Beruflich Dokumente

Kultur Dokumente

Hammer Crusher

Hochgeladen von

dlodha5Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hammer Crusher

Hochgeladen von

dlodha5Copyright:

Verfügbare Formate

HAMMER CRUSHER:Hammer crusher can crush materials with different sizes into equal particle, which favors the

next procedure. The material crushed by the Hammer Crusher (Hammer Mill) through the collisions between high-speed hammer and materials. Hammer crusher (hammer mill) is applicable for various hard and fragile materials, such as limestone, coal, salt, gypsum, alum, brick and tile, etc. The crushing compressive strength of materials should not be in excess of 150Mpa. Hammer crusher is mainly used in industries such as cement, steel production coal separation, electricity generation, building materials and compound fertilizer, etc. The hammer crusher is mainly composed by the box, rotor, hammer, impacting lining board and the screening bar. The advantages of hammer crusher are:1. Reliable mechanical structure, 2. High productivity and 3. Favorable applicability.

Working Principle of Hammer Mill Crusher: In the hammer mill machine, the motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammers. When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them under the effect of impacting, hitting, cutting and grinding of the hammer; the crushed products meeting the required size can be discharged by the outlet and become the final products; Under the rotor, there is screening bar. The crushed materials whose granularity is smaller than the size of the screen hole will be discharged from the screening bar; and the coarse materials larger than the size of the screen hole will remain on the screening bar to be hit and ground again by the hammer and finally they are all discharged out of the machine from the screening bar. . Types of Hammer Mill: Hammer crusher has various types and can be classified According to the number of rotor into 1. Single rotor hammer crusher and 2. Double rotor hammer crusher According to the arrangement of the hammer on the rotary table 1. Single-row hammer mill and 2. Multi -row hammer mill Accordance with the direction of rotation of rotor classified into 1. Reversible hammer crusher and 2. Irreversible hammer crusher

In addition, there is still simple type hammer mill such as ring hammer mill crusher. Among them, the most widely used is single-rotor single-row hammer mill .

Application:Hammer crusher machine is suitable for crushing all kinds of medium hard materials with weak corrosivity. The materials to be crushed by this machine should be no more than 100MPa in compression strength, and less than 15% in water content rate. It can be used for crushing coal, salt, chalk, gypsum, tile and limes tone, and it can also be used for crushing fiber structure, elastic mood pieces, paper or crushing the asbestos cement for recycling asbestos fiber. In addition, the hammering machine can be used not only in crushing production line and s and making production line, but in the ore dressing line for replacing cone crusher.

Characteristics of Hammer Crusher Machine: 1. The working hammer is anti -abrasion and anti -impact. 2. The granularity of the products can be adjusted according to the customers requirements . 3. The structure of the whole machine is compacted, thus solving the problem of powder dust pollution in the crushing workshop and dust leakage of the machine. 4. The machine has many advantages such as beautiful designing model , compacted structure, less easy-wearing parts and convenient repair, so that it is an updated product.

Advantages of Single-stage hammer crusher are as follow:1. Big reduction ratio: maximum feeding size is 1. 3-1. 5m; 3-150mm of discharging size. 2. High fineness of discharging size: favorable shape with aggregate, the powdery material is no more than 20%. 3. Simple process: the two or three stage crushing is reduced into single stage. 4. Economical: small capacity of matched motor, which greatly reduces the production cost.

Das könnte Ihnen auch gefallen

- Lec-14,15 Jaw Crusher, Roll Crusher, Ball Mill (Mod)Dokument20 SeitenLec-14,15 Jaw Crusher, Roll Crusher, Ball Mill (Mod)prakhar mishraNoch keine Bewertungen

- Modeling and Analysis of Rotor Shaft Assembly of Hammer Mill CrusherDokument46 SeitenModeling and Analysis of Rotor Shaft Assembly of Hammer Mill CrusherPrudhvi VasagiriNoch keine Bewertungen

- Crushing EquipmentsDokument42 SeitenCrushing Equipmentsranjeevkumar100% (4)

- Managing Mill Maintenance - Roller Mill MaintenanceDokument7 SeitenManaging Mill Maintenance - Roller Mill MaintenanceMilling and Grain magazine100% (1)

- Rugged Single-Shaft Hammer Crusher for 2500mm MaterialsDokument1 SeiteRugged Single-Shaft Hammer Crusher for 2500mm MaterialspeymanNoch keine Bewertungen

- Hammer Crushers - GeneralDokument48 SeitenHammer Crushers - GeneralAnonymous PVXBGg9TNoch keine Bewertungen

- Raw Mill Vertical Roller Mill PDFDokument58 SeitenRaw Mill Vertical Roller Mill PDFganong itbNoch keine Bewertungen

- CrusherDokument22 SeitenCrusherArun PrasadhNoch keine Bewertungen

- Single Toggle Jaw Crusher Manufacturers, Single Toggle Jaw Crusher For SaleDokument3 SeitenSingle Toggle Jaw Crusher Manufacturers, Single Toggle Jaw Crusher For SaleHashani Anuttara AbeygunasekaraNoch keine Bewertungen

- Single Toggle Jaw Crusher OTSUKATEC-2Dokument7 SeitenSingle Toggle Jaw Crusher OTSUKATEC-2moddysNoch keine Bewertungen

- Instruction Book of Jaw Crusher - Frank (JOYAL)Dokument21 SeitenInstruction Book of Jaw Crusher - Frank (JOYAL)Angel Gonzalez Barbosa100% (1)

- Jaw Crusher Working Principle GuideDokument19 SeitenJaw Crusher Working Principle GuideRodrigo GarcíaNoch keine Bewertungen

- Enexco BrochureDokument35 SeitenEnexco BrochureErin CraigNoch keine Bewertungen

- Impact CrusherDokument8 SeitenImpact CrusherSharath MenonNoch keine Bewertungen

- 23 HaverDokument36 Seiten23 HaverkonstantasNoch keine Bewertungen

- WobblerDokument1 SeiteWobblerptjpcsbyNoch keine Bewertungen

- FG-Spiral Classifier Operating ManualDokument5 SeitenFG-Spiral Classifier Operating ManualRogelio Israel LedesmaNoch keine Bewertungen

- Ash and Slag Handling SystemsDokument3 SeitenAsh and Slag Handling Systemsrmm99rmm99Noch keine Bewertungen

- Trio - Group Washers LogDokument4 SeitenTrio - Group Washers LogCemYurtseverNoch keine Bewertungen

- Allmineral SIMADokument39 SeitenAllmineral SIMAkselvan_1Noch keine Bewertungen

- Vibrating FeederDokument7 SeitenVibrating FeederRk Upadhyay100% (1)

- Working and Maintenance of Crushing EquipmentDokument53 SeitenWorking and Maintenance of Crushing EquipmentKeshav ChhawchhariaNoch keine Bewertungen

- Reverse Air Bag House PDFDokument4 SeitenReverse Air Bag House PDFRanga VamshiNoch keine Bewertungen

- Hms Drum PlantDokument2 SeitenHms Drum Plantrichard gutierrezNoch keine Bewertungen

- Failure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFDokument9 SeitenFailure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFCezar PajaresNoch keine Bewertungen

- Lafarge Pakistan Cement WPU 200 C380 JCP 09 2011 Assembled ReportDokument25 SeitenLafarge Pakistan Cement WPU 200 C380 JCP 09 2011 Assembled ReportAamirKhanNoch keine Bewertungen

- TROUBLESHOOTING OF Cement Plant Mechanical and Electrical EquipmentDokument66 SeitenTROUBLESHOOTING OF Cement Plant Mechanical and Electrical EquipmentCorrosion FactoryNoch keine Bewertungen

- 15th NCB Technical PaperDokument10 Seiten15th NCB Technical PaperSalah RomdaniNoch keine Bewertungen

- Grinding Process Within Vertical Roller Mills Experiment and SimulationDokument5 SeitenGrinding Process Within Vertical Roller Mills Experiment and SimulationDirceu Nascimento100% (1)

- Muller Mixer Machine - Specifications and Description - SuryaDokument2 SeitenMuller Mixer Machine - Specifications and Description - Suryakeshab_machineries100% (1)

- Hammer Crusher User ManualDokument10 SeitenHammer Crusher User ManualJuan MoralesNoch keine Bewertungen

- Ball Mill Machine Guide - Less than 40 CharactersDokument2 SeitenBall Mill Machine Guide - Less than 40 Characterspadma26327Noch keine Bewertungen

- Presentation-Hydraulic System in VRPMDokument24 SeitenPresentation-Hydraulic System in VRPMmsvprasadNoch keine Bewertungen

- Ball Mill MaintainanceDokument3 SeitenBall Mill MaintainanceKritish ShettyNoch keine Bewertungen

- VRM OKoookuuiiiiljjjjyggyyDokument8 SeitenVRM OKoookuuiiiiljjjjyggyyRakaNoch keine Bewertungen

- Vertical Roller MillDokument3 SeitenVertical Roller MillChaitanya Chinta0% (1)

- Microsoft Word - Technical Paper-No.8Dokument5 SeitenMicrosoft Word - Technical Paper-No.8Sam ShiddoNoch keine Bewertungen

- Filter Bags Datasheet PDFDokument9 SeitenFilter Bags Datasheet PDFRamya MadhuNoch keine Bewertungen

- AUMUND Pan Conveyors Fd0a10Dokument24 SeitenAUMUND Pan Conveyors Fd0a10Bruno100% (1)

- 9.inspeksi Belt ConveyorDokument18 Seiten9.inspeksi Belt ConveyorYogi Prakoso NNoch keine Bewertungen

- Maintenance of Crushers: R S BaislaDokument52 SeitenMaintenance of Crushers: R S BaislaRavindranath BheemisettyNoch keine Bewertungen

- Coal Mill Wear Measurement 29.09.2014Dokument1 SeiteCoal Mill Wear Measurement 29.09.2014Durga PrasadNoch keine Bewertungen

- DT II A Belt ConveyorDokument1 SeiteDT II A Belt ConveyorBunkun15Noch keine Bewertungen

- ThyssenKrupp Gyratory CrushersDokument12 SeitenThyssenKrupp Gyratory CrushersSokitome100% (1)

- Rolling Bearings VRMDokument2 SeitenRolling Bearings VRMRollerJonnyNoch keine Bewertungen

- 01.0 - 22146.002E - Hydraulic SystemDokument126 Seiten01.0 - 22146.002E - Hydraulic SystemShariq Khan100% (1)

- 2 200901loeschetadipatri 120803014722 Phpapp01Dokument4 Seiten2 200901loeschetadipatri 120803014722 Phpapp01Sai Sricharan ReddyNoch keine Bewertungen

- Crushing Principles and Equipment: by Evgueni Porokhovoi. 2019Dokument53 SeitenCrushing Principles and Equipment: by Evgueni Porokhovoi. 2019DubistWhite100% (1)

- Better Grinding Systems with V-Separator and VSK-SeparatorDokument5 SeitenBetter Grinding Systems with V-Separator and VSK-SeparatorGerman Gabriel Anaya VegaNoch keine Bewertungen

- HYDRAULIC POWER UNIT MANUALDokument21 SeitenHYDRAULIC POWER UNIT MANUALChancadores ChileNoch keine Bewertungen

- Influence of Quartz Particles On Wear in Vertical Roller Mills.Dokument9 SeitenInfluence of Quartz Particles On Wear in Vertical Roller Mills.chienhamthepNoch keine Bewertungen

- ConyevorsDokument9 SeitenConyevorsRohan MalkarNoch keine Bewertungen

- Hot Alignment 2009Dokument97 SeitenHot Alignment 2009Anonymous V210wtJiZNoch keine Bewertungen

- OK MillDokument52 SeitenOK MillHazem Hasan100% (1)

- 45-Vibrating Screens PDFDokument12 Seiten45-Vibrating Screens PDFAnonymous NxpnI6jC100% (2)

- Introduction to ACC Cement CompanyDokument36 SeitenIntroduction to ACC Cement CompanyPrabir Kumar PatiNoch keine Bewertungen

- Type SDFC Sizes 290 To 1040 - EngDokument2 SeitenType SDFC Sizes 290 To 1040 - EngKUNALJAYNoch keine Bewertungen

- Crusher SolectionDokument7 SeitenCrusher SolectionSomnath BanerjeeNoch keine Bewertungen

- 19PWCHE1431Dokument6 Seiten19PWCHE1431Khan AaghaNoch keine Bewertungen

- Particle Technology: Size Reduction EquipmentsDokument7 SeitenParticle Technology: Size Reduction EquipmentsMubarak AhmadNoch keine Bewertungen

- Major Raw Material Required For Iron MakingDokument2 SeitenMajor Raw Material Required For Iron Makingdlodha5100% (1)

- Industrial CrushersDokument4 SeitenIndustrial Crushersdlodha5100% (1)

- 3 Phase Not 4 PhaseDokument1 Seite3 Phase Not 4 Phasedlodha5Noch keine Bewertungen

- To Bull Head Hammer at VSP:-: Composition of 50 CR Mo 4Dokument12 SeitenTo Bull Head Hammer at VSP:-: Composition of 50 CR Mo 4dlodha5Noch keine Bewertungen

- Pressure Control Flare StackDokument44 SeitenPressure Control Flare Stackdlodha5Noch keine Bewertungen

- Ring CraneDokument4 SeitenRing Cranedlodha5Noch keine Bewertungen

- VFD ImportantDokument13 SeitenVFD Importantdlodha5Noch keine Bewertungen

- MAT224 User Guide-Aug25-2020Dokument32 SeitenMAT224 User Guide-Aug25-2020YJ WangNoch keine Bewertungen

- Learn About Rocks and MineralsDokument6 SeitenLearn About Rocks and MineralsDarwin SawalNoch keine Bewertungen

- ManualDokument2 SeitenManualJose Arthur AbellaNoch keine Bewertungen

- ZINCALUME Steel Technical Bulletins V14.0Dokument31 SeitenZINCALUME Steel Technical Bulletins V14.0beck.26Noch keine Bewertungen

- Hojas Msds 2011 Aceite RidgidDokument7 SeitenHojas Msds 2011 Aceite RidgidPer CYNoch keine Bewertungen

- Your Refrigerant For Sustainable Chilling and FreezingDokument8 SeitenYour Refrigerant For Sustainable Chilling and FreezingJavier AffifNoch keine Bewertungen

- Llautó M38 CuZn37Dokument2 SeitenLlautó M38 CuZn37Josep TanuNoch keine Bewertungen

- Synthesis of Fuel From Waste PlasticDokument63 SeitenSynthesis of Fuel From Waste Plasticamirah1999Noch keine Bewertungen

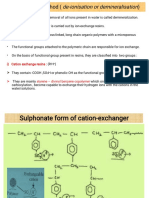

- Ion Exchange ProcessDokument10 SeitenIon Exchange Process056 Jatin GavelNoch keine Bewertungen

- Ilovepdf Merged RemovedDokument19 SeitenIlovepdf Merged RemovedNeet AspirantNoch keine Bewertungen

- Experiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerDokument5 SeitenExperiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerswatkoolNoch keine Bewertungen

- Functional Biopolymers: Mohammad Abu Jafar Mazumder Heather Sheardown Amir Al-Ahmed EditorsDokument586 SeitenFunctional Biopolymers: Mohammad Abu Jafar Mazumder Heather Sheardown Amir Al-Ahmed EditorsMonique BarretoNoch keine Bewertungen

- Niclal 38, Cumn10Ni4: (Shunt Grade)Dokument2 SeitenNiclal 38, Cumn10Ni4: (Shunt Grade)Marcel KuhneNoch keine Bewertungen

- Plastic Roads: A Sustainable Solution to Plastic WasteDokument8 SeitenPlastic Roads: A Sustainable Solution to Plastic WasteShahid Bhat0% (1)

- Waste Disposal Information Municipality WallisellenDokument1 SeiteWaste Disposal Information Municipality WallisellenCalimeroNoch keine Bewertungen

- Culvert Estimate 600mm PipeDokument6 SeitenCulvert Estimate 600mm Pipedhiraj KumarNoch keine Bewertungen

- Plastic FormingDokument11 SeitenPlastic FormingAngeloLorenzoSalvadorTamayoNoch keine Bewertungen

- Van Der WaalsDokument2 SeitenVan Der WaalsDwi Esti KusumandariNoch keine Bewertungen

- M&MSDokument2 SeitenM&MSASIST MechNoch keine Bewertungen

- What Is X-Ray Powder Diffraction (XRD) : Bragg's LawDokument8 SeitenWhat Is X-Ray Powder Diffraction (XRD) : Bragg's LawsafiNoch keine Bewertungen

- SoapsDokument7 SeitenSoapsLucita P. CatarajaNoch keine Bewertungen

- Surfactant Assisted Synthesis of Cuprous Oxide (Cu O) Nanoparticles Via Solvothermal ProcessDokument7 SeitenSurfactant Assisted Synthesis of Cuprous Oxide (Cu O) Nanoparticles Via Solvothermal ProcessNILTHON FRANCO POMA HUARINGANoch keine Bewertungen

- Pitch Control: Environmental BenefitsDokument3 SeitenPitch Control: Environmental Benefitsfcchemicalsupply CompanyNoch keine Bewertungen

- Industrial MixersDokument22 SeitenIndustrial MixersKaustubh ThawkarNoch keine Bewertungen

- Outokumpu Stainless Steel For Automotive IndustryDokument20 SeitenOutokumpu Stainless Steel For Automotive IndustrychristopherNoch keine Bewertungen

- KP200Dokument4 SeitenKP200DrGanesh Kame100% (1)

- Discharge Plasma and Ion - Surface InteractionsDokument50 SeitenDischarge Plasma and Ion - Surface InteractionsIriantoNoch keine Bewertungen

- Peelman 2013Dokument32 SeitenPeelman 2013Jennilou CortesNoch keine Bewertungen

- Sample Concept PapersDokument30 SeitenSample Concept PapersEmily Dueñas SingbencoNoch keine Bewertungen