Beruflich Dokumente

Kultur Dokumente

Checklist Mutu

Hochgeladen von

Imelda Gisela Prima PaskhalienCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Checklist Mutu

Hochgeladen von

Imelda Gisela Prima PaskhalienCopyright:

Verfügbare Formate

ELEMENT

DESCRIPTION

OK NOK N/A

EXPLANATION/NOTES

REFERENCE (IF ANY)

1. PRIMARY PRODUCTION

1.1 Environmental hygiene 1.1.1 Primary food production should not be carried on in areas where the presence of potentially harmful substances could lead to an unacceptable level of such substances in food. Potential sources of contamination from the environment should be considered. 1.2.1 The potential effects of primary production activities on the safety and suitability of food should be considered at all times. In particular, this includes identifying all specific aspects in such activities where a high probability of contamination may exist and taking specific measures to minimise that probability. 1.2.2 Measures should as far as practicable be implemented to: control contamination from air, soil, water, feedstuffs, fertilisers (including natural fertilisers), pesticides, veterinary drugs or any other agent used in primary production; control raw material and animal health so that it does not pose a threat to human health through food consumption, or adversely affect the suitability of the product; protect raw materials for food from faecal and other contamination. 1.2.3 In particular, care should be taken to manage waste and store harmful substances appropriately. 1.2.4 Programmes on farms and in primary production companies which achieve specific food safety goals are becoming an important part of primary production and should be encouraged. 1.3 Handling, storage and transport 1.3.1 Procedures should be in place to: sort food and food ingredients to segregate material which is evidently unfit for human consumption; dispose of any rejected material in a hygienic manner; protect food and food ingredients from contamination by pests or plant diseases, or by chemical, physical or microbiological contaminants or other objectionable substances during handling, storage and transport. 1.3.2 Care should be taken to prevent, so far as practicable, deterioration and spoilage through appropriate measures which may include controlling temperature, humidity, and/or other controls. 1.4 Cleaning, maintenance and personal hygiene 1.4.1 Appropriate facilities and procedures should be in place to ensure that: any necessary cleaning and maintenance is carried out effectively; an appropriate degree of personal hygiene is maintained. . .

1.2 Hygienic production of food sources

2.1 LOCATION 2.1.1 Establishment 2.1.1.1 Establishments should not be located anywhere where it is clear that there will remain a threat to food safety or suitability. In particular, establishments should normally be located away from: environmentally polluted areas and industrial activities which pose a serious threat of contaminating food; areas subject to flooding unless sufficient safeguards are provided; areas affected by or prone to infestations of pests or plant diseases; areas where waste, either solid or liquid, cannot be removed effectively. 2.1.2.1 Equipment should be located so that it: permits adequate use and cleaning; functions in accordance with its intended use; facilitates good hygiene practices, including monitoring.

2.1.2 Equipment

2.2 BUILDINGS AND ROOMS 2.2.1 Design and layout 2.2.1.1 Where appropriate, the internal design and layout should permit good hygiene practices, including protection against hazardous contamination and cross-contamination. 2.2.2.1 Structures within buildings for the OK processing of foods should be built of suitable materials and be easy to maintain, clean and, where appropriate, able to be disinfected. 2.2.2.2 The surfaces of walls, partitions and OK floors should be made of impervious materials with no toxic effect in normal use. 2.2.2.3 Walls and partitions should have a OK smooth surface up to a height appropriate to the activities. 2.2.2.4 Floors should be constructed to allow OK adequate drainage and cleaning. Struktur dari bangunan ini sudah kokoh dan terdiri dari material yang mudah dibersihkan.

2.2.2 Internal structures and building materials

Langit-langitnya menggunakan eternit sedangkan lantai terbuat dari keramik yang mudah dibersihkan, menarik dan terkesan bersih. Permukaan dinding rata sehingga kecil peluang kontaminasi. Lantai keramik mudah dibersihkan sedangkan lantai tempat mencuci didesain dengan kemiringan khusus agar mudah proses penurunan airnya. Kemungkinan kontaminasi cukup kecil karena ruangan ini tertutup sehingga bagian atasnya aman untuk proses produksi. Jendelanya tidak ada. Yang ada hanya ventilasi dan letaknya di atas sehingga untuk membersihkan perlu alat yang tinggi untuk mencapainya.

2.2.2.5 Ceilings and overhead fixtures should be OK constructed and finished to minimise the accumulation of dirt and condensation, and contamination by the shedding of particles. 2.2.2.6 Windows should be constructed to be NOK easy to clean and to minimise the accumulation of dirt. Where necessary, they should be fitted with removable and cleanable insect-proof screens. Where necessary, windows should be fixed. 2.2.2.7 Doors should have smooth, non- OK absorbent surfaces, and should be easy to clean, maintain and disinfect. 2.2.2.8 Surfaces that come into direct contact NOK with food should be in sound condition, made of durable materials and easy to clean, maintain and disinfect. They should be made of smooth,

Pintu terbuat dari besi yang dicat warna biru dan untuk proses pembersihannya hanya dilap saja jika sudah kotor. Alat yang kontak dengan makanan sudah terbuat dari stainless steel dan aluminium sehingga aman dari karat tetapi alat yang digunakan untuk menuang teh masih terbuat dari plastik dimana

non-absorbent materials that are inert to the food, and can withstand repeated cleaning and disinfecting under normal operating conditions 2.2.3 Temporary/mobile facilities; vending machines 2.2.2.5 Facilities and structures should be NOK located, designed and constructed to avoid, as far as possible, contaminating food and harbouring pests. 2.2.3.2 Any potential food hazards associated OK with such facilities should be adequately identified and controlled to ensure the safety and suitability of food. 2.3 EQUIPMENT 2.3.1 General 2.3.1.1 Equipment components and reusable OK containers coming into direct contact with food should be designed and constructed to ensure that, where necessary, they can be adequately cleaned, disinfected and maintained to avoid contamination of the product. 2.3.1.2 Equipment components and containers OK should be made of materials with no toxic effect in normal use.

polimer dapat bermigrasi jika terkena panas.

Ruang produksi dekat dengan toilet yang mmenungkinkan terjadinya kontaminasi.

Pengontrolan terhadap fasilitas terjadi hanya dengan mengamati kondisi fisik dari fasilitas yang ada.

Secara umum, peralatan yang mengalami kontak langsung dengan makanan bisa dibongkar pasang sehingga mudah dalam membersihkannya.

Komponen dari peralatan tidak terbuat dari substansi yang berbahaya atau dapat menyebabkan kontaminasi. Peralatan terbuat dari aluminium dan stainless steel kecuali alat untuk menuang teh dalam gelas yang masih terbuat dari plastik. Peralatan dapat dipindahkan dari tempatnya sehingga bisa dilakukan perawatan, pengecekan atau pembersihan ruangan.

2.3.1.3 Where necessary, equipment should be OK durable and movable or capable of being disassembled to allow for maintenance, cleaning, disinfection, monitoring and, for example, to facilitate inspection for pests. 2.3.2 Food control and monitoring of equipment 2.3.2.1 In addition to the general requirements in OK paragraph 2.3.1, equipment used to cook, heat treat, cool, store or freeze food should be designed to achieve the required product temperatures as rapidly as possible (in the interests of food safety and suitability) and maintain them effectively. 2.3.2.2 The equipment should also be designed N/A to allow temperatures to be recorded and controlled. Where necessary, the equipment should have effective means of controlling and recording humidity, air-flow and any other process parameters likely to have a detrimental effect on the safety or suitability of food. 2.3.3 Containers for waste and inedible substances 2.3.3.1 Containers for waste, by-products and OK substances not intended for human consumption or dangerous, should be identifiable and suitably constructed, and, where appropriate, made of impervious materials. 2.3.3.2 Containers used to hold dangerous NOK substances should be identified and, where appropriate, be lockable to prevent malicious or accidental contamination of food.

Peralatan yang digunakan masih manual, contohnya seperti peralatan yang telah digunakan untuk memasak kemudian didinginkan dan dibersihkan.

Hal tersebut tidak terlalu dibutuhkan dalam skala rumah makan karena akan meningkatkan biaya investasi peralatan.

Tempat untuk sampah padat (sisa mie) dimasukkan ke dalam tempat sampah yang dirangkap plastik (kresek), sedangkan limbah cair langsung dibuang ke saluran pembuangan. Peralatan untuk menuang teh yang digunakan terbuat dari bahan plastik, yang mana jika terkena panas akan terjadi migrasi polimer-polimer plastik ke produk pangan. Saran: Sebaiknya, peralatan yang digunakan terbuat dari stainless steel atau bahan lain yang tidak mudah terurai jika terkena panas.

2.4 FACILITIES 2.4.1 Water supply 2.4.1.1 An adequate supply of potable water with OK appropriate facilities for its storage, distribution and temperature control, should be available Untuk proses produksi digunakan air PAM yang dimasak terlebih dahulu hingga mendidih. Sedangkan air yang digunakan untuk minum

whenever necessary at all times. Potable water should at least meet the specifications in the WHO Guidelines for Drinking Water Quality. 2.4.1.2 Separate systems for non-potable water OK (for use in, for example, fire control, steam production, freezing) should be identified as such and should not connect with, or allow reflux into, drinking water systems.

berasal dari air galon yang dibeli di depot air minum. Air minum dan air yang digunakan untuk proses produksi terpisah.

2.4.2 Drainage of liquids and waste flows

2.4.2.1 Adequate drainage and waste disposal NOK systems should be provided. They should be designed, constructed and maintained so that the risk of contaminating food or the potable water supply is avoided.

Saluran pembuangan limbah terbuka sehingga dapat menimbulkan bau dan kontaminasi yang dapat sampai ke produk tetapi sudah cukup baik karena ditutupi dengan jeruji besi.

2.4.3 Cleaning

2.4.3.1 Adequate facilities, suitably designed, OK should be provided for cleaning utensils and equipment that come into contact with food. Such facilities should have an adequate supply of cold and hot (suitably temperature controlled) potable water where necessary. 2.4.4.1 Adequate means of hygienically washing OK and drying hands, including wash basins and a supply of cold and hot (suitably temperature controlled) water should be available. 2.4.4.2 Toilets of appropriate hygienic design OK should be available. 2.4.4.3 Adequate changing personnel should be available. facilities for OK

Sudah tersedia tempat untuk mencuci peralatan.

2.4.4 Personal hygiene, facilities and toilets

Untuk cuci tangan telah disediakan wastafel yang dilengkapi dengan sabun dan untuk mengeringkan tangan dapat menggunakan serbet. Tersedia toilet yang terjamin kebersihannya.

Toilet biasanya juga difungsikan sebagai kamar ganti. Hal ini dikarenakan tidak ada seragam khusus untuk pegawai (hanya butuh celemek saja). Fasilitas-fasilitas yang ada sudah diatur sedemikian rupa akan tetapi letaknya masih kurang strategis. Toilet masih 1 ruangan dengan ruang produksi pembuatan mie dan dibiarkan terbuka, sehingga dapat menimbulkan kontaminasi. Saran: Sebaiknya ruang produksi terpisah dengan toilet. Dalam proses pemasakan menggunakan patokan suhu. mie tidak

2.4.4.4 The above mentioned facilities should be NOK suitably located and designed.

2.4.5 Temperature control

2.4.5.1 Facilities for heating, refrigerating and freezing food, or for storing refrigerated or frozen foods, should be suitable for reaching and maintaining the set conditions in order to guarantee food safety. 2.4.6.1 Adequate mechanical or natural ventilation should be provided to: minimise airborne contamination of food (e.g. from aerosols or condensation droplets). control ambient temperatures. control humidity.

OK

2.4.6 Air quality and ventilation

OK

Telah tersedia ventilasi udara yang cukup pada tiap ruangan sehingga dapat terjadi pertukaran udara yang baik walaupun tidak ada jendela.

2.4.6.2 Ventilation systems should be designed N/A

Tidak ada design khusus pada pembuatan

and constructed so that the air does not flow from contaminated areas to clean areas and, where necessary, they can be adequately maintained and cleaned. 2.4.7 Lighting 2.4.7.1 The intensity and colour of the lighting OK should be sufficient to ensure the production and handling of safe food.

ventilasi. Ventilasi yang ada posisinya terlalu tinggi sehingga sulit untuk dibersihkan. Saran: sebaiknya pembuatan ventilasi diperhitungkan agar dapat dibersihkan secara berkala sehingga tidak menimbulkan kontaminasi. Pada ruang produksi digunakan lampu dengan intensitas cahaya yang cukup terang. Pada ruang pemasakan dan penyajian menggunakan sinar matahari, jika malam hari menggunakan lampu yang cukup memadai untuk penerangannya. Pada lampu tidak terdapat penutup lampu yang bila lampu pecah dapat mengkontaminasi makanan. Hal ini merupakan faktor yang tidak dianggap penting. Saran: sebaiknya lampu yang digunakan diberi penutup lampu agar jika pecah tidak langsung mengkontaminasi produk. Ada tempat khusus untuk menyimpan bahan baku seperti tepung terigu, telur dan bahan lainnya. Tempat penyimpanan terbuka sehingga dapat menimbulkan kontaminasi serangga dan tikus. Saran: tempat penyimpanan harus didesain tertutup rapat sehingga dapat terbebas dari pest. Tempat penyimpanan makanan diletakkan terpisah dari tempat yang dapat menimbulkan kontaminasi.

2.4.7.2 Lighting fixtures should, where NOK appropriate, be protected to ensure that food is not contaminated by breakages.

2.4.8 Storage

2.4.8.1 Adequate facilities for the storage of food OK ingredients and non-food materials (e.g. cleaning materials, lubricants, fuels) should be provided. 2.4.8.2 Food storage facilities should be NOK designed and constructed to: - permit adequate maintenance and cleaning. - avoid pest access and harbourage. - effectively protect food against contamination. - minimise loss of product. 2.4.8.3 Storage facilities should be designed, OK constructed and maintained to prevent the malicious or accidental contamination of food with hazardous substances.

3.1 Control of potential food hazards

3.1.1 Food companies should control food N/A hazards through the use of systems such as HACCP. These control systems should be used throughout the entire food chain to guarantee the safety and suitability of food throughout the shelflife of the product.

Rumah makan mie Kota Kembang tidak menggunakan prinsip HACCP dalam mengontrol adanya resiko pada produk yang dihasilkan. Tidak diterapkannya HAACP pada rumah makan ini karena rumah makan tersebut merupakan usaha skala kecil saja.

3.2 Key factors of hygiene control systems 3.2.1 Time and temperature control 3.2.1.1 Time and temperature control systems NOK should be in place during heating, cooling and storage where necessary for the production and safety of food. Control systems cover critical limits, recording and testing the accuracy of the measuring equipment. 3.2.2.1 The effect of other process steps such as NOK chilling, thermal processing, irradiation, drying, chemical preservation, vacuum or modified atmospheric packaging, on the safety and suitability of food should be considered. 3.2.3.1 Where microbiological, chemical or NOK physical specifications are important for food safety, such specifications should be based on sound scientific principles and should specify, where appropriate, monitoring procedures, action limits and analysis methods. 3.2.4.1 Where necessary, raw materials and OK Tidak ada sistem kontrol untuk suhu dan waktu pada saat pemasakan dan penyimpanan karena butuh biaya besar.

3.2.2 Specific process steps

Belum dipertimbangkan mengenai adanya efek dari setiap tahapan produksi karena masih dalam skala kecil.

3.2.3 Microbiological and other properties

Tidak ada spesifikasi-spesifikasi dan monitoring khusus mengenai standar mikrobiologi, fisik dan kimia yang diterapkan pada produk ini.

3.2.4 Microbiological

Bahan baku yang digunakan terpisah dari bahan

cross-contamination

unprocessed food should be separated from processed food.

effectively

jadi sehingga dapat kontaminasi silang.

mengurangi

resiko

3.2.4.2 Where necessary, access to processing NOK areas or departments should be restricted or controlled. Access and control procedures should be established and recorded. 3.2.4.3 All surfaces, utensils, equipment, fixtures OK and fittings should be clean and where necessary disinfected after contact with unprocessed food in order to prevent contamination. 3.2.5 Physical and chemical contamination 3.2.5.1 Systems should be in place to prevent NOK contamination of foods by foreign bodies (e.g. glass, metal, dust, hazardous fumes) and hazardous chemicals. 3.2.5.2 Suitable and effective detection or OK screening devices should be used where necessary. 3.3 Requirements for incoming materials 3.3.1 Specifications 3.3.1.1 No raw material or ingredient should be OK accepted by a food company if it is known to contain parasites, undesirable micro-organisms, pesticides, veterinary drugs or toxic, decomposed or extraneous substances which would not be reduced to an acceptable level by normal sorting and/or processing. Where necessary, specifications for raw materials should be established and applied. 3.3.2.1 Where appropriate, raw materials or OK ingredients should be inspected and sorted before processing. Where necessary, laboratory tests should be performed in order to establish fitness for use. Only suitable, sound raw materials should be used. 3.3.3.1 Stocks of raw materials and ingredients OK should be managed (stock rotation, first-in-firstout).

Tidak dilakukan pengontrolan pada jalan untuk masuk ruang produksi serta tidak ada dokumentasi dari setiap prosedur yang dilakukan. Pembersihan peralatan dilakukan secara rutin dan pada saat yang diperlukan.

Pencegahan kontaminasi fisik dilakukan dengan penyortiran dan pengontrolan. Sedangkan untuk pencegahan kontaminasi kimia belum dilakukan. Penyortiran dilakukan secara manual dan efektif.

Semua bahan baku yang masuk pastinya dibeli dengan standar tertentu yang dilihat dari keadaan fisiknya saja.

3.3.2 Intake inspection

Selalu ada proses penyortiran sebelum bahan tersebut digunakan walaupun tidak sampai menggunakan tes laboratorium.

3.3.3 Stock rotation

Ada pengaturan penggunaan bahan baku dimana bahan baku yang dibeli dahulu itu yang digunakan dahulu.

3.4 Packaging 3.4.1 Design and materials 3.4.1.1 Packaging design and materials should NOK provide adequate protection for foods to minimise contamination, prevent damage, and accommodate proper labelling. 3.4.2.1 Packaging materials and gases must be OK non-toxic and should not pose a threat to the safety and suitability of food under the specified conditions of storage and use. 3.4.3.1 Reusable packaging should be OK sufficiently durable, easy to clean and, where necessary, easy to disinfect. Pengemas yang digunakan untuk makanan yang dibawa pulang sudah dapat melindungi produk dari kontaminasi fisik walaupun masih menggunakan plastik yang memungkinkan migrasi polimer. Pengemas yang digunakan tidak berbahaya dan aman.

3.4.2 Food-grade materials and gases

3.4.3 Reusable packaging 3.5 Water 3.5.1 Water in contact with food

Tidak menggunakan pengemas yang dapat digunakan kembali.

3.5.1.1 Only potable water should be used in food handling and production, with the following exceptions: for steam production, fire control and other similar purposes not connected with food. in certain food processes (e.g. chilling) and in

OK

Air yang digunakan untuk proses produksi adalah air PAM, sedangkan air dalam galon digunakan untuk air minum saja.

production areas, and places where this does not constitute a hazard to the safety and suitability of food (e.g. the use of clean sea water). 3.5.2 Reuse of recirculated treated water 3.5.2.1 Water recirculated for reuse should be treated and maintained in such a condition that no risk to the safety and suitability of food results from its use. This process should be effectively monitored. 3.5.3.1 Recirculated water for reuse which has received no further treatment and water recovered from the processing of food by evaporation or drying may be used, provided its use does not constitute a risk to the safety and suitability of food. 3.5.4.1 Potable water should be used. 3.5.5.1 Ice should be made from water that complies with the requirements of paragraph 2.4.1. Ice and steam should be produced, handled and stored so that contamination is avoided. 3.5.5.2 Steam used in direct contact with food or food contact surfaces should not contain any components or additives that constitute a threat to the safety of food. 3.6 Management and supervision 3.6.1 Type of control and supervision 3.6.2 Necessary knowledge 3.6.1.1 The type of control and supervision used NOK will depend on the size of the business, the nature of its activities and the type of food. 3.6.2.1 Managers and supervisors should have OK enough knowledge of the principles and practices of food safety and suitability to be able to judge potential risks, take appropriate preventive and remedial action, and ensure that effective monitoring and supervision takes place. Tidak ada pengontrolan dan supervisi karena ini hanya skala kecil saja. Produsen waaupun tidak ada pengetahuan khusus yang detail tetapi mengerti sedikit tentang kemaanan pangan. NOK Air yang telah digunakan tidak dapat didaur ulang karena tidak ada proses pengolahan limbah yang dilakukan. Jika ada daur ulang maka dibutuhkan biaya yang sangat besar. Tidak dilakukan proses daur ulang air yang sudah digunakan.

3.5.3 Reuse of recirculated untreated water

NOK

3.5.4 As an ingredient 3.5.5 Ice and steam

OK OK

Sudah menggunakan air yang layak minum. Air yang digunakan untuk membuat es sudah layak minum.

N/A

Tidak menggunakan pemasakannya.

uap

dalam

proses

3.7 Documentation and records 3.7.1 Records 3.7.1.1 Where necessary, appropriate records of N/A processes, production and distribution should be kept and retained for a period that exceeds the shelf-life of the food. 3.7.2.1 Documentation should enhance the N/A effectiveness and credibility/reliability of the food safety system. Tidak ada proses pencatatan karena rumah makan ini hanya skala kecil saja.

3.7.2 Effectiveness and credibility 3.8 Recall procedures 3.8.1 Effective procedures

Tidak ada proses pencatatan karena rumah makan ini hanya skala kecil saja.

3.8.1.1 Managers should ensure that effective OK procedures are in place to deal with any food safety hazard and to enable the complete, rapid recall of any implicated lot or delivered product from the market. 3.8.2.1 Where a product has been withdrawn N/A because of an immediate health hazard, other products which are produced and/or handled under similar conditions and which may present a similar hazard to public health, should be evaluated for safety and may need to be

Prosedur yang dilakukan sudah cukup efektif walaupun belum terlalu memperhatikan keamanan pangannya.

3.8.2 Tracing and Tracking

Belum ada peristiwa pengembalian produk seperti itu selama ini.

withdrawn. The need for public warnings should be considered. 3.8.3 Destruction or reprocessing 3.8.3.1 Recalled foods should be held under N/A supervision until they are destroyed, used for purposes other than human consumption, or reprocessed in a way that ensures their safety. Belum ada peristiwa pengembalian produk seperti itu selama ini maka hal ini tidak dilakukan.

4 ESTABLISHMENT: MAINTENANCE AND SANITATION

4.1 Maintenance and cleaning 4.1.1 General 4.1.1.1 Establishments and equipment should be OK kept in an appropriate state of repair and condition to: - facilitate all cleaning procedures. - function as intended, particularly at critical steps. - prevent contamination of food, e.g. from metal shards, flaking plaster, debris and chemicals. 4.1.1.2 Cleaning should remove food residues OK and dirt which may be a source of contamination. The necessary cleaning methods and materials will depend on the nature of the food business. Disinfection may be necessary after cleaning. 4.1.1.3 Cleaning materials and chemicals should OK be handled and used carefully and in accordance with manufacturers' instructions. 4.1.1.4 Cleaning materials and chemicals should, OK if necessary, be stored separately from food in clearly marked containers to avoid the risk of malicious or accidental contamination of food. 4.1.2 Cleaning procedures and methods 4.1.2.1 Cleaning and disinfection methods N/A should be specified in writing. The water used should meet the requirements in paragraph 2.4.1. Contamination of foods with cleaning materials should be avoided. Semua peralatan sudah ditempatkan pada tempat yang tepat sehingga mencegah kontaminasi.

Sudah ada proses pembersihan setiap hari untuk menghindari terjadinya kontaminasi.

Material pembersih seperti sabun sudah digunakan sesuai dengan prosedur yang benar. Walaupun tidak diberi tanda khusus tetapi bahan pembersih diletakkan di tempat yang berbeda dari bahan makanan. Tidak ada penulisan prosedur khusus untuk metode pembersihan karena pembersihan menggunakan bahan dan alat yang mudah dalam penggunaannya.

4.2 Cleaning methods 4.2.1 Specifications 4.2.1.1 Cleaning and disinfection programmes N/A should ensure that all parts of the establishment are kept appropriately clean, and should include the cleaning of the cleaning equipment itself. Where written cleaning programmes are used, they should cover the following aspects: Areas, items of equipment and utensils to be cleaned; Responsibility for particular tasks; Method and frequency of cleaning; Monitoring arrangements. Where appropriate, programmes should be drawn up in consultation with technical advisors. 4.2.2.1 Cleaning and disinfection programmes N/A should be continually and effectively monitored for their suitability and effectiveness and, where necessary, documented. Tidak ada penulisan tentang program yang mencakup tentang tugas, metode pembersihan, dll. karena ini hanya skala kecil saja.

4.2.2 Monitoring en verification

Tidak ada dokumentasi dan pengontrolan khusus hanya saja jika sudah kotor maka akan dibersihkan dan biasanya berlangsung setiap hari.

4.3 Pest control 4.3.1 General 4.3.1.1 Good safety practices should be OK employed to avoid creating an environment conducive to pests. Good sanitation, inspection Sudah ada inspeksi dan sanitasi yang baik terhadap datangnya bahan baku yang akan digunakan.

of incoming materials and good monitoring can minimise the likelihood of infestation and thereby limit the need for pesticides. 4.3.2 Preventing access 4.3.2.1 Buildings should be kept in good repair OK and condition to prevent pest access and to eliminate potential breeding sites. 4.3.2.2 Holes, drains and other places where OK pests are likely to gain access should be kept sealed. Measures such as wire mesh screens on items that cannot be sealed (for example on open windows, doors and fans) will reduce the problem of pest entry. 4.3.2.3 Animals should, wherever possible, be NOK excluded from the company grounds and food production equipment. 4.3.3 Harbourage 4.3.3.1 Potential food sources should be stored NOK and in pest-proof containers and/or stacked above infestation/contamina the ground and away from walls. tion 4.3.3.2 Areas both inside and outside food OK establishments should be kept clean. Where necessary, refuse should be stored in covered, pest-proof containers. 4.3.4 Monitoring en detection 4.3.4.1 Records of periodic inspections of N/A establishments and their environment should be kept and should be accessible. 4.3.5.1 Pest infestations should be dealt with OK immediately and without adversely affecting food safety or suitability. Bangunan sudah dibuat untuk mencegah akses dari tikus dan perkembangbiakannya karena selalu dibersihkan setiap hari. Pntu sudah diberi penutup agar tikus tidak bisa masuk, begitu pula dengan selokan juga sudah diberi jeruji agar tikus tidak masuk.

Pintu utama memang dibuka tetapi ada kursi duduk di dekat pintu utama sehingga dapat menjaga binatang masuk ke dalam area rumah makan. Memang tidak dimasukkan ke dalam kontainer khusus tetapi sudah diletakkan di atas lantai dan ada yang berdekatan langsung dengan dinding. Area baik di dalam dan di luar rumah makan sudah bersih.

Tidak ada pencatatan inspeksi khusus secara berkala tentang lingkungan di area rumah makan hanya jika sudah kotor amaka akan dibersihkan sehingga tidak mengganggu pemandangan. Perlindungan bahan terhadap tikus sudah dilakukan sehingga tidak akan mempengaruhi keamanan pangan.

4.3.5 Eradication

4.4 Waste management 4.4.1 Removal, storage 4.4.1.1 Suitable provision should be made for the OK removal and storage of waste. Waste must not be allowed to accumulate in food handling, food storage, other working areas and the adjoining environment except so far as is unavoidable for the proper functioning of the business. 4.4.2.1 Waste stores should be kept sufficiently clean. OK Semua limbah padat sudah diletakkan dalam plastik tempat sampah dan ditunggu sampai penuh dahulu baru setelah itu dibuang karena akan lebih efektif sedangkan untuk limbah cair langsung dibuang ke selokan. Tempat pembuangan sampah sudah tertata dengan rapi.

4.4.2 Cleaning 4.5 Sanitation 4.5.1 Monitoring 4.5.2 Verification

4.5.1.1 The effectiveness of sanitation systems should be monitored.

NOK

Monitoring tidak dilakukan dengan detail hanya jika dirasa sudah kotor baru dibersihkan. Tidak ada inspeksi dan pengamatan sanitasi secara periodik apalagi sampai menggunakan tes mikrobiologi karena ini hanya skala kecil saja.

4.5.2.2 Sanitation systems should be verified N/A periodically by means of inspections or, where necessary, microbiological sampling of the environment and food contact surfaces. The systems should be regularly reviewed and adapted to reflect changed circumstances. 4.5.3.1 Sanitation systems should be reviewed periodically and adapted to reflect changed circumstances N/A

4.5.3 Review

Tidak ada review khusus secara periodik tentang sanitasi karena ini hanya skala kecil saja.

5.1 Health status

5.1.1 Prevention

5.1.1.1 A system should be in place to ensure OK that people known, or suspected, to be suffering from, or to be a carrier of a disease or illness likely to be transmitted through food, are prevented from entering any food handling area. 5.1.1.2 Any person infected in this way should OK immediately report the illness or symptoms of illness to the management. Medical examination of a food handler or processor should be carried out if clinically or epidemiologically indicated.

Jika pekerja sakit maka harus meuntup bagian yang sakit agar tidak mengkontaminasi bahan pangan tersebut.

Pekerja yang sakit akan melapor pada Tante Dania sehingga tidak akan mengkontaminasi bahan pangan tersebut.

5.2 Illness and injuries 5.2.1 Conditions to be reported 5.2.1.1 Conditions that should be reported to the OK management so that any need for medical examination and/or possible exclusion from food handling can be considered, include: jaundice diarrhoea vomiting fever sore throat with fever visibly infected skin lesions (burns, cuts etc.) discharges from the ear, eye or nose. Para pekerja yang sakit akan melapor kepada Tante Dania sehingga ia bisa membantu memberikan obat dan tidak akan mengkontaminasi produk.

5.3 Personal cleanliness 5.3.1 Protective clothing 5.3.1.1 Food handlers should maintain a high NOK degree of personal cleanliness and, where appropriate, wear suitable protective clothing, head covering, and footwear. 5.3.2.1 Where personnel with wounds are OK permitted to continue working, cuts and other wounds should be covered by suitable waterproof dressings. Pekerja menggunakan pakaian sewajarnya saja tetapi ada yang tidak mengenakan kaos. Saran: sebaiknya pekerja mengguankan kaos minimal kaos singlet. Jika ada luka dapat dibalut dengan plester sehingga tidak mengkontaminasi produk.

5.3.2 Cuts and other wounds

5.3.3 Washing hands 5.3.3.1 Personnel should always wash their OK hands when personal cleanliness may affect food safety, for example: at the start of food handling activities. Immediately after using the toilet. after handling raw or contaminated products where this could result in contamination of other food items. Personnel should avoid handling ready-to-eat food unnecessarily. 5.4 Personal behaviour 5.4.1 Smoking, eating, blowing the nose 5.4.1.1 People who work with food should refrain OK from behaviour which could result in contamination of food, for example: smoking spitting chewing or eating blowing the nose or coughing over unprotected food. Personal effects such as jewellery, watches, NOK hairgrips, pins or other items should not be worn or brought into food handling areas if they pose a threat to the safety and suitability of food.

Di dekat area pembuatan mie, ada dapur yang terdiri dari wastafel pencucian piring sehingga bisa mencuci tangan sedangkan di daerah penyajian juga ada tempat pencucian peralatan yang bisa digunakan untuk mencuci tangan.

Para pekerja sudah dapat mengerti tentang peraturan untuk tidak merokok atau melakukan tindakan yang akan mengkontaminasi.

5.4.2 Jewellery

Tante Dania dan anaknya masih menggunakan cincin dan gelang yang bisa menyebabkan kontaminasi. Saran: tidak menggunakan perhiasan yang dapat menyebabkan kontaminasi.

5.5 Visitors 5.5.1 Hygiene and behaviour 5.5.1.1 Visitors to food producing, processing or NOK handling areas should, where appropriate, wear protective clothing and adhere to the applicable personal hygiene provisions and rules. Pengunjung yang ingin masuk seperti kami tidak menggunakan seragam khusus karena bisnis ini hanya skala kecil saja.

6. TRANSPORTATION

6.1 General 6.1.1 Food should be adequately protected OK Bahan pangan diproteksi dengan bantuan

during transportation in order to ensure its safety. 6.2 Requirements 6.2.1 Where necessary, vehicles and containers should be designed so that they: do not contaminate foods or packaging. can be effectively cleaned and, where necessary, disinfected. permit effective separation of different foods or foods from non-food items where necessary. provide effective protection from contamination, including dust, smoke and fumes. can effectively maintain the temperature, humidity, atmosphere and other conditions necessary to protect food from harmful or undesirable microbial growth and deterioration likely to render it unsuitable for consumption. allow any necessary temperature, humidity and other conditions to be checked. OK

pengemas selama transportasi. Kendaraan yang digunakan untuk mengantarkan bahan baku adalah kendaraan biasa saja dan terbebas dari kontaminasi karena selalu dibersihkan sedangkan bahan pangan tersebut juga terlindungi oleh kemasan yang ada.

6.3 Use and maintenance

6.3.1 Vehicles and containers for transporting OK food should be kept in an appropriate state of cleanliness, repair and condition. 6.3.2 Where the same vehicle or container is OK used for transporting different foods, or nonfoods, effective cleaning and, where necessary, disinfection should take place between loads. 6.3.3 Where appropriate, particularly in bulk NOK transport, vehicles and containers should be designated and marked for food use only and should only be used for that purpose.

Kontainer atau kendaraan untuk transportasi terawat baik. Selalu ada pembersihan transportasi bahan baku. sebelum proses

Kendaraan yang digunakan adalah kendaraan pribadi yang memungkinkan dipakai oleh anggota keluarga.

7. PRODUCT INFORMATION AND CONSUMER AWARENESS

7.1 Lot identification 7.1.1 Lot identification is essential in product N/A recall and also helps effective stock control (paragraph 3.2.). Each container of food should be permanently marked to identify the producer and the lot (see Codex General Standard for the Labelling of Pre-packaged Foods, Codex STAN 1-1985). 7.2.1 All food products should be accompanied N/A by or bear information to enable the next person in the food chain to handle, sell, store and prepare and use the product safely and correctly. 7.3.1 Prepackaged foods should be labelled with N/A clear instructions to enable the next person in the food chain to handle, display, store and use the product safely (see Codex General Standard for Labelling of Pre-packaged Foods, Codex STAN 1-1985). 7.4.1 Health information programmes should N/A cover the general principles of food safety and suitability. Such programmes should enable consumers to understand the importance of any product information and to follow any instructions accompanying products, and make informed choices. In particular, consumers should be informed of the relationship between time and temperature control and foodborne illness. Tidak ada informasi sedetail itu karena rumah makan ini hanya skala kecil.

7.2 Product information

Tidak ada informasi sedetail itu karena rumah makan ini hanya skala kecil.

7.3 Labelling

Tidak ada pelabelan karena rumah makan ini hanya skala kecil.

7.4 Consumer education

Tidak ada informasi sedetail itu karena rumah makan ini hanya skala kecil.

8. TRAINING

8.1 Awareness and responsibilities 8.1.1 All personnel should be aware of their role OK and responsibility in protecting food from contamination and deterioration. Pekerja sadar dan bertanggung jawab mencegah kontaminasi walaupun masih ada yang belum menggunakan baju.

8.1.2 Food handlers should have the necessary OK knowledge and skills to enable them to handle food safely and properly. Those who handle strong cleaning chemicals or other potentially hazardous chemicals should be instructed in safe handling techniques. 8.2 Training programmes 8.2.1 Factors to take into account when N/A assessing the level of training required include: the nature of the food, in particular its ability to sustain growth of pathogenic or microorganisms. the manner in which the food is handled and packed, including the probability of contamination. the extent and nature of processing or further preparation before consumption the conditions under which the food will be stored. the expected length of time before use or consumption. 8.3.1 Periodic assessments of the effectiveness N/A of training and instruction programmes should be made. Routine supervision and checks should also be implemented to ensure that procedures are being carried out effectively. 8.3.2 Managers and supervisors at food NOK businesses should have the necessary knowledge of the principles and practices of food safety and suitability to be able to judge potential risks and take the necessary action to remedy defects (see paragraph 3.5). 8.4 Refresher training 8.4.1 Training programmes should be routinely N/A reviewed and updated where necessary. 8.4.2 Systems should be in place to ensure that NOK food handlers remain aware of all procedures necessary to maintain the safety and suitability of food.

Karena sudah 30 tahun menjalani usahanya, maka Tante Dania sudah mengerti tentang keamanan pangan walaupun tidak sangat detail sekali.

Belum ada trainning khusus hanya melalui nasehat dan perintah saja dari Tante Dania.

8.3 Instruction and supervision

Belum ada program tersebut karena rumah makan ini dalam skala kecil.

Pengetahuannya hanya sekilas saja dan tidak detail sekali.

Belum ada program tersebut karena rumah makan ini dalam skala kecil. Tante Dania sadar dengan prosedur yang baik untuk meningkatkan keamanan.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- ECC Condition-Gasoline StationDokument3 SeitenECC Condition-Gasoline StationKim Howard CastilloNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Nav StudDokument138 SeitenNav StudcarmenNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- How To Celebrate An Eco Sensitive Diwali?: 1. Air Pollution Through FirecrackersDokument7 SeitenHow To Celebrate An Eco Sensitive Diwali?: 1. Air Pollution Through Firecrackershimanshu21_4uNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- ENGR 302 Energy and EnvironmentDokument4 SeitenENGR 302 Energy and EnvironmentYuna AnjosNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- JNPT's Waste Management PlanDokument16 SeitenJNPT's Waste Management PlanNishant PantNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Exp.6-Jar TestDokument9 SeitenExp.6-Jar Testمحمد أمير لقمانNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Igbc NotesDokument10 SeitenIgbc NotesSweety09010% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- NSTP ResearchDokument2 SeitenNSTP ResearchKaye PurificacionNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Adaptive ManagementDokument25 SeitenAdaptive ManagementSweet WaterNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- DULUX Diamond Matt Safety SheetDokument8 SeitenDULUX Diamond Matt Safety SheetjustinNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Acid Rain - Can Chalk Dissolve? - Results TableDokument4 SeitenAcid Rain - Can Chalk Dissolve? - Results TablecgNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- ARRB Permeable Pavements 23rdDokument14 SeitenARRB Permeable Pavements 23rdPWQGroupNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Environmental Pollution: Effect of Pollution On The HealthDokument3 SeitenEnvironmental Pollution: Effect of Pollution On The HealthShahzad ShafiNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Soil Gas Monitoring in The Vadose Zone: Standard Guide ForDokument36 SeitenSoil Gas Monitoring in The Vadose Zone: Standard Guide ForNeilRyanNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

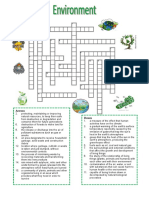

- Environment Crossword PuzzleDokument2 SeitenEnvironment Crossword Puzzleamrinarizan48Noch keine Bewertungen

- Mitsubishi Power, Ltd. - Power Plants: Gas Turbine Combined Cycle (GTCC) Power PlantsDokument2 SeitenMitsubishi Power, Ltd. - Power Plants: Gas Turbine Combined Cycle (GTCC) Power PlantsKR PANoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Desalination EngineeringDokument8 SeitenDesalination EngineeringShafayet A SiddiqueNoch keine Bewertungen

- Environment Toxicology and HealthDokument3 SeitenEnvironment Toxicology and HealthAkshitaNoch keine Bewertungen

- Project Proposal - CasabuenaDokument7 SeitenProject Proposal - CasabuenaGwen CasabuenaNoch keine Bewertungen

- Admission Test Exam Question Sep 2018Dokument3 SeitenAdmission Test Exam Question Sep 2018masud64% (11)

- Water Supply System in IndiaDokument10 SeitenWater Supply System in IndiaAbhay SisodiaNoch keine Bewertungen

- External MBR Vs Internal MBRDokument8 SeitenExternal MBR Vs Internal MBRwacsii ccasullaNoch keine Bewertungen

- 7th Sem CivilDokument19 Seiten7th Sem CivilNeeraj Kumar ThakurNoch keine Bewertungen

- Improving Efficiency and Emissionsof Small Ships by The Use of Hybrid Electrical Propulsion (Bennabi)Dokument10 SeitenImproving Efficiency and Emissionsof Small Ships by The Use of Hybrid Electrical Propulsion (Bennabi)Eden SarmentoNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- GEMSS-M-15 Rev 02 - Desalination Plant and Desalinated Water TanksDokument20 SeitenGEMSS-M-15 Rev 02 - Desalination Plant and Desalinated Water TanksKaramSobhyNoch keine Bewertungen

- Environmental Impact in Brewery: Master Programme Kaho Sint - LievenDokument26 SeitenEnvironmental Impact in Brewery: Master Programme Kaho Sint - LievenisabeljaramillogNoch keine Bewertungen

- Chapter 12 - Surface Water TreatmentDokument36 SeitenChapter 12 - Surface Water TreatmentDwi Yerlis RahmiNoch keine Bewertungen

- 130 - 5-Leachate From Sanitary LandfillsDokument33 Seiten130 - 5-Leachate From Sanitary LandfillsfaridkhanNoch keine Bewertungen

- TRCI - 2009 Tank Farm GuidelinesDokument70 SeitenTRCI - 2009 Tank Farm Guidelinesdg997Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Cce 408Dokument4 SeitenCce 408Neetor TendekayiNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)