Beruflich Dokumente

Kultur Dokumente

Ruskin Fd-35 Submittal

Hochgeladen von

Nedunuri.Madhav MurthyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ruskin Fd-35 Submittal

Hochgeladen von

Nedunuri.Madhav MurthyCopyright:

Verfügbare Formate

3900 Dr. Greaves Rd.

Kansas City, MO 64030 (816) 761-7476 FAX (816) 765-8955

FD35 AND FD35SS MULTIPLE BLADE STATIC FIRE DAMPER

11/2 HOUR RATING UL555 RATED FOR USE IN STATIC SYSTEMS APPLICATION

The FD35 and FD35SS are 11/2 hour rated multiple blade static fire dampers. The FD35 is constructed with galvanized steel 3-V blades and FD35SS, 304 or 316 stainless steel. FD35 series can be installed vertically in walls or horizontally in floors.

STANDARD CONSTRUCTION

FRAME FD35 5" x 1" x 16 gage (127 x 25 x 1.52) galvanized steel hat channel, structurally superior to 13 gage (2.3) channel frame. FD35SS 5" x 1" x 16 gage (127 x 25 x 1.52) galvanized steel hat channel. BLADES 16 gage (1.52) galvanized, 304 or 316 stainless steel triple vee groove, approximately 6" (152) on center. BEARINGS Stainless steel sleeve, pressed into frame. LINKAGE Concealed in frame. AXLES 1/2" (13) plated steel hex or 300 series stainless steel. FUSIBLE LINK 165F (74C) standard. 212F (100C) available. DAMPER WEIGHT Approximately 8 lbs. per sq. ft. without damper sleeve.

DAMPER SIZES FD35

MINIMUM SIZE Vertical or Horizontal Installation 8"w x 6"h (203 x 152). MAXIMUM SIZE Single Section Vertical or Horizontal Installation 36"w x 48"h (914 x 1219). Multiple Section Vertical or Horizontal Installation 120"w x 96"h (3048 x 2438).

The FD35 and FD35SS dampers meet the requirements for fire dampers established by: National Fire Protection Association NFPA Standards 90A, 92A, 92B and 101 ICC International Building Codes CSFM California State Fire Marshal Listing #3225-245:005

FD35SS

MINIMUM SIZE Vertical or Horizontal Installation 8"w x 6"h (203 x 152). MAXIMUM SIZE Single Section Vertical or Horizontal Installation 30"w x 48"h (762 x 1219). Multiple Section Vertical or Horizontal Installation 90"w x 48"h (2286 x 1219).

SEE COMPLETE MARKING ON PRODUCT

UL555 Classification R5531

FM Approvals Specification Tested Product (Option)

OPTIONS

FM Approvals as Specification Tested Product. SP100 Switch Package to remotely indicate damper blade position. FAST Angle for one side angle installations. PFMA Angles for two side angle installation Sleeve of various lengths and gages to ensure field compliance with UL installation requirements. Jamb Seals stainless steel flexible metal compression type. Blade Seals silicone blade edge seals. Crank Lever to assist with testing and fuse link replacement GA, Grille Access for one side installation and out of wall applications (see models IBD2GA or DIBD2GA) OW, Out of Wall of application where the damper can not be installed within the plane of the wall or floor. NOTES: 1. Dimensions in inches, parentheses ( ) indicate millimeters. 2. Damper assembly furnished actual size.

Spec FD35 & FD35SS-510/Replaces FD35 & FD35SS-404

ALL STATED SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE OR OBLIGATION.

Ruskin May, 2010

AMCA LICENSED LEAKAGE AND AIR PERFORMANCE DATA

Ruskin Company certifies that the FD35 and FD35SS shown hereon are licensed to bear the AMCA Seal. The ratings shown are based on tests and procedures performed in accordance with AMCA Publication 511 and comply with the requirements of the AMCA Certified Ratings Program. The AMCA Certified Ratings Seal applies to air performance for the FD35 and FD35SS.

To determine the AMCA Licensed air performance: Locate the applicable feet per minute face velocity on the bottom of the velocity vs. pressure drop chart below. Move up the chart to the most appropriate size damper line. From the intersection point, move left to determine the pressure drop on the left side of the chart.

VELOCITY vs. PRESSURE DROP

PRESSURE DROP (INCHES W.G.)

FACE VELOCITY FEET/MINUTE AMCA Fig. 5.3

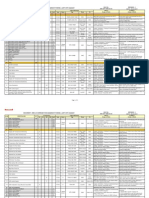

DAMPER DIMENSIONAL DATA

5 (127) Sleeve Length 18 (406) 71/2 (191)

71/2 (191)

Sleeve Dimensions

48 (1219) Max.

90 (2286) Max.

96 (2438) Max.

120 (3048) Max.

FD35SS Multiple Section

FD35 Multiple Section

FUSE LINK ADJUSTMENT

To Test or Replace the Fuse Link 1. Loosen the nuts on the J-bolt (Do not remove the nuts all together). 2. Remove the truarc ring. 3. Turn the jackshaft to open the damper and remove the fuse link. 4. Cycle the damper full open to full close positions, making sure the damper operates freely. The damper should be able to spring closed in any position. 5. Replace the fuse link and adjust the damper into the original position. Note: The damper can be adjusted in any position for volume control operation.

6 3 2

CAUTION

Damper assembly is under spring tension. Care should be taken to avoid bodily injury or damage to the damper assembly.

ITEM DESCRIPTION 1. Multiple Blade Fire Damper 2. Fusible Link Issue E 3. Fuse Link Linkage 4. J-Bolt 5. Truarc Ring 1/4 (6) 6. Over Center Linkage 7. Jackshaft Assembly

4 5 7

SLEEVE TRANSITION DIMENSIONAL INFORMATION

DUCT TRANSITION CONNECTIONS FD35 and FD35SS dampers may be supplied with Round, Oval and Rectangular duct connections. Style B R CR WR C WC LO CO WO Description Units Under 6 (152) Tall Round Non-Sealed (Low Pressure) Round Sealed (Medium Pressure) Round Welded (High Pressure) Rectangular Sealed (Low and Medium Pressure) Rectangular Welded (High Pressure) Oval Non-Sealed (Low Pressure) Oval Sealed (Medium Pressure) Oval Welded (High Pressure) MINIMUM and MAXIMUM SIZES Round Transitions Minimum 6 (152) diameter Maximum FD35 94 (2388) diameter Maximum FD35SS 46 (1168) diameter Rectangular and Oval Transitions Minimum 6w x 4h (152 x 102) diameter Maximum FD35 118w x 94 (2997 x 2388) Maximum FD35SS 88w x 46 (2235 x 1168) B Style Transitions Minimum height 4 (102) B style transitions are utilized on units where the damper height is less than 6 (152). Consult Ruskin for other available styles and sizes. Note: For medium pressure units (Styles CR, C and CO) the collar extends 11/2 (38) beyond the sleeve length and for low pressure and high pressure units (Styles R, WR, WC and LO) the collar extends 21/2 (64) beyond the sleeve length.

The square damper size will be 2 (51) larger in width and height than the round, oval or rectangular duct size ordered.

Sleeve Length

A + 2 (51)

Sleeve Length

A + 2 (51)

B + 2 (51) B

B + 2 (51)

A Sleeve Length

See Note

Style C and WC

Sleeve Length

See Note

Style LO, CO and WO

Dia. + 2 (51)

6 (152) B

Dia + 2 (51)

Style B

Diameter

See Note

Style R, CR and WR

SUGGESTED SPECIFICATION

Furnish and install at locations shown on plans or as described in schedules AMCA Certified fire dampers constructed and tested in accordance with UL Safety Standard 555 that meet or exceed the following specifications. Fire Dampers shall be produced in an ISO 9001 certified factory. Damper frame, where size permits, shall be constructed using Uniframe Design Concept (UDC) and shall be minimum 16 gage (1.52) galvanized steel [or stainless steel] formed into a structural hat channel superior to 13 gage (2.30) channel frame. Top and bottom frame members on dampers less than 12 high shall be low profile design to maximize the free area of these smaller dampers. Damper blades shall be single skin 16 gage (1.52) galvanized steel [or stainless steel] with three longitudinal grooves for reinforcement. Bearings shall be stainless steel sleeve turning in an extruded hole in the frame for maximum life. Each fire damper shall have a 11/2 hour fire protection rating and shall be supplied with a 165F (74C) or 212F (100C) fusible link. Fire dampers shall be approved for vertical or horizontal mounting as required by the location and shall be installed using steel sleeves, angles and other materials and practice required to provide an installation in accordance with the damper manufacturers installation instructions. In addition, the fire dampers shall be AMCA licensed for air performance and shall bear the AMCA Certified Ratings Seal. The FD35 and FD35SS carry a 11/2 hour UL fire damper label and is classified as a static damper for use in HVAC systems that shut down during a fire. Optional FM Approvals Specification Each fire damper shall be listed in Factory Mutual (FM) Approvals Specification Tested Product and labeled accordingly. Fire dampers shall be Ruskin model FD35 (or FD35SS). (Consult www.ruskin.com for electronic version of this Quick spec as well as for complete 3- part CSI MasterFormat Specifications)

3900 Dr. Greaves Rd. Kansas City, MO 64030 (816) 761-7476 FAX (816) 765-8955 www.ruskin.com

Printed on recycled paper using vegetable based inks

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- 1B 2 1 Types Fire PumpsDokument25 Seiten1B 2 1 Types Fire Pumpsharoub_nasNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Answer Key of Revision Worksheet TA-2Dokument6 SeitenAnswer Key of Revision Worksheet TA-2Nedunuri.Madhav MurthyNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- 02-Construction Manager Civil BuildingsDokument2 Seiten02-Construction Manager Civil BuildingsNedunuri.Madhav MurthyNoch keine Bewertungen

- Draft Letter - High RiseDokument1 SeiteDraft Letter - High RiseNedunuri.Madhav MurthyNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Dongre Associates Balance Work/snag List 10th Floor: Tower QC 2, Gift CityDokument6 SeitenDongre Associates Balance Work/snag List 10th Floor: Tower QC 2, Gift CityNedunuri.Madhav MurthyNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Toilet No 15MM 20MM 15Mm Insulation T1 T2 T3 T4 T5 T6 T7 T8 T9 T10 T11 T12 T13 T14 T15 T16 Actual Rate of Each Toilet From Old MeasurementDokument1 SeiteToilet No 15MM 20MM 15Mm Insulation T1 T2 T3 T4 T5 T6 T7 T8 T9 T10 T11 T12 T13 T14 T15 T16 Actual Rate of Each Toilet From Old MeasurementNedunuri.Madhav MurthyNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Accoustic Results SummaryDokument1 SeiteAccoustic Results SummaryNedunuri.Madhav MurthyNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- MOM of MEP Meeting 16 11 2012 - XLSXDokument2 SeitenMOM of MEP Meeting 16 11 2012 - XLSXNedunuri.Madhav MurthyNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Balance Works Planning-Qc2Dokument2 SeitenBalance Works Planning-Qc2Nedunuri.Madhav MurthyNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- BMT Check List - XLSXDokument6 SeitenBMT Check List - XLSXNedunuri.Madhav MurthyNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- 18th Floor Snag ListDokument1 Seite18th Floor Snag ListNedunuri.Madhav MurthyNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Order Details: Order ID: SAP14050587113 Order Date: Mon 5th May 2014 12:26pmDokument1 SeiteOrder Details: Order ID: SAP14050587113 Order Date: Mon 5th May 2014 12:26pmNedunuri.Madhav MurthyNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- ETA SummeryDokument1 SeiteETA SummeryNedunuri.Madhav Murthy100% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Response by ETA Response by HAIL Response by ANCDokument14 SeitenResponse by ETA Response by HAIL Response by ANCNedunuri.Madhav MurthyNoch keine Bewertungen

- Madhava ResumeDokument5 SeitenMadhava ResumeNedunuri.Madhav MurthyNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- BMS IO Summary For QC2 R1 20.02.2013Dokument9 SeitenBMS IO Summary For QC2 R1 20.02.2013Nedunuri.Madhav Murthy100% (2)

- Case Study Analysis of Apex Corporation PDFDokument2 SeitenCase Study Analysis of Apex Corporation PDFAJNoch keine Bewertungen

- STR Mpa-MpmDokument8 SeitenSTR Mpa-MpmBANGGANoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Steel-Concrete Composite Building Under Seismic Forces, D. R. Panchal (Research) PDFDokument9 SeitenSteel-Concrete Composite Building Under Seismic Forces, D. R. Panchal (Research) PDFsmartman35100% (1)

- Online Bank SynopsisDokument7 SeitenOnline Bank SynopsisPrashant VermaNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Data Structures and Algorithms: (CS210/ESO207/ESO211)Dokument24 SeitenData Structures and Algorithms: (CS210/ESO207/ESO211)Moazzam HussainNoch keine Bewertungen

- Manual Ni Usrp 2920Dokument56 SeitenManual Ni Usrp 2920Anghye Plata100% (1)

- Superb 2 Aditional HeaterDokument2 SeitenSuperb 2 Aditional Heaterpalle larsenNoch keine Bewertungen

- Module Tes Answer Key: Student B Student ADokument2 SeitenModule Tes Answer Key: Student B Student AKremena KoevaNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- System Failure AnalysisDokument9 SeitenSystem Failure AnalysisHermance Yosepf Setiarto Harimurti50% (2)

- Case Study #3 ThermodynamicsDokument6 SeitenCase Study #3 ThermodynamicsColeene Forteza100% (1)

- Conversion of A Scroll Compressor To An Expander For Organic Rankine Cycle: Modeling and AnalysisDokument162 SeitenConversion of A Scroll Compressor To An Expander For Organic Rankine Cycle: Modeling and Analysisdr_kh_ahmed100% (1)

- ZX60-P105LNDokument4 SeitenZX60-P105LNMuhammad AsadNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- LC 2539Dokument16 SeitenLC 2539Kelly JonesNoch keine Bewertungen

- Blue Solar Charge Controller MPPT: NOT AcceptedDokument12 SeitenBlue Solar Charge Controller MPPT: NOT Accepted1382aceNoch keine Bewertungen

- Structural Equation Model : Determinant of Customer Satisfaction and It S Implications On Customer EngagementDokument15 SeitenStructural Equation Model : Determinant of Customer Satisfaction and It S Implications On Customer EngagementGSA publishNoch keine Bewertungen

- Biochemical Oxygen DemandDokument18 SeitenBiochemical Oxygen DemandUnputdownable Bishwarup100% (1)

- AOO Personal Information FDokument8 SeitenAOO Personal Information FOdhiambo OwinoNoch keine Bewertungen

- Accounts Payable by ORACLEUGDokument164 SeitenAccounts Payable by ORACLEUGPraveenReddyBNoch keine Bewertungen

- Indonesia's First Maritime Service Solution Provider: Company ProfileDokument10 SeitenIndonesia's First Maritime Service Solution Provider: Company Profilemuh_akbar2451Noch keine Bewertungen

- Shear Stress Though Tapered Pipe Thread - Eng-TipsDokument4 SeitenShear Stress Though Tapered Pipe Thread - Eng-TipsrodrigoperezsimoneNoch keine Bewertungen

- GCash OrientationDokument27 SeitenGCash OrientationArmiel SarmientoNoch keine Bewertungen

- Session Plan CarpentryDokument8 SeitenSession Plan Carpentrymark abayonNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Operation and Maintenance Manual: Mux-2200E Integrated Service MultiplexerDokument82 SeitenOperation and Maintenance Manual: Mux-2200E Integrated Service Multiplexerlee.tetleie1675Noch keine Bewertungen

- Simple Free-Energy InformationDokument11 SeitenSimple Free-Energy InformationDrago MelovNoch keine Bewertungen

- GANTREX® MK6 Rail PadDokument4 SeitenGANTREX® MK6 Rail PadwickremasingheNoch keine Bewertungen

- Commercial Vehicles BrochureDokument20 SeitenCommercial Vehicles Brochurebinhtb14Noch keine Bewertungen

- AULA 13 - RespondidoDokument4 SeitenAULA 13 - RespondidoRanyelle WanessaNoch keine Bewertungen

- Synchronous LearningDokument3 SeitenSynchronous Learningaspittell3080Noch keine Bewertungen

- SMDokument36 SeitenSMharan2000Noch keine Bewertungen

- Dilg-Mbcrpp Isf Q2 2023Dokument2 SeitenDilg-Mbcrpp Isf Q2 2023Mallari GabrielNoch keine Bewertungen

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesVon EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNoch keine Bewertungen