bewertungen

- Filter Class..Dokument2 SeitenFilter Class..Mudassar Idris RautNoch keine Bewertungen

- MTD Spare Parts Price ListDokument940 SeitenMTD Spare Parts Price ListDeb WenzelNoch keine Bewertungen

- Request Penawaran Spareparts Unit Hitachi ZX210MF-5GDokument8 SeitenRequest Penawaran Spareparts Unit Hitachi ZX210MF-5GHEXOMNoch keine Bewertungen

- Bettis CBA 725Dokument16 SeitenBettis CBA 725kutts76100% (1)

- Design Information: Planning Conventional MountingDokument7 SeitenDesign Information: Planning Conventional Mountingmcad12Noch keine Bewertungen

- Mechanical Seal Selection For VSDs PDFDokument3 SeitenMechanical Seal Selection For VSDs PDFAnonymous 1XHScfCINoch keine Bewertungen

- Corrosion Rate CalculationDokument4 SeitenCorrosion Rate CalculationMohammed JassimNoch keine Bewertungen

- Samsung K57ADokument31 SeitenSamsung K57ADavid Argote BellidoNoch keine Bewertungen

- E - Service - 530223 Control Boards OverviewDokument7 SeitenE - Service - 530223 Control Boards OverviewGregory StewartNoch keine Bewertungen

- Samsung+CL21M6WKX XAO+CL21A11MQKX+Chassis K57A (N)Dokument53 SeitenSamsung+CL21M6WKX XAO+CL21A11MQKX+Chassis K57A (N)Gregory StewartNoch keine Bewertungen

- Marketing ProgramsDokument8 SeitenMarketing ProgramsGregory StewartNoch keine Bewertungen

- SMD CatalogDokument80 SeitenSMD Catalogpbradaric91% (11)

- User ManualDokument1 SeiteUser ManualGregory StewartNoch keine Bewertungen

- BVR BOP: Technical Instruction ManualDokument9 SeitenBVR BOP: Technical Instruction ManualGregory StewartNoch keine Bewertungen

- Coin-Operated D-Series Drying TumblersDokument6 SeitenCoin-Operated D-Series Drying TumblersGregory StewartNoch keine Bewertungen

- SMD CatalogDokument80 SeitenSMD Catalogpbradaric91% (11)

- General Electric TD1495PBS1Dokument6 SeitenGeneral Electric TD1495PBS1Gregory StewartNoch keine Bewertungen

- SP W5180N PDFDokument3 SeitenSP W5180N PDFGregory StewartNoch keine Bewertungen

- Air PDFDokument59 SeitenAir PDFGregory StewartNoch keine Bewertungen

- SB Self-Service Laundry ENG LoDokument12 SeitenSB Self-Service Laundry ENG LoGregory StewartNoch keine Bewertungen

- RDCV - : Technical Instruction ManualDokument12 SeitenRDCV - : Technical Instruction ManualGregory StewartNoch keine Bewertungen

- Hercules 15 Marketing BrochureDokument8 SeitenHercules 15 Marketing BrochureGregory StewartNoch keine Bewertungen

- Technical Support Documentation I N S I D E B O P V A L V E (B V R)Dokument1 SeiteTechnical Support Documentation I N S I D E B O P V A L V E (B V R)Gregory StewartNoch keine Bewertungen

- RDCVDokument2 SeitenRDCVGregory StewartNoch keine Bewertungen

- X Type Safety JointDokument1 SeiteX Type Safety JointGregory StewartNoch keine Bewertungen

- S S, B C: Tandard Izes Ores AND OnnectionsDokument1 SeiteS S, B C: Tandard Izes Ores AND OnnectionsGregory StewartNoch keine Bewertungen

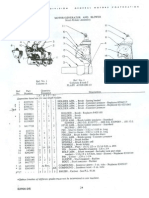

- H - W D P W C U D: EVI ATE Rill IPE Eight AND Enter Pset ImensionsDokument1 SeiteH - W D P W C U D: EVI ATE Rill IPE Eight AND Enter Pset ImensionsGregory StewartNoch keine Bewertungen

- Porta EscobillaDokument1 SeitePorta EscobillaGregory StewartNoch keine Bewertungen

- Clmetal PDFDokument35 SeitenClmetal PDFGregory StewartNoch keine Bewertungen

- Heavy PDFDokument869 SeitenHeavy PDFGregory StewartNoch keine Bewertungen

- Drill PipeDokument1 SeiteDrill PipeGregory StewartNoch keine Bewertungen

- Selection Information H-And J-Frame Thermal-Magnetic Molded Case 150 and 250 Ampere Frame-Class 611Dokument1 SeiteSelection Information H-And J-Frame Thermal-Magnetic Molded Case 150 and 250 Ampere Frame-Class 611Gregory StewartNoch keine Bewertungen

- FeldSp en PDFDokument18 SeitenFeldSp en PDFGregory StewartNoch keine Bewertungen

- 8150005S PDFDokument2 Seiten8150005S PDFGregory StewartNoch keine Bewertungen

- DDEC II and III Wiring DiagramsDokument13 SeitenDDEC II and III Wiring Diagramstwhiteman200682% (49)

- Tips 76 PDFDokument20 SeitenTips 76 PDFGregory StewartNoch keine Bewertungen

- Simoreg1q Device Braking To Defined Speed PDFDokument10 SeitenSimoreg1q Device Braking To Defined Speed PDFGregory StewartNoch keine Bewertungen

- Oil Catch CanDokument8 SeitenOil Catch CanReem MinnisNoch keine Bewertungen

- D 2609 - 00 - Rdi2mdktukve PDFDokument5 SeitenD 2609 - 00 - Rdi2mdktukve PDFAndre CasteloNoch keine Bewertungen

- MR 16 HD849 ServiçoDokument473 SeitenMR 16 HD849 ServiçoTecsul Máquinas e Manutenção100% (1)

- Whats New in SolidCAM2007 R11Dokument78 SeitenWhats New in SolidCAM2007 R11pocerilloNoch keine Bewertungen

- Calculations of Machine DesignDokument56 SeitenCalculations of Machine Designbalakalees100% (2)

- Number:: Evaluation SubjectDokument25 SeitenNumber:: Evaluation SubjectReinel OrjuelaNoch keine Bewertungen

- General Items & Small Goods: Mouthpiece BrushesDokument53 SeitenGeneral Items & Small Goods: Mouthpiece BrusheswrojasNoch keine Bewertungen

- GostDokument29 SeitenGostMoldoveanu Teodor80% (5)

- F366Dokument5 SeitenF366Gustavo SuarezNoch keine Bewertungen

- Gears - Engineering InformationDokument138 SeitenGears - Engineering InformationGiang T LeNoch keine Bewertungen

- TFP1580 02 2017Dokument16 SeitenTFP1580 02 2017Julio César Arce CalvoNoch keine Bewertungen

- ScrewDokument20 SeitenScrewIxora MyNoch keine Bewertungen

- Blueprint Reading For Welders Spiral Bound Version Ebook PDF VersionDokument61 SeitenBlueprint Reading For Welders Spiral Bound Version Ebook PDF Versionramona.evans546100% (35)

- VULCAN-162M HT SeriesDokument1 SeiteVULCAN-162M HT SeriesBe HappyNoch keine Bewertungen

- Petrol Filling StationsDokument20 SeitenPetrol Filling StationsAdel A. Abdelaziz100% (1)

- Tubulares Hydril WThread (WT) PDFDokument28 SeitenTubulares Hydril WThread (WT) PDFAnonymous VUH1VkS2j100% (2)

- 05 Needle ValveDokument12 Seiten05 Needle ValvePukhraj DagaNoch keine Bewertungen

- NAS577Dokument5 SeitenNAS577Andrei Cozma100% (1)

- HM 300Dokument1.056 SeitenHM 300João Guardado100% (4)

- CW62100Ex3000 已好Dokument4 SeitenCW62100Ex3000 已好846213Noch keine Bewertungen

- Fastener Weight ChartDokument9 SeitenFastener Weight ChartTricolor C ANoch keine Bewertungen

- CEMS A 31 Part IDokument28 SeitenCEMS A 31 Part ISuman PawarNoch keine Bewertungen

- Final Report On Electric Car Jack 3 PDFDokument30 SeitenFinal Report On Electric Car Jack 3 PDFify100% (2)

- UPVC Pipes & Fittings Upload 11.03.2019Dokument20 SeitenUPVC Pipes & Fittings Upload 11.03.2019Rushan LakdimuthuNoch keine Bewertungen

- Types of StudsDokument2 SeitenTypes of Studsadib nassarNoch keine Bewertungen

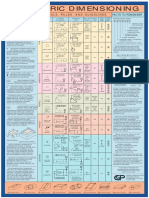

- Geometric Dimensioning: Symbols, Rules, and Guidelines Facts To Remember Facts To RememberDokument3 SeitenGeometric Dimensioning: Symbols, Rules, and Guidelines Facts To Remember Facts To RememberAlex Dobrescu100% (2)

- Turner Question and Answer Bank 2014Dokument88 SeitenTurner Question and Answer Bank 2014bijukumarg93% (30)

- Drylin General Drive Technology - SLW Linear ActuatorsDokument17 SeitenDrylin General Drive Technology - SLW Linear ActuatorsCRISTOBAL SALINAS ESTAYNoch keine Bewertungen

- 2002 Seadoo Shop Manual 1Dokument557 Seiten2002 Seadoo Shop Manual 1Anthony Windover100% (1)

- DAN8Dokument14 SeitenDAN81021210122 mech.12Noch keine Bewertungen