Beruflich Dokumente

Kultur Dokumente

AK Receiver Bending

Hochgeladen von

Adam HemsleyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AK Receiver Bending

Hochgeladen von

Adam HemsleyCopyright:

Verfügbare Formate

AK Receiver Bending From a Tapco Flat

A tutorial by 1952Sniper February 2006

(originally posted on http://www.s sboards.!o" by 1952Sniper# $$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$ % de!ided to write this tutorial a&ter ha'ing spent a day and a hal& bending re!ei'ers. %t "ight be a help to those o& you who are interested in bending your own re!ei'ers &ro" a &lat. (ysel& and another &oru" "e"ber (%)ll let hi" !hi"e in i& he wants to identi&y hi"sel&# did a whole pro'erbial s***$load o& the"+ and % now now "ore about the pro!ess than % e'er wanted to+ ,-,. % won)t pretend it)s the be$all end$all o& bending re!ei'ers. %t)s .ust "y e/perien!e+ and a good starting point. 0ou guys that ha'e used other "ethods and other bending &i/tures+ &eel &ree to !hi"e in and add in&o. For starters+ it)s a lot o& &un. %& you)re only bending a !ouple+ it)s a relati'ely si"ple tas that should ta e no ti"e at all. %& you)re doing as "any as we did+ though+ it)s a lot o& wor and needs to be well planned. 0ou should !ount on &atigue be!o"ing an issue. 1i'e yoursel& plenty o& ti"e &or brea s. And be aware o& when you)re getting tired+ be!ause that)s when a!!idents start to happen. 2e ha'e the hand in.uries and sore li"bs to pro'e it. 3he pro!ess we used too right at 15 "inutes to go &ro" a &lat to a bent re!ei'er+ &ro" start to &inish. 4ut we a'eraged about 5 re!ei'ers &or e'ery 6 hours spent. 3hat in!ludes brea s+ re$organi7ing tools+ periodi! !leanup+ et!.+ without &eeling li e we had to rush so "u!h that our 8uality le'el had to su&&er. 4ending a &lat into a re!ei'er should generally re8uire the &ollowing steps: 1. Asse"ble the inside die around the &lat 2. 1rease the hell out o& e'erything 6. 9ress it into the outer &or" :. S8uee7e the asse"bly in a 'ise to eli"inate possible bowing in the "iddle 5. ;a""er or otherwise bend o'er the upper rails 6. %n'ert the asse"bly and no! out the inside die and re!ei'er <. =isasse"ble inside &or" and no! re!ei'er o&& o& it %)ll go into detail on ea!h step. % should note that not all bending .igs (&i/tures# are !reated e8ual. 3here are a lot o& di&&erent designs out there+ although they al"ost all basi!ally wor using the sa"e prin!iple. And i& your &i/ture is !reated to the proper di"ensions+ it should yield the sa"e results no "atter how it)s put together. 3he result+ o& !ourse+ being a bent re!ei'er that)s ready &or &itting/tri""ing and asse"bly to a parts it. 3he &i/ture we used was one that % bought &ro" a "e"ber o& an A> building board+ and is based on the ernel rin design (&or those o& you who are &a"iliar with that userna"e#. %t wor s great and is robust enough to last through a lot o& bends. 4elow is a pi!ture o& the inside &or" (the die# and its asso!iated pie!es+ ne/t to one o& the 3ap!o &lats we were about to bend. %)ll apologi7e in ad'an!e &or the !rappy pi!tures. % had to use "y old digital !a"era be!ause "y good one was out o& .ui!e and % !ouldn)t &ind the !harger. Anyway+ in the pi!ture below you !an see the upper part o& the die+ the lower plate that sandwi!hes the &lat inside+ : bolts that !la"p it all together+ and two aligner pins with brass nobs on the".

%)ll also pause here to gi'e !redit to the gentle"an that built this bending &i/ture and sold it to "e. ;e has "ore &or sale and is an e/tre"ely help&ul and &riendly guy. 1oes by the userna"e s"ittyg. o'er on gun!o.net+ and he has e/pressed interest in selling the" on this board too. %n &a!t+ % see that he)s a "e"ber here. So loo &or a post &ro" hi" in the trade/sale &oru"s. ;is bending &i/ture wor ed well &or "e and although % ha'en)t used any other types+ % will say that this one "ore than "et "y needs. % now se'eral o& you A> builders are loo ing &or a bending &i/ture+ and % !an tell you that s"ittyg. will do his best to "a e sure you)re satis&ied and answer any 8uestions you ha'e. Support &or a sold produ!t goes a long way with "e+ and he)ll de&initely gi'e support &or his produ!t. And by the way+ %)" not being paid &or endorsing his bending &i/ture. % .ust thin he)s got a good produ!t at a good pri!e+ and pro'ides good ser'i!e. A? all around+ and % highly re!o""end his bending &i/ture.

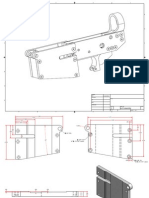

Step 1: Assemble the die around the flat -n this parti!ular bending &i/ture design+ you install the aligner pins through the botto" o& the botto" plate+ then through the aligner holes on the &lat (whi!h are the s"all holes at the 'ery &ront and rear o& the &lat#. 3his is then lined up with the botto" o& the die+ and the aligner pins are inserted there as well. All 6 pie!es will be lined up per&e!tly. @o "easuring or &iddling ne!essary. 3he bolts are then inserted through the top o& the die and they are threaded into the botto" plate. %t)s i"portant to tighten these bolts &airly tight to ensure that the &lat stays put. 3he : bolts rea!h through the e/isting openings in the &lat (the pistol grip s!rew hole+ the trigger hole+ and two through the "ag well opening#. 3hey si"ply draw the botto" plate tight to the die. 3hen the aligner pins are re"o'ed. -n!e the aligner pins are re"o'ed+ the only thing holding the &lat in align"ent is the !o"pression o& the bolts. So tor8ue the" down pretty good+ but not tight enough to strip threads. Aust a &ir" tug with a so! et wren!h is what % did. 2hen you get the botto" plate on with the &lat installed+ it loo s li e this:

@ote that you !an see the botto"s o& the : bolts+ and the aligner pins are still in pla!e. 3his botto" plate ser'es se'eral &un!tions as &ar as % !an tell. %t eeps the botto" o& the &lat positioned properly. %t also eeps the botto" &ro" bowing out when the sides are bent+ gi'ing ni!e !risp !orners. %t also ser'es as a guide inside the &or" as it)s pressed in. 3he width o& the botto" plate is the sa"e as the width o& the outside o& your re!ei'er a&ter bending. So the re!ei'er walls B&ollowB the botto" plate into the .ig.

Step 2: Grease all contact surfaces of the bending fi ture A&ter the aligner pins are re"o'ed+ you)ll want to grease the hell out o& the botto" o& the &lat+ where it will BrideB the outside &or" when it)s being bended. 2e used (obil 1 syntheti! grease. %t)s red in !olor+ as you !an see below. -thers use a/le grease or other inds o& grease. 2hate'er &loats your boat. Aust "a e sure it)s a good 8uality grease that lubri!ates well.

And here)s a pi!ture o& the top o& the die with the &lat installed. %t is i"portant to ,%1;3,0 grease the !onta!t sur&a!es between the inside die and the inside o& the re!ei'er. -therwise you !ould ha'e a hell o& a ti"e getting the re!ei'er o&& o& it later a&ter it)s been bent around all : !orners o& the die. % only tried it on!e without grease on the inside o& the re!ei'er+ and had a hard ti"e. So % !ontinued to grease it and didn)t ha'e any "ore proble"s. 4ut do it lightly+ so it isn)t so"ething that)s ha'ing to be s8uee7ed out when you press the die into the outside &or".

%)ll also ta e this opportunity to point out the inletting on the die &or the "aga7ine stabili7er di"ples+ and note that they)re slotted so the di"ples !an ride in that !hannel later+ as you re"o'e the !o"pleted re!ei'er &ro" the die. 3his die also had an inletted area &or the di"ple at the sele!tor le'er. %t did not ha'e any inletting &or the C$0 a/is di"ples or the sele!tor le'er not!h or the bulge around the le&t side sele!tor le'er hole. 3he new 3ap!o &lats ha'e all these di"ples on the"+ but they didn)t see" to be a&&e!ted in the bending pro!ess and they &ared .ust &ine. So+ be&ore "o'ing on to the third step+ you)ll want to grease the outside &or" as well. @ot only on top where the &lat will !onta!t it when you start bending+ but espe!ially at the !orners o& the &or" that "a e the &old+ as well as the inside &a!e. 3his is the "ost !riti!al area. %& it)s not greased su&&i!iently+

you will get s!arring on the outside o& your re!ei'er as it slides down inside the &or". 0ou !an see that % ha'e the top and insides o& the &or" greased+ with the asse"bled die sitting upside down+ ready to be &lipped o'er and pla!ed into it. 3oo "u!h grease is better than not enough. 4e generous.

Step !: Bend the sides of the flat up 9la!e the asse"bled die into the top o& the outside &or" and !enter it in the &or" so you)re not too !lose to the ends. 3hen !enter the entire asse"bly under the ra". =ouble !he! that your aligner pins are re"o'ed and that e'erything is ready to go.

@ow snug up the ra" to the top+ and start pressing down. %& it)s !entered !orre!tly+ both sides should start to &old up at the sa"e rate+ as you see below.

So"eti"es the sides will gently &old up &lush to the die+ but in "ost !ases % &ound that they would rea!h a point where they BsnapB to the sides+ and the whole shop press goes S9D-%@11111111E 3hat)s &ine. Aust be aware o& this+ and go slowly when it)s !lose to the point. As you pro!eed &urther+ the sides should be straight up 'erti!ally in the &or"+ tight against the inside die.

>eep pressing it down into the &or" until the top o& the die is at least &lush with the top o& the outside &or". So"eti"es+ as the die is pressed in+ one end will tend to go down &aster than the other. % ept sear!hing &or a Bsweet spotB on the top o& the die that would ensure e'en plunging lengthwise+ but ea!h &lat would go in di&&erently. %& one end sin s down &irst+ you)ll need to reposition the ra" to try to get the other side down. 2ith this parti!ular bending &i/ture+ the bolt heads on top presented a proble". % didn)t want to be pressing on the bolt heads+ so % had li"ited roo" between the "iddle bolts in whi!h to pla!e the ra". 2hen one end would sin &aster than the other+ we would ha'e to pull the entire asse"bly and turn it 90 degrees so the ra" !ould get all the way to the end o& the die (the shop press &ra"e wasn)t wide enough to si"ply shi&t the &i/ture to the side &ar enough#. So then+ pressing on the end o& the die and using a pie!e o& bar sto! to shi" up and ensure that the ra" wasn)t tou!hing a bolt head+ we !ould press the high end down into the &or". %t was a si"ple enough way to do it and wor ed well. %n the pi!ture below+ you)ll see what %)" tal ing about. %n this !ase+ the die went into the &or" e'enly. 4ut sin!e the rear o& the re!ei'er is taller than the &ront+ it be!o"es ob'ious that the rear end o& the die needs to go down &urther into the &or" than the &ront. So that)s what we)re doing here+ trying to get it so the top o& our bent re!ei'er is e'en.

As % said+ ea!h &lat would go into the &or" di&&erently. So"eti"es+ when one end was riding high and we)d go to press that end in+ the other end would start li&ting ba! up slightly. -ther ti"es it wouldn)t. Aust play it by ear and ad.ust your ra" position as ne!essary to get the die down into the &or". %t really goes pretty 8ui! ly+ so don)t start thin ing this is a "a.or deal. -n!e the die is pressed down with the top !orners about &lush with the outside &or"+ it)s good to go. 3a e it out o& the press.

Step ": #ompress the sides of the form =epending on the design o& your outside &or"+ you "ay e/perien!e bowing in the "iddle during the pressing operation. % did noti!e a s"all gap in ours+ right at the "iddle o& the re!ei'er. And % "ean s"all li e perhaps a !ouple thousandths o& an in!h. So"e designs "ay not ha'e a noti!eable gap+ but %)d bet you would &ind that it bowed in the "iddle i& you too detailed "easure"ents. %t)s sa&e to assu"e that all &or"s will bow. So the easiest thing to do is .ust ta e your entire asse"bly with the die still in it+ and s8uee7e it tightly in a 'ise to !o"press the sides and sharpen up your botto" !orners o& your re!ei'er. 0ou)ll see any gaps !lose right up+ and the grease will s8uee7e out. 3hat "eans it)s good to go.

Step $: Bend the upper rails 3here are 'arious ways o& doing this. So"e bending &i/tures are sold with an a!!essory that uses the press to &old the top rails o'er. So"e people si"ply ha""er the" o'er with a ha""er+ wor ing &ro" one end to the other and then s"a! ing on top o& the die on!e the rails are &olded o'er+ to get out the lu"ps. (y partner !a"e up with the Bwor ing barB as a great way to ha""er the upper rails o'er without lu"ps. And it wor ed li e a !ha"p. %t)s .ust a long pie!e o& &lat bar with handles welded to it. 0ou ha""er on the wor ing bar and it translates the &or!e to the rails in a uni&or" "anner to get ni!e s"ooth bends with !risp !orners. 3his re8uires two people. -ne person stands on one side o& the ben!h 'ise and holds the wor ing bar by the handles so that it)s al"ost &lat on top o& the outside &or"+ with one side o& the &lat bar against the rail on the opposite side o& the 'ise &ro" where he)s standing. 3he other person+ standing opposite the &irst person+ s"a! s the &lat bar+ starting at one end and wor ing to the other end. @ote that in this pi!ture+ it)s .ust being held in pla!e with one hand &or display. 3he bar holder needs to be dire!tly behind the 'ise+ holding both pipe handles to align it properly as the ha""er "an "a es ea!h stro e.

3his needs to be done with the bending &i/ture !la"ped in the 'ise+ not only to eep the sides o& the re!ei'er tight against the die &or a good uni&or" bend+ but to eep the die &ro" slipping down in the outside &or". As the upper rails start to bend o'er+ the person holding the wor ing bar needs to eep it at the sa"e angle as the rail until the bar is 'erti!al ("eaning that the rails are laying &lush on top o& the die#. 3he ha""er operator .ust wor s up and down the wor ing bar. 2e used a 5$lb sledge ha""er and % &ound it generally too "e 5 stri es along the length o& the bar &or ea!h BpassB. A&ter % "ade a pass+ the angle would be !hanged and %)d "a e another pass. %t usually too us 6 passes to get the rails laying down &lat on top o& the die. 3hat)s only 15 ha""er stri es on the wor ing bar &or ea!h rail. 2hen the rail was laying &lush on top+ we)d "a e one "ore pass B&or good "easureB+ "a ing "ore li e 5 stri es (!loser together# to ensure uni&or"ity. 3he result was superb.

3he tri! is .ust to ta e your ti"e+ "a e good solid ha""er stri es with a hea'y sledge ha""er+ and to eep the wor ing bar at the !orre!t angle. And depending on how "any re!ei'ers you)re "a ing+ be prepared to ha'e to repair your wor ing bar. -urs was beat all to hell on the top. % was ha'ing so "u!h &un+ % was 'ery eager on the sledge ha""er. :$# %n retrospe!t+ the wor ing bar would ha'e been better i& the handles were at about a 120 degree angle &ro" the &lat bar instead o& 90 degrees as ours were. 2hen stri ing near the end o& the bar+ % had to be !are&ul not to hit "y asso!iate)s hands as he was holding the handles. So+ i& you want to "a e a wor ing bar &or the upper rails+ eep sa&ety in "ind. and angle the handles out away &ro" the "iddle where the ha""er will be stri ing. %t)s also a good idea to ha'e a step stool or so"e way o& getting higher abo'e your 'ise as the angle !hanges on the upper rails. 0ou don)t want to be swinging a sledge ha""er that high. 1et abo'e it so you .ust ha'e to li&t it and "ostly let gra'ity do the .ob when it)s at that angle. %t)ll "a e the .ob a lot easier and you)ll get "ore uni&or"+ solid blows. And this is one o& the steps where &atigue will get you. % busted "y nu! le a &ew ti"es when % was tired and "ade a glan!ing blow o&& the wor ing bar. Sa&ety &irst+ ya now.

Step %: Remove the die from the outside form 3his is &airly straight&orward. -n!e the upper rails are bent and pass your 8uality !ontrol inspe!tion+ un!la"p the &i/ture &ro" the 'ise. -pen the .aws o& the 'ise a bit wider+ turn the &i/ture upside down and set it on top o& the .aws. 3a e a pie!e o& bar sto! and at least a 5$lb sledge ha""er and ha""er

the die ba! out. %t should start !o"ing out o& the outside &or" and go between the open .aws o& the 'ise. ,ay a pad o& so"e sort in there so i& it &alls out it won)t get dinged up. =on)t put your hand under there to !at!h it as your buddy ha""ers it outE As "e about how "y &inger got s"ushed when the 5$lb sledge ha""er and the weight o& the die landed on it. And eep in "ind+ when you)re doing this+ you)re ha""ering on the underside o& the botto" plate o& the die. %& your bolts that !in!h up the &lat inside the die are protruding &ro" the botto" o& this botto" plate (as ours were by .ust about 1/5B#+ you)ll want to be !are&ul not to hit the" with your bar sto! when ha""ering out the die &ro" the outside &or".

2hen the inside die !o"es out+ you will noti!e that the sides tend to spring ba! .ust a tad away &ro" the &or". 3his is nor"al+ and to be e/pe!ted. %t will be pulled ba! together at the trunnion lo!ations when you build this into an A> ri&le+ with the ri'ets or s!rews (or whate'er you)re using#+ as well as at the !enter support. So don)t worry about it.

0ou)ll also see in this pi!ture+ that there is grease where the top rails were &olded o'er. 3his "a es a handy gauge o& your upper rail bending pro!edure. %& you properly greased the area+ it will s8uee7e the grease out when the upper rails are tight on the top o& the die.

Step &: Remove the receiver from the die

So now the die is out o& the outside &or". 0ou !an re"o'e the bolts to un!la"p the re!ei'er &ro" the die+ whi!h should release the botto" plate. 0ou)ll also noti!e that+ oddly enough+ your &lat a!tually loo s a lot li e an A> re!ei'er.

@ow+ the botto" plate is released and you si"ply need to re"o'e the die &ro" inside the re!ei'er. 3he ni!e thing about the bending &i/ture we used was that the top o& the die had a raised strip down the "iddle that was parallel with the botto". So this "ade a handy pla!e to !la"p in a 'ise as shown below+ and ta e another pie!e o& bar sto! and tap the re!ei'er o&& the &or" slowly+ "a ing sure not to de&or" any "etal. %& you greased it properly+ it should !o"e o&& with little e&&ort and only light taps. 2e tapped on the rear end o& the re!ei'er where it)s a ni!e wide bearing sur&a!e+ to "ini"i7e any proble"s.

Summar' and miscellaneous comments

3hat)s itE 0ou)re doneE 0ou should ha'e a bent re!ei'er now. 2ipe o&& all the grease and get to building your A>. As % said at the beginning+ this pro!ess should ta e 15$20 "inutes on!e you get the hang o& it. 3he really hard wor is already done &or you i& you)re using a 3ap!o &lat that already has all the holes in it. % !hose to use &lats that didn)t ha'e trunnion holes in the" already be!ause o& the "ethod %)" going to use &or "ounting "y trunnions will be di&&erent. 4ut the pre!ision part o& &abri!ating a re!ei'er is all in the &lats and the bending .ig. %t)s al"ost idiot$proo& (noti!e % said Bal"ostF :$# #. 4e&ore % wrap this up+ % do want to point out a &ew other things. A lot o& builders that ha'e bent their own &lats ha'e noti!ed stret!hing/distortion around the "ag well opening. 3his is presu"ably be!ause there isn)t really any "etal on the botto" o& the re!ei'er in that area+ and as it bends in the &i/ture+ it pulls up on the sides. % did not noti!e any distortion o& the "ag opening whatsoe'er. %t si"ply wasn)t an issue &or us. 3he design o& the &or" (with two bolts through the "ag well whi!h put a good bind on the "etal on either side o& the opening# plus !opious a"ounts o& grease in the &i/ture ept it &ro" e'er being an issue. Another !o""on issue is elongation o& the trigger pin (0$a/is# hole. And we did see that on our re!ei'ers. 4e!ause that hole is so !lose to the !orner+ the botto" o& the 0 is on the bend+ and there isn)t any "etal abo'e it be!ause o& the hole+ so it doesn)t bend li e the rest o& the re!ei'er. 3his leads to the trigger pin hole ha'ing a BdipB at the botto". 0ou !an see it in the &irst pi!ture o& Step < o& "y tutorial+ abo'e. 3his is easily &i/ed by wor ing the "etal gently with a ha""er around the botto" !orner be&ore tapping it o&& o& the die. 2e !hose not to worry about it be!ause it)s an o'ersi7ed hole anyway+ so it)s inherently stronger than the s"aller hole on the other side already. 9lus it)ll be heat treated. And the pin isn)t going to be loose in the hole or anything+ as the distortion is relati'ely "inor there. %t)s really "ostly .ust a !os"eti! issue as &ar as % !an tell. %& it bothers you+ round it o'er with a ha""er and wor it ba! to the original shape o& the hole. @o biggie. 3ools. 3o bend a &lat+ you)ll need so"e basi! tools or at least a!!ess to the". -b'iously+ you)ll need a shop press. 3he 20$ton "odel &ro" ;arbor Freight wor ed li e a !ha"p. A 12$ton should do it too+ % hear. % e'en thin it !ould be done by hand+ with a de'i!e %)'e designed. %t will be undergoing testing possibly in the near &uture+ but "ore on that later. For now+ the sa&e bet is using a press. %t "a es short wor o& it. 0ou)ll also need a good solid "ounted 6B ben!h 'ise. % !ouldn)t see doing it with a s"aller one. All the ha""ering and !o"pressing that)s needed &or this using the 'ise+ a s"aller one would be !hallenged to get the .ob done. G'erybody needs a 6B 'ise anyway+ so .ust buy one. ;arbor Freight is your &riend. 3hen there is the wor ing bar+ i& you !an get one "ade or "a e one yoursel&. %t sa'es a lot o& ti"e and trouble %(;-. ;a""er$wise+ we did pretty "u!h e'erything with a 5$lb sledge (bending the upper rails and re"o'ing the die &ro" the outside &or"# and a 6$ pounder &or lighter wor li e no! ing o&& the re!ei'er &ro" the die. A plain$.ane so! et set &or the bolts on the die. A !an o& grease and 9,G@30 o& shop rags+ as well as degreaser. 4ut what !a"e in the "ost handy was "is!ellaneous bar sto! . 2e used it &or shi""ing the ra" on the press when repositioning to the ends o& the die+ we used it &or ha""ering the die out o& the &or"+ we used it &or ha""ering the re!ei'er o&& the die+ and we used it &or shi"s in !ases where we had pushed the die too &ar into the &or" and needed to push it ba! up and botto" it out against the botto" plates o& the &or". % highly re!o""end ha'ing so"e pie!es o& bar sto! laying around+ o& 'arious si7es and shapes.

So that should pretty "u!h !o'er "y e/perien!e with bending &lats and detail how to use this parti!ular bending &i/ture. 1i'e it a whirl and en.oy yoursel&.

Das könnte Ihnen auch gefallen

- Practical Guide to the Operational Use of the PPS-43 Submachine GunVon EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunNoch keine Bewertungen

- AK-47, AK-74 Headspace ChecksDokument4 SeitenAK-47, AK-74 Headspace ChecksNormNoch keine Bewertungen

- AKM 47 ReceiverDokument7 SeitenAKM 47 ReceiverMika100% (6)

- AK Bolt Gap SetupDokument22 SeitenAK Bolt Gap SetupAdam Hemsley100% (2)

- AK-47 Select Fire Full-Auto ConversionDokument16 SeitenAK-47 Select Fire Full-Auto Conversion(Administrator)100% (10)

- Grasshopper Ak-47 Jig GuncoDokument5 SeitenGrasshopper Ak-47 Jig Guncoterrencebelles100% (2)

- AK-47 Souptonuts 5Dokument7 SeitenAK-47 Souptonuts 5tshirley47100% (3)

- AK-47 Select Fire Full-Auto ConversionDokument16 SeitenAK-47 Select Fire Full-Auto Conversioniannicelli9967% (3)

- AR15 Barrel Nut IndexingDokument1 SeiteAR15 Barrel Nut IndexingMike Nichlos100% (3)

- Blueprints PPSH41 Yugo49-57 American180 Browning1919Dokument7 SeitenBlueprints PPSH41 Yugo49-57 American180 Browning1919Mika100% (2)

- AR15 AutoDokument28 SeitenAR15 AutoChris Fox100% (10)

- AR15 Pin and Spring SizesDokument2 SeitenAR15 Pin and Spring SizesMike Nichlos91% (11)

- AK-47 Select Fire ConversionDokument16 SeitenAK-47 Select Fire ConversionScott Opgenorth86% (7)

- 2008-11!23!233015 Receiver Template 7 SimplifiedDokument1 Seite2008-11!23!233015 Receiver Template 7 Simplifiedpalaciosro100% (3)

- Firearms - Blueprint - Sten MK III Sub Machine Gun Receiver BondDokument1 SeiteFirearms - Blueprint - Sten MK III Sub Machine Gun Receiver Bondanjan971% (14)

- Ruger 10 22 Rifle Full Auto ConversionDokument22 SeitenRuger 10 22 Rifle Full Auto Conversionspanky6276100% (2)

- United States "Patents PDFDokument17 SeitenUnited States "Patents PDFTien Nguyen VanNoch keine Bewertungen

- Stamped and Milled AK Receiver Identification - From UltiMAKDokument4 SeitenStamped and Milled AK Receiver Identification - From UltiMAKblowmeasshole1911100% (4)

- Print - How To Build An AK-47Dokument8 SeitenPrint - How To Build An AK-47Lord Ellam100% (5)

- Build AR15 LowersDokument4 SeitenBuild AR15 LowersBuildAR15Lowers67% (3)

- MG 42 Semi ManualDokument50 SeitenMG 42 Semi Manualscout50100% (7)

- Ar15 PartsDokument10 SeitenAr15 PartsGlockvader100% (10)

- Fabricating The AR-15 Rifle Lightning LinkDokument5 SeitenFabricating The AR-15 Rifle Lightning Link(Administrator)93% (15)

- Sterling Build V2Dokument16 SeitenSterling Build V2Nester Tovar100% (2)

- Build An AK 47 PDFDokument36 SeitenBuild An AK 47 PDFwienslaw580480% (15)

- Bolt Together AR15 Receiver 042910Dokument11 SeitenBolt Together AR15 Receiver 042910IM_JohnnyV100% (7)

- BarrelDokument1 SeiteBarrelNO2NWO100% (2)

- Uzi Receiver Blueprints AaDokument7 SeitenUzi Receiver Blueprints AaMamoun Kh Omari100% (2)

- High Volume Automatic and Semi ADokument15 SeitenHigh Volume Automatic and Semi ANester Tovar100% (1)

- StenDokument23 SeitenStenegrandis1100% (3)

- Bolt Action 3Dokument10 SeitenBolt Action 3browar444100% (2)

- Us1517483 PDFDokument10 SeitenUs1517483 PDFJin SongNoch keine Bewertungen

- Scratch Built AR 15 Bolt Together Receiver PlansDokument10 SeitenScratch Built AR 15 Bolt Together Receiver PlansGary MeekerNoch keine Bewertungen

- Ruger 10-22 Select Fire Full Auto ConversionDokument0 SeitenRuger 10-22 Select Fire Full Auto Conversiongalak12001100% (2)

- SKS Variants Full Auto ConversionDokument13 SeitenSKS Variants Full Auto ConversionFranke Schein100% (1)

- Ruger 10-22 Receiver BlueprintDokument2 SeitenRuger 10-22 Receiver Blueprintelvergonzalez1100% (1)

- Building A Complete AR-15 Lower RecieverDokument27 SeitenBuilding A Complete AR-15 Lower RecieverDelta Exrae100% (11)

- 15 Minute AR15 Trigger JobDokument5 Seiten15 Minute AR15 Trigger Jobdougpfaff100% (4)

- AK47 Parts Check ListDokument1 SeiteAK47 Parts Check ListChris Furlong100% (2)

- Sterling mk4 SMG PDFDokument24 SeitenSterling mk4 SMG PDFDejan BuckicNoch keine Bewertungen

- AK47 Parts Blueprints in ARABICDokument256 SeitenAK47 Parts Blueprints in ARABICNick Rosati90% (10)

- M 16 RedactedDokument9 SeitenM 16 Redactednotarealaccount92% (13)

- Practical Guide to the Operational Use of the UZI Submachine GunVon EverandPractical Guide to the Operational Use of the UZI Submachine GunNoch keine Bewertungen

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsVon EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNoch keine Bewertungen

- Practical Guide to the Operational Use of the PPSh-41 Submachine GunVon EverandPractical Guide to the Operational Use of the PPSh-41 Submachine GunBewertung: 5 von 5 Sternen5/5 (2)

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsVon EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsNoch keine Bewertungen

- Practical Guide to the Operational Use of the M79 Grenade LauncherVon EverandPractical Guide to the Operational Use of the M79 Grenade LauncherNoch keine Bewertungen

- The Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsVon EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsBewertung: 5 von 5 Sternen5/5 (3)

- Practical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRVon EverandPractical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRNoch keine Bewertungen

- Practical Guide to the Operational Use of the M203 Grenade LauncherVon EverandPractical Guide to the Operational Use of the M203 Grenade LauncherNoch keine Bewertungen

- Practical Guide to the Operational Use of the DShK & DShKM Machine GunVon EverandPractical Guide to the Operational Use of the DShK & DShKM Machine GunNoch keine Bewertungen

- Gunsmithing the AR-15, Vol. 1: How to Maintain, Repair, and AccessorizeVon EverandGunsmithing the AR-15, Vol. 1: How to Maintain, Repair, and AccessorizeBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Pumpkin Spice BreadDokument3 SeitenPumpkin Spice BreadAdam HemsleyNoch keine Bewertungen

- JKulstad Bed No2Dokument15 SeitenJKulstad Bed No2Adam HemsleyNoch keine Bewertungen

- Fender Setup GuideDokument21 SeitenFender Setup GuideAdam Hemsley100% (2)

- Cinnabon Goodness! The BEST Cinnabon Clone On The Web!Dokument23 SeitenCinnabon Goodness! The BEST Cinnabon Clone On The Web!Adam HemsleyNoch keine Bewertungen

- One Skillet Chicken and Tomato RisottaDokument15 SeitenOne Skillet Chicken and Tomato RisottaAdam HemsleyNoch keine Bewertungen

- The Drum SanderDokument7 SeitenThe Drum SanderAdam Hemsley100% (1)

- Another Drum SanderDokument13 SeitenAnother Drum SanderAdam Hemsley100% (1)

- Cheese and Spinach Stuffed MushroomsDokument2 SeitenCheese and Spinach Stuffed MushroomsAdam HemsleyNoch keine Bewertungen

- Traditional Scotch PiesDokument2 SeitenTraditional Scotch PiesAdam HemsleyNoch keine Bewertungen

- 86 - Cutting Diagram - Table Saw Thickness SanderDokument1 Seite86 - Cutting Diagram - Table Saw Thickness SanderAdam HemsleyNoch keine Bewertungen

- Trigger Slap and Doubling Trouble ShootingDokument8 SeitenTrigger Slap and Doubling Trouble ShootingAdam Hemsley100% (2)

- Complete Step by Step AK BuildingDokument70 SeitenComplete Step by Step AK BuildingAdam Hemsley90% (39)

- Lathe Powered Drum SanderDokument6 SeitenLathe Powered Drum SanderAdam HemsleyNoch keine Bewertungen

- Stoner 63 Weapon SystemDokument53 SeitenStoner 63 Weapon SystemAdam Hemsley100% (1)

- FN FAL Gas Block Conversion InfoDokument2 SeitenFN FAL Gas Block Conversion InfoAdam HemsleyNoch keine Bewertungen

- Screw Build AKMS With Underfolder NotesDokument8 SeitenScrew Build AKMS With Underfolder NotesAdam HemsleyNoch keine Bewertungen

- Firearms - Gary Hill - .45 Minuteman SMGDokument13 SeitenFirearms - Gary Hill - .45 Minuteman SMGAdam Hemsley100% (2)

- The AK Short Throw TriggerDokument6 SeitenThe AK Short Throw TriggerAdam Hemsley100% (1)

- Dogger Treats!!!Dokument47 SeitenDogger Treats!!!Adam Hemsley100% (1)

- Advanced Cigar Box Guitar ConstructionDokument179 SeitenAdvanced Cigar Box Guitar ConstructionDocStevens100% (6)

- Bass Guitar Setup GuideDokument62 SeitenBass Guitar Setup GuideAdam Hemsley100% (3)

- Tips N TricksDokument24 SeitenTips N TricksAdam HemsleyNoch keine Bewertungen

- AK47 - AKM Technical Drawings RussianDokument70 SeitenAK47 - AKM Technical Drawings RussianAndy Berg100% (11)

- EXERCISES 1 Present & PastDokument3 SeitenEXERCISES 1 Present & Pastdanny ferdito gustiawan0% (1)

- Julius Caesar..Dokument41 SeitenJulius Caesar..bharat_sasi100% (1)

- School Based-Child Protection PolicyDokument9 SeitenSchool Based-Child Protection PolicyMaria Theresa Deluna Macairan100% (4)

- Civ Pro DigestsDokument9 SeitenCiv Pro DigestsIshNoch keine Bewertungen

- DT Hot TipsDokument12 SeitenDT Hot TipsChaNoch keine Bewertungen

- Les 1965Dokument104 SeitenLes 1965sureshNoch keine Bewertungen

- The Crucible Act III QuizDokument4 SeitenThe Crucible Act III QuizJanel EdwardsNoch keine Bewertungen

- ER Ejercito vs. ComelecDokument3 SeitenER Ejercito vs. ComeleckristinevillanuevaNoch keine Bewertungen

- Management of Benzodiazepine Misuse and Dependence: Jonathan Brett Bridin MurnionDokument4 SeitenManagement of Benzodiazepine Misuse and Dependence: Jonathan Brett Bridin MurnionLucius MarpleNoch keine Bewertungen

- Torts Fores Case DigestDokument7 SeitenTorts Fores Case Digestninya09Noch keine Bewertungen

- KeynoteAdvanced Unit6 Readingp69Dokument2 SeitenKeynoteAdvanced Unit6 Readingp69Anh-5A-18 Vũ Ngọc ThảoNoch keine Bewertungen

- Matthew Fann Sexually Violent Predator NotificationDokument1 SeiteMatthew Fann Sexually Violent Predator NotificationMichael_Lee_RobertsNoch keine Bewertungen

- UNE (Universal NPC Emulator)Dokument12 SeitenUNE (Universal NPC Emulator)Christian GronauNoch keine Bewertungen

- Holding Hands With WampumDokument281 SeitenHolding Hands With WampumElwys EnarêNoch keine Bewertungen

- American English File Second Edition PDFDokument169 SeitenAmerican English File Second Edition PDFKamila CerqueiraNoch keine Bewertungen

- Romance of The Rose (Critical Analysis)Dokument3 SeitenRomance of The Rose (Critical Analysis)Mark MerrillNoch keine Bewertungen

- Namma Kalvi 9th Social Science Ganga Guide em Civics FullDokument41 SeitenNamma Kalvi 9th Social Science Ganga Guide em Civics FullS.Bala Ganesh67% (3)

- Malaysia - Bar Council Legal Aid CentreDokument3 SeitenMalaysia - Bar Council Legal Aid CentremiramooNoch keine Bewertungen

- 13-4178 Amicus Brief of Robert George, Et Al.Dokument45 Seiten13-4178 Amicus Brief of Robert George, Et Al.Equality Case FilesNoch keine Bewertungen

- Pune ProgramDokument2 SeitenPune ProgramPrabal Frank NandwaniNoch keine Bewertungen

- The Feminist Standpoint by Nancy HartsockDokument26 SeitenThe Feminist Standpoint by Nancy HartsockMelissa Birch67% (3)

- Armies - Bretonnia - 2003 - 6th Edition - (OCR)Dokument83 SeitenArmies - Bretonnia - 2003 - 6th Edition - (OCR)Thomas AllemandNoch keine Bewertungen

- What Is A SacramentDokument21 SeitenWhat Is A SacramentSheila Marie Anor100% (1)

- Kristine Berry-Child Development-WeeblyDokument3 SeitenKristine Berry-Child Development-Weeblyapi-392387857Noch keine Bewertungen

- 17 Philippine Aguila Satellite Vs LichaucoDokument4 Seiten17 Philippine Aguila Satellite Vs LichaucoJema LonaNoch keine Bewertungen

- James B. Henderson v. National Fidelity Life Insurance Company, 257 F.2d 917, 10th Cir. (1958)Dokument4 SeitenJames B. Henderson v. National Fidelity Life Insurance Company, 257 F.2d 917, 10th Cir. (1958)Scribd Government DocsNoch keine Bewertungen

- Dr. Nay Zin Latt Threatened Natioal Reconciliation in MyanmarDokument1 SeiteDr. Nay Zin Latt Threatened Natioal Reconciliation in MyanmarthakhinRITNoch keine Bewertungen

- Robbery and DacoityDokument21 SeitenRobbery and DacoitySiddhant SodhiaNoch keine Bewertungen

- Fidelity Certification of TrustDokument2 SeitenFidelity Certification of Trustvicki forchtNoch keine Bewertungen

- Max Scheler's Phenomenology of ShameDokument11 SeitenMax Scheler's Phenomenology of Shamesarajamalsweet100% (1)