Beruflich Dokumente

Kultur Dokumente

HW 5 Pro 4

Hochgeladen von

ybobbyxOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HW 5 Pro 4

Hochgeladen von

ybobbyxCopyright:

Verfügbare Formate

1. Callister 6.

47 Estimate the Brinell and Rockwell hardness for the following: (a) The naval brass for which the stress-strain behavior is shown in Figure 6.12. (b) The steel alloy for which the stress-strain behavior is shown in Figure 6.21.

2. Callister 7.23 (a) From the plot of yield strength versus (grain diameter)-1/2 for a 70 Cu-30 Zn cartridge brass, Figure 7.15, determine values for the constants ! 0 and k y in Equation 7.7. (b) Now predict the yield strength of this alloy when the average grain diameter is 2.0 " 10 !3 mm .

3. Callister 7.29 Two previously undeformed specimens of the same metal are to be plastically deformed by reducing their cross-sectional areas. One has circular cross section, and the other is rectangular; during deformation the circular cross section is to remain as such. Their original and deformed dimensions are as follows: Circular (diameter, mm) Original dimensions Deformed dimensions 18.0 15.9 Rectangular (mm) 20 ! 50 13.7 ! 55.1

Which of these specimens will be the hardest after plastic deformation, and why?

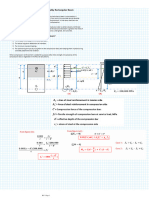

4. Callister 8.5 A specimen of a 4340 steel alloy with a plane strain fracture toughness of 54.8 MPa m (50ksi in ) is exposed to a stress of 1030 MPa (150,000 psi). Will this specimen experience fracture if it is known that the largest surface crack is 0.5mm (0.02in.) long? Why or why not? Assume that the parameter Y has a value of 1.0.

5. Callister 8.6 Some aircraft component is fabricated from an aluminum alloy that has a plane strain fracture toughness of 40 MPa m (36.4 ksi in ). It has been determined that fracture results at a stress of 300 MPa (43,500 psi) when the maximum (or critical) internal crack length is 4.0 mm (0.16in.). For this same component and alloy, will fracture occur at a stress level of 260 MPa (38,000 psi) when the maximum internal crack length is 6.0 mm (0.24 in.)? Why or why not?

6. Core 8.20

Work hardening: yield strength increases after plastic deformation due to the creation of new dislocations and to increasing numbers of dislocation entanglements. Solid solution strengthening: ! y increases because substitution or interstitial alloying elements distort the crystal lattice and thus hinder dislocation motion. Precipitation hardening: 2nd phase particles dispersed throughout a material hinder dislocation motion. Grain boundary strengthening: because of adjacent grains are misaligned with respect to each other, increased stress is needed to move dislocations across grain boundaries. Reducing the grain size thus imposes more impediments to dislocation motion and consequently increases ! y .

7. Core 8.28

There must be one or more defects such as surface scratches or internal cracks that exceed the critical flaw size such that brittle fracture is catalyzed at a stress below the maximum possible.

8. Core 8.31

9. Core 8.21

Das könnte Ihnen auch gefallen

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsVon EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNoch keine Bewertungen

- Recitation 2Dokument1 SeiteRecitation 2azizieh5701Noch keine Bewertungen

- CH 07Dokument12 SeitenCH 07Madeline NgoNoch keine Bewertungen

- Home Assignment 5Dokument2 SeitenHome Assignment 5SantoshNoch keine Bewertungen

- Assignment 6 2023Dokument2 SeitenAssignment 6 2023Linhan ChuNoch keine Bewertungen

- CH 08Dokument8 SeitenCH 08Ingi Abdel Aziz Srag0% (1)

- Engineering Material: Assignment # 01Dokument3 SeitenEngineering Material: Assignment # 01Hussain AliNoch keine Bewertungen

- My PaperDokument9 SeitenMy PaperBelal HyariNoch keine Bewertungen

- Assignment No. 1 Materials Science and MetallurgyDokument2 SeitenAssignment No. 1 Materials Science and MetallurgySamruddhi MirganeNoch keine Bewertungen

- MCEN30017 Tutorial 2Dokument3 SeitenMCEN30017 Tutorial 2vsanthanamNoch keine Bewertungen

- Assignment ProcessDokument2 SeitenAssignment ProcessMuhammad Nazmul Hassan KhanNoch keine Bewertungen

- Assignment 1 Mech 321 Properties and Failure of Materials Jan 2009Dokument2 SeitenAssignment 1 Mech 321 Properties and Failure of Materials Jan 2009DSGNoch keine Bewertungen

- Improved Bolt Models For Use in Global Analyses of Storage and Transportation Casks Subject To Extra-Regulatory LoadingDokument8 SeitenImproved Bolt Models For Use in Global Analyses of Storage and Transportation Casks Subject To Extra-Regulatory LoadingHanan IbrahimNoch keine Bewertungen

- Performance of Jumbo Beam-to-Column Connections With High Strength SteelDokument9 SeitenPerformance of Jumbo Beam-to-Column Connections With High Strength SteelMuhammad irfan javaidNoch keine Bewertungen

- Homework#6 F14 - M E 311Dokument1 SeiteHomework#6 F14 - M E 311Jeremy PriestNoch keine Bewertungen

- MSE 227 Chapter 8 HWDokument1 SeiteMSE 227 Chapter 8 HWjosewilliam85Noch keine Bewertungen

- Unit-IV DSR Answer AssignmentDokument3 SeitenUnit-IV DSR Answer Assignmenttejasgujar15Noch keine Bewertungen

- Design: of Steel StructuresDokument2 SeitenDesign: of Steel StructureskarthiksampNoch keine Bewertungen

- Balok Komposit Baja Berselubung BetonDokument11 SeitenBalok Komposit Baja Berselubung BetonFuadNoch keine Bewertungen

- Composite Beams and Slabs1Dokument9 SeitenComposite Beams and Slabs1rameshbabu_1979100% (1)

- Purlin Design To AISI LRFD Using Rational Buckling Analysis 09007dcc809cfddfDokument14 SeitenPurlin Design To AISI LRFD Using Rational Buckling Analysis 09007dcc809cfddfEmrE GöktuĞ100% (1)

- Special Features of Friction Hardening of Austenitic Steel With Unstable G-PhaseDokument3 SeitenSpecial Features of Friction Hardening of Austenitic Steel With Unstable G-PhaseSinhro018Noch keine Bewertungen

- Elastic Buckling Behavior of Steel FrameDokument16 SeitenElastic Buckling Behavior of Steel FrameSang NguyenNoch keine Bewertungen

- Planted ColumnDokument7 SeitenPlanted Columnabdul khaderNoch keine Bewertungen

- References: CEEN 043 Behavior & Properties of Engineering MaterialsDokument7 SeitenReferences: CEEN 043 Behavior & Properties of Engineering MaterialskishoryawaleNoch keine Bewertungen

- 7 4Dokument8 Seiten7 4Izwan HassanNoch keine Bewertungen

- EsdDokument3 SeitenEsdHrishikesh BhavsarNoch keine Bewertungen

- Ce 2014 Fundamental of Concrete, Steel and Timber StructureDokument22 SeitenCe 2014 Fundamental of Concrete, Steel and Timber StructureKyaw Zin HeinNoch keine Bewertungen

- Behaviour of Cold Formed Steel Single and Compound Plain Angles in CompressionDokument13 SeitenBehaviour of Cold Formed Steel Single and Compound Plain Angles in Compressionthiya123Noch keine Bewertungen

- HW Ch7 1Dokument12 SeitenHW Ch7 1Chenhg ChengNoch keine Bewertungen

- Nonlinear Finite Element Analysis On Seismic PerfoDokument8 SeitenNonlinear Finite Element Analysis On Seismic PerfoSang NguyenNoch keine Bewertungen

- Performance Criteria For Dissipative Steel Plate Shear Walls StructuresDokument8 SeitenPerformance Criteria For Dissipative Steel Plate Shear Walls StructuresgiorgosantzelidisNoch keine Bewertungen

- Dislocation MotionDokument40 SeitenDislocation Motionart180Noch keine Bewertungen

- CCB 241 - Assignment 1 - Due On 21 Feb. 2023Dokument7 SeitenCCB 241 - Assignment 1 - Due On 21 Feb. 2023aaschlysebakisoNoch keine Bewertungen

- CFRP Bridge BeamsDokument5 SeitenCFRP Bridge BeamsAnonymous nQ9RqmNoch keine Bewertungen

- Seismic Behaviour of Fibre Reinforced Concrete Frames: G Campione, L La Mendola and G ZingoneDokument8 SeitenSeismic Behaviour of Fibre Reinforced Concrete Frames: G Campione, L La Mendola and G Zingonecivilstructure.singhbrothersNoch keine Bewertungen

- Aci 318-02Dokument3 SeitenAci 318-02Fiorella CondorNoch keine Bewertungen

- CH6 AssignmetDokument11 SeitenCH6 AssignmetHasan AhmedNoch keine Bewertungen

- Seismic Design StorageTanks Ed2010Dokument39 SeitenSeismic Design StorageTanks Ed2010VladSimionNoch keine Bewertungen

- Universiti Tun Hussein Onn Malaysia Final Examination Semester I SESSION 2009/2010Dokument15 SeitenUniversiti Tun Hussein Onn Malaysia Final Examination Semester I SESSION 2009/2010Muhammad AzriNoch keine Bewertungen

- HW #7Dokument4 SeitenHW #7c_sierra34Noch keine Bewertungen

- Gate DoS (1997-2014)Dokument36 SeitenGate DoS (1997-2014)Tejas PatilNoch keine Bewertungen

- Interrelationships Between Reinforcing Bar Physical Properties and Seismic DemandsDokument92 SeitenInterrelationships Between Reinforcing Bar Physical Properties and Seismic DemandsDiego Leonel Suárez VásquezNoch keine Bewertungen

- Sub: RCC and Steel Module-35CDokument21 SeitenSub: RCC and Steel Module-35Cady999Noch keine Bewertungen

- Concept Check Answers Ch6Dokument5 SeitenConcept Check Answers Ch6Ruben Abreu100% (1)

- SOMDokument14 SeitenSOMAditya ojhaNoch keine Bewertungen

- Ashok Dmm1Dokument4 SeitenAshok Dmm1Praveen KumarNoch keine Bewertungen

- Materials and Cold Work of Forming: 2.1 Steel StandardsDokument23 SeitenMaterials and Cold Work of Forming: 2.1 Steel Standardshunter8080Noch keine Bewertungen

- Closed-Book Practice-Ch 06 (2016!07!31)Dokument8 SeitenClosed-Book Practice-Ch 06 (2016!07!31)JuanNoch keine Bewertungen

- BG1005 - 2010 - Part II - HW#1Dokument4 SeitenBG1005 - 2010 - Part II - HW#1blueworld_918094Noch keine Bewertungen

- Tutorial 2 20152016Dokument4 SeitenTutorial 2 20152016kishoreNoch keine Bewertungen

- EW Resistant Coupling BeamsDokument5 SeitenEW Resistant Coupling Beamscadel100% (1)

- An Analysis of The Behavior of Hybrid Steel Beam - RC Column ConnectionDokument13 SeitenAn Analysis of The Behavior of Hybrid Steel Beam - RC Column ConnectionEhsan WasimNoch keine Bewertungen

- Grillage Analysis of Structures Consist of Steel I-BeamsDokument17 SeitenGrillage Analysis of Structures Consist of Steel I-Beamsjust_u_prettyNoch keine Bewertungen

- Lesson 4.1Dokument10 SeitenLesson 4.1Joylene Dayrit KIMNoch keine Bewertungen

- Minmum Links in ColumnsDokument12 SeitenMinmum Links in ColumnsdurssiNoch keine Bewertungen

- Nonlinear Material Properties of StructuralDokument9 SeitenNonlinear Material Properties of Structuralkhawaja AliNoch keine Bewertungen

- Technical Note On Analysis of Support Structure - V2.1Dokument18 SeitenTechnical Note On Analysis of Support Structure - V2.1unnicyriacNoch keine Bewertungen

- 2018 April CE201-D - Ktu QbankDokument2 Seiten2018 April CE201-D - Ktu Qbanklakshmi dileepNoch keine Bewertungen

- COB-2019-0527 Linear Elastic Fracture Mechanics Analysis of A Square Hollow Structural Steel Section ProfileDokument9 SeitenCOB-2019-0527 Linear Elastic Fracture Mechanics Analysis of A Square Hollow Structural Steel Section ProfileAlbert AlmeidaNoch keine Bewertungen

- Frequency Lab Bode PlotsDokument28 SeitenFrequency Lab Bode PlotsybobbyxNoch keine Bewertungen

- C H O CO H 2O+ 3.76 N Look at Fuel Find Amount of C HDokument3 SeitenC H O CO H 2O+ 3.76 N Look at Fuel Find Amount of C HybobbyxNoch keine Bewertungen

- Engineering in The Roman EmpireDokument9 SeitenEngineering in The Roman EmpireybobbyxNoch keine Bewertungen

- MECH 340 Cheat SheetDokument5 SeitenMECH 340 Cheat SheetybobbyxNoch keine Bewertungen

- Civl 495 SpeechDokument2 SeitenCivl 495 SpeechybobbyxNoch keine Bewertungen

- Engineering in The Roman EmpireDokument9 SeitenEngineering in The Roman EmpireybobbyxNoch keine Bewertungen

- Elizabeth Sutter: PAWS Mike Chestnut Spay/Neuter ClinicDokument1 SeiteElizabeth Sutter: PAWS Mike Chestnut Spay/Neuter ClinicybobbyxNoch keine Bewertungen

- Section 1: Magnetic Field Due To CurrentsDokument9 SeitenSection 1: Magnetic Field Due To CurrentsybobbyxNoch keine Bewertungen

- CH 33Dokument12 SeitenCH 33ybobbyxNoch keine Bewertungen

- DiscussionDokument1 SeiteDiscussionybobbyxNoch keine Bewertungen

- CH 27 Part IIDokument2 SeitenCH 27 Part IIybobbyxNoch keine Bewertungen

- Solution HW 5 Part If All 12Dokument8 SeitenSolution HW 5 Part If All 12ybobbyxNoch keine Bewertungen

- pg1 PDFDokument1 Seitepg1 PDFSanjeev GuptaNoch keine Bewertungen

- E - 2 - Effect of Casting Shape and Size On Solidification TimeDokument6 SeitenE - 2 - Effect of Casting Shape and Size On Solidification Timeoğuz kağanNoch keine Bewertungen

- Principles of Topical Therapy: Presented By: DR .Anjali Singh Junior Resident Department of DermatologyDokument25 SeitenPrinciples of Topical Therapy: Presented By: DR .Anjali Singh Junior Resident Department of DermatologyRiyaSinghNoch keine Bewertungen

- RingMethod Zuidema WatersDokument2 SeitenRingMethod Zuidema WatersJack Yoseph Martinez OrtegaNoch keine Bewertungen

- IB-DU1000 Metal-Enclosed Bus PDFDokument12 SeitenIB-DU1000 Metal-Enclosed Bus PDFdestro57Noch keine Bewertungen

- Iisc PHD Thesis FormatDokument4 SeitenIisc PHD Thesis Formatmichelelataseattle100% (2)

- TWM 3178 PDSDokument2 SeitenTWM 3178 PDSsunnyooiNoch keine Bewertungen

- Biocomposites Guide PDFDokument40 SeitenBiocomposites Guide PDFShirah CoolNoch keine Bewertungen

- Householders Guide To Flat RoofingDokument24 SeitenHouseholders Guide To Flat RoofingBudi SudrajatNoch keine Bewertungen

- Series LF210-5 Specification SheetDokument2 SeitenSeries LF210-5 Specification SheetWattsNoch keine Bewertungen

- Completions and WorkoverDokument309 SeitenCompletions and WorkoverFan Jack67% (3)

- Industrial ReportDokument64 SeitenIndustrial Reportfuad ullahNoch keine Bewertungen

- Formulation Development and Evaluation of Unit Moulded Herbal Semisolid Jelly Useful in Treatment of Mouth UlcerDokument9 SeitenFormulation Development and Evaluation of Unit Moulded Herbal Semisolid Jelly Useful in Treatment of Mouth UlcerLaeeq R MalikNoch keine Bewertungen

- Oxylink - Starting Point Formulation: Acrylic Direct To Metal Coating Based On Posichem PC-Mull AC 16-2Dokument2 SeitenOxylink - Starting Point Formulation: Acrylic Direct To Metal Coating Based On Posichem PC-Mull AC 16-2Thanh VuNoch keine Bewertungen

- Experiment A Test For Lipid Result: Result When Added To WaterDokument5 SeitenExperiment A Test For Lipid Result: Result When Added To WaterSuu Wan0% (2)

- SANDVIK - Steel Designation and Markings - STA-02-030EDokument4 SeitenSANDVIK - Steel Designation and Markings - STA-02-030EPetr HavelNoch keine Bewertungen

- Chemical Compositions of Banana Peels (Musa Sapientum) Fruits Cultivated in Malaysia Using Proximate AnalysisDokument6 SeitenChemical Compositions of Banana Peels (Musa Sapientum) Fruits Cultivated in Malaysia Using Proximate AnalysiszawNoch keine Bewertungen

- Electrozincados en 10152 (2009)Dokument18 SeitenElectrozincados en 10152 (2009)joaopedrosousaNoch keine Bewertungen

- 444 Data SheetDokument2 Seiten444 Data SheetSabareesh MylsamyNoch keine Bewertungen

- EZ Torque: Hydraulic Cathead User's ManualDokument35 SeitenEZ Torque: Hydraulic Cathead User's ManualJuan Garcia100% (1)

- Carbon and Its Compounds - Shobhit NirwanDokument17 SeitenCarbon and Its Compounds - Shobhit NirwanBhaskar 8287Noch keine Bewertungen

- 531 (1999) T. R. Golub: Science Et AlDokument8 Seiten531 (1999) T. R. Golub: Science Et AlBair PuigNoch keine Bewertungen

- Iso 14687 3 2014Dokument11 SeitenIso 14687 3 2014Tatiana Sainara Maia FernandesNoch keine Bewertungen

- Cci Valve 100DSVDokument8 SeitenCci Valve 100DSVyg89Noch keine Bewertungen

- NTSE Stage 1 State Level Model Paper 10Dokument30 SeitenNTSE Stage 1 State Level Model Paper 10Om Prakash100% (1)

- Aquaponics IntegrationofhydroponicswaquacultureDokument28 SeitenAquaponics IntegrationofhydroponicswaquacultureDimas Urip SNoch keine Bewertungen

- Worksheet2-Water QualityDokument4 SeitenWorksheet2-Water QualityJoewellyn LimNoch keine Bewertungen

- 2014 Online Catlog - PDF MonDokument50 Seiten2014 Online Catlog - PDF Monjaag2000Noch keine Bewertungen

- 01-0019-01 Flame Methods Manual For AADokument117 Seiten01-0019-01 Flame Methods Manual For AARobert Larry Cordova DiazNoch keine Bewertungen

- LBR 2014 - ReDokument62 SeitenLBR 2014 - ReEugen XhaferajNoch keine Bewertungen