Beruflich Dokumente

Kultur Dokumente

Power JA04 Dahanu

Hochgeladen von

spalaniyandi0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

227 Ansichten3 SeitenAnil Ambani is chairman of India's largest power company, Reliance energy. His company owns 885 MW worth of power plants in the states of Maharashtra, goa, and Andhra Pradesh. The company's 500-MW coal-fired Dahanu Thermal Power Station is a top plant of 2004. It consistently ranks among the cleanest--as well as the most reliable--generating stations.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAnil Ambani is chairman of India's largest power company, Reliance energy. His company owns 885 MW worth of power plants in the states of Maharashtra, goa, and Andhra Pradesh. The company's 500-MW coal-fired Dahanu Thermal Power Station is a top plant of 2004. It consistently ranks among the cleanest--as well as the most reliable--generating stations.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

227 Ansichten3 SeitenPower JA04 Dahanu

Hochgeladen von

spalaniyandiAnil Ambani is chairman of India's largest power company, Reliance energy. His company owns 885 MW worth of power plants in the states of Maharashtra, goa, and Andhra Pradesh. The company's 500-MW coal-fired Dahanu Thermal Power Station is a top plant of 2004. It consistently ranks among the cleanest--as well as the most reliable--generating stations.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

TOP PLANTS

Dahanu Thermal Power Station,

Dahanu Taluka, India

Owner/operator: Reliance Energy Ltd.

Although this nine-year-old, 500-MW power plant is coal-fired, it consistently

ranks among the cleanest—as well as the most reliable—generating sta-

tions in India. In a developing country where air pollution is worsening,

the Dahanu Thermal Power Station disproves the notion that energy pro-

duction and environmental protection are mutually exclusive.

By Ken Wicker

ision, skill, and determination have 2004. Since it went on-line in 1995, Plant layout

V made Anil Ambani—chairman of

Mumbai-based Reliance Energy

Ltd.—a very successful man. With assets of

Dahanu (Figure 1) has earned a reputation

for being one of the most reliable, effi-

cient, and clean power plants in India.

Indeed, Dahanu showcases a number of

state-of-the-art technologies, some rarely

seen elsewhere in India:

$2.3 billion and annual revenues of $1.8 bil- Statistics validate that reputation. The

lion, his company has long been a force in most recent annual rating of Indian plants ■ A digital distributed control and manage-

India’s electric power sector. Reliance owns (see table) finds Dahanu at the top of four ment information system from Zurich-

885 MW worth of power plants in the states categories: load factor, heat rate, fewest based Asea Brown Boveri Inc. (ABB).

of Maharashtra, Goa, Andhra Pradesh, and trips, and fewest unplanned outages. ■ An electrohydraulic-converter turbine

Kerala, as well as power distributors serving According to Ambani, Dahanu has been governing system designed by Munich-

25 million customers in Mumbai (formerly successful because, “As the flagship station based Siemens and manufactured by New

Bombay), New Delhi, and Orissa. of Reliance’s fleet, it showcases our efforts Delhi–based Bharat Heavy Electricals

Among Reliance’s generating assets to generate power reliably, cleanly, and Ltd. (BHEL).

are two conventional combined-cycle cost-effectively, without compromising the ■ An electrostatic precipitator and low-NOx

plants totaling 385 MW, another one of health of our neighbors or the safety of our burner management system from BHEL.

48 MW powered by naphtha, and a 7.6- workers.” At Reliance, he explains, “The ■ Several concrete volute cooling water

MW wind farm. But it is the company’s drive to succeed starts at the top—with circulating pumps designed by Bergeron

500-MW coal-fired Dahanu Thermal me—and works its way down through the Rateau (Olympides, France) and manu-

Power Station—located 75 miles from corporate structure. That relentless pursuit factured by Kirloskar Brothers Ltd.

Mumbai on India’s west coast—that of excellence has helped make Dahanu a (Pune, India).

POWER is recognizing as a Top Plant of trend-setter in the Indian power industry.” ■ A stack and ambient air SO x /NO x -

monitoring system from St. Louis–based

Emerson Process Management.

■ An optical ground wire (OPGW) from

Toronto-based Phillips-Fitel Inc. that

gives Dahanu broadband Internet access.

Dahanu’s boiler, from BHEL, is a sin-

gle-drum, natural-circulation, radiant heat

and balanced-draft unit with tilting tangen-

tial burners. Its firing equipment includes

high-energy arc igniters, air-cooled oil

guns, low-NO x burners, and an infrared

remote flame monitoring system.

The plant’s twin Siemens KWU steam

turbines (each rated at 250 MW) are three-

pressure, condensing, tandem-compound,

single-shaft machines with reheat. Their

high-pressure turbine is single-cylinder

while the low-pressure turbine has a double-

flow cylinder. The generators driven by the

steam turbines are two-pole and were

1. Live long and prosper. India’s 500-MW Dahanu Thermal Power Station isn’t new, designed by Siemens and manufactured by

but POWER is nonetheless honoring it for its track record of operations and environmental

BHEL. Their rotor and stator windings are

excellence. Courtesy: Reliance Energy Ltd.

hydrogen-cooled by units within the genera-

46 www.powermag.platts.com POWER | July/August 2004

TOP PLANTS

One reason Dahanu has been able to

Dahanu’s eight-year track record

operate so cleanly is its single stack; from a

height of 900 feet, it disperses emissions

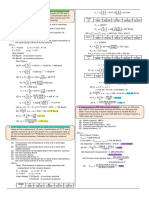

Fiscal Load factor Availability Heat rate Trips Unplanned

year (%) factor (%) (Btu/kWh) per 1,000 hours outages

over a wide area. Another is the plant’s elec-

trostatic precipitator (Figure 3), which col-

1996–97 73.19 80.25 9,412 3.2714 60 lects 99.9% of flyash and particulates. Yet

1997–98 85.00 90.49 9,270 1.8293 32 another reason is constant monitoring of

1998–99 76.55 92.24 9,274 1.2376 25 emissions. Four ambient air quality stations

1999–00 88.68 98.42 9,178 0.2892 9 let operators know how much pollution is

escaping the plant’s emissions-reduction

2000–01 82.68 92.33 9,178 1.2982 24

systems. Reliance uses a van to monitor air

2001–02 87.83 93.02 9,206 0.2455 7 quality over a larger area.

2002–03 90.53 91.03 9,175 0.6270 16 Dahanu also has excellent health and

2003–04 100.34a 96.84 8,988a 0.1170a 4a safety records and is an active member of

Note: a. Best in India the National Safety Council of India.

Majumdar says internal and external safety

Source: Reliance Energy Ltd. audits are conducted on a regular basis. The

plant holds the Indian record for the longest

tors’ frames, which are pressure-resistant, the area—but that’s not the case. According accident-free period—1,267 days—and

gas-tight, and equipped with end shields. to Majumdar, it is consistently one of the won a National Safety Award in 2001 in

Power leaves Dahanu on nine 220-kV lines. least polluting coal-fired power plants in recognition of its safety performance. It is

Dahanu was the first power plant in the country. equipped with a closed-circuit TV system

India to adopt the ISO 9001 quality man- The O&M systems also play a big part and a state-of-the-art fire protection system

agement system and ISO 14001 environ- in keeping Dahanu profitable. All competi- with the latest in safety controls.

mental management system. Has following tive markets, including India’s, reward the

best practices made a difference? Take lowest-cost generators. In an effort to mini- A well-trained, satisfied staff

another look at the table; the plant’s key mize Dahanu’s generating costs, Reliance Like most businesses in India, Dahanu has

operating statistics typically have improved has put all of its business processes— a large staff. In addition to its 188 execu-

year after year. Sophisticated equipment is including the ones used to manage money tives, the plant has 308 nonexecutive

partially responsible for Dahanu’s world- and manpower—under the umbrella of an employees. Typically, about 250 contract

class performance. But so is plant manage- enterprise resource planning (ERP) system. laborers also can be found working there at

ment’s systemic approach to operations and Supplied by Ramco Systems Ltd. (Chennai, any time.

maintenance—the domain of Prabir K. India), the ERP system integrates the Majumdar manages some very skilled

Majumdar, Dahanu’s deputy general man- plant’s O&M and materials-management people. All of his engineers are graduates

ager of O&M (Figure 2). systems while providing links to human of reputable universities and have at least

resources, purchasing, financials, and con- one year of in-house O&M training under

It’s the systems, Sahib tract-management applications and data. their belt. The training program includes

According to Majumdar, Dahanu’s man- Dahanu is the first Indian power plant to time in the classroom, on-the-job training,

agement has always used modern power use such a system. Majumdar says it has work on a simulator, and a visit to the man-

station O&M practices to keep the plant helped managers implement best practices ufacturing facilities of one of the plant’s

running reliably and efficiently. “To and departments operate more uniformly. equipment suppliers. The Central Electrici-

achieve those goals,” he says, “we use ty Authority of India has accredited

automation wherever possible and insist Emissions and safety Dahanu’s training center as a Class-I Insti-

that all procedures be strictly followed.” At management tute for Power Plant Engineers.

Dahanu, there are automated systems for: Dahanu’s environmental management sys- It was Majumdar’s idea to make the sim-

tem helps keep the plant’s airborne emis- ulator sessions part of the training program,

■ Operations management and performance sions within the prescribed limits of

monitoring Maharashtra’s Pollution Control Board

■ Condition-based maintenance management and India’s National Ambient Air Quality

■ Comprehensive fuel management Standards. Says Majumdar, “Our emis-

■ Quality management sions levels are also well below World

■ Safety management Bank limits. But we’re constantly striving

■ Environmental management to lower them even further.”

■ Spares management Over the past seven years, Reliance and

the Dahanu plant have won eight awards for

The plant’s fuel-management system—a environmental performance. The two most

first in India—precisely controls the blend- prestigious were the Millennium Business

ing of low-ash, low-sulfur Indian and Award for Environmental Achievement—

Indonesian coals. It even oversees a coal- given to the plant in 2000 by the United

washing facility at the Indian mine where Nations and the International Chamber of 2. Taskmaster. Prabir K. Majumdar,

Dahanu’s deputy general manager of O&M,

80% of the plant’s fuel comes from. Burn- Commerce—and a 1999 Environment Per-

in the central control room. Courtesy:

ing 2.1 million tons of coal annually, formance Award from the Indian Council of

Reliance Energy Ltd.

Dahanu could easily be a major polluter in Power Utilities.

48 POWER | July/August 2004

TOP PLANTS

turnover. Another reason employees are

loyal is their fondness for the plant’s cricket

stadium, library, swimming pool, and gym-

nasium—all provided by Reliance.

Good neighbor policy

Management of the Dahanu plant takes its

corporate responsibility seriously. Reliance

supports various community initiatives and

social activities in and around Dahanu

Taluka, a predominantly rural area where

the main occupations are fishing and farm-

ing. Several of the programs that Reliance

pays for or subsidizes enable or help local

children to get an education. The plant also

has funded the construction of schools and

sea walls and the maintenance of local

dams.

To date, Dahanu has spent about

$550,000 on various community develop-

3. Air cleaner. Dahanu’s electrostatic precipitator, from Bharat Heavy Electricals Ltd., is ment activities and Majumdar is proud of

99.9% efficient. Courtesy: Reliance Energy Ltd. that figure. However, he’s unwilling to

let the plant rest on its laurels. “We’re

constantly looking for ways to help the

to make his engineers more familiar with all are trained to do just a few tasks and do community. Recently, for example, we

of the plant’s many sophisticated systems. them well. But Majumdar believes that vari- modernized the local train station. That

Majumdar is also a big fan of cross-training, ety in a daily regime makes a job interesting kind of behavior does not go unnoticed

which is an alien concept in developing and helps ensure that top personnel stick by the community. They are very appre-

nations. Elsewhere, O&M types typically around. In his department, there is little ciative of our philanthropy.” ■

50 POWER | July/August 2004

Das könnte Ihnen auch gefallen

- Hvac Factsheet BasicsDokument3 SeitenHvac Factsheet BasicsAnwar SyedNoch keine Bewertungen

- Air BechtelDokument34 SeitenAir BechtelBhargav ChaudhariNoch keine Bewertungen

- Combined Cycle Gas Turbine Gyanendra Sharma NPTI DelhiDokument148 SeitenCombined Cycle Gas Turbine Gyanendra Sharma NPTI DelhiNPTINoch keine Bewertungen

- TSPL GST Petition - AnnexuresDokument407 SeitenTSPL GST Petition - AnnexuresVIVEK anandNoch keine Bewertungen

- History of Desalination Cost EstimationsDokument17 SeitenHistory of Desalination Cost EstimationsGiovanniStirelliNoch keine Bewertungen

- Combustion Analysis Basics: Tune-Up Procedure-Using An Electronic Combustion AnalyzerDokument19 SeitenCombustion Analysis Basics: Tune-Up Procedure-Using An Electronic Combustion AnalyzerTin Aung KyiNoch keine Bewertungen

- Nemmeli DesalDokument4 SeitenNemmeli DesalTushar NeelratanNoch keine Bewertungen

- Interview With GMRDokument8 SeitenInterview With GMRAnupamaa SinghNoch keine Bewertungen

- Optical Character RecognitionDokument7 SeitenOptical Character RecognitionHoodFigaNoch keine Bewertungen

- Nabha Power Limited: (A Wholly Owned Subsidiary of L&T Power Development LTD)Dokument10 SeitenNabha Power Limited: (A Wholly Owned Subsidiary of L&T Power Development LTD)AshokShettyNoch keine Bewertungen

- T4S5O4 Paper PDFDokument17 SeitenT4S5O4 Paper PDFtrung2iNoch keine Bewertungen

- Od-Ops-Syst-003 Procedure For Testing and Maintenance To Avoid Excessiveover Speeding of Prime MoversDokument1 SeiteOd-Ops-Syst-003 Procedure For Testing and Maintenance To Avoid Excessiveover Speeding of Prime MoversDeepak KansalNoch keine Bewertungen

- Reading Coal Flame in Tangentially Fired BoilerDokument4 SeitenReading Coal Flame in Tangentially Fired Boilerbhaskar1rkumar4092Noch keine Bewertungen

- To Reduce Auxiliary PowerDokument15 SeitenTo Reduce Auxiliary PowerMohit GuptaNoch keine Bewertungen

- Reference Standards For Thermal Power PlantsDokument29 SeitenReference Standards For Thermal Power PlantsSenthil Kumar SubramanianNoch keine Bewertungen

- NP 2656Dokument294 SeitenNP 2656Anonymous 1hOgJqwZuzNoch keine Bewertungen

- Oin Ops Chem 014 Recommendations of Epri WorkshopDokument15 SeitenOin Ops Chem 014 Recommendations of Epri WorkshopraniNoch keine Bewertungen

- Adani EnterprisesDokument22 SeitenAdani EnterprisesJay SutharNoch keine Bewertungen

- Saehan Industries Inc. KoreaDokument13 SeitenSaehan Industries Inc. Koreadalton2004Noch keine Bewertungen

- Lakshmi Narain NTPC Aux Power Consumption ReductionDokument14 SeitenLakshmi Narain NTPC Aux Power Consumption Reductionmoorthymtps_54120305Noch keine Bewertungen

- Conference - Digitisation of Power PlantsDokument4 SeitenConference - Digitisation of Power PlantsPriyanka RawatNoch keine Bewertungen

- Andhra Pradesh Code of Technical InterfaceDokument40 SeitenAndhra Pradesh Code of Technical InterfacechcrrNoch keine Bewertungen

- Pitney Bowes DMT Solutions GuideDokument60 SeitenPitney Bowes DMT Solutions GuideAlaa RefaatNoch keine Bewertungen

- Gary Wojda - MSCA - Barcode PDFDokument29 SeitenGary Wojda - MSCA - Barcode PDFMohankumarNoch keine Bewertungen

- Table 5 - Service Factor, A.C. Induction Motors: Part 8. Auxiliary Equipment - Chapter 2. Motors and Motor ControlsDokument1 SeiteTable 5 - Service Factor, A.C. Induction Motors: Part 8. Auxiliary Equipment - Chapter 2. Motors and Motor ControlsKarthikeyan SankarrajanNoch keine Bewertungen

- Energy Efficiency Through Better OM PracticesDokument21 SeitenEnergy Efficiency Through Better OM PracticessrinivasgillalaNoch keine Bewertungen

- Coal Quality Impacts-FinalJan - 2010 PDFDokument15 SeitenCoal Quality Impacts-FinalJan - 2010 PDFaruninchinaNoch keine Bewertungen

- MRO On The Move: Outsourcing Maintenance, Repair and OperationsDokument12 SeitenMRO On The Move: Outsourcing Maintenance, Repair and Operationssha_yadNoch keine Bewertungen

- Improvement of Pulverized Coal Combustion Technology For Power GenerationDokument129 SeitenImprovement of Pulverized Coal Combustion Technology For Power Generationsaliyarumesh2292100% (1)

- A Discussion Paper On India's Perform Achieve and Trade (PAT) SchemeDokument20 SeitenA Discussion Paper On India's Perform Achieve and Trade (PAT) SchemeAkhilesh GuptaNoch keine Bewertungen

- PG Procedure - GMRDokument18 SeitenPG Procedure - GMRK NiteshNoch keine Bewertungen

- Energy Audit of Auxiliary Power Consumption: Atar Singh Dy. Director Npti FaridabadDokument27 SeitenEnergy Audit of Auxiliary Power Consumption: Atar Singh Dy. Director Npti FaridabadHiltonNoch keine Bewertungen

- Artificial Intelligence in Power StationDokument8 SeitenArtificial Intelligence in Power StationFile Share botNoch keine Bewertungen

- Permeate Flow Rate - An Overview - ScienceDirect TopicsDokument16 SeitenPermeate Flow Rate - An Overview - ScienceDirect Topicsseifelsaie100% (1)

- GMR Corporate Brochure 2020Dokument70 SeitenGMR Corporate Brochure 2020JoJo kNoch keine Bewertungen

- Reliability Guideline: Primary Frequency ControlDokument14 SeitenReliability Guideline: Primary Frequency ControlAnonymous AOsAXgNoch keine Bewertungen

- PP ChemDokument55 SeitenPP ChemRoony RoxxNoch keine Bewertungen

- Water Conservation Options For Power GenerationDokument13 SeitenWater Conservation Options For Power Generationsevero97Noch keine Bewertungen

- Technical Guideline Number 01: Environmental Impact AssessmentDokument6 SeitenTechnical Guideline Number 01: Environmental Impact Assessmentk.r.sureshbabuNoch keine Bewertungen

- Role of Various Factors On Coal CombustionDokument51 SeitenRole of Various Factors On Coal CombustionAbhijeet DuttaNoch keine Bewertungen

- Perform Achieve & Trade (PAT) : A Journey ThroughDokument20 SeitenPerform Achieve & Trade (PAT) : A Journey ThroughSHAMSIK2002Noch keine Bewertungen

- 3 Introduction To Technical Loss of Power SystemDokument23 Seiten3 Introduction To Technical Loss of Power SystemاحمدعليNoch keine Bewertungen

- Going Lean: Professor Peter Hines & David TaylorDokument54 SeitenGoing Lean: Professor Peter Hines & David Taylorwides7Noch keine Bewertungen

- Reliance Infrastructure Thermal Power Plant, DahanuDokument9 SeitenReliance Infrastructure Thermal Power Plant, Dahanusitaram sahuNoch keine Bewertungen

- Energy Audit of Combined Cycle Power Plant: A Case Study: Umair Ahmed, Prof. Javed Ahmad ChatthaDokument6 SeitenEnergy Audit of Combined Cycle Power Plant: A Case Study: Umair Ahmed, Prof. Javed Ahmad ChatthaUdhayakumar VenkataramanNoch keine Bewertungen

- Introduction To Electricity Act 2003: Presented by Indu Maheshwari Dy. DirectorDokument41 SeitenIntroduction To Electricity Act 2003: Presented by Indu Maheshwari Dy. DirectorSantosh Kumar100% (1)

- Determination of The Most Opportune Time For Industrial Circuit Breaker ReplacementDokument12 SeitenDetermination of The Most Opportune Time For Industrial Circuit Breaker ReplacementInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Clcs Air Fuel CombustionDokument37 SeitenClcs Air Fuel CombustionkanchanNoch keine Bewertungen

- Boiler Journal - AVT & OT TratmentDokument4 SeitenBoiler Journal - AVT & OT TratmentabdoelandhakimNoch keine Bewertungen

- Presented By-T.Mahendra Reddy Ankur Sahoo Shubham VarmaDokument30 SeitenPresented By-T.Mahendra Reddy Ankur Sahoo Shubham VarmaShubham VermaNoch keine Bewertungen

- GMRASP Brochure 2016 PDFDokument16 SeitenGMRASP Brochure 2016 PDFramkumarNoch keine Bewertungen

- Pumps Used As Turbines Power Recovery Energy EfficDokument13 SeitenPumps Used As Turbines Power Recovery Energy EfficJhonis CoelhoNoch keine Bewertungen

- Welcome To Presentation On Generator Construction by Pawan BhatlaDokument19 SeitenWelcome To Presentation On Generator Construction by Pawan BhatlarahulNranaNoch keine Bewertungen

- Construction of Alternator - Electrical4uDokument5 SeitenConstruction of Alternator - Electrical4uM Kumar MarimuthuNoch keine Bewertungen

- Resent Development PDFDokument4 SeitenResent Development PDFAnurag porteNoch keine Bewertungen

- Activity 2.2Dokument2 SeitenActivity 2.2itsmiicharlesNoch keine Bewertungen

- Lesson 4 - Thermal Power PlantsDokument22 SeitenLesson 4 - Thermal Power PlantsHafsa AlhaddabiNoch keine Bewertungen

- Hydro Power Plants and Thermal Power PlantsDokument32 SeitenHydro Power Plants and Thermal Power PlantsAbhishek KaleNoch keine Bewertungen

- Article Supercritical Control en 37630Dokument4 SeitenArticle Supercritical Control en 37630etong saturninaNoch keine Bewertungen

- Solar-Generated Superheated Steam For: Clean, Reliable ElectricityDokument4 SeitenSolar-Generated Superheated Steam For: Clean, Reliable Electricityhaitam terribleNoch keine Bewertungen

- Volume01 Arr 10may11Dokument138 SeitenVolume01 Arr 10may11spalaniyandiNoch keine Bewertungen

- Geenrator Seal Oil PR ReportDokument5 SeitenGeenrator Seal Oil PR ReportspalaniyandiNoch keine Bewertungen

- Exercise For Knee Injuries PDFDokument11 SeitenExercise For Knee Injuries PDFspalaniyandiNoch keine Bewertungen

- Handbook of Orthopedic RehabilitationDokument201 SeitenHandbook of Orthopedic Rehabilitationbutby100% (20)

- Traction: Immobilization Reduction Inflamation Fracture DislocationDokument17 SeitenTraction: Immobilization Reduction Inflamation Fracture DislocationAgung TryNoch keine Bewertungen

- A Complete Health GuideDokument37 SeitenA Complete Health Guidegoyal.pavanNoch keine Bewertungen

- Calculation MethodDokument12 SeitenCalculation Methodspalaniyandi100% (1)

- Next Generation Gas Turbine Systems StudyDokument180 SeitenNext Generation Gas Turbine Systems Studyspalaniyandi100% (1)

- Secondary Blade PaperDokument12 SeitenSecondary Blade PaperspalaniyandiNoch keine Bewertungen

- Brochures ListDokument1 SeiteBrochures ListspalaniyandiNoch keine Bewertungen

- GT Reheat StudyDokument112 SeitenGT Reheat StudyspalaniyandiNoch keine Bewertungen

- 61 Risk AcceptanceDokument11 Seiten61 Risk AcceptanceLTE002Noch keine Bewertungen

- Properties of GasesDokument1 SeiteProperties of GasesspalaniyandiNoch keine Bewertungen

- Condenser and Heat Exchanger Tube RestorationDokument6 SeitenCondenser and Heat Exchanger Tube RestorationspalaniyandiNoch keine Bewertungen

- Risk-Based Component Life Management in Fossil Power Plants A. JovanovicDokument14 SeitenRisk-Based Component Life Management in Fossil Power Plants A. JovanovicspalaniyandiNoch keine Bewertungen

- Qu Ali Ty Assu Ran Ce Progr AmDokument51 SeitenQu Ali Ty Assu Ran Ce Progr AmspalaniyandiNoch keine Bewertungen

- Damage Analysis of Welded JointsDokument12 SeitenDamage Analysis of Welded JointsspalaniyandiNoch keine Bewertungen

- New Jersey Clean Air CouncilDokument16 SeitenNew Jersey Clean Air CouncilspalaniyandiNoch keine Bewertungen

- Creep Resistant Steels For Power PlantDokument28 SeitenCreep Resistant Steels For Power PlantspalaniyandiNoch keine Bewertungen

- Presentation in EnglishDokument13 SeitenPresentation in EnglishspalaniyandiNoch keine Bewertungen

- Maintenance OrganizationDokument10 SeitenMaintenance Organizationspalaniyandi100% (1)

- Ecosusta in en Erg y Sys Te Ms P Vt. LTD., P UneDokument18 SeitenEcosusta in en Erg y Sys Te Ms P Vt. LTD., P UnespalaniyandiNoch keine Bewertungen

- Thermax LTD KhopoliDokument1 SeiteThermax LTD KhopolispalaniyandiNoch keine Bewertungen

- Weld Repair of A Petrochem ComponentDokument7 SeitenWeld Repair of A Petrochem ComponentspalaniyandiNoch keine Bewertungen

- Risks in Power PlantDokument20 SeitenRisks in Power Plantspalaniyandi100% (1)

- Steam Seal CondDokument2 SeitenSteam Seal CondspalaniyandiNoch keine Bewertungen

- Lifting OperationsDokument45 SeitenLifting Operationsspalaniyandi100% (1)

- Turbine BulletinDokument12 SeitenTurbine BulletinspalaniyandiNoch keine Bewertungen

- Turbine Blade in South AfricaDokument17 SeitenTurbine Blade in South Africaapi-3696230Noch keine Bewertungen

- HydroDokument38 SeitenHydroAnonymous Twr4Nt8Noch keine Bewertungen

- Turbine FundamentalsDokument102 SeitenTurbine FundamentalsBalkishan Dyavanapelly90% (10)

- Ch1 - Steam Power PlantsDokument44 SeitenCh1 - Steam Power Plantsaminjoe93100% (1)

- USA Gas Cycles Diesel DualDokument4 SeitenUSA Gas Cycles Diesel DualRaymartNoch keine Bewertungen

- In Situ Repair Welding of Steam Turbine ShroudDokument7 SeitenIn Situ Repair Welding of Steam Turbine ShroudClaudia MmsNoch keine Bewertungen

- Mobil DTE™ Oil Named Series V68Dokument3 SeitenMobil DTE™ Oil Named Series V68julian jimenezNoch keine Bewertungen

- Model Question PaperDokument2 SeitenModel Question PaperpvjotaniyaNoch keine Bewertungen

- Design and Modeling of Axial Micro Gas TurbineDokument39 SeitenDesign and Modeling of Axial Micro Gas Turbineshareque siddiquiNoch keine Bewertungen

- Impulse Turbine and Reaction TurbineDokument5 SeitenImpulse Turbine and Reaction Turbinerahul100% (1)

- ChevronTexaco Darajat IIIDokument2 SeitenChevronTexaco Darajat IIIgarygolden100% (1)

- 1966 - Jachens - Steam Turbines Their ConstructionDokument19 Seiten1966 - Jachens - Steam Turbines Their Constructionanuragriles100% (1)

- Science Form 3Dokument63 SeitenScience Form 3qq23583% (6)

- Gas Turbine Terminology.Dokument7 SeitenGas Turbine Terminology.chahrazed bngNoch keine Bewertungen

- HR Planning - Bhel (1) Prateek3Dokument85 SeitenHR Planning - Bhel (1) Prateek3prateek kumar0% (1)

- SST-600 Industrial Steam Turbines: Up To 100 MWDokument4 SeitenSST-600 Industrial Steam Turbines: Up To 100 MWsertackcdgNoch keine Bewertungen

- Industrial Visit ReportDokument24 SeitenIndustrial Visit ReportParayatham ManasaNoch keine Bewertungen

- Degradation of The Mechanical Integrity of Steam Turbine Steels Due To Stress-Corrosion Cracking in Acidic WaterDokument14 SeitenDegradation of The Mechanical Integrity of Steam Turbine Steels Due To Stress-Corrosion Cracking in Acidic WaterLeila safiddineNoch keine Bewertungen

- Thermal Power Generation PDFDokument177 SeitenThermal Power Generation PDFGauravNoch keine Bewertungen

- Specification of HEFEI GAS TURBINE POWER PLANTDokument48 SeitenSpecification of HEFEI GAS TURBINE POWER PLANTSalmanEjaz100% (1)

- Iso 10816 3 2009Dokument11 SeitenIso 10816 3 2009ivan castroNoch keine Bewertungen

- Of Steam Turbine-Generators: I Method For Predicting The PerformanceDokument40 SeitenOf Steam Turbine-Generators: I Method For Predicting The PerformancenckpourlasNoch keine Bewertungen

- Steam TurbineDokument77 SeitenSteam Turbine94gauravNoch keine Bewertungen

- On Industrial Training in Bhel HaridwarDokument38 SeitenOn Industrial Training in Bhel HaridwarYogesh SurveNoch keine Bewertungen

- Gas TurbinesDokument11 SeitenGas Turbinesmustafa benzer67% (3)

- Steam Turbine Modeling: 10.1 Basic DescriptionDokument13 SeitenSteam Turbine Modeling: 10.1 Basic DescriptionFatima NusserNoch keine Bewertungen

- FPCL Power Plant (MECHANICAL)Dokument43 SeitenFPCL Power Plant (MECHANICAL)Syed umer asif100% (2)

- Major Faults in An Alternator and Their ProtectionDokument13 SeitenMajor Faults in An Alternator and Their Protectiongreg100% (1)

- Ontario Power Generation's Nanticoke Power PlantDokument3 SeitenOntario Power Generation's Nanticoke Power PlantHatem AbdelrahmanNoch keine Bewertungen

- ATD UNIT 3 & 4 AssignmentsDokument4 SeitenATD UNIT 3 & 4 AssignmentsOm PrakashNoch keine Bewertungen