Beruflich Dokumente

Kultur Dokumente

Analysis of Limit Cycles in An Indusirial Ox0 Reactor

Hochgeladen von

Tom MoltonOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Analysis of Limit Cycles in An Indusirial Ox0 Reactor

Hochgeladen von

Tom MoltonCopyright:

Verfügbare Formate

Chemicd Engineering Science. Printed in Great Britain.

Vol.

47.

No. 9-l

I. pp. 2547-2552.

1992.

NQ9-2509/92 $5.00+0.00 1992 Pergamon Press Ltd

ANALYSIS

P.W.M.

OF

LIMIT

CYCLES

IN AN

INDUSIRIAL

OX0

REACTOR

(present

Vleeschhouwer, University of Amsterdam, Department of Chemical Engineering address: Dow Benelux N.V ., P.0.Bo.x 48, 4530 AA Terneuzen, T?te Netherlands) R.D. Garton, Exxon Chemical International Inc., Hermeslaan 2, B-1831 Machelen, Belgium of

Chemical Engineering The Netherlands

J.M.H.

Portuin,

Nieuwe

University of Amsterdam, Department Achtergracht 166, 1018 WV Amsterdam,

INTRODUCTION in reaction engineering (list of The stability of reacting systems is an important item 1990) concerning perturbation analysis literature). A recent paper (Vleeschhouwer and Fortuin. of a reacting system has shown quantitative agreement between theoretically predicted and experimentally found dynamic behaviour of a 0.25 L cooled continuous stirred tank reactor with a first-order exothermic reaction. The same perturbation analysis accurately predicts the conditions under which the hydroformylation in an industrial 6000 L 0x0 reactor will operate in a state of self-sustained oscillation (Type 3, Table l), and the conditions under which the damped (Type 1). steady state will be either a spiral point (Type 2) or asymptotically Sustained oscillations of the reacting system in the industrial 0x0 reactor are unequivocally identified to be a classical limit cycle with regard to e.g. frequency, amplitude, wave shape simulated and measured frequencies and amplitudes of and operating conditions. Moreover, the temperature oscillations agree fairly well. The cobalt catalyzed 0x0 reaction has been well described in literature over many years. The main reaction chemistry involves the sequential conversion of a mixture of olefin isomers to aldehyde and alcohols: Olefins + Aldehydes + Alcohols, Over a significant range of conditions near the steady state, however, the system can exothermic reaction in order to apply directly effectively be reduced to a single, first order, the perturbation analysis results from the above-mentioned paper. In spite of the simplifying assumptions of a single reaction in a perfectly mixed reactor, the observed behaviour of an industrial 0x0 reactor agrees remarkably well with the predictions of perturbation theory as applied to a model system. 1. THE MODEL unsteady component and energy balances of a CSTR will be of the reacting system (Vleeschhouwer and Fortuin, 1990): cf (1 + c k,

7 c

The following the behaviour T dc/dt y 7 dT/dt

used

to describe

exp(-TA/T) T) + kc r (c/of) A,T hold: r rS and A,T (Ts Tr)

exP(-TA/T)

(1)

(2)

r/rh) conditions = 0 eqs

(Tr

Under dc/dt

steady-state 0

the following

equations T, in: A,T, ;

; dT/dt

of c, from T

; c (1)

cs

; T results -

(3)

Elimination =r TA

to (3) 1))]-1

[ln{k,

(A,T/A,T

where

A,T

A,T/(l+(r/Th))

(4)

Equation (4) represents a so-called Sshaped curve, i.e. the locus of points representing steady states at given values of kc, TA, hT, 7 and Th. If in the reacting system infinitesimally small perturbations bc. 6T and Sr from steadystate conditions occur the following equations hold:

2547

2548

P. H. M.

VLEESCHHOUWER

er

al.

D18

C-

ca

6f.2,

T,

6T and

rs

6r.

(5)

From eqs (1) to (5) and application to the reaction-rate equation: r k,

C exp(-T&T)

of

the

first-order

approximation

of

the

Maclaurin

series

(6)

it can

be

obtained 2A UsT

{(

that

(Vleeschhouwer + B2 I>(1 (6T) +

and -

Fortuin, 0. 7)

1990): (7) {7 (1 AsT/dmT))-l (8)

d2(6T)/dt2 where

d{GT)/dt TA/Tz -

: 2A B2 -

r/rh)/(r

A,T/A,,J)-

B2)

- A,T

2 TA/T,}(~

+ T/Th)/(Y

(9)

and

D-

4(A2

(10)

In eqs (8) and (9) the parameter 2A governs the dynamic behaviour of the reacting system, and the parameter B2 the slope of the S-shape curve. D is the diiriminant of the characteristic equation of eq. (7). If D C 0. the period 7C of the temperature oscillations after a perturbation 6T of the steady-state temperature of the reacting system follows from: rc 2ZlDI -t (11)

Each type of steady state has a specific combination of signs of the values of 2A, B2 and D respectively; each set of three signs indicates a separate steady-state type resulting in the six different steady-state types mentioned in Table 1 (Vleeschhouwer and Fortuin, 1990). TABLE I: TYPES of OF value B2 + + + + D + STEADY of STATE OF A CSTR

Type

t

1 2 3 4 5 6

Sign 2A

Behaviour after a perturbat ion asymptotic damping spiral point stable oscillations asymptotic oscillations transit ion transition

+ + +

+ + +

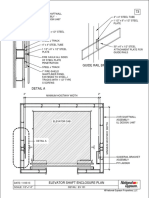

The family of One way to map the various types of steady state is shown in Fig-l. S-shaped curves can be calculated from Eq.(4), using the parameters from Tables 2 and 3. Each curve The curves differ only by the value of the heat-transfer parameter US. represents the locus of steady operating states as the reference temperature T, is varied, for T,. example, by changing the coolant temperature The locus of sign changes of 2A, B2 and D, may also be plotted on the same coordinates, The two showing the six regions where the six different steady-state types would exist. have steady states in the regions industrial examples, discussed in the following sections, and are both in the vicinity of the border identified by the small boxes shown in Fig.1 between Type 2 (spiral), and Type 3 (stable oscillation) steady states. 2. THE OX0 REACTION olefins and synthesis gas (CO, H2) to aldehydes and alcohols. The the industrial oxonation of mixed olefin isomers: Ai+B+C each of which has a different reaction rate; B Components Ai represents olefin isomers, which partially converts to 0x0 alcohol, component C. represents aldehyde. the main product, At a fixed concentration of catalyst and synthesis gas all the reactions are apparent first In the neighbourhood of the steady operating state the overall 0x0 order and irreversible. reaction scheme converts describes

The 0x0 following

D18

Analysis of limit cycles in an industrial 0x0 reactor

2549

reaction can be described by: A + B. where A is a single pseudo-component olefii and B represents all the products both parallel and sequential to the intermediate aldehyde, that are responsible for generating the heat of reaction. A single value of both the reaction-rate constant and the reaction enthalpy can be chosen such that a first-order model predicts both the degree of conversion of the feed and the reaction heat at the steady state being investigated (single-poiut collocation). The apparent activation energy is known from independant experiments and has not been adjusted. Note that the reaction parameters are no longer intensive properties but depend on operating variables. However, over the narrow operating conditions being considered, the first-order model is thought to be an adequate representation of the actual process. 3. THE INDUSTRIAL OX0 REACTOR The industrial 0x0 reactor is a gas-lift loop type with integral heat exchanger. Gas sparged loop reactors are common in the industry and may be of two types, either with an internal or an external recirculation loop. This one has an external loop as shown in Fig. 2. Cooling water flows through the heat exchanger at a high rate and is assumed to be effectively isothermal. The 0x0 reactor can be made to operate with a recirculation-to-feed ratio greater than 1O:l ; the temperature gradients in the reactor are relatively small. Kinetic and selectivity measurements show that the 0x0 reactor can be modelled as a CSTR. The values of the parameters concerning the reactors and the reacting system are presented in Table 2. All results reported for these reactors are for open loop operation. TABLE 2: VALUES REFERRING TO THE TWO INDUSTRIAL. value unit OX0 REACTORS.

symbo 1 REACTOR PARAMETERS effective mass of solid parts heat capacity of the reactor heat losses REACTING-SYSTEM PARAMETERS heat capacity of feed heat capacity of reacting liquid density of liquid in the reactor feed temperature activation temperature heat of reaction

(-AQ)

cP

10000 460 175000 2700 2400 650 303, (30) 11000 159000

kg ?

K-l W J J kg-l K-l

kg-l K-l kg mm3 K, (OC) K J 11101-l

Any backmixed reactor is subject to interaction of the mixing and the chemical reaction, especially during transients. During a steady state, however, whether a limit cycle or a point-stable state, the natural frequency of the present industrial reacting system under normal operating conditions is too low to be affected by or to affect the hydrodynamics of the reactor contents. The small axial temperature gradient that exists in the 0x0 reactor during steady-state operation also appears during the occurrence of a limit cycle. The overall heat-transfer coefficient is subject to fouling over time and the values used in this study were calculated by applying a heat balance on several steady states in the time frame of the experiments. Calculated results are not very sensitive to the heat losses or to the effective mass of the metallic parts of the 0x0 reactor, and reasonable estimates of these parameters were made. 4. LIMIT CYCLES IN TWO INDUSTRIAL OX0 REACTORS Two examples of limit-cycles obtained during operation of two industrial 0x0 reactors were selected to be compared to simulations and to the results of the perturbation analysis. Nominal steady-state operating conditions are summarized in Table 3. Figure 3, which refers to Reactor 1, shows a limit cycle of relatively large amplitude that was eliminated after increasing the coolant temperature by 4 w. The perturbation model predicts this steady state to be a limit cycle of relatively large amplitude according to the value of 2A and the position near the lower Hopf-bifurcation boundary (see Fig. 1). The model predicts a period of 26 minutes while the actual period was 25 minutes (see Table 3). Figures 3 and 4 compare the plant data with the numerical simulation for the reacting system in Reactor 1.

2550

P. H. M. VLEESCHHOUWER

sral.

D18

Figure 5 illustrates a limit cycle with a lower feed flow rate of higher concentration being fed to Reactor 2 of identical construction. A sustained oscillation in the oxo-reactor temperature occurred when the coolant temperature wag 158 C.

TABLE

3:

OPERATING

CONDITIONS

FOR

TWO INDUSTRIAL 1 Reactor 182 163+170 3.2 7.81 9.7.107 98000 3+2 25 26 17.7 5.2 1 1 Zeactor

OX0 2

REACTORS unit

symbol Steady-state temperature Coolant temperature Feed flow rate Feed concent rat ion Frequency fact or Heat transfer parameter Type of steady state Actual period Predicted period Residence time Effective liquid volume T,

TC @ Cf

US

TC 70 7

42

178 164 2.76 9.42 6-l-107 118000 3 28 28 20.5 5.2

C kg s-l mol kg-1 a-1 W K-l min min min m3

The steady state became a spiral point (Type 2) when the coolant temperature was reduced to 156 C, and the limit cycle reoccurred when the coolant temperature was increased to 160 C. Similar to the temperature in Reactor 1, the amplitude of the limit cycle can be decreased by increasing the coolant temperature. However, the behavlour of the reacting system in Reactor 2 shows that the coolant temperature can be reduced sufficiently to eliminate cyclic operation, but with the added risk that a transition to a large amplitude limit A detail of the limit cycle cycle can occur following a small change in operating conditions. at T, = 158 at the transition between C is shown in Fig. 5. The large peaks occur point-stable and cyclic operation as the coolant temperature is increased. At the conditions of Reactor 2. the perturbation model predicts that the lower boundary to large amplitude limit cycles would occur at T, = 162 *C, and the upper boundary between small amplitude C. A simulation of the oscillations and point-stable steady states would occur at T, = 177 in Reactor 2 shows a behaviour which is similar to that of the actual reacting system with a predicted period equal to the observed period of 28 minutes (see reacting system, The differences in steady-state Table 3). temperatures between the simulated and the measured data can be explained by the temperature gradients that exist in the industrial reactor. The data from the industrial reacting system represent the maximum temperature of the reactor contents and the minimum temperature of the coolant and not the effective isothermal operating conditions of an equivalent CSTR. 5. CONCLUSIONS Selfsustained oscillations of the temperature of the reacting system in a open-loop, industrial-ale 0x0 reactor have been unequivocally identified to be classical limit cycles. The based upon the frequency, wave shape and the operating conditions of the reactor. presented data referred to two different types of feed in two different 0x0 reactors. The industrial data show that the amplitude of a limit cycle decreases as the coolant temperature is increased, as predicted by theory and bench-scale experiments. From a should avoid conditions placing practical viewpoint, the design of an industrial 0x0 reactor near the lower Hopf-bifurcation boundary where dangerous the operating state anywhere Depending on how well an industrial reacting system can be temperature peaks can occur. the results of perturbation theory analysis alone are represented by first-order kinetics, adequate to identify the limitations of the 0x0 reactor design and operating conditions with regard to limit-cycle operation. the quantitative agreement between perturbation theory For the industrial examples presented, and the boundaries of cyclic operation are remarkable considering the first order single phase single reaction assumptions that were required to model the system.

D18

Analysis of limit cycles

in an industrial 0x0 reactor

255 1

NOTATION

2A 82

C

of CP CPf "Dpv kc m mw r S T TA

TC ; r

dynamic-condition slope-condition concentration concentration

parameter in eq.(8) parameter in eq.(9) of the key component of the key component in

s-1 s-2

average heat capacity heat capacity of the heat capacity of the asymptotic-condition

the feed of the reacting liquid feed solid parts of the reactor parameter in eq.(lO)

mol kg-l mol k -l J kg- Q K-1 J kg-l K-l J kg-l K-l

s-2 s-1 kg kg

t li AaT AmT 47

first-order reaction-rate constant in eq.(6) mass of the reaction liquid in the reactor mass of the solid parts of the reactor reaction rate heat-transfer surface area of the cooling tubes temperature of the reacting system in the reactor activation temperature inlet temperature of the coolant temperature of the feed reference temperature; the temperature of reactor contents during operation without chemical reaction, + 2-f - =,)(I + 7/7h)-l =r - T, + (AQ/GkCpf) time overall heat transfer coefficient of the cooling tubes adiabatic temperature rise, A,T (-AH cf)/C f

maXimUm temperature rise, dmT AaT/{ + 7/7h)

mol m2

s -1

K K K K K

S

AH

AQ Y 7

7C

7h 0

index s

steady-state temperature rise react ion enthalpy heat production due to mixing and stirring dimensionless heat capacity, y - Cp/Cpf + residence time, 7 - m/a period of an oscillation, ~~ - 2 x IDI-* heat conduction time, 7h m Cpf/US mass flow rate refers to steady-state conditions LITERATURE

m&,/(mCpf)

W mB2 K-l K K K J mol-I W 1

S S Eg s-1

Brandes, H., Hofmann H. Wicke, E. and Grundlagen der chemischen (I 964). Prozessregelung, Beiheft zur Zeitschrift Regelungstechnik, R. Oldenbourg Verlag. Munchen. Heemskerk, A.H. Dynamical hehaviour of liquid-phase reaction systems, (I980), Ph.D.Thesis, University of Amsterdam, Amsterdam, The Netherlands - Heerden, van C. (1953), Autothermic processes, properties and reactor design, Ind. Engng.

Chem. 45, 1242. - Hugo, P. and Wirges, H.P. (1978). Theoretical and experimental study of self-sustained oscillations in a stirred tank reactor, ACS Symp. Ser.. 65, 498. - Uppal. A., Ray, W.H. and Poore, A.B. (1974). On the dynamic behavior of continuous stirred tank reactors, Chem. Engng. Sci., 29, 967. - Vermeulen. D.P. (1986), Transient hehaviour of a chemical reaction system in a CSTR, Ph.D.Thesis, University of Amsterdam, Amsterdam, The Netherlands - Vleeschhouwer, P.H.M. and Fortuin, J.M.H. (1990). Theory and experiments concerning the stability of a reacting system in a CSTR, A.1.Ch.E. Journal 36, 961. - Vleeschhouwer, P.H.M (1991), The hehaviour of a reacting system during batchwlse and continuous operation, Ph.D.Thesis, University of Amsterdam, Amsterdam, The Netherlands.

2552

P. H.

M.

VLEESCHHOUWER

et ui.

D18

I FWd+w

Fig.1: Steady of T, states and US. at various values ig.2: Gas-lift industrial loop-type scale (6 0x0 m ). reactor:

200

190

I80

;____________r

M

.__

0

I440 28M 4320 S760 7200 6640 10080 II520 12p60 14400

Fig.3:

Measured reacting

tcmperoturc system in 0x0

oscillations Reactor 1.

of

the

ig.4:

Simulated reacting

temperature system in 0x0

oscillations Reactor 1.

of

the

240.

Fig.5:

Measured reacting

temperature system in 0x0

oscillations Reactor 2.

of

the

Fig.6:

Simuloted reacting

temperature system in 0x0

oscillations Reactor 2.

of

the

Das könnte Ihnen auch gefallen

- Adiabatic Reactors Final Lab Group 1-ADokument22 SeitenAdiabatic Reactors Final Lab Group 1-AHaris SheikhNoch keine Bewertungen

- Reactor Design ProjectDokument13 SeitenReactor Design ProjectSusi UmifarahNoch keine Bewertungen

- Dimitris Achlioptas Ucsc Bsoe Baskin School of EngineeringDokument22 SeitenDimitris Achlioptas Ucsc Bsoe Baskin School of EngineeringUCSC Students100% (1)

- Lab Report CSTR 40LDokument26 SeitenLab Report CSTR 40LAnonymous NyvKBW33% (3)

- Stoichiometric TableDokument22 SeitenStoichiometric TableMark Antony LevineNoch keine Bewertungen

- Art6 WesterterpDokument8 SeitenArt6 WesterterpCristhian GómezNoch keine Bewertungen

- Parametric Sensitivity and Runaway in Tubular ReactorsDokument9 SeitenParametric Sensitivity and Runaway in Tubular ReactorsHyun Tae HwangNoch keine Bewertungen

- Tutorial 1 2018Dokument6 SeitenTutorial 1 2018EstherNoch keine Bewertungen

- Lab Report CSTR 40LDokument26 SeitenLab Report CSTR 40LHazieqahNoch keine Bewertungen

- Chapter 8 - Steadystate Non-Isothermal ReactorDokument49 SeitenChapter 8 - Steadystate Non-Isothermal ReactorAbdul Majid IaNoch keine Bewertungen

- Models - Heat.turbulent Heat ExchangerDokument18 SeitenModels - Heat.turbulent Heat ExchangerMaximiliano FaríaNoch keine Bewertungen

- ExercisesDokument13 SeitenExercisesRajpriya GuptaNoch keine Bewertungen

- Optimization of A Sofc System: Influence of Design and Operation Parameters On System EfficincyDokument8 SeitenOptimization of A Sofc System: Influence of Design and Operation Parameters On System Efficincy10 000 de cartiNoch keine Bewertungen

- Keywords: Steam Reforming, Dynamics, Hydrogen, Fuel Cell, SimulationDokument7 SeitenKeywords: Steam Reforming, Dynamics, Hydrogen, Fuel Cell, SimulationMuhammad HarisNoch keine Bewertungen

- Anleitung CVT B EnglischDokument14 SeitenAnleitung CVT B EnglischN193746Noch keine Bewertungen

- Rxn10 - FEMLAB-Fixed Bed ReactorDokument15 SeitenRxn10 - FEMLAB-Fixed Bed ReactorvijendranbNoch keine Bewertungen

- Stirred Tank by MAUREENDokument27 SeitenStirred Tank by MAUREENJimNoch keine Bewertungen

- Cstr-Experiment 2Dokument7 SeitenCstr-Experiment 2Dhiyyah MardhiyyahNoch keine Bewertungen

- Design of A Plug Flow Reactor (PFR) : Parameters ValuesDokument10 SeitenDesign of A Plug Flow Reactor (PFR) : Parameters ValuesDee RajanNoch keine Bewertungen

- Lab 1 - CSTRDokument22 SeitenLab 1 - CSTRnur athilahNoch keine Bewertungen

- R05320802chemicalreactionengineeringiiDokument8 SeitenR05320802chemicalreactionengineeringiiSanthosh KumarNoch keine Bewertungen

- Therm Is TorDokument4 SeitenTherm Is TorJashim UddinNoch keine Bewertungen

- Chemical Reactors: DC DT RDokument8 SeitenChemical Reactors: DC DT ROsas Jessica UwoghirenNoch keine Bewertungen

- Thermo Dynamics Question BankDokument3 SeitenThermo Dynamics Question Banknisar_ulNoch keine Bewertungen

- CSTRDokument25 SeitenCSTRAinul Mardhiah Abdul Rahim100% (1)

- HW 2 K 1606Dokument7 SeitenHW 2 K 1606Primus OngNoch keine Bewertungen

- Iodination of Acetone 1Dokument6 SeitenIodination of Acetone 1Felecia SotilleoNoch keine Bewertungen

- Intercompany Memorandum: Cal Chem Corporation To: Date: Fall Quarter File: CHE 435 FromDokument5 SeitenIntercompany Memorandum: Cal Chem Corporation To: Date: Fall Quarter File: CHE 435 FromChong Ru YinNoch keine Bewertungen

- CHE273 Vacation AssignmentDokument6 SeitenCHE273 Vacation AssignmentmustafaNoch keine Bewertungen

- Adiabatic FBR DesignDokument10 SeitenAdiabatic FBR DesignRana UzairNoch keine Bewertungen

- Liquid Phase ReactorDokument22 SeitenLiquid Phase Reactorkrishy19s100% (2)

- Energy Balances On Non-Reactive Processes PDFDokument36 SeitenEnergy Balances On Non-Reactive Processes PDFMohammed AlmoriseyNoch keine Bewertungen

- Lecture 20: The Fixed Bed Catalytic Reactor: RXN RXNDokument10 SeitenLecture 20: The Fixed Bed Catalytic Reactor: RXN RXNreddi ramuNoch keine Bewertungen

- Reactor Physics Calculations For The Control of The Advanced Neutron Source ReactorDokument8 SeitenReactor Physics Calculations For The Control of The Advanced Neutron Source ReactorleelavinodhanNoch keine Bewertungen

- rr220802 Chemical Engineering Thermodynamics IDokument8 Seitenrr220802 Chemical Engineering Thermodynamics ISRINIVASA RAO GANTANoch keine Bewertungen

- Acetone Project StatementDokument7 SeitenAcetone Project StatementAmr TarekNoch keine Bewertungen

- Fund Chem Reax Eng CH 9Dokument29 SeitenFund Chem Reax Eng CH 9Alaa HussienNoch keine Bewertungen

- Ammonia SynthesisDokument9 SeitenAmmonia SynthesisMohammed Shafi AhmedNoch keine Bewertungen

- R5210305 ThermodynamicsDokument1 SeiteR5210305 ThermodynamicssivabharathamurthyNoch keine Bewertungen

- Models - Chem.multicomponent Tubular ReactorDokument24 SeitenModels - Chem.multicomponent Tubular ReactorsutrimaNoch keine Bewertungen

- DeneyDokument13 SeitenDeneyTuğbaNoch keine Bewertungen

- Code: 9A03302 B.Tech II Year I Semester (R09) Regular & Supplementary Examinations December/January 2013/14Dokument4 SeitenCode: 9A03302 B.Tech II Year I Semester (R09) Regular & Supplementary Examinations December/January 2013/14sivabharathamurthyNoch keine Bewertungen

- Batch ReactorDokument12 SeitenBatch ReactorShashi RaajNoch keine Bewertungen

- DBPS ProjectDokument12 SeitenDBPS ProjectitsinyagainNoch keine Bewertungen

- Theory of DistillationDokument18 SeitenTheory of DistillationjaviercdeaeNoch keine Bewertungen

- HE3 - Semi-Batch Reactor - Text PDFDokument5 SeitenHE3 - Semi-Batch Reactor - Text PDFAmesh ChiyogamiNoch keine Bewertungen

- 1415 Exam 1 (ICP) (EN)Dokument5 Seiten1415 Exam 1 (ICP) (EN)김하은Noch keine Bewertungen

- Fuel Cell 3-D Modelling Using A Logarithmic Approximation in MATLAB &simulinkDokument10 SeitenFuel Cell 3-D Modelling Using A Logarithmic Approximation in MATLAB &simulinkSahar ShNoch keine Bewertungen

- QBTD NPH RulesDokument2 SeitenQBTD NPH RulesAarya JohnNoch keine Bewertungen

- CSTR 40LDokument16 SeitenCSTR 40LhishamNoch keine Bewertungen

- Boon PinDokument13 SeitenBoon PinjayaprinaNoch keine Bewertungen

- 19me3dcetd Etd Question BankDokument3 Seiten19me3dcetd Etd Question BankPratyush NandanNoch keine Bewertungen

- A Modern Course in Statistical PhysicsVon EverandA Modern Course in Statistical PhysicsBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringVon EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNoch keine Bewertungen

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasVon EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNoch keine Bewertungen

- QW 3151Dokument5 SeitenQW 3151Tom MoltonNoch keine Bewertungen

- Estimating The Impact of Grade Retention: A Heterogenous AnalysisDokument34 SeitenEstimating The Impact of Grade Retention: A Heterogenous AnalysisTom MoltonNoch keine Bewertungen

- American Political Science AssociationDokument3 SeitenAmerican Political Science AssociationTom MoltonNoch keine Bewertungen

- LijphartDokument3 SeitenLijphartTom MoltonNoch keine Bewertungen

- Question 5Dokument1 SeiteQuestion 5Tom MoltonNoch keine Bewertungen

- Guide Rail Bracket AssemblyDokument1 SeiteGuide Rail Bracket AssemblyPrasanth VarrierNoch keine Bewertungen

- English Literature Coursework Aqa GcseDokument6 SeitenEnglish Literature Coursework Aqa Gcsef5d17e05100% (2)

- Calculating Measures of Position Quartiles Deciles and Percentiles of Ungrouped DataDokument43 SeitenCalculating Measures of Position Quartiles Deciles and Percentiles of Ungrouped DataRea Ann ManaloNoch keine Bewertungen

- PCI Secure Software Standard v1 - 0Dokument67 SeitenPCI Secure Software Standard v1 - 0Antonio ClimaNoch keine Bewertungen

- Ansi Numerical CodeDokument6 SeitenAnsi Numerical Codekachra13Noch keine Bewertungen

- Nanomedicine Lecture 2007Dokument59 SeitenNanomedicine Lecture 200778912071Noch keine Bewertungen

- Opening The Third EyeDokument13 SeitenOpening The Third EyekakamacgregorNoch keine Bewertungen

- SAP IAG Admin GuideDokument182 SeitenSAP IAG Admin GuidegadesigerNoch keine Bewertungen

- User Manual - Wellwash ACDokument99 SeitenUser Manual - Wellwash ACAlexandrNoch keine Bewertungen

- Araldite 2020 + XW 396 - XW 397Dokument6 SeitenAraldite 2020 + XW 396 - XW 397Paul Dan OctavianNoch keine Bewertungen

- Brain Alchemy Masterclass PsychotacticsDokument87 SeitenBrain Alchemy Masterclass Psychotacticskscmain83% (6)

- Physiology of Eye. Physiology of VisionDokument27 SeitenPhysiology of Eye. Physiology of VisionSmartcool So100% (1)

- Software Requirements SpecificationDokument9 SeitenSoftware Requirements SpecificationSu-kEm Tech LabNoch keine Bewertungen

- Kharrat Et Al., 2007 (Energy - Fuels)Dokument4 SeitenKharrat Et Al., 2007 (Energy - Fuels)Leticia SakaiNoch keine Bewertungen

- Grade 10 LP Thin LensDokument6 SeitenGrade 10 LP Thin LensBrena PearlNoch keine Bewertungen

- Adore You - PDFDokument290 SeitenAdore You - PDFnbac0dNoch keine Bewertungen

- Anin, Cris Adrian U. Experiment Water Flirtation ELECTIVE 103Dokument2 SeitenAnin, Cris Adrian U. Experiment Water Flirtation ELECTIVE 103Cris Adrian Umadac AninNoch keine Bewertungen

- Local, Local Toll and Long Distance CallingDokument2 SeitenLocal, Local Toll and Long Distance CallingRobert K Medina-LoughmanNoch keine Bewertungen

- DLP in EmpowermentDokument13 SeitenDLP in EmpowermentTek Casonete100% (1)

- Mechanical Vibration and Oscillation in Transmission LinesDokument27 SeitenMechanical Vibration and Oscillation in Transmission LinesChhatrapal SinghNoch keine Bewertungen

- Pinto pm5 Tif 02Dokument24 SeitenPinto pm5 Tif 02Salem BawazirNoch keine Bewertungen

- Problem Solving Questions: Solutions (Including Comments)Dokument25 SeitenProblem Solving Questions: Solutions (Including Comments)Narendrn KanaesonNoch keine Bewertungen

- Indiana Property Tax Benefits: (This Form Must Be Printed On Gold or Yellow Paper)Dokument2 SeitenIndiana Property Tax Benefits: (This Form Must Be Printed On Gold or Yellow Paper)abramsdcNoch keine Bewertungen

- Bai Tap Avtc2 PrepositionsDokument5 SeitenBai Tap Avtc2 PrepositionsShy NotNoch keine Bewertungen

- RELATIVE CLAUSES 1º Bachillerato and KeyDokument3 SeitenRELATIVE CLAUSES 1º Bachillerato and Keyrapitanoroel0% (2)

- E10.unit 3 - Getting StartedDokument2 SeitenE10.unit 3 - Getting Started27. Nguyễn Phương LinhNoch keine Bewertungen

- Reflection Frog 1Dokument3 SeitenReflection Frog 1mariamNoch keine Bewertungen

- Acc 13 Februari 23 PagiDokument19 SeitenAcc 13 Februari 23 PagisimbahNoch keine Bewertungen