Beruflich Dokumente

Kultur Dokumente

Proiect Final

Hochgeladen von

ValentinIonitaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Proiect Final

Hochgeladen von

ValentinIonitaCopyright:

Verfügbare Formate

Cuprins

1.Date de intrare.1

2.Calculul fortelor din sistem.1

2.1.Schema transmisiei...2

3.Calculul angrenajului planetar.3

4.Calculul angrenajului melcat..18

5.Calculul transmisiei prin curele..22

6.Calculul transmisiei prin lant..25

1

1. Date de intrare

Sa se proiecteze o transmisie pentru ridicarea unei greutatii, pornind de la urmatoarele date:

- Greutarea G = F = 3000kg = 30000N

- Turatia motorului n = 1500 rot/min

- Timpul de ridicare t = 50 s

- Inaltimea de ridicat h = 20 m

- Diametru tambur D = 2.5 m

2. Calculul fortelor din sistem

Calculul transmisiei

- Viteza de ridicare a greutatii V = h / t = 20 / 50 =0.4 m/s

- Puterea la iesire P

out

= F * V = 30000 * 0.4 = 12000 W = 12 kW

Motor electric

- Turatia motorului n = 1500 rot/min

- Diametru tambur D = 2.5 m

- Viteza de iesire a transmisiei n

out

= 60 * V / * D = 60 * 0.4 / * 2.5 = 3.055 [rot/min]

- Momentul de iesire din transmisie T

out

= 9.55 * 10^6 * P

out

/ n

out

= 9.55 * 10^6 * 12 /

3.055 = 37512274 Nmm

- Raportul de transmitere al sistemului este i

s

= n

imp

/ n

out

= 1500 / 3.055 = 490

Randamentul motorului

- Angrenaj melcat i

AM

= 20 80, ales i

AM

= 50

- Angrenaj cilindric i

AC

= 2 10, ales i

AC

= 8

- Trammisie lant-curea i

AC

= 1.2 1.5, ales i

L,C

= 1.25

- Randament transmisie =

AC

*

AM

*

LC

= 0.97 * 0.6 * 0.98 = 0.57

- Putere de intrare P

inp

= P

out

/ = 12 / 0.57 = 21kW

2

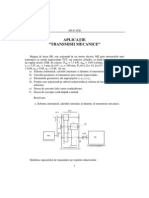

2.1 Schema transmisiei

V

G

Transmisie melc -roata melcata

Transmisie curea sau lant

Sistem planetar

Motor electric

3

3. Calculul angrenajului planetar

Pentru calculele angrenajelor si a transmisiilor care compun acest sistem mecanic s-a folosit

programul de calcul MDesign. In ceea ce urmeaza vor fi prezentate rezultatele obtinute in

urma introducerii in program a datelor calculate in capitolele anterioare.

i

t

= i

AM

* i

AC

* i

LC

= 50 * 8 * 1.25 = 490 unde i

AM

= i angrenaj melcat

i

AC

= i angrenaj cilindric

i

LC

= i transmisie lant sau curea

p

1

= p

motor

/ n

s

= 21 / 3 = 7kW, unde n

s

este numarul de sateliti n

s

= 3

1

=

=

1500

8

= 187.5 rot/min

Date de intrare: i

AC

= 1 + z

4

+ z

1

z

1

/ 2 + z

2

= z

4

/ 2

Date de iesire: z

2

/ z

1

= ?

+ z

2

/ z

1

= z

4

/ 2 * z

1

= i

AC

U = z

2

/ z

1

= (i

AC

1) / 2

Treapta 1: U = (8 1) / 2 = 3.5

z

1

= 20 dinti

Fig. Angrenaj planetar

4

Input data:

Spur Gear, Gear Rack

Calculation method Spur gear

Calculation variants All

Calculation standard ISO 6336

Type of toothing External toothing

Spur gear geometry

Basic data

Normal modulus mn = 4 mm

Helical angle | : 10

Centre distance a : 0 mm

Driving element Pinion

Input of geometry z1, i

Number of teeth (pinion) z1 = 20

Number of teeth (wheel) z2 = 60

Translation ratio i = 3

Pinion Wheel

Tooth width b = 40 42 mm

Input methode topland shortening No input

Addendum modification according to DIN 3992/3993

Input methode profile shift coefficients No input

Optimization for profile shift coefficient Special case (very high

strength capacity)

Basic gear rack Pinion Wheel

Tip clearance factor cP* = 0.25 0.25

Root fillet radius factor f P* = 0.38 0.38

Pressure angle op = 20

Tooth-tip thickness factor san* = 0.3

Pinion Wheel

Tooth-tip height factor haP* = 1 1

Residual fillet undercut spr : 2 2 mm

Cutter data Pinion Wheel

Number of cutter teeth z0 : 0 0

Basic gear rack profile shift coefficient x0 : 0 0

Spur Gear Calculation - Strength

Drive data

Load case Nominal load

Application factor KA = 1.35

Performance P = 7 kW

Rotation speed (pinion) n1 = 1500 1/min

Lifetime Lh = 10000 h

Lubrication

Viscosity class for 40 voil = 68 cSt

5

Oil temperature uoil = 50 C

Force level (according to FZG-test) 12

Type of oil distribution Splash lubrication

Material selection

Pinion - materials (strength values) according to MDESIGN database

International materials no

Material designation 18CrNiMo7-6

Material number 1.6587

Material group Casehardening steel

Heat treatment / State trial hardened

Standard dimension dNm = 16 mm

Standard dimension dNp = 16 mm

Ultimate strength for dNm RmN = 1200 N/mm

Yield point for dNp RpN = 850 N/mm

Tooth root strength oFlim = 430 N/mm

Surface durability (pitting) oHlim = 1500 N/mm

Type of Material 7

Modulus of elasticity E = 210000 N/mm

Poisson's ratio v = 0.3

Hardness scale HB

Hardness = 0

Density = 7850 kg/m

Linear expansion factor o = 12 10^-6/K

Temperature T = 20 C

Wheel - materials (strength values) according to MDESIGN database

International materials no

Material designation 18CrNiMo7-6

Material number 1.6587

Material group Casehardening steel

Heat treatment / State trial hardened

Standard dimension dNm = 16 mm

Standard dimension dNp = 16 mm

Ultimate strength for dNm RmN = 1200 N/mm

Yield point for dNp RpN = 850 N/mm

Tooth root strength oFlim = 430 N/mm

Surface durability (pitting) oHlim = 1500 N/mm

Type of Material 7

Modulus of elasticity E = 210000 N/mm

Poisson's ratio v = 0.3

Hardness scale HB

Hardness = 0

Density = 7850 kg/m

Linear expansion factor o = 12 10^-6/K

Temperature T = 20 C

Spur gear calculation material Pinion Wheel

Structure factor XW = 1 1.15

Thermal conductivity = 50 40 N/(s*K)

Heat capacity cM = 485 500 N*m/(k

g*K)

Root roughness Rz = 16 16 m

6

Tooth flank roughness Rz = 4 4 m

Data width load factor

Tooth modification No

Bearing span l = 100 mm

Eccentricity (pinion) s : 20 mm

Shaft diameter at pinion dsh = 10 mm

Factor K' = 1.33

Type of helical toothing Simple

Face load factor (root stress) KF| : 0

Face load factor (contact stress) KH| : 0

Face load factor (scuffing load) KB| : 0

Transverse load factors

Transverse load factor (root stress) KFo : 0

Transverse load factor (contact stress) KHo : 0

Transverse load factor (scuffing load) KBo : 0

General input Pinion Wheel

Gearing quality 7 8

Design Disk Disk

Inner diameter of rim di : 0 0 mm

Tooth modification, base relief Ca : 0 0 m

Loading type Pulsating Alternating

Pittings allowed? no yes

Minimal root safety SFmin = 1.1

Minimal flank safety SHmin = 1.2

Minimal scuffing load safety SBmin = 1.3

Standard gauge spur gear

General data Pinion Wheel

Deviation of teeth thickness (DIN 3967) - -

Tolerances of teeth thickness (DIN 3967) - -

Number of teeth dimension k : 0 0

Spherical dimension- and roll diameter DM : 0 0 mm

Deviation of centre distances (DIN 3964) -

Free input deviations Pinion Wheel

Upper deviation of teeth thickness Asne : 100 120 m

Lower deviation of teeth thickness Asni : -12 0 m

Machining allowance q : 4 mm

Upper deviation of centre distances Aae : 15 m

Lower deviation of centre distances Aai : -20 m

Results:

General data

Effective number of teeth ratio u = 3.500

Effective translation ratio i = 3.500

Transverse pressure angle ot = 20.284

Pressure angle at pitch cylinder owt = 23.537

Ground lead |b = 9.391

Zero centre distance ad = 182.777 mm

7

Centre distance a = 187.000 mm

Profile shift coefficient (pinion) x1 = 0.5288

Profile shift coefficient (wheel) x2 = 0.6100

Sum profile shift coefficient xs = 1.1388

Length of path of contact go = 13.184 mm

Length of recess path ga = 8.387 mm

Length of approach path gf = 4.797 mm

Transverse contact ratio co = 1.102

Overlap ratio c| = 0.553

Total contact ratio c = 1.654

Number of teeth z = 20 70

Virtual number of teeth of helical gear zn = 20.864 73.024

Geometrical data

Reference diameter d = 81.234 284.319 mm

Base diameter db = 76.197 266.688 mm

Pitch diameter dw = 83.111 290.889 mm

Root diameter df = 75.465 279.199 mm

V-circle diameter dv = 85.465 289.199 mm

Tip diameter da = 91.117 294.852 mm

Theoretical tip diameter da th = 93.465 297.199 mm

Root form circle diameter dFf = 114.235 309.730 mm

Root form diameter dNf = 79.766 284.606 mm

Specific sliding at point A ,A = -0.523

Specific sliding at point E ,E = -0.759

Tooth thickness on the tip cylinder san = 3.399 3.896 mm

Tooth depth h = 7.826 7.826 mm

Addendum ha = 4.941 5.266 mm

Dedendum hf = 2.885 2.560 mm

Bottom clearance c = 1.000 1.000 mm

Tip shortening k = 1.1739 1.1739 mm

Normal base pitch pen = 11.809 mm

Transverse base pitch pet = 11.969 mm

Normal pitch on base cylinder pbn = 11.809 mm

Transverse pitch on base cylinder pbt = 11.969 mm

Cutter data of gear rack

Cutter data pinion type cutter

Number of teeth z0 = 0 0

Profile shift coefficient x0 = 0.000 0.000

Topland height factor haP0* = 1.250 1.250

Root height factor hfP0* = 1.000 1.000

Actual topland play ctat = -9.936 -9.914 mm

Reference diameter d0 = 0.000 0.000 mm

Base diameter db0 = 0.000 0.000 mm

Tip diameter da0 = 10.000 10.000 mm

Deddendum diameter (generation) dfE = 98.976 302.755 mm

Centre distance a0 = 49.782 153.647 mm

Zere centre distance ad0 = 40.617 142.160 mm

Pressure angle at pitch cylinder owt0 = 40.066 29.789

8

Results of calculation strength

Forces, moment, speed

Transverse tangential load

at reference cylinder

Ft = 1097.159 N

Transverse tangential load

at pitch cylinder

Ftw = 1072.381 N

Radial load at pitch cylinder Frw = 467.100 N

Axial load at pitch cylinder Faw = 189.090 N

Tooth load at pitch cylinder Fw = 1184.879 N

Moment (pinion) T1 = 44.563 N*m

Moment (wheel) T2 = 155.972 N*m

Line load

= 37.029 N/mm

Peripheral speed at reference cylinder v = 6.380 m/s

Peripheral speed at pitch cylinder vw = 6.528 m/s

Rotation speed (pinion) n1 = 1500.000 1/min

Rotation speed (wheel) n2 = 428.571 1/min

Number of loading cycle (pinion) NL1 = 900000000

Number of loading cycle (wheel) NL2 = 257142857

General factors

Hekix slope deviation fH| = 12.000 22.000 m

Transverse pitch deviation fpe = 13.000 22.000 m

Profile form deviation ffo = 15.000 26.000 m

Effective meshing slope deviation fpe eff = 20.688 m

Effective profile form deviation ffo eff = 24.462 m

Flank line deviation F|x = 943.948 m

Manufacturing - flank line deviation fma = 22.000 m

Flank line deviation through pinion def. fsh = 693.194 m

Reduced mass / tooth width mred = 0.024 kg/mm

Individual spring rigidity c' = 20.044 N/(mm*m)

Meshing spring rigidity c = 19.414 N/(mm*m)

Resonance velocity (pinion) nE1 = 13687.152 1/min

Resonance velocity (gear) nE2 = 3910.615 1/min

Basic velocity NR = 0.110

Dynamic factor Kv = 1.911

Face load factor (root stress) KF| = 12.552

Face load factor (contact stress) KH| = 22.684

Face load factor (scuffing load) KB| = 22.684

Transverse load factor (root stress) KFo = 1.000

Transverse load factor (contact stress) KHo = 1.000

Transverse load factor (scuffing load) KBo = 1.000

Helix angle factor KB = 1.000

Pitting load capacity

Zone factor ZH = 2.269

Elasticity factor ZE = 191.646

Contact ratio factor Zc = 0.966

Helix angle factor Z| = 0.992

Lubricant factor (static) ZL = 1.000

Lubricant factor (dyn.) ZL = 0.946

Velocity factor (static) Zv = 1.000

Velocity factor (dyn.) Zv = 0.988

Roughness factor (static) ZR = 1.000

Roughness factor (dyn.) ZR = 0.984

Work hardening factor ZW = 1.000

Life factor for contact stress (static) ZNT = 1.600

1.600

9

Life factor for contact stress (dyn.) ZNT = 1.000

1.000

Size factor (static) ZX = 1.000

1.000

Size factor (dyn) ZX = 1.000

1.000

Single pair tooth contact factor ZB = 1.043 ZD = 1.000

Pitting stress limit (static) oHG = 2400.000 2400.000 N/mm

Pitting stress limit (dyn) oHG = 1379.230 1379.230 N/mm

Allowable flank pressure (static) oHP = 2000.000 2000.000 N/mm

Allowable flank pressure (dyn) oHP = 1149.358 1149.358 N/mm

Contact stress oH = 2192.500 2192.500 N/mm

Safety factor for pitting (static) SH = 1.095 1.095

Safety factor for pitting (dyn) SH = 0.629 0.629

Attainable lifetime Lh = 11.161 39.063 h

Root load capacity

Overlapping factor (root stress) Yc = 0.926

Helix angle factor Y| = 0.954

Tooth form factor YF = 5.028 4.958

Stress correction factor YS = 1.451 1.506

Life factor for tooth root stress (static) YNT = 2.500 2.500

Life factor for tooth root stress (dyn) YNT = 1.000 1.000

Relativ notch sensitivity factor (static) YorelT = 0.962 0.965

Relativ notch sensitivity factor (dyn) YorelT = 0.962 0.970

Relativ survace factor (static) YRrelT = 1.000 1.000

Relativ survace factor (dyn) YRrelT = 0.982 0.982

Size factor (static) YX = 1.000 1.000

Size factor (dyn) YX = 1.000 1.000

Tooth root stress limit (static) oFG = 2067.308 2075.619 N/mm

Tooth root stress limit (dyn) oFG = 812.668 819.468 N/mm

Allowable root stress (static) oFP = 1879.371 1886.926 N/mm

Allowable root stress (dyn) oFP = 738.789 744.971 N/mm

Tooth root stress oF = 1545.182 1581.725 N/mm

Safety factor for tooth breakage (static) SF = 1.338 1.312

Safety factor for tooth breakage (dyn) SF = 0.526 0.518

Attainable lifetime Lh = 197.345 176.689 h

Scuffing load capacity

Angle factor Xo| = 1.026

Lubricant factor XS = 1.000

Flash temperature calculation way

Load distribution factor XI = 1.000

Flash factor XM = 1.655

Structur factor XB = 0.195

Tangential line force at weigth wBt = 1605.450 N/mm

Scuffing temperature u = 445.253 C

Corrosion safety factor SB = 27.494

Integral calculation way

Flash factor XM = 1.654

Geometry factor (pinion tip) XBE = 0.224

Pitch factor XQ = 1.000

Tip relief factor XCa = 1.000

Contact ratio factor Xc = 0.366

Mass temperature uM = 51.640 C

Integral temperature uint = 55.155 C

Scuffing integral temperature uintS = 445.253 C

Corrosion safety factor SintS = 8.073

Scuffing load safety factor SSL = 76.668

10

Ultimate strength for pinion Rm = 944.8 mm (for deff = 76.20 mm )

Ultimate strength for gear Rm = 750.5 mm (for deff = 266.69 mm )

Yielding point for pinion Re = 669.2 mm (for deff = 76.20 mm )

Yielding point for gear Re = 531.6 mm (for deff = 266.69 mm )

Results check gauge

Case centre distance a = 187.000 mm

Maximum case centre distance amax = 187.015 mm

Minimum case centre distance amin = 186.980 mm

Theoretical backlash jt = -0.107 mm

Maximum theoretical backlash jt max = 0.023 mm

Minimum theoretical backlash jt min = -0.238 mm

Upper deviation of teeth thickness Asne = 100.000 120.000 m

Lower deviation of teeth thickness Asni = -12.000 0.000 m

Tolerance of teeth thickness Tsn = 112.000 120.000 m

Fluctuation of teeth thickness Rs = 20.000 36.000 m

Nominal teeth thickness (theoretical) snth = 7.823 8.059 mm

Nominal teeth thickness sn = 16.380 16.633 mm

Maximum nominal teeth thickness sn max = 16.436 16.693 mm

Minimum nominal teeth thickness sn min = 16.324 16.573 mm

Base tangent length (theoretical) Wkth = 43.947 117.947 mm

Base tangent length Wk = 51.989 126.003 mm

Maximum base tangent length Wk max = 52.041 126.060 mm

Minimum base tangent length Wk min = 51.936 125.947 mm

Number of teeth dimension k = 4 10

Measure roller diameter DM = 8.000 7.000 mm

Radial gauge spheres/roller Mrk = 55.397 158.252 mm

Maximum radial gauge spheres/roller Mrke = 55.437 158.309 mm

Minimum radial gauge spheres/roller Mrki = 55.357 158.196 mm

Diametral gauge spheres Mdk = 110.794 316.505 mm

Diametral gauge roller MdR = 110.794 316.505 mm

Factor of deviation of base tangent length Aw = 0.940 0.940

Factor of deviation radial spheres/roller Amr = 0.709 0.938

Factor of deviation diametral roller Amd = 1.419 1.877

Factor of deviation diametral spheres Amd = 1.415 1.876

11

Specific sliding accord. to DIN 3960

External toothing

x1 = 0.529

x2 = 0.610

xs = 1.139

ga = 8.387

gf = 4.797

go = 13.184

Kga1 = 0.259

Kga2 = 0.148

Kgf1 = 0.148

Kgf2 = 0.259

spec. sliding

,A = -0.523

,E = -0.759

Meshing Line

[mm]

Kg ,

0.89

-0.89

1.8

-1.8

2.7

-2.7

3.5

-3.5

0

0 7.468 22.403 37.338 52.273 67.208

,1

,2

C

A E

Kg1

Kg2

0.513

-0.513

1.797

-1.797

0.259

0.148

-0.259

-0.148

Tooth profile (evolvent) pinion

df1

d1

dw1

da1

12

Tooth profile (evolvent) gear

df2

d2

dw2

da2

Gap of tooth (envelope curve, evolvent) pinion

df1

d1

dw1

da1

13

Gap of tooth (envelope curve, evolvent) gear

df2

d2

dw2

da2

Side view pinion

df1 d1 da1

Side view gear

df2 d2 da2

14

Front view pinion

df1 d1 da1

Front view gear

df2 d2 da2

Gear wheel (evolvent ) pinion

15

Gear wheel (evolvent ) gear

Pinion, Pitting Bearing Capacity Diagram

material : 18CrNiMo7-6

load cycle

oHG

[N/mm]

0

600

1200

1800

2400

3000

2

10

3

10

4

10

5

10

6

10

7

10

8

10

9

10

10

10

load cycle [-] lifetime [h]

10

10 111111.11

9

10 11111.11

8

10 1111.11

7

10 111.11

6

10 11.11

5

10 1.11

4

10 0.11

3

10 0.01

2

10 0.00

static

time strength

fatigue strength

16

Gear, Pitting Bearing Capacity Diagram

material : 18CrNiMo7-6

load cycle

oHG

[N/mm]

0

600

1200

1800

2400

3000

2

10

3

10

4

10

5

10

6

10

7

10

8

10

9

10

10

10

load cycle [-] lifetime [h]

10

10 388888.89

9

10 38888.89

8

10 3888.89

7

10 388.89

6

10 38.89

5

10 3.89

4

10 0.39

3

10 0.04

2

10 0.00

static

time strength

fatigue strength

Pinion, Root Bearing Capacity Diagram

material : 18CrNiMo7-6

load cycle

oFG

[N/mm]

0

600

1200

1800

2400

3000

2

10

3

10

4

10

5

10

6

10

7

10

8

10

9

10

10

10

load cycle [-] lifetime [h]

10

10 111111.11

9

10 11111.11

8

10 1111.11

7

10 111.11

6

10 11.11

5

10 1.11

4

10 0.11

3

10 0.01

2

10 0.00

static

time strength

fatigue strength

17

Gear, Root Bearing Capacity Diagram

material : 18CrNiMo7-6

load cycle

oFG

[N/mm]

0

600

1200

1800

2400

3000

2

10

3

10

4

10

5

10

6

10

7

10

8

10

load cycle [-] lifetime [h]

8

10 3888.89

7

10 388.89

6

10 38.89

5

10 3.89

4

10 0.39

3

10 0.04

2

10 0.00

static

time strength

fatigue strength

18

4. Calculul angrenajului melcat

Pentru calculul angrenajului melcat sau folosit urmatoarele date de intrare

2

,

1,

-la pinionul angrenajului

P

1

= P

inp

*

= 21 * 0.98 = 20.58 kW

n

2

= n

1

/ i

AC

= 1500 / 8 = 187.5 rot/min

i = 50

u =

1

unde

2

reprezinta numarul de dinti de la roata,

1

reprezinta numarul de inceputuri ale

melcului

2

=30...60

1

= 2

Daca

1

=1, randamentul este scazut

19

With the following program, based on the groundwork calculations of DIN 3996 Method C, the strength

examination (pitting bearing capacity, root bearing capacity), safety against deflection, safety against

temperature and wear bearing strength of cylindrical worm gear pairs will be calculated.

The groundwork calculations for the module are described by the following DIN specifications:

- DIN

3974

Teil 1, Edition November

1995

(Accuracy of worms and worm gears,

general bases)

- DIN

3974

Teil 2, Edition November

1995

(Accuracy of worms and worm gears,

tolerances)

- DIN

3975

Edition October 1976 (Terms and definitions for cylindrical

worm gears with shaft angle 90)

- DIN

3976

Edition November

1980

(Cylindrical worms)

- DIN

3996

Entwurf Edition September

1996

(Calculation of load capacity of cylindrical

worm gear pairs)

- DIN

3998

Teil 4, Edition September

1976

(Denominations on gears and gear pairs,

worm gear pairs)

Input data:

Cylindrical worm gear pairs

Main form of the flanks Flank main form ZI

Angle of action o = 20

Diameter-Center distance relation dm1/a : 0.33

Axial-/Front modulus m : 0 mm

Reference diameter dm1 : 0 mm

Thread z1 = 1

Number of teeth (gear) z2 = 50

Driving element worm

Center Distance a = 300 mm

Addendum modification coefficient x : 0.5

Face width of the worm b1 : 200 mm

Face width of the gear b2 : 80 mm

Application factor KA = 1.25

Normal performance P2 = 13 kW

Rotational velocity n1 = 214 1/min

Lifetime Lh = 1000 h

Gear width b2H : 0 mm

Rim width b2R : 0 mm

Num. of radial bearing wheels (worm shaft) r = 1

Allowable reduction tooth thickness factor deltas* : 0.2

Allowable reduction mass dmlim : 1.5 kg

Lubrication

Lubrication system splash lubrication

20

Oil base mineral oil

Lubrication viscosity v = 150 mm/s

Lubrication temperature toil = 60 C

Worm gear no

Injection mass for injection lubrication Qoil : 0.05 m/s

Case with ventilator

Worm gear bearing

Gear bearing Employed gear bearing

Distance of the worm shaft bearing l1 = 100 mm

Distance of the worm shaft l11 = 40 mm

Worm - Material (strength values) according to Own assignment

Material designation 16MnCr5

Material number 1.7131

Material group Unalloyed structural steel

Heat treatment / State none

Standard dimension dNm = 40 mm

Standard dimension dNp = 40 mm

Ultimate strength for dNm RmN = 490 N/mm

Yield point for dNp RpN = 295 N/mm

Modulus of elasticity E = 215000 N/mm

Poisson's ratio v = 0.3

Density = 7850 kg/m

Elongation at break Amin = 20 %

Yield point ratio Rp/Rm Rp/Rm <= 0.75

Gear - Material (strength values)

Material Designation

GGG-40

Material number

0.7040

Density = 7 kg/dm

Modulus of elasticity E = 98100 N/mm

Poisson's ratio v = 0.3

Tooth root strength oFlim = 115 N/mm

Surface durability (pitting) oHlim = 490 N/mm

Material/Lubrication factor WML = 1

Material factor (gear) YW = 1.3

Gearing Quality (gear) 7

Avg. Roughness (tooth flank, worm) Rz = 1.6 m

Idling power loss Pvo : 0 W

Results:

Geometry

Effective number of teeth ratio u = 50.0000

21

Speed ratio i = 50.0000

Axial-/Front modulus m = 9.8235 mm

Diametral quotient q = 10.0778

Normal modulus mn = 9.7755 mm

Normal tooth thickness snm = 15.3554 mm

Basic pitch angle b = 20.7556

Reference pitch angle m = 5.6668

Angle of action ox = 20.0904

Reference spiral angle |m = 84.3332

Axial pitch px = 30.8615 mm

Normal pitch pn = 30.7107 mm

Basic cylinder pitch pb = 28.8586 mm

Lead (worm) pz1 = 30.8615 mm

Reduced lead (worm) pz1red = 4.9118 mm

worm gear

Reference diameter dm = 99.0000

501.0000 mm

Addendum diameter da = 118.6471

520.6471 mm

Root diameter df = 75.4235

477.4235 mm

Pitch diameter d = -

491.1765 mm

Basic diameter db = 25.9211 mm

Tip diameter de = -

530.4706 mm

Tooth depth h = 21.6118

21.6118 mm

Addendum ha = 9.8235

14.7353 mm

Dedendum hf = 11.7882

6.8765 mm

Tooth force

worm gear

Normal - tangential force Ftm = 16174.4434

1.1578e+005 N

Normal - axial force Fxm = -1.1578e+005

-1.6174e+004 N

Normal - radial force Frm = 44700.8970

-4.4701e+004 N

Normal - component of force Fnm = 1.3062e+005

1.3062e+005 N

Efficiency

Middle tooth coefficient of friction zm = 0.033190

Angle of friction z = 1.901

Gear efficiency qz = 74.69 %

Total efficiency qges = 72.45 %

Gear power loss Pvz = 4405.15 W

Idling power loss Pvo = 34.18 W

Bearing race power loss Pvlp = 478.77 W

Bond power loss Pvd = 24.71 W

Total power loss pv = 4942.81 W

General factors

Middle circumferential speed vm1 = 1.1093 m/s

22

Middle rubbing speed vgm = 1.1147 m/s

Rotational velocity (gear) n2 = 4.3 1/min

Torsion moment (worm) T1 = 800.635 N*m

Torsion moment (gear) T2 = 29003.972 N*m

Performance (worm) P1 = 17.943 kW

Worm loading cycle number NL1 = 1.284e+007

Gear loading cycle number NL2 = 2.568e+005

Characteristic (average flank pressure) pm* = 1.05417

Characteristic (average glide path) s* = 67.71593

Characteristic (average lubric. split thickn.) h* = 0.06403

Gear mass temperature (splash lubrication)

Gear mass temperature vM = 86.68 C

Deflection (worm)

Resultant deflection om = 0.001081 mm

Limited deflection olim = 0.098235 mm

Safety against deflection So = 90.90

Wear bearing strength

Average lubrication split thickness hminm = 0.0819 m

Glide path sw = 20538.51 m

Wear intensity Jw = 5.614e-008

Allowable wear abrasion owlimn = 1.9551 mm

Existing wear abrasion own = 1.1530 mm

Safety against wear SW = 1.70

Temperature Safety (splash lubrication)

Oil sump temperature vs = 76.87 C

Limit of oil sump temperature vslim = 90.00 C

Safety against injection lubrication ST = 1.17

Pitting bearing capacity

Substitute - E - Modulus Ered = 148051.57 N/mm

Lifetime factor ZH = 1.6000

Model factor ZS = 0.9682

lubricant factor Zoil = 0.8900

Speed factor ZV = 0.9887

Average flank pressure oHm = 582.87 N/mm

Limit of flank pressure oHG = 667.98 N/mm

Safety against pitting SH = 1.15

Root bearing Capacity

Dedendum chord (tooth, front section) sft2 = 24.2691 mm

Form factor YF = 1.1738

Overlap factor Yeps = 0.5000

Raising factor Y = 1.0049

Rim thickness factor YK = 1.0000

Lifetime factor YNL = 1.4818

Limit of shear stress tFG = 170.41 N/mm

Existing shear stress (root) tF = 108.62 N/mm

Safety against root stress SF = 1.57

23

5. Calculul transmisiei prin curele

Pentru calculul transmisiei prin curele sau folosit urmatoarele date de intrare:

P = P

inp

= 21kW

n

3

= n

1

/ (i

AC

*

i

AM

) = 1500 / (8 * 50) = 3.75 rot/min

i = 1.25

n

4

= n

3

/ i

LC

= 3.75 / 1.25 = 3 rot/min

The groundwork calculations for the Narrow V-Belts module are described by DIN 7753, part 2, April 1976 edition.

The following DIN specifications will also be utilized:

- DIN 323 part 1, edition 8/74 standard numbers

- DIN 323 part 2, edition 11/74 standard numbers

- DIN 7753 part 1, edition 1/88 infinite narrow V-belts

- DIN 2211 part 1, edition 3/84 narrow V-belt pulleys

- DIN 2215 edition 3/75 infinite V-belts

The program considers open two-pulley-design in horizontal, perpendicular, or helical alignment.

The standard performance values for narrow V-belts are standardized according to DIN 7753 part 2, lieing however far below the

present state of the technique, so that the performance values of the manufacturer Continental (for SKR, SPZ, SPA, SPB, SPC) and

Optibelt (SKR 19) will be used as the basis for this module.

If the performance data of the narrow V-belt deviates from the basic length, then this will be considered through the length factor,

c3 . Also here the specifications of the manufacturer Continental and Optibelt serve as the basis.

Input data:

Narrow V-Belts

24

Operational Factor c2 = 1.3

For Transmitting Performance P = 21 kW

Driving Velocity n1 : 3.75 1/min

Driven Velocity n2 : 3.05 1/min

Max. Pulley Diameter dmax = 2000 mm

Approximate Axis Position e' : 2500 mm

Translation Ratio i : 1.25

Results:

Data Depends on the Belt Profile:

Belt Profile accord. to DIN 7753 SPC

Standard Performance of the Belt PN = 0.79 kW

Required Belt Number z = 32

Outer Length La = 11230 mm

Face Width of the Belt Pulley kbr = 824.50 mm

Valid Results For All Profiles:

Driving Pulley Effective Diameter dr1 = 1600 mm

Driven Pulley Effective Diameter dr2 = 2000 mm

Driving Pulley Velocity n1 = 4 1/min

25

Driven Pulley Velocity n2 = 3 1/min

Translation Ratio i = 1.25

Effective Length Lw = 11200 mm

Axis Position e = 2765 mm

Axis Post. Adjust. Range at the Feed y = 168 mm

Axis Adjust. Range at the Grip x = 336 mm

Belt Contact Angle Sml. Pulley |1 = 172

Angle Factor c1 = 0.98

Length Factor c3 = 1.10

Belt Velocity v = 0.31 m/s

Bending Frequency fB = 0.06 1/s

Circumferential Force Fu = 86899 N

Dynamic Shaft Loading Fw = 95582 N

26

6. Calculul transmisiei prin curele

Pentru calculul transmisiei prin lant sau folosit urmatoarele date de intrare:

P = P

inp

= 21kW

n

3

= n

1

/ (i

AC

*

i

AM

) = 1500 / (8 * 50) = 3.75 rot/min

i = 1.25

n

4

= n

3

/ i

LC

= 3.75 / 1.25 = 3 rot/min

z

1

= 60

z

2

= i * z

1

= 1.25 * 60 = 75

The calculation module is based upon DIN ISO 10823 "Guidance on the selection of roller chain drives". This international standard

refers to roller chains and chain wheels in accordance with ISO 606.

The selection procedures and the chain ratings in ISO 10823 provide for roller chain drives with a life expectancy of approximately

15,000 hours under the following conditions:

- Utilisation of a suitable method of lubrication (as shown on the results page),

- Use of a lubricating oil with a suitable viscosity class (table can be selected to be shown on results page)

- Centre distance measures between 30 and 50 times the chain pitch,

- Arc of contact of not less than 120 on the drive sprocket,

- Usage of chain adjustment.

In ISO 10823 it is specifically recommended to consult with the supplier of the equipment intended to be used to ensure its

suitability.

Input data:

Roller Chains ISO 10823

Method of calculation Calculation of all suitable chains

Type of roller chain to be used European Type (DIN 8187)

Input power P = 12 kW

Input speed n1 = 3.75 1/min

27

Number of teeth on driver sprocket z1 = 60

Number of teeth on driven sprocket z2 = 75

Drive ratio i = 1.25

Approximate centre distance a0 = 2000 mm

Define minimum and maximum centre distance? No

Characteristics of driver machine Smooth running

Characteristics of driven machine Smooth running

Application factor to allow for the operating conditions f1 = 1

Factor for number of teeth on drive sprocket f2 = 0.37

Corrected power Pc = 4.44 kW

Allow adjustment of factors f1 and f2? No

Display intermediate results on output page? No

Display listing of viscosity classes of lubricating oil on output page? No

Results:

General results

Chain

type

Strands Pitchp

mm

LinksX SpeedV

m/s

Max.

center

distancea

mm

Lubrication

range

48B 1 76.200 122 0.286 2068.421 2

40B 2 63.500 132 0.238 2042.223 1

48B 2 76.200 122 0.286 2068.421 2

32B 3 50.800 148 0.191 2041.036 1

40B 3 63.500 132 0.238 2042.223 1

48B 3 76.200 122 0.286 2068.421 2

28

Lubrication range 1: Oil supply by means of oil can or brush, applied manually at frequent intervals

Lubrication range 2: Drip-feed lubrication

Lubrication range 3: Oil bath or disc lubrication

Lubrication range 4: Forced-feed lubrication with filter and, if necessary, an oil cooler

29

Calcul de arbori

Unde 160 mm este raza de rostogolire.

160

Das könnte Ihnen auch gefallen

- Mathcad - Sedinta NR 2,3,4,5,6,7,8,9,10Dokument29 SeitenMathcad - Sedinta NR 2,3,4,5,6,7,8,9,10Arteni PaulNoch keine Bewertungen

- Teorie ReductorDokument20 SeitenTeorie ReductorAdi ȘvețNoch keine Bewertungen

- Lucrare de Disertatie Recipient Sub Presiune Cu Dispozitiv de AmestecareDokument21 SeitenLucrare de Disertatie Recipient Sub Presiune Cu Dispozitiv de AmestecareConstantin Dumitriu100% (3)

- Proiect OMDokument46 SeitenProiect OMdamyandreiNoch keine Bewertungen

- Memoriu de CalculDokument8 SeitenMemoriu de CalculClaudiu AileneiNoch keine Bewertungen

- Proiect MPDPDokument18 SeitenProiect MPDPPop GabrielNoch keine Bewertungen

- Proiect Om2 PT BereaDokument40 SeitenProiect Om2 PT BereaBasalic GeorgeNoch keine Bewertungen

- Calculul Regimurilor de Aschiere Piesa de Tip ArboreDokument23 SeitenCalculul Regimurilor de Aschiere Piesa de Tip ArboreAmariei Cosmin-EmanuelNoch keine Bewertungen

- Presa Cu Piulita RotitoareDokument18 SeitenPresa Cu Piulita RotitoareCristianovici RasinarNoch keine Bewertungen

- ProiectDokument22 SeitenProiectSerban Valeriu100% (1)

- Freza MelcDokument6 SeitenFreza MelcAndrei PavelNoch keine Bewertungen

- Cric Auto Cu ParghiiDokument23 SeitenCric Auto Cu ParghiiMaxim Ionela100% (1)

- Organe de MasiniDokument6 SeitenOrgane de Masinikiosan_florynNoch keine Bewertungen

- Proiect ReductorDokument22 SeitenProiect ReductordanacatalinaNoch keine Bewertungen

- Freza Melc Modul Pentru Prelucrarea Roţilor Cilindrice Cu Dinţi Drepţi Si InclinatiDokument6 SeitenFreza Melc Modul Pentru Prelucrarea Roţilor Cilindrice Cu Dinţi Drepţi Si InclinatiAdrian GhizilăNoch keine Bewertungen

- Ambreiaj CalculDokument18 SeitenAmbreiaj CalculLucia ZotescuNoch keine Bewertungen

- AmbreajDokument24 SeitenAmbreajClaudia MarianaNoch keine Bewertungen

- Itinerariu Tehnologic Mecanism de AvansDokument34 SeitenItinerariu Tehnologic Mecanism de AvansPetricas BogdanNoch keine Bewertungen

- Tema EIM 2 Transmisii Prin CureleDokument5 SeitenTema EIM 2 Transmisii Prin CureleAlin PetricaNoch keine Bewertungen

- Vinciul-Proiect Organe de MasiniDokument16 SeitenVinciul-Proiect Organe de MasiniMaxim IonelaNoch keine Bewertungen

- Proiect Reductor Prisecaru 1Dokument33 SeitenProiect Reductor Prisecaru 1Marian Adrian IlauNoch keine Bewertungen

- Om ProiectDokument32 SeitenOm ProiectGeorge PanceaNoch keine Bewertungen

- Calculul Unui Acumulator de Presiune Recipient de Hidrofor PDFDokument14 SeitenCalculul Unui Acumulator de Presiune Recipient de Hidrofor PDFIonut JoeNoch keine Bewertungen

- Proiect de Scule AschietoareDokument13 SeitenProiect de Scule AschietoareSabau AndrasNoch keine Bewertungen

- Proiect PSPDokument14 SeitenProiect PSPclaudette0803Noch keine Bewertungen

- Proiect Tehnologia Constructiilor de MasiniDokument19 SeitenProiect Tehnologia Constructiilor de MasiniAlexandra SeranNoch keine Bewertungen

- Reductor de Turatie Cu Roti Dintate Conice Cu Dinti DreptiDokument50 SeitenReductor de Turatie Cu Roti Dintate Conice Cu Dinti DreptiRaDeOnXNoch keine Bewertungen

- Regimul de AschiereDokument11 SeitenRegimul de AschiereRindasu TudorelNoch keine Bewertungen

- Calcul Recipient Sub Presiune - XMCD PDFDokument25 SeitenCalcul Recipient Sub Presiune - XMCD PDFluci9005Noch keine Bewertungen

- Presa Cu SurubDokument10 SeitenPresa Cu SurubBrendea Mariana GabrielaNoch keine Bewertungen

- Proiectarea Transmisiei Prin Curele TrapezoidaleDokument4 SeitenProiectarea Transmisiei Prin Curele Trapezoidalelumagm100% (1)

- Proiect CMMDokument29 SeitenProiect CMMmarian fanut serbanNoch keine Bewertungen

- Reductor Orizontal Cu o Singura TreaptaDokument35 SeitenReductor Orizontal Cu o Singura TreaptaKuor3Noch keine Bewertungen

- Proiect T.F.P. - Sedinta 7+8 Unicat PDFDokument25 SeitenProiect T.F.P. - Sedinta 7+8 Unicat PDFRobyNoch keine Bewertungen

- ProiectDokument16 SeitenProiectTudorNoch keine Bewertungen

- Proiectarea Unui Robinet Cu VentilDokument14 SeitenProiectarea Unui Robinet Cu Ventilionpopa8990Noch keine Bewertungen

- Om 1Dokument15 SeitenOm 1Andrei TudorasNoch keine Bewertungen

- Cric Telescopic DramuletZDokument24 SeitenCric Telescopic DramuletZDelia DogaruNoch keine Bewertungen

- Universitatea Tehnică Din Cluj - MefDokument18 SeitenUniversitatea Tehnică Din Cluj - MefFlorina PopNoch keine Bewertungen

- Proiect Organe de Masini - Dragos CalugarasuDokument16 SeitenProiect Organe de Masini - Dragos CalugarasuBorboly ClaudiuNoch keine Bewertungen

- Reductor VerticalDokument22 SeitenReductor Verticalponea92Noch keine Bewertungen

- Proiect Regim Aschiere Si NormareDokument37 SeitenProiect Regim Aschiere Si NormareTrimbitas PaulNoch keine Bewertungen

- Proiect Excel CcarDokument12 SeitenProiect Excel CcarIonel AlexandruNoch keine Bewertungen

- Calculul Surubului Cu BileDokument7 SeitenCalculul Surubului Cu BileComan ovidiuNoch keine Bewertungen

- Proiect PSA Freza Cilindro-FrontalaDokument6 SeitenProiect PSA Freza Cilindro-FrontalaSimion AlexNoch keine Bewertungen

- Cuplaje - ProblemeDokument7 SeitenCuplaje - ProblemedanutvasileNoch keine Bewertungen

- Proiect OmDokument21 SeitenProiect Omclaudette0803Noch keine Bewertungen

- Calculul Si Constructia Unui Reductor Cu Ajutorul Curelelor TrapezoidaleDokument20 SeitenCalculul Si Constructia Unui Reductor Cu Ajutorul Curelelor TrapezoidaleCatalin LazarNoch keine Bewertungen

- Proiect Bazele Prelucrarii Prin Deformare PlasticaDokument21 SeitenProiect Bazele Prelucrarii Prin Deformare PlasticaRaluca HancianuNoch keine Bewertungen

- Calcul Presa Cu Piulita FixaDokument14 SeitenCalcul Presa Cu Piulita FixadantopanNoch keine Bewertungen

- Din 3961 1 Precision Gears TechDokument19 SeitenDin 3961 1 Precision Gears Techbrijesh4evNoch keine Bewertungen

- Freza MelcDokument6 SeitenFreza MelcCogianu PetruNoch keine Bewertungen

- Dispozitive Tehnologice: Specializarea Inginerie Industrială - TCMDokument17 SeitenDispozitive Tehnologice: Specializarea Inginerie Industrială - TCMTudorNoch keine Bewertungen

- Proiect Cca2Dokument12 SeitenProiect Cca2Juli B.Noch keine Bewertungen

- 1.proiect BielaDokument24 Seiten1.proiect BielaZusuNoch keine Bewertungen

- Autobetoniera 165 KW, 4.2m3 2350rot, MinDokument28 SeitenAutobetoniera 165 KW, 4.2m3 2350rot, MinJhonNoch keine Bewertungen

- Transmisie Mecanica Cu Reductor CO-CIDokument45 SeitenTransmisie Mecanica Cu Reductor CO-CIDorian Cristian VatavuNoch keine Bewertungen

- Proiect Tehnologi de FabricatieDokument18 SeitenProiect Tehnologi de FabricatieMitrea Corina50% (2)