Beruflich Dokumente

Kultur Dokumente

Technical Document On Smoke Extract & Car Park Fans

Hochgeladen von

Tanveer AzizOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Technical Document On Smoke Extract & Car Park Fans

Hochgeladen von

Tanveer AzizCopyright:

Verfügbare Formate

carparkventilation.

com

IAD

Date: 2/11/2007

TECHNICAL ----DOCUMENT

SMOKE EXTRACT FANS

Author: Alan Macklin, Group Technical Manager

The major cause of death in the event of a fire is due to smoke inhalation. Elta Fans smoke extract fans are widely used to assist the evacuation of occupants by creating a smoke free layer. The removal of smoke and hot gases assists in saving lives, providing fire fighting access and limiting fire and smoke damage. Smoke and heat exhaust systems are classified as safety equipment and it is essential that the smoke extract fans operate reliably in the event of a fire emergency. The main aims of smoke and heat exhaust systems are: To keep access and escape routes clear of smoke. To aid fire fighting operations To delay or prevent flashover or full fire development To reduce the subsequent damage to the building structure and its contents.

Legislation

It is a mandatory requirement in the European Union that all smoke extract fans are independently tested to EN 12101-3:2002 Smoke and heat control systems Specification for powered smoke and heat exhaust ventilators. This standard covers the testing, design and production controls that are required before the manufacturer can obtain product certification from the appropriate notified body. Elta Fans has extended its EC Certification for smoke related fan units with BSI, making it one of the largest certified standard product ranges available within Europe. Compliance with the requirements of this standard shall be demonstrated by: Initial type testing Factory production control by the manufacturer. Type Approval of a Range of Units The Standard clearly defines the particular units from within a declared range which must be tested. The minimum testing required can be summarised as: The unit with the highest stressed impeller. At least two sizes of fans at their highest rotational speed. The unit with the smallest frame motor at its maximum declared output. The maximum motor frame at its maximum declared output. One size of all the declared accessories within the range. Elta Fans certification was awarded following rigorous smoke test programmes.

Elta Group

46 Third Avenue, Pensnett Trading Estate, Kingswinford, West Midlands, DY6 7US, United Kingdom Tel: +44 (0)1384 275760 Email: info@eltagroup.co.uk Fax: +44 (0)1384 275770 Website: www.eltagroup.com

carparkventilation.com

IAD

Initial Type Testing

BSRIA in the UK CTICM in France TUV in Germany

--- TECHNICAL --DOCUMENT

There are only a small number of approved test houses within the EU. The major ones being located at:

The essential test conditions are: The fan manufacturer should submit the air and sound performance of the unit at ambient temperature to current ISO and BS standards assuming standard tip clearances apply and also taking account of the increased clearance required for high temperature operations. Ambient temperature must be between 15C and 40C. Volume flow rate should not change by more than 10% or the static pressure by more than 20% during the test (i.e. from end of warm-up period to end of test). After 15 minutes of running at the test temperature the power should be switched off for 2 minutes. The fan is then re-started and run on for its total test period.

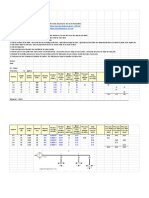

E N121 01-3

Temp

C la s s F 400 (400 C for 2 h ou r s)

400

Figure 1. Temperature versus Time test cycle for F400 classification

Motor off for 2 mins

Am bient

Motor on for 15 mins Test rig burner on

Time

Factory Production Control

The purpose behind these controls is to give maximum confidence to the user, as well as the general public; that product when installed in a smoke control system is fit for purpose and will meet its stated temperature and running time. Full design and construction details and drawings, as well as materials used in the units construction, have to be declared at initial type testing. Any subsequent change during the products life has to be reported to the assessing body, who will at their discretion require a re-test or allow the change to be applied to the original tested product. The manufacturer shall establish, document and maintain a factory control system which shall ensure the conformity of the product, covering:

Control of raw and incoming materials Production process Regular inspection and procedures Routine production test procedure This system should form part of a highlighted procedure within the companys EN ISO 9001 system.

The fan manufacturer, whilst having to hold current EN ISO 9001:2000 for its company systems, also has to be awarded its EC- Certification for the product. Elta Fans in both Fareham and Kingswinford produce the Smokevent, Jetvent and induction smoke product ranges to meet these exacting standards. Elta Group

46 Third Avenue, Pensnett Trading Estate, Kingswinford, West Midlands, DY6 7US, United Kingdom Tel: +44 (0)1384 275760 Email: info@eltagroup.co.uk Fax: +44 (0)1384 275770 Website: www.eltagroup.com

carparkventilation.com

IAD

Impulse Ventilation

--- TECHNICAL --DOCUMENT

Ventilation of covered car parks is essential for removing harmful vehicle exhaust fumes and providing assistance to fire fighters by clearing smoke in the event of a fire. The most significant development to the car park industry in recent years has been the introduction of proven tunnel ventilation fan principles in the form of impulse fans. This innovative approach provides major benefits in terms of smoke control as well as reduced capital and installation costs. Eltas Impulse fans eliminate the need for distribution ductwork with resultant lower extract system resistance, reduced power consumption by the fan(s), and hence savings in terms of system running costs. The system of impulse ventilation is based on a number of small high velocity fans in place of the distribution ductwork. The impulse fans are carefully positioned to direct the airflow towards the main extract fan intake points. The main extract fans are sized to provide the required flow rates, but given the reduced need (or complete elimination) of ducting within the car-park area, do not have to overcome the system resistance inherent in a fully ducted ventilation system. Impulse fans operate on well proven tunnel ventilation principles, producing a high velocity jet which thrusts against the air in front of the fan imparting momentum to all the surrounding air through entrainment as it diffuses. The volume of entrained air is significantly greater than the air quantity passing through the fan. Impulse fan performance is rated in terms of the thrust developed by the fan, which is the product of the mass flow rate times the change in velocity. In practical terms, this equates to the volume flow rate times the air density times the fan outlet velocity and is measured in Newtons (N).

Figure 2. Impulse fans running showing air entrainment

British Standards

Until recently there was no British Standard for car park ventilation, with systems being designed to the Building Regulations Approved Document F (AD-F) for general ventilation and Approved Document B (AD-B) for fire safety. The British Standard, BS7346-7: Code of practice on functional recommendations and calculation methods for smoke and heat control systems for covered car parks, was published in October 2006. The standard is primarily concerned with the removal of smoke and heat, but also deals with vehicle emissions due to the dual use of the ventilation systems. The standard refers to both AD-F and AD-B of the Building Regulations and includes the following four alternative approaches to ventilation: Natural ventilation Ducted mechanical ventilation Impulse ventilation Smoke and heat exhaust ventilation system (SHEVS)

The standard gives recommendations and guidance on functional and calculation methods for impulse systems having the following three design objectives: Impulse ventilation to achieve smoke clearance by dispersal Impulse ventilation to assist fire fighting access Impulse ventilation to protect means of escape Elta Group

46 Third Avenue, Pensnett Trading Estate, Kingswinford, West Midlands, DY6 7US, United Kingdom Tel: +44 (0)1384 275760 Email: info@eltagroup.co.uk Fax: +44 (0)1384 275770 Website: www.eltagroup.com

carparkventilation.com

IAD

--- TECHNICAL --DOCUMENT

Elta Fans Jetvent impulse ventilation range

Elta Fans Smokevent Fans

The Elta Group is a 50 million family of businesses with operations in six countries on four continents which, together with a network of international distributors, provides quality fans and related air movement equipment to customers worldwide.

For further information please contact:

Elta Group Marketing Department:

Jenna Chambers: +44 (0)1384 275766 - jchambers@eltagroup.co.uk Tim Vaughan: +44 (0)1384 275 765 - tvaughan@eltagroup.co.uk

46 Third Avenue, Pensnett Trading Estate, Kingswinford, West Midlands, DY6 7US, United Kingdom

Elta Group

46 Third Avenue, Pensnett Trading Estate, Kingswinford, West Midlands, DY6 7US, United Kingdom Tel: +44 (0)1384 275760 Email: info@eltagroup.co.uk Fax: +44 (0)1384 275770 Website: www.eltagroup.com

Das könnte Ihnen auch gefallen

- Jet FanDokument44 SeitenJet FanHai Pham100% (1)

- Acmv Technical ReportDokument10 SeitenAcmv Technical Reportarun kurlanNoch keine Bewertungen

- Expansion Tank CalculationsDokument5 SeitenExpansion Tank Calculationspsjjoshi0% (1)

- Smoke Management For Retails Calculation PDFDokument1 SeiteSmoke Management For Retails Calculation PDFSudhir KulkarniNoch keine Bewertungen

- StairCase Press-Eclipse - (Printed 29.01.2020) PDFDokument3 SeitenStairCase Press-Eclipse - (Printed 29.01.2020) PDFmhmdjdgmailcomNoch keine Bewertungen

- CHW Pump - HotelDokument7 SeitenCHW Pump - HotelTiffany CombsNoch keine Bewertungen

- CHW Pipe Straight Pressure DropDokument2 SeitenCHW Pipe Straight Pressure DropDesigner ForeverNoch keine Bewertungen

- Drain Pipe Work of Indoor UnitDokument24 SeitenDrain Pipe Work of Indoor UnitMiguel AbuegNoch keine Bewertungen

- Smoke Spill 2Dokument2 SeitenSmoke Spill 2Briana JenkinsNoch keine Bewertungen

- Tunnel Fire Ventilation CalculationsDokument6 SeitenTunnel Fire Ventilation Calculationsakat zkyNoch keine Bewertungen

- Heat Recovery Units RangeDokument35 SeitenHeat Recovery Units RangeGabetsos KaraflidisNoch keine Bewertungen

- Integration - H VAC Fans and Smoke Control - Control EngineeringDokument5 SeitenIntegration - H VAC Fans and Smoke Control - Control EngineeringMohamedAhmedFawzyNoch keine Bewertungen

- 10-Mechanical Extract System-Car Park VentilationDokument18 Seiten10-Mechanical Extract System-Car Park VentilationAli Ruhsen Cete100% (1)

- PRICE - Air Distribution GuideDokument5 SeitenPRICE - Air Distribution Guidenvenkat.narayan100% (1)

- FM200 CalculationsDokument2 SeitenFM200 CalculationsHamdy AdelNoch keine Bewertungen

- Calculation For Fire Size - Smoke Spill System Location Production A3 & A4 Production C3 & C4Dokument1 SeiteCalculation For Fire Size - Smoke Spill System Location Production A3 & A4 Production C3 & C4Lee SienNoch keine Bewertungen

- RJA Smoke Control Modeling Report - Sahara Mall Expansion - 12 August 2010Dokument44 SeitenRJA Smoke Control Modeling Report - Sahara Mall Expansion - 12 August 2010Subharajk100% (1)

- Heat Load Calculation ExampleDokument5 SeitenHeat Load Calculation ExampleJoshua RanjithNoch keine Bewertungen

- Fire-2017-Corridor SmokeDokument1 SeiteFire-2017-Corridor Smokemhmdjdgmailcom100% (1)

- Staircase Pressurization Calculation SheetDokument4 SeitenStaircase Pressurization Calculation SheetTariq AsgharNoch keine Bewertungen

- L&T MLCP East Block HVAC Heat Load SUMMARYDokument3 SeitenL&T MLCP East Block HVAC Heat Load SUMMARYSatheesh Kumar NatarajanNoch keine Bewertungen

- Staircase PressurizationDokument8 SeitenStaircase PressurizationSimon LawNoch keine Bewertungen

- TCVN 7336-2003 Fire Protection Automatic Sprinkler System (En)Dokument24 SeitenTCVN 7336-2003 Fire Protection Automatic Sprinkler System (En)canniumNoch keine Bewertungen

- Article - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFDokument8 SeitenArticle - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFphilipyongNoch keine Bewertungen

- Staircase Pressurisation Calculation Rev-04Dokument36 SeitenStaircase Pressurisation Calculation Rev-04Anish KumarNoch keine Bewertungen

- Stair Case Pressurization - DARDokument4 SeitenStair Case Pressurization - DARKoushikNoch keine Bewertungen

- Example Kitchen Ventilation CalculationDokument4 SeitenExample Kitchen Ventilation Calculationwillis0000Noch keine Bewertungen

- HVAC LOAD CalculationDokument2 SeitenHVAC LOAD CalculationbookjamanNoch keine Bewertungen

- Static CalculationDokument4 SeitenStatic CalculationAshique Muhammed T MNoch keine Bewertungen

- Duct Leakage TesterDokument8 SeitenDuct Leakage TesterJay PresleyNoch keine Bewertungen

- Hot Water Heater Sizing Guidelines: I. DefinitionsDokument8 SeitenHot Water Heater Sizing Guidelines: I. DefinitionsMac ShaikNoch keine Bewertungen

- Technical Handbook Air CurtainsDokument13 SeitenTechnical Handbook Air Curtainsaca111111Noch keine Bewertungen

- Ahu Coil SelectionDokument6 SeitenAhu Coil SelectionpsjjoshiNoch keine Bewertungen

- 02 Cooling Load Calculation - HAPDokument2 Seiten02 Cooling Load Calculation - HAPU DEEPAKNoch keine Bewertungen

- CAL-03 - Staircase Pressurization CalculationDokument4 SeitenCAL-03 - Staircase Pressurization CalculationAbdul Sami100% (1)

- Atrium Natural Smoke CalculationsDokument5 SeitenAtrium Natural Smoke CalculationsRamiAl-fuqahaNoch keine Bewertungen

- Stair Case-01 Pressurisation Calculation: 3.3 7.255 2.56 64.78 2.2 1.1 - 6.6 Walls (Tight) Door Frame (Single Leaf)Dokument7 SeitenStair Case-01 Pressurisation Calculation: 3.3 7.255 2.56 64.78 2.2 1.1 - 6.6 Walls (Tight) Door Frame (Single Leaf)Shabeer HamzaNoch keine Bewertungen

- 04-Sprinkler SystemDokument32 Seiten04-Sprinkler SystemRavi100% (1)

- SPF Stair Case FanDokument2 SeitenSPF Stair Case FanAla ShakerNoch keine Bewertungen

- Air System Sizing Summary For 0008 SMOKING ROOMDokument1 SeiteAir System Sizing Summary For 0008 SMOKING ROOMSaiful Imran Mohamed YusofNoch keine Bewertungen

- Staircase Pressurization SPV BuildingDokument2 SeitenStaircase Pressurization SPV BuildingNandan RajeNoch keine Bewertungen

- Lift Well Pressurization Calculation TOWER C - (G+17)Dokument4 SeitenLift Well Pressurization Calculation TOWER C - (G+17)KoushikNoch keine Bewertungen

- Kazma SMOKE VENTILATION SYSTEMDokument2 SeitenKazma SMOKE VENTILATION SYSTEMRoin BanerjiNoch keine Bewertungen

- Carrierdes1 PDFDokument163 SeitenCarrierdes1 PDFDomingo RuizNoch keine Bewertungen

- Presurization CalculationsDokument10 SeitenPresurization CalculationsvinaygvmNoch keine Bewertungen

- ASHRAE 90 1 Kadj Calculator Revision 5Dokument9 SeitenASHRAE 90 1 Kadj Calculator Revision 5Basil OguakaNoch keine Bewertungen

- Staircase PressurizationDokument8 SeitenStaircase PressurizationKrishna PATEL100% (1)

- Door LeakagesDokument1 SeiteDoor LeakagespsjjoshiNoch keine Bewertungen

- Light Hazard Design Criteria (Guide) : Check Highest Expected Ceiling TemperatureDokument13 SeitenLight Hazard Design Criteria (Guide) : Check Highest Expected Ceiling Temperatureمحمد الامينNoch keine Bewertungen

- Hvac Pipe SizingDokument1 SeiteHvac Pipe SizingRaja Antony100% (1)

- 03.pressurisation Calculation Semenyih Blok ADokument3 Seiten03.pressurisation Calculation Semenyih Blok ABriana JenkinsNoch keine Bewertungen

- Elevator Lobby Pressurization 1Dokument2 SeitenElevator Lobby Pressurization 1Mohamed MonamNoch keine Bewertungen

- Car Park VentilationDokument3 SeitenCar Park VentilationBayhonElmer67% (3)

- Ariston Electric Water HeatersDokument2 SeitenAriston Electric Water HeatersSuresh SubbarayanNoch keine Bewertungen

- Documents Room DY Auto Heat Load RaphaDokument18 SeitenDocuments Room DY Auto Heat Load RaphaShaikh TauseefNoch keine Bewertungen

- Design Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionDokument1 SeiteDesign Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionpsjjoshiNoch keine Bewertungen

- Design Calculation Sheet: System Class Class A Class B Class C Class D Class E Class FDokument3 SeitenDesign Calculation Sheet: System Class Class A Class B Class C Class D Class E Class FMohd Najeeb Ali FathaanNoch keine Bewertungen

- Smokecontrol Car Park VentilationDokument4 SeitenSmokecontrol Car Park VentilationallovidNoch keine Bewertungen

- Leaflet Car Park VentilationDokument20 SeitenLeaflet Car Park VentilationPhạm Thanh SơnNoch keine Bewertungen

- CPD Car Park Ventilation PDFDokument49 SeitenCPD Car Park Ventilation PDFAdrian Mușat100% (1)

- PROGER Company ProfileDokument122 SeitenPROGER Company ProfileTanveer AzizNoch keine Bewertungen

- ProfileDokument23 SeitenProfileTanveer AzizNoch keine Bewertungen

- ESC Cleanroom Design GuideDokument6 SeitenESC Cleanroom Design GuideTanveer AzizNoch keine Bewertungen

- Mep BrochureDokument16 SeitenMep BrochureTanveer AzizNoch keine Bewertungen

- Paper ID 233Dokument1 SeitePaper ID 233Tanveer AzizNoch keine Bewertungen

- SEASIF Company ProfileDokument64 SeitenSEASIF Company ProfileTanveer AzizNoch keine Bewertungen

- KsaprofileenDokument24 SeitenKsaprofileenTanveer AzizNoch keine Bewertungen

- 4-1 EN Frese DELTA T Control System JUN 17Dokument5 Seiten4-1 EN Frese DELTA T Control System JUN 17Tanveer AzizNoch keine Bewertungen

- 52000427BD-Alliance-Airport Expansion (R-2) - EmailDokument3 Seiten52000427BD-Alliance-Airport Expansion (R-2) - EmailTanveer AzizNoch keine Bewertungen

- 03 - Thermostat & Accessories - EmailDokument24 Seiten03 - Thermostat & Accessories - EmailTanveer AzizNoch keine Bewertungen

- Control Valves: Leading The Way in Piping NeedsDokument32 SeitenControl Valves: Leading The Way in Piping NeedsTanveer AzizNoch keine Bewertungen

- Mechanical Valves & Flexible Joints: Leading The Way in Piping NeedsDokument40 SeitenMechanical Valves & Flexible Joints: Leading The Way in Piping NeedsTanveer AzizNoch keine Bewertungen

- 068 TECH F2000 Saddle RemoteDokument2 Seiten068 TECH F2000 Saddle RemoteTanveer AzizNoch keine Bewertungen

- UL Listed 42 Bar HFC-227ea (FM-200) Clean Agent SystemDokument6 SeitenUL Listed 42 Bar HFC-227ea (FM-200) Clean Agent SystemTanveer AzizNoch keine Bewertungen

- MOSELECTRO Group of CompaniesDokument23 SeitenMOSELECTRO Group of CompaniesTanveer AzizNoch keine Bewertungen

- Al Jezeera Steel Work Profile PDFDokument44 SeitenAl Jezeera Steel Work Profile PDFcetc qatarNoch keine Bewertungen

- Working Principle of Holtop Fresh Air Dehumidification SystemsDokument1 SeiteWorking Principle of Holtop Fresh Air Dehumidification SystemsTanveer AzizNoch keine Bewertungen

- ERV Intelligent Controllers: Latest Update For Holtop Intelligent Controllers: WIFI Connection FunctionDokument1 SeiteERV Intelligent Controllers: Latest Update For Holtop Intelligent Controllers: WIFI Connection FunctionTanveer AzizNoch keine Bewertungen

- Item 9A Fan Model: CFT 630 C/W Fda 630 C SYSTEM: 21500 CFM at Est. 100 PA Motor: 11Kw / 4 Pole / Class FDokument1 SeiteItem 9A Fan Model: CFT 630 C/W Fda 630 C SYSTEM: 21500 CFM at Est. 100 PA Motor: 11Kw / 4 Pole / Class FTanveer AzizNoch keine Bewertungen

- Heat&Energy: With PM2.5 Purification FunctionDokument6 SeitenHeat&Energy: With PM2.5 Purification FunctionTanveer AzizNoch keine Bewertungen

- Project TemplatesDokument66 SeitenProject TemplatesfouzunNoch keine Bewertungen

- 7Dokument1 Seite7Tanveer AzizNoch keine Bewertungen

- OSID Smoke Detection: FeaturesDokument2 SeitenOSID Smoke Detection: FeaturesTanveer AzizNoch keine Bewertungen

- 2 PDFDokument1 Seite2 PDFTanveer AzizNoch keine Bewertungen

- 2 PDFDokument1 Seite2 PDFTanveer AzizNoch keine Bewertungen

- Item 1 FAM MODEL: TDA 560/12AA/5/24 SYSTEM: 3400 CFM at 180 PA Motor: 0.75Kw / 4 Pole / Class FDokument1 SeiteItem 1 FAM MODEL: TDA 560/12AA/5/24 SYSTEM: 3400 CFM at 180 PA Motor: 0.75Kw / 4 Pole / Class FTanveer AzizNoch keine Bewertungen

- Item Fan No Model System: Kruvent Industries (M) SDN BHDDokument1 SeiteItem Fan No Model System: Kruvent Industries (M) SDN BHDTanveer AzizNoch keine Bewertungen

- Method Statement Sample Fire AlarmDokument6 SeitenMethod Statement Sample Fire AlarmFaress Aladdin100% (3)

- Item 1 FAM MODEL: TDA 560/12AA/5/24 SYSTEM: 3400 CFM at 180 PA Motor: 0.75Kw / 4 Pole / Class FDokument1 SeiteItem 1 FAM MODEL: TDA 560/12AA/5/24 SYSTEM: 3400 CFM at 180 PA Motor: 0.75Kw / 4 Pole / Class FTanveer AzizNoch keine Bewertungen

- Coil Selection FormatDokument6 SeitenCoil Selection FormatTanveer AzizNoch keine Bewertungen

- Installation BardDokument26 SeitenInstallation BardMukti AwanNoch keine Bewertungen

- Tds Hydrodrain 2016Dokument4 SeitenTds Hydrodrain 2016ugurNoch keine Bewertungen

- Volvo Edc III Tad 1241 2 Workshop ManualDokument7 SeitenVolvo Edc III Tad 1241 2 Workshop Manualmary100% (55)

- Specification 13320 Revision7Dokument40 SeitenSpecification 13320 Revision7bilgipaylasimNoch keine Bewertungen

- AirstageDokument76 SeitenAirstagedaviko313Noch keine Bewertungen

- Sample Fans and Blowers Problems #1Dokument8 SeitenSample Fans and Blowers Problems #1DEKUU MidoriyaNoch keine Bewertungen

- 3 - 5 - Ark - Non Return DamperDokument8 Seiten3 - 5 - Ark - Non Return DamperblindjaxxNoch keine Bewertungen

- Daikin CAT 903-1 LR Air Terminal Units CatalogDokument106 SeitenDaikin CAT 903-1 LR Air Terminal Units CatalogHussain Al SanonaNoch keine Bewertungen

- Method Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDokument15 SeitenMethod Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDonny Subarja100% (2)

- Iso 10294-3-1999Dokument16 SeitenIso 10294-3-1999Nguyen Trung KienNoch keine Bewertungen

- Aerofom - Alu Glass Tape Technical Data SheetDokument1 SeiteAerofom - Alu Glass Tape Technical Data SheetChris SolonNoch keine Bewertungen

- Wedi MaterialsDokument53 SeitenWedi MaterialsAvk SanjeevanNoch keine Bewertungen

- Thermal Audit Report On A WHRB at A Sponge Iron PlantDokument36 SeitenThermal Audit Report On A WHRB at A Sponge Iron Plantparthi20065768Noch keine Bewertungen

- Air Duct Sizing - SI & Imperial UnitsDokument2 SeitenAir Duct Sizing - SI & Imperial UnitsJunior Engineer100% (1)

- Edmt341410c Rxqtay PDFDokument832 SeitenEdmt341410c Rxqtay PDFscribdquyNoch keine Bewertungen

- Hvac Notes & Eqpt. Schedules: Design GroupDokument12 SeitenHvac Notes & Eqpt. Schedules: Design GroupAnkush NayarNoch keine Bewertungen

- RCC - SDS Sir Format - 06-Aug-21 (SEP-21)Dokument15 SeitenRCC - SDS Sir Format - 06-Aug-21 (SEP-21)Baladaru Krishna PrasadNoch keine Bewertungen

- N N Total: Design CriteriaDokument6 SeitenN N Total: Design Criteriaprabhuanand1986Noch keine Bewertungen

- 50EES (3 5) Option 1Dokument17 Seiten50EES (3 5) Option 1sirishghrceNoch keine Bewertungen

- Fire Protection Design ManualDokument51 SeitenFire Protection Design ManualNaveen NagarajNoch keine Bewertungen

- Sizing An Exhaust FanDokument1 SeiteSizing An Exhaust Fanomar mohd zainiNoch keine Bewertungen

- 2006 IBC Guide To SCS - Dr. Klote and Doug EvansDokument20 Seiten2006 IBC Guide To SCS - Dr. Klote and Doug EvansWalker Donuji100% (2)

- HVAC ManhoursDokument34 SeitenHVAC ManhoursSharad SawantNoch keine Bewertungen

- Brivis Ducted Gas Heater Operation Manual PDFDokument36 SeitenBrivis Ducted Gas Heater Operation Manual PDFicbidtNoch keine Bewertungen

- Honeywell E3Point - QuickStart GuideDokument2 SeitenHoneywell E3Point - QuickStart GuideCam DennisNoch keine Bewertungen

- Din en 12101 8 PDFDokument40 SeitenDin en 12101 8 PDFadel rihana100% (1)

- RGX-S-61-1340-101 Part 1Dokument16 SeitenRGX-S-61-1340-101 Part 1Moha KarthickNoch keine Bewertungen

- Dokumen - Tips - Urs User Requirement Specification Template r01Dokument12 SeitenDokumen - Tips - Urs User Requirement Specification Template r01lmqasemNoch keine Bewertungen

- Fire Alarm System 2013 PDFDokument32 SeitenFire Alarm System 2013 PDFArman Ul Nasar100% (3)