Beruflich Dokumente

Kultur Dokumente

01 - Progressive Cavity Pumps, Downhole Pumps and Mudmotors

Hochgeladen von

dubang69Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

01 - Progressive Cavity Pumps, Downhole Pumps and Mudmotors

Hochgeladen von

dubang69Copyright:

Verfügbare Formate

Chapter I

BENEFITS OF PROGRESSING CAVITY PUMPS

From the standpoint of flow and pressure range, PC pumps compete well with any other type of pump design. They can handle pump flows from fractions of gallons per minute to several thousand gallons per minute. Pressure capability depends on the number of stages (leads of the stator), and typically reaches 800-1,000 psi. The range of fluids they can handle is enormous, with viscosities ranging from waterlike (1 cSt), to fluidlike (clay, cement, and sludge with viscosities up to 1,000,000 cSt). Since the rotor and stator have an interference fit (a plated metallic rotor in an elastomer-lined stator), and low rotating speed, the internal shear rates are very low. When applied in the food industry, these pumps are sometimes known to pump cherries or apples, which move through the internal passages with no damage. The pulsation-free flow and quiet operation of PC pumps are additional advantages for shear-sensitive pumpages.

PC pumps are excellent self-primers and have good suction characteristics. They are tolerant to entrained air and gases, and produce minimal churning or foaming. Another major feature of these machines is their high tolerance to contamination and abrasion. Often called a "lastresource pump," PC pumps are often utilized for extremely abrasive applications, because of a unique property of the elastomer that lines up the stator tube and resists abrasion. These elastomers are made from regular rubber (Buna) or more exotic materials, such as Viton, Teflon, and others. As versatile as they are, PC pumps do have limitations, primarily size. To prevent flow "slip" (leakage from higher discharge pressure back to suction), the number of rotor/stator leads (stages) must be increased as pressure is increased. This, in turn, increases the overall length of the unit. For such highpressure applications, it is sometimes difficult to retrofit an existing installation, where smaller pumps (such as centrifugal) have been operating in the past. However, when space is not an issue, this limitation is not a factor. Another reason for PC pumps' larger size is their low speed, which requires a gear reducer (or a belt drive) between the motor driver and the pump. This can result in added cost. However, the recent advent of variable frequency drives (VFDs) has allowed elimination of gear reducers and, at the same time, has introduced a new capability to vary flow while pumping against a given pressure. Another PC pump limitation is fluid compatibility with the elastomer. Some chemicals may cause problems with the elas-

tomer and others may cause swelling. For corrosive applications, Viton or even Teflon stators are selected. Elastomers also impose certain temperature limitations, as compared to fully metallic pumps. Typically, PC pumps are used where temperatures do not exceed 3OO-35OE PC pumps should not run dry, except for a very short time, because heat generated at the interference between the rotor and stator may cause elastomer failures, often called "chunking" or "debonding."

Das könnte Ihnen auch gefallen

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsVon EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNoch keine Bewertungen

- Kel-1 GAs Lift1Dokument12 SeitenKel-1 GAs Lift1Indra ArdiansyahNoch keine Bewertungen

- Depositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12Von EverandDepositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12Noch keine Bewertungen

- Lecture 1 PDFDokument17 SeitenLecture 1 PDFMoustafa KandelNoch keine Bewertungen

- Development and Application of Classical Capillary Number Curve TheoryVon EverandDevelopment and Application of Classical Capillary Number Curve TheoryNoch keine Bewertungen

- Ch1 Advanced Reservoir Engineering 2007Dokument78 SeitenCh1 Advanced Reservoir Engineering 2007Tino NasselNoch keine Bewertungen

- Confined Fluid Phase Behavior and CO2 Sequestration in Shale ReservoirsVon EverandConfined Fluid Phase Behavior and CO2 Sequestration in Shale ReservoirsNoch keine Bewertungen

- Horizontal Barriers For Controlling Water ConingDokument8 SeitenHorizontal Barriers For Controlling Water ConingBahman MatouriNoch keine Bewertungen

- Example #11-Evaluating Spacing (Example11.csv)Dokument1 SeiteExample #11-Evaluating Spacing (Example11.csv)wizerth apkNoch keine Bewertungen

- RTA Example Files: Table of Contents Example Name File Type Concepts IllustratedDokument1 SeiteRTA Example Files: Table of Contents Example Name File Type Concepts Illustratedwizerth apkNoch keine Bewertungen

- Assigement 1 Pete 473Dokument7 SeitenAssigement 1 Pete 473Lija BinuNoch keine Bewertungen

- Generacion de Type CurvesDokument16 SeitenGeneracion de Type CurvesFlorcita ReyesNoch keine Bewertungen

- Example #12-Simulated Solution Gas Drive 1 (Example12.csv) : Using The Numerical ModelDokument3 SeitenExample #12-Simulated Solution Gas Drive 1 (Example12.csv) : Using The Numerical Modelwizerth apkNoch keine Bewertungen

- Undersaturated Oil-Gas Simulation - Impes Type Solution: o Os GS So oDokument9 SeitenUndersaturated Oil-Gas Simulation - Impes Type Solution: o Os GS So onaefmubarakNoch keine Bewertungen

- 3 Secondary Recovery (1) .PPT Ok OkDokument36 Seiten3 Secondary Recovery (1) .PPT Ok OkEslam Atif AzkolNoch keine Bewertungen

- Compositional and Black Oil Reservoir SimulationDokument8 SeitenCompositional and Black Oil Reservoir SimulationCamiloAndresGuerreroNoch keine Bewertungen

- Well Test Course ExecirsesDokument4 SeitenWell Test Course ExecirsesBambang AriyantoNoch keine Bewertungen

- Kal War 2017Dokument10 SeitenKal War 2017khusnul9Noch keine Bewertungen

- Deconvolution of Wellbore Pressure and Flow Rate: Fikrl J. Kuchuk, Richard G. Carter, LWS AyestaranDokument7 SeitenDeconvolution of Wellbore Pressure and Flow Rate: Fikrl J. Kuchuk, Richard G. Carter, LWS AyestaranSergio FloresNoch keine Bewertungen

- TablasDokument6 SeitenTablasDaniel GutierrezNoch keine Bewertungen

- Simulation Study of Technical and Feasible Gas Lift PerformanceDokument24 SeitenSimulation Study of Technical and Feasible Gas Lift PerformanceTorryNoch keine Bewertungen

- Permeability Determination From Well Log DataDokument10 SeitenPermeability Determination From Well Log DataJorgeNoch keine Bewertungen

- Drill Stem Testing (DST)Dokument5 SeitenDrill Stem Testing (DST)rayan alkurdiNoch keine Bewertungen

- HW 13Dokument5 SeitenHW 13Yahya TawakalNoch keine Bewertungen

- Fluid Flow Exercises: Porosity, Permeability, Darcy's LawDokument3 SeitenFluid Flow Exercises: Porosity, Permeability, Darcy's LawMohamed SahnounNoch keine Bewertungen

- Well Logging: KfupmDokument22 SeitenWell Logging: KfupmDatabase KevinNoch keine Bewertungen

- Project Res - Sim - Assignment SP17 1Dokument5 SeitenProject Res - Sim - Assignment SP17 1Priozky Pratama PurbaNoch keine Bewertungen

- Lecture 5 Inflow Peorformance RelationsDokument14 SeitenLecture 5 Inflow Peorformance RelationsMahesh sinhaNoch keine Bewertungen

- Exercise 1: Matrix-Fracture Transfer Estimation in A Transient Well TestDokument10 SeitenExercise 1: Matrix-Fracture Transfer Estimation in A Transient Well TestsergeyNoch keine Bewertungen

- Analysis and Interpretation of Water-Oil-Ratio PerformanceDokument19 SeitenAnalysis and Interpretation of Water-Oil-Ratio PerformanceriochigNoch keine Bewertungen

- PVT Experiments: Separator Test: by Admin 13 October 2017Dokument2 SeitenPVT Experiments: Separator Test: by Admin 13 October 2017saeed0% (1)

- Well Test Analysis Reveals Reservoir ParametersDokument5 SeitenWell Test Analysis Reveals Reservoir ParametersChai CwsNoch keine Bewertungen

- 09 Well Test Interpretation in Hydraulically Fracture WellsDokument30 Seiten09 Well Test Interpretation in Hydraulically Fracture WellstauseefaroseNoch keine Bewertungen

- SKPP 3513 Assignment 3 Solution Gas DriveDokument5 SeitenSKPP 3513 Assignment 3 Solution Gas DriveZul AtfiNoch keine Bewertungen

- Spe 184834 MSDokument11 SeitenSpe 184834 MSSSNoch keine Bewertungen

- Tesis Hall Plot PDFDokument188 SeitenTesis Hall Plot PDFjlbarretoaNoch keine Bewertungen

- Aps U9 Test Review KeyDokument5 SeitenAps U9 Test Review Keydeez nutsNoch keine Bewertungen

- Permeability Upscaling MethodsDokument48 SeitenPermeability Upscaling Methodsoilkgas31Noch keine Bewertungen

- PTE 526 Natural Gas Engineering: BY Engr. J. O. OwolabiDokument124 SeitenPTE 526 Natural Gas Engineering: BY Engr. J. O. Owolabiokeke ekeneNoch keine Bewertungen

- Production II - Lecture 2Dokument8 SeitenProduction II - Lecture 2علي التميميNoch keine Bewertungen

- Paper Sucker RodDokument8 SeitenPaper Sucker RodAchmad Hairil100% (1)

- Solved Exercises in Nodal AnalysisDokument4 SeitenSolved Exercises in Nodal Analysisirene pafra100% (1)

- Part 12 Superposition Single and Multi WellDokument22 SeitenPart 12 Superposition Single and Multi WellChai Cws0% (1)

- Assignment 1 - ProsperDokument9 SeitenAssignment 1 - ProsperMuhammad Amirullah SanadiNoch keine Bewertungen

- Coats Elements of Reservoir SimulationDokument199 SeitenCoats Elements of Reservoir SimulationWelsinsin Kevin SinNoch keine Bewertungen

- TM4112 - 13 Interpreting Dynamic ModelDokument39 SeitenTM4112 - 13 Interpreting Dynamic ModelRay YudaNoch keine Bewertungen

- Development of A Correlation For The Estimation of Condensate To Gas Ratio and Other Key Gas Properties From Density Molecular WeightDokument18 SeitenDevelopment of A Correlation For The Estimation of Condensate To Gas Ratio and Other Key Gas Properties From Density Molecular WeightDorothyNRNoch keine Bewertungen

- Tutorial 1 EG501LDokument3 SeitenTutorial 1 EG501Lyehuoy110% (1)

- CTGL Case StudyDokument18 SeitenCTGL Case StudywasayrazaNoch keine Bewertungen

- Formation Damage Causes and SolutionsDokument24 SeitenFormation Damage Causes and SolutionsDinesh KanesanNoch keine Bewertungen

- Application of Water Alaternating Gas (Wag) Injection For Heavy Oil Recovery in Niger DeltaDokument71 SeitenApplication of Water Alaternating Gas (Wag) Injection For Heavy Oil Recovery in Niger DeltaNdifreke Nsima WilliamsNoch keine Bewertungen

- Pump Intake Pressure Determined From Fluid Levels Dynamometers and Valve Test MeasurementsDokument13 SeitenPump Intake Pressure Determined From Fluid Levels Dynamometers and Valve Test Measurementsenriqueg_53Noch keine Bewertungen

- Modern Well Test AnalysisDokument41 SeitenModern Well Test AnalysisFatimah AzzahraNoch keine Bewertungen

- Water Influx 2 PDFDokument44 SeitenWater Influx 2 PDFFaridz HimawanNoch keine Bewertungen

- Van Everdingen, A. F. The Skin Effect and Its Influence On The Productive Capacity of A WellDokument6 SeitenVan Everdingen, A. F. The Skin Effect and Its Influence On The Productive Capacity of A WellSolenti D'nouNoch keine Bewertungen

- Rock/Oil Interactions and Core Handling Effects on WettabilityDokument97 SeitenRock/Oil Interactions and Core Handling Effects on WettabilityMARCO100% (1)

- EclipseDokument134 SeitenEclipseQuynhAnh NguyenNoch keine Bewertungen

- Multiphase Method For Converting WHP To BHPDokument7 SeitenMultiphase Method For Converting WHP To BHPHichem FakhfekhNoch keine Bewertungen

- Pressure Transient AnalysisDokument27 SeitenPressure Transient Analysisbayu anggaraNoch keine Bewertungen

- WT AssignmentDokument27 SeitenWT Assignmentabdilrhman sulimanNoch keine Bewertungen

- Applsci 09 04597Dokument11 SeitenApplsci 09 04597dubang69Noch keine Bewertungen

- Normas Revista ICPDokument9 SeitenNormas Revista ICPdubang69Noch keine Bewertungen

- A Comparative Study of Solvent-Free and Highly Efficient Pinene Hydrogenation Over PD On Carbon, Alumina, and Silica SupportsDokument15 SeitenA Comparative Study of Solvent-Free and Highly Efficient Pinene Hydrogenation Over PD On Carbon, Alumina, and Silica Supportsdubang69Noch keine Bewertungen

- MembranesDokument22 SeitenMembranesdubang69Noch keine Bewertungen

- Infrared Spectra of Methanol, Ethanol, and N-Propanol: Earle PlylerDokument6 SeitenInfrared Spectra of Methanol, Ethanol, and N-Propanol: Earle Plylerdubang69Noch keine Bewertungen

- An Overview of The Effects of Fuel Molecular Structure On The Combustion and Emissions Characteristics of Compression Ignition EnginesDokument16 SeitenAn Overview of The Effects of Fuel Molecular Structure On The Combustion and Emissions Characteristics of Compression Ignition Enginesdubang69Noch keine Bewertungen

- Basic Catalysis On MgO Generation CharacterizationDokument28 SeitenBasic Catalysis On MgO Generation Characterizationdubang69Noch keine Bewertungen

- Compilation of Foreign Motor Vehicle Import RequirementsDokument108 SeitenCompilation of Foreign Motor Vehicle Import Requirementsdubang69Noch keine Bewertungen

- Energies 09 00028Dokument12 SeitenEnergies 09 00028Vinayak MhaskeNoch keine Bewertungen

- Combustion The Chemical Struct of Opposed Flow Diff Flames of C3 Oxygenated Hydrocarbons (Isopropanol, Dimethoxy Methane, and Dimethyl Carbonate) and Their MixturesDokument9 SeitenCombustion The Chemical Struct of Opposed Flow Diff Flames of C3 Oxygenated Hydrocarbons (Isopropanol, Dimethoxy Methane, and Dimethyl Carbonate) and Their Mixturesdubang69Noch keine Bewertungen

- 1 PB PDFDokument6 Seiten1 PB PDFdubang69Noch keine Bewertungen

- Basic Catalysis On MgO Generation CharacterizationDokument28 SeitenBasic Catalysis On MgO Generation Characterizationdubang69Noch keine Bewertungen

- Dai 2016Dokument8 SeitenDai 2016dubang69Noch keine Bewertungen

- Chiappe Tta 1984Dokument7 SeitenChiappe Tta 1984dubang69Noch keine Bewertungen

- US3673066 Process For The Accelerated Obtaining of Terpenic Oxides Using Ultraviolet LightDokument3 SeitenUS3673066 Process For The Accelerated Obtaining of Terpenic Oxides Using Ultraviolet Lightdubang69Noch keine Bewertungen

- CHEM 344 Stereochemistry ReviewDokument9 SeitenCHEM 344 Stereochemistry Reviewdubang69Noch keine Bewertungen

- Organometallic Compunds in CatalystsDokument10 SeitenOrganometallic Compunds in Catalystsdubang69Noch keine Bewertungen

- Article RTCODokument11 SeitenArticle RTCOdubang69100% (1)

- Nanoparticles in CatalystsDokument8 SeitenNanoparticles in Catalystsdubang69Noch keine Bewertungen

- 15-Hydroperoxydehydroabietic Acid-A Contact Allergen in Colophony From Pinus SpeciesDokument5 Seiten15-Hydroperoxydehydroabietic Acid-A Contact Allergen in Colophony From Pinus Speciesdubang69Noch keine Bewertungen

- Catalyst HeterogenizationDokument9 SeitenCatalyst Heterogenizationdubang69Noch keine Bewertungen

- Methods For Analysis of Sequential Kinetic MechanismDokument16 SeitenMethods For Analysis of Sequential Kinetic Mechanismdubang69100% (1)

- Design of PCP WellsDokument28 SeitenDesign of PCP Wellsdubang6975% (4)

- ACTCOEFFDokument34 SeitenACTCOEFFFatih FıratNoch keine Bewertungen

- Ione-Aa00-Pe-Cm-0032 Mechanical Run-In Test Procedure - Rev. ADokument20 SeitenIone-Aa00-Pe-Cm-0032 Mechanical Run-In Test Procedure - Rev. AYusuf100% (1)

- Write Up On Turbine Lube Oil SystemDokument5 SeitenWrite Up On Turbine Lube Oil SystemAmit Balot100% (1)

- Oil Tanker Loading ProceduresDokument13 SeitenOil Tanker Loading Proceduresdhanaskr12100% (2)

- NES NC Liquid Ring Pump OM Manual CompressedDokument25 SeitenNES NC Liquid Ring Pump OM Manual CompressedAlex NgNoch keine Bewertungen

- H14LCDokument1 SeiteH14LCgil1187Noch keine Bewertungen

- Injection Pump Specification SheetDokument3 SeitenInjection Pump Specification SheetAndres ContrerasNoch keine Bewertungen

- Design of An Advanced Marine WaterjetDokument9 SeitenDesign of An Advanced Marine Waterjetgnd100Noch keine Bewertungen

- Method of Periodic Maintenance of Wds-6 Locomotives in Steel PlantsDokument47 SeitenMethod of Periodic Maintenance of Wds-6 Locomotives in Steel PlantsPraveen Kumar RoutNoch keine Bewertungen

- Lorentz Pp150-Pp200 Ac Powerpack Manual enDokument3 SeitenLorentz Pp150-Pp200 Ac Powerpack Manual enejboerioNoch keine Bewertungen

- Lombardini 6LD Work Shop Manual GR 6 Matr 1-5302-387Dokument60 SeitenLombardini 6LD Work Shop Manual GR 6 Matr 1-5302-387Wim PeetersNoch keine Bewertungen

- Casappa - PL-04-T-ADokument92 SeitenCasappa - PL-04-T-AMihai Popa100% (1)

- 6D125-2 Engine (PC450-6) Shop Manual (SEBM006410)Dokument366 Seiten6D125-2 Engine (PC450-6) Shop Manual (SEBM006410)cuthuongtho92% (51)

- 01 4jb1ti EngineDokument77 Seiten01 4jb1ti Enginevitor santosNoch keine Bewertungen

- MANUAL Evo CS CS GEN2Dokument27 SeitenMANUAL Evo CS CS GEN2Luke greenawayNoch keine Bewertungen

- Project Guide - Generator SetDokument99 SeitenProject Guide - Generator Setkarthikmanikandan1234Noch keine Bewertungen

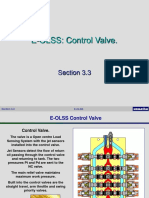

- 3.3 E-OLSS Control ValveDokument12 Seiten3.3 E-OLSS Control Valveeko sunaryo100% (1)

- Models For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationDokument11 SeitenModels For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationElias TascaNoch keine Bewertungen

- Manual - Operacion Ingles - Wacker Rd12aDokument112 SeitenManual - Operacion Ingles - Wacker Rd12aTesla EcNoch keine Bewertungen

- Wa0003Dokument276 SeitenWa0003mogahid jojo75% (8)

- 374F HRC Key Features and BenefitsDokument10 Seiten374F HRC Key Features and BenefitsDAnielNoch keine Bewertungen

- 39MLD STP at Daulatganj - Survey, Investigation, Design, Supply, ConstructionDokument56 Seiten39MLD STP at Daulatganj - Survey, Investigation, Design, Supply, ConstructionNaveen NagisettiNoch keine Bewertungen

- Amc For Ahp Operation and Maintenance For Nabha Power LimitedDokument96 SeitenAmc For Ahp Operation and Maintenance For Nabha Power LimitedLaxmi Laxmi dNoch keine Bewertungen

- Important PointsDokument9 SeitenImportant PointssaadwingNoch keine Bewertungen

- Disassembly/Assembly Manual Model SR2100 (DRAX) : RJ-DA-16 05/10Dokument35 SeitenDisassembly/Assembly Manual Model SR2100 (DRAX) : RJ-DA-16 05/10Erica HenryNoch keine Bewertungen

- Technical Specification Combustiom Modifications Lot 1 For TenderDokument184 SeitenTechnical Specification Combustiom Modifications Lot 1 For TendervrajtilakNoch keine Bewertungen

- Poster PresentationDokument3 SeitenPoster PresentationNipun RavalNoch keine Bewertungen

- SPATA Vol. 2 PDFDokument132 SeitenSPATA Vol. 2 PDFPaul0% (1)

- Manual Wilden P2-METAL PDFDokument28 SeitenManual Wilden P2-METAL PDFMarco SilvaNoch keine Bewertungen

- Test Plan for Perkins T4.401 LP18 Pump 8923A050Dokument2 SeitenTest Plan for Perkins T4.401 LP18 Pump 8923A050veshatNoch keine Bewertungen

- Sandvik DL431-7C: Underground Drill RigDokument4 SeitenSandvik DL431-7C: Underground Drill RiglidoNoch keine Bewertungen

- Industrial Piping and Equipment Estimating ManualVon EverandIndustrial Piping and Equipment Estimating ManualBewertung: 5 von 5 Sternen5/5 (7)

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Asset Integrity Management for Offshore and Onshore StructuresVon EverandAsset Integrity Management for Offshore and Onshore StructuresNoch keine Bewertungen

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideVon EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideBewertung: 2 von 5 Sternen2/5 (1)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionVon EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionBewertung: 4.5 von 5 Sternen4.5/5 (16)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesVon EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertBewertung: 3 von 5 Sternen3/5 (2)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaVon EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaBewertung: 4 von 5 Sternen4/5 (5)

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Pipeline Integrity: Management and Risk EvaluationVon EverandPipeline Integrity: Management and Risk EvaluationBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsVon EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsBewertung: 5 von 5 Sternen5/5 (1)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisVon EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNoch keine Bewertungen

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsVon EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsNoch keine Bewertungen

- Practical Reservoir Engineering and CharacterizationVon EverandPractical Reservoir Engineering and CharacterizationBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesVon EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesBewertung: 4 von 5 Sternen4/5 (2)

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilVon EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilNoch keine Bewertungen

- Fire in the Night: The Piper Alpha DisasterVon EverandFire in the Night: The Piper Alpha DisasterBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Experimental Design in Petroleum Reservoir StudiesVon EverandExperimental Design in Petroleum Reservoir StudiesNoch keine Bewertungen

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationVon EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesVon EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNoch keine Bewertungen

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsVon EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNoch keine Bewertungen

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryVon EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNoch keine Bewertungen

- Petroleum Rock Mechanics: Drilling Operations and Well DesignVon EverandPetroleum Rock Mechanics: Drilling Operations and Well DesignBewertung: 5 von 5 Sternen5/5 (1)