Beruflich Dokumente

Kultur Dokumente

How To CNC Router

Hochgeladen von

CaioeFabiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

How To CNC Router

Hochgeladen von

CaioeFabiCopyright:

Verfügbare Formate

Building a CNC Router

What makes up a CNC router?

! ! ! ! ! ! ! !

Frame (aluminum extrusions) Stepper motors Lead screws Linear rails and bearings Bearings (bearing blocks) Aluminum plate Motor mounts Electrical control box with power supply and stepper motor drivers

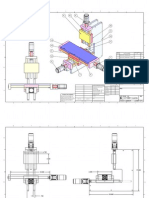

Below is a simple CNC router. The router uses aluminum extrusions to support the linear rails and bearings on the X and Y axis. The design is what is called a moving table machine. The top part is fixed and bolted to the table. The bottom part (X axis) moves in and out on linear rails and bearings. This design is very rigid and allows the user to machine very accurate parts. The next couple of pages will explore the parts need to build this type of CNC router. This CNC router is a simpler version of the one on my web page (www.campbelldesigns.com) that I built for Wylie High School. The machine at Wylie high school uses an aluminum frame for the base.

X Axis

Below is a picture of the X axis. The X axis consists of a pair of linear rails mounted on a pair of aluminum extrusions. Mounted to the rails are four ball bearing runner blocks . A frame of aluminum extrusions is mounted to the runner blocks and make up the moving table In the center is a lead screw with an anti backlash nut, At the far end is a motor mount and a stepper motor. When the stepper motors turns, the table moves back and forth on the linear rails,

A motor mount is attached to the table at the far end. On one end a stepper motor is attached and the opposite end has a bearing block that contains two sets of bearings. The turned end of the lead screw rides on the inside of the bearings. Not shown is a flexible coupler which is attached to the shaft of the stepper motor and the end of the lead screw.

The other end of the lead screw is attached to another square extrusion with a bearing block. The end of the lead screw is threaded. During assembly, a nut is placed on the thread and tightened (pre loaded) to the point that it remove any play on the lead screw.

Mounted on the lead screw is an anti backlash nut. The nut is attached to the carriage assembly that makes up the moving table assembly.

Below is a picture of the Y axis. The Y axis is constructed similar to the X axis, and is mounted on the back of the Bridge (aluminum extrusion). The Y axis moves back and forth and at the same time moves the Z axis assembly.

Z axis assembly

The Z axis assembly consists of a pair of rails and four bearings. Attached to the bearings is a flat plate. Between the rails is a lead screw and anti backlash nut. One end of the lead screw is attached to the shaft on the stepper motor through a flexible coupler. The front plate moves up and down powered by the stepper motor. Attached to the front plate is another plate that has a router bracket attached.

Das könnte Ihnen auch gefallen

- Modular CNC Mini Mill Assy-01Dokument1 SeiteModular CNC Mini Mill Assy-01ModularCNC100% (1)

- CNC Plasma TableDokument37 SeitenCNC Plasma Tablenjsoffice100% (1)

- Home Built CNCDokument110 SeitenHome Built CNCBobby Chipping100% (4)

- CNC Plasma Torch ConstructionDokument2 SeitenCNC Plasma Torch ConstructionMariane MottaNoch keine Bewertungen

- Modular CNC Linear SlideDokument2 SeitenModular CNC Linear SlideModularCNC100% (2)

- CNC Machine DIY InstructionDokument65 SeitenCNC Machine DIY Instructioncxin168100% (3)

- 3 Axis CNC Router (Research Paper)Dokument20 Seiten3 Axis CNC Router (Research Paper)Rameshwar Chape100% (1)

- CNC Instructables PDFDokument13 SeitenCNC Instructables PDFNadim AhmedNoch keine Bewertungen

- CNC Programming History and ToolsDokument23 SeitenCNC Programming History and ToolsSaurabh DuggalNoch keine Bewertungen

- Modular CNC Router 2009v1 FREE PLANSDokument10 SeitenModular CNC Router 2009v1 FREE PLANSModularCNC57% (7)

- CNC Router AluminioDokument48 SeitenCNC Router AluminioCássio Santos100% (2)

- Mach3 Software Installation GuideDokument9 SeitenMach3 Software Installation Guidegabrieldromano1Noch keine Bewertungen

- CNC PlanDokument1 SeiteCNC PlanKevin Blaner100% (1)

- Die FormingDokument4 SeitenDie FormingMohit KambojNoch keine Bewertungen

- Machinists Screw JackDokument3 SeitenMachinists Screw Jackmauri_ros100% (1)

- CNC Router ProjectDokument32 SeitenCNC Router ProjectanouarNoch keine Bewertungen

- CNC Controller RZNC 0901 User Manual RuDokument34 SeitenCNC Controller RZNC 0901 User Manual RuEmill CncNoch keine Bewertungen

- DiY. Homemade Router Laser CNC.Dokument9 SeitenDiY. Homemade Router Laser CNC.Djordje Tasic100% (3)

- Mini Lathe CNC ConversionDokument7 SeitenMini Lathe CNC ConversioneFalegname100% (5)

- Jinan Blue Elephant CNC Machinery Co.,Ltd NNTT Technical Instruction DocumentDokument80 SeitenJinan Blue Elephant CNC Machinery Co.,Ltd NNTT Technical Instruction Documentfaysela100% (1)

- Mini Mill Assembly Drawings-2009Dokument5 SeitenMini Mill Assembly Drawings-2009ModularCNCNoch keine Bewertungen

- AXBB E ManualDokument29 SeitenAXBB E ManualKenny HebertNoch keine Bewertungen

- Syntec InfoDokument14 SeitenSyntec InfoGeorgi HelyanNoch keine Bewertungen

- MCT-08001 Assembly - Sheet1Dokument4 SeitenMCT-08001 Assembly - Sheet1ModularCNC100% (2)

- ModularCNC 72x14x4 Large RouterDokument3 SeitenModularCNC 72x14x4 Large RouterModularCNC100% (1)

- CNCDokument63 SeitenCNCSahil Bangia100% (1)

- Modular CNC Mini CNC Mill Kit Parts ListDokument1 SeiteModular CNC Mini CNC Mill Kit Parts ListModularCNC100% (1)

- Momus Design CNC Router Manual Version 2.1Dokument178 SeitenMomus Design CNC Router Manual Version 2.1Francisco Teruel100% (8)

- Soft Limit ProcedureDokument11 SeitenSoft Limit Procedureradio-chaserNoch keine Bewertungen

- MTS MillingDokument77 SeitenMTS MillingCnc Page100% (1)

- Complete 850Dokument140 SeitenComplete 850inthemoney8100% (1)

- CNC Router Plans - Download Free CNC Router PlansDokument2 SeitenCNC Router Plans - Download Free CNC Router PlansRed ErickNoch keine Bewertungen

- Modular CNC Mini Lathe-1Dokument2 SeitenModular CNC Mini Lathe-1ModularCNC100% (1)

- Mini CNC 01 PDFDokument9 SeitenMini CNC 01 PDFJohny EnglishNoch keine Bewertungen

- CNC Wood Router, 3 Axis CNC RouterDokument4 SeitenCNC Wood Router, 3 Axis CNC RouterMarius DanilaNoch keine Bewertungen

- Mini CNC Printer GuideDokument25 SeitenMini CNC Printer GuideakashNoch keine Bewertungen

- Metal FormingDokument7 SeitenMetal FormingAl Fredo100% (3)

- Elements of CNC MachineDokument40 SeitenElements of CNC MachineAmit Vijhani100% (2)

- Combination CNC Machine and 3D PrinterDokument50 SeitenCombination CNC Machine and 3D PrinterClaudio RussoNoch keine Bewertungen

- Building A CNC RouterDokument37 SeitenBuilding A CNC RouterDavid Morris50% (4)

- CncFor2018 PDFDokument44 SeitenCncFor2018 PDFGeorge Vlad Andronic100% (2)

- Chapter 4 Jigs and FixturesDokument111 SeitenChapter 4 Jigs and FixturesNursyafaizHakimNoch keine Bewertungen

- CNC - A Manufacturing ProcessDokument43 SeitenCNC - A Manufacturing Processnaveenkumar_madasett100% (2)

- CNC Usb Controller MK 3Dokument20 SeitenCNC Usb Controller MK 3Antonio Jiménez100% (1)

- Arduino Mini CNC Plotter DIYDokument9 SeitenArduino Mini CNC Plotter DIYArdhika Dhennis Putra Ananda100% (2)

- All the Halo 3 news that's fit to print in your CNC machineDokument29 SeitenAll the Halo 3 news that's fit to print in your CNC machineScott Giefer0% (1)

- Threading Operations of Lathe SystemDokument37 SeitenThreading Operations of Lathe SystemResshille Ann T. SalleyNoch keine Bewertungen

- Taig Micro Mill & Micro Lathe Mach3 Setup For CNCDokument26 SeitenTaig Micro Mill & Micro Lathe Mach3 Setup For CNCdarkokovacicNoch keine Bewertungen

- CNC Software Conversion UtilityDokument11 SeitenCNC Software Conversion UtilityTegoeh SankenryokuNoch keine Bewertungen

- Sheet FormingDokument4 SeitenSheet Formingvenkat_222123Noch keine Bewertungen

- Sheet Metal ShopDokument35 SeitenSheet Metal ShopAshish SinghNoch keine Bewertungen

- ACESORIOScatalog PDFDokument80 SeitenACESORIOScatalog PDFlmelmelmeNoch keine Bewertungen

- CNC Plan FinalDokument5 SeitenCNC Plan FinalAlex HC100% (2)

- HMT Mandrel Bending 101Dokument80 SeitenHMT Mandrel Bending 101zaiofracassadoNoch keine Bewertungen

- Steering Types: Cam and Lever TypeDokument2 SeitenSteering Types: Cam and Lever TypeabhiNoch keine Bewertungen

- 2020B CNC Machine ManualDokument33 Seiten2020B CNC Machine ManualFelipeAndrésLondoñoGrandaNoch keine Bewertungen

- Parts of Lathe-WPS OfficeDokument2 SeitenParts of Lathe-WPS OfficeJayvee FamisaranNoch keine Bewertungen

- Automobile Systems: Unit - IIDokument30 SeitenAutomobile Systems: Unit - IISasankBabuNoch keine Bewertungen

- Rear Axle Drive and Shaft PresentationDokument47 SeitenRear Axle Drive and Shaft PresentationmharitmsNoch keine Bewertungen

- Steel Grades and Surface TreatmentsDokument12 SeitenSteel Grades and Surface TreatmentsGross Meltiade AlexanderNoch keine Bewertungen

- Excavation Removal-PlanDokument34 SeitenExcavation Removal-PlanABDELKADER BENABDALLAHNoch keine Bewertungen

- SRA166 210 01A BrochureDokument2 SeitenSRA166 210 01A BrochureXanti Zabala Da RosaNoch keine Bewertungen

- Technology Absorption - AdaptationDokument5 SeitenTechnology Absorption - AdaptationRohit BhandariNoch keine Bewertungen

- Learning Activity Sheet Effects of Waste On People's Health and The EnvironmentDokument2 SeitenLearning Activity Sheet Effects of Waste On People's Health and The EnvironmentLeanne Dela CruzNoch keine Bewertungen

- Piso Techo Ciac R410a Nuevo Modelo PDFDokument1 SeitePiso Techo Ciac R410a Nuevo Modelo PDFjuanNoch keine Bewertungen

- Report On Visvesvaraya Iron and Steel Plant, Bhadravathi.Dokument11 SeitenReport On Visvesvaraya Iron and Steel Plant, Bhadravathi.Ramesh Kavitha Sanjit 18BME0677Noch keine Bewertungen

- Traditional Machining Processes Research AdvancesDokument242 SeitenTraditional Machining Processes Research AdvancesGema Rodriguez DelgadoNoch keine Bewertungen

- Basic Principles of MetallurgyDokument28 SeitenBasic Principles of MetallurgysanjeevNoch keine Bewertungen

- Vishay Dale Wirewound Resistors GuideDokument5 SeitenVishay Dale Wirewound Resistors GuideDAS1300Noch keine Bewertungen

- Utilization of Regrind Materials in PVC Extrusion ProcessingDokument1 SeiteUtilization of Regrind Materials in PVC Extrusion ProcessingAntonius PrakosaNoch keine Bewertungen

- Glassy Metals IIIDokument265 SeitenGlassy Metals IIICristian HoreaNoch keine Bewertungen

- HVAC Systems for Pharmaceutical ManufacturingDokument76 SeitenHVAC Systems for Pharmaceutical ManufacturingUMIE UMAIRA KM-PelajarNoch keine Bewertungen

- 300i ServiceDokument408 Seiten300i ServiceMichael Klein100% (1)

- Lube 1090Dokument2 SeitenLube 1090ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNoch keine Bewertungen

- Bioreactors TypesDokument6 SeitenBioreactors TypesHeinerMontalvoNoch keine Bewertungen

- Introduction InsulatorsDokument14 SeitenIntroduction InsulatorsEyad A. Feilat100% (1)

- Oil Filled Transformers Standard Testing ProcedureDokument17 SeitenOil Filled Transformers Standard Testing ProcedureNajeeb AbbasiNoch keine Bewertungen

- Heat Pump - SiUS341615E - Final PDFDokument337 SeitenHeat Pump - SiUS341615E - Final PDFMurilo AquinoNoch keine Bewertungen

- Temperature Monitoring Device ManualDokument4 SeitenTemperature Monitoring Device ManualthomasNoch keine Bewertungen

- Manual STAHL Ex PZC Overpressure Monitoring SystemDokument18 SeitenManual STAHL Ex PZC Overpressure Monitoring SystemEdel Weiss50% (2)

- F01D500 Installation GuideDokument192 SeitenF01D500 Installation GuideRamil CaluagNoch keine Bewertungen

- DesalinationDokument17 SeitenDesalinationmanishaNoch keine Bewertungen

- Austempered Ductile Iron Castings: Standard Specification ForDokument9 SeitenAustempered Ductile Iron Castings: Standard Specification ForRaja Hone0% (1)

- Electronic Thermostat Circuit Using TransistorsDokument2 SeitenElectronic Thermostat Circuit Using Transistorstim schroderNoch keine Bewertungen

- 80 Degree FreezerDokument6 Seiten80 Degree FreezerDaryl ChianNoch keine Bewertungen

- CG Ceiling Fans UnderlightDokument8 SeitenCG Ceiling Fans Underlightprakash_garudNoch keine Bewertungen

- NonstandardDokument39 SeitenNonstandarda04205Noch keine Bewertungen

- NAAMM NOMMA Finishes Manual PDFDokument116 SeitenNAAMM NOMMA Finishes Manual PDFMichaelTorresNoch keine Bewertungen

- Midea Klima Katalogus Midea Main 2008 EngDokument43 SeitenMidea Klima Katalogus Midea Main 2008 EngJoao NogueiraNoch keine Bewertungen